Learn the differences between ESD solid vinyl tile and interlocking ESD tile. The post compares specs, installation, maintenance and intangibles.

Terms, Terms, Terminology – What’s the proper name for a floor that gets rid of static?

10 min read, 4 min videos

Have you been asked to select a flooring material that’s supposed to eliminate or minimize static charges on people when they walk on the floor?

What do you call such a floor?

Section 09 61 36 of The Construction Specifications Institute calls a floor designed to prevent static discharge a Static-Resistant Flooring Treatment. That makes sense: the purpose of the floor is to resist static.

Wait: doesn’t it also make sense to describe the floor as static control? Control as in eliminate, mitigate, inhibit? You guessed it: another CSI category (09660) is called Static Control Flooring.

What’s the difference between static control and static resistant? Before you answer here’s another CSI category: 09 65 33. This category is called Conductive Resilient Flooring. Already we’ve got three different terms for walking surfaces that eliminate static on human beings.

In addition to those three, there is antistatic flooring. Also spelled anti static flooring or sometimes anti-static flooring. Other descriptive terms include conductive, static dissipative, grounded, static-free, electrostatic discharge (ESD) flooring, ESD safe, shock resistant, static mitigating, non-static and low static generating.

In their internet searches, some people resort to using application-oriented terms in the hopes of whittling down the possible options based on suitability. In the Google (or Yahoo or Bing) search box, they’ll plug in words like: data center flooring, hospital operating room flooring, cleanroom tile, MRI suite flooring or flooring for handling explosives. You could have a field day thinking up all the possible word combinations for this type of walking surface.

Several years ago we actually created an Excel spread sheet that contained over 2000 possible word combinations for something that is supposed to do the following:

• Permanently prevent static on people who are standing or moving

• Be certifiable to some standard that verifies safety and performance

• Meet the requirements of the space, environment and application

We hear questions and comments about this dilemma every day.

Confusion about static-control terminology is the number one reason we get calls from end-users asking us to test their ESD flooring solution because something just “doesn’t seem right.”

Recently, we were asked to test an anti-static high pressure laminate (AKA HPL) installed on raised access flooring panels in a semiconductor fabrication facility. The client believed their maintenance department or chemicals the maintenance team used had damaged their HPL floor because the floor was no longer antistatic. As a result, extremely low levels of static discharge — lower voltages than can be felt by a person – were zapping static-sensitive parts.

As it turned out, the HPL floor was incapable of discharging static on people as they walked. The floor lacked the most basic attribute required to transport electricity from one place to another: the HPL floor contained no electrically conductive components, such as carbon, graphite, silver or gold. Without electrical conductivity, it is impossible for electricity to move through a material. As a result, electricity was getting stuck. Static charges, generated when people walked, stayed on the people and on the floor. We call that kind of electricity – the kind of electrical charge that stays in place, is stagnant, that doesn’t move – static electricity.

The HPL floor was insulative – that is, the opposite of conductive. Think of an electrical plug. There’s a reason you don’t get a shock when you plug your hair dryer into an AC electrical outlet. It’s because the plug is made of an insulative plastic material. If the plug were made with conductive materials, electricity would flow through it. And you would get a shock.

The static-control floor they thought they were buying was not the floor they received.

So how do you find this elusive floor with no universal name? A floor that, if you don't describe it correctly, could get you the opposite of what you wanted?

You can start by doing your homework. There are plenty of resources to help you sort through all the confusing technical terms. The ESD Association is an organization that, in their words, is “dedicated to advancing the theory and practice of electrostatic discharge (ESD) avoidance.” This membership association provides training and certification and hosts events for people interested in learning more about ESD. You can hire a consulting firm, like Dangelmayer and Associates whose “dream team” of researchers, engineers, and ESD experts can custom-tailor an ESD program that best suits your industry and application. You can consult a glossary of ESD terms, read articles and blog posts, listen to podcast episodes, or watch videos about electrostatic discharge.

Terms, terms, terminology – and standards

Here’s the thing: it doesn’t really matter what you call the floor. We know what you’re thinking – wha–? Doesn’t matter? You’re telling us to invest in a floor that might not solve our problem?

No. Of course not. That’s not what we’re saying at all.

All those confusing descriptors and technical terms are precisely that: descriptors and technical terms. Do they all mean the same thing? No. But, again, it really doesn’t matter.

What does matter is, first, you know the standards. ESD Standards are industry-specific. It’s crucial to familiarize yourself with the standards set by your particular industry for your application. Learn about ESD standards and standard test methods here.

Standards cover two attributes: resistance and walking body voltage (aka charge generation).

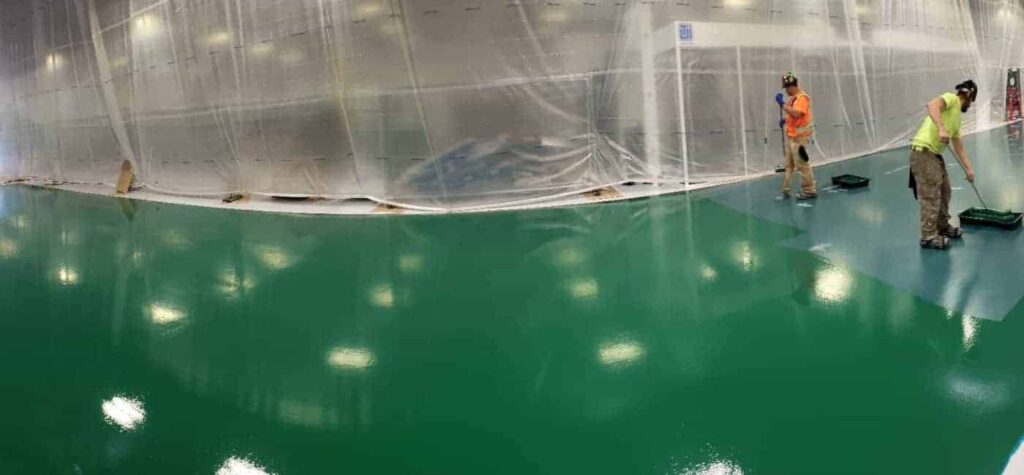

Electrical resistance determines how quickly – or slowly – the floor should transport charges to ground. The higher the resistance of the floor, the slower charges will drain from people and the walking surface to ground. The lower the resistance (higher conductivity) the faster charges will move. Some industries – munitions, for example – prefer high conductivity/low resistance. Other industries – telecom, FAA, PSAPs, banks and other end-user industries – require static dissipative flooring. Learn more about dissipative and conductive flooring here.

The second attribute is charge generation – or how much static the floor generates when people walk. Charge generation is distinct from resistance/conductivity. In order to draw static away from people and prevent static from building on people, the floor must be grounded, which requires having some degree of conductivity. But, as long as the floor measures below 1.0 x 10E9, it meets one of the two critical parameters for most static control applications.

A floor’s charge generation properties represent the second and more important performance parameter. Electronics manufacturing and handling operations require floors to produce no more than 100 volts of static on people wearing protective footwear. End-user spaces like server rooms require that floors generate no more than 500 volts. Again, the amount of allowed static generation is industry and application specific. Learn more about static generation (walking body voltage) here.

Standard Test Methods (STM)

Resistance and charge generation are measured following standard test methods required in ANSI/ESD S20.20, the standard set for the electronics manufacturing and handling facilities.

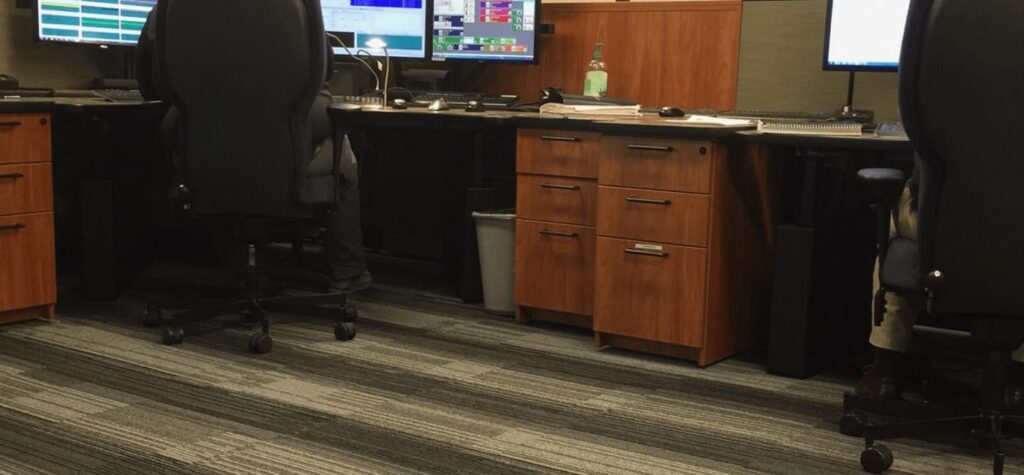

As we’ve said, the standards, which determine what the measurements should be, are industry specific. Electronics manufacturing and handling follow ANSI/ESD S20.20. Telecom spaces (including PSAPs and critical call centers) follow Motorola R56 and ATIS 0600321. The FAA and facilities that use FAA flight equipment follow FAA 019f. These standards provide guidelines for suitable resistance and charge generation measurements. Again, they are all different. Learn about standards for electronics manufacturing and handling, data centers, telecom and PSAPs, FAA, healthcare, DOD, Army Corps of Engineers here.

Standard Test Methods describe the way you conduct the tests. For most applications, Standard Test Methods follow methods in ANSI/ESD S20.20. A handful of industries, typically military and munitions, measure resistance differently, using higher applied voltages. Learn about test methods here.

Who’s wearing what kind of shoes?

The third thing you need to know is what kind of shoes people will wear in the space. Floors made with static-generating materials like PVC – certain vinyl and epoxies, for example – generate static unless everyone in the space wears special static-control shoes. These floors would not work in spaces like a 9-1-1 call center, FAA flight tower, bank or networked office where people wear regular street shoes. In those spaces, the floor should be made from low-generating materials like ESD carpet or rubber. Learn more about footwear and ESD floors.

These three things are crucial. They encompass all you need to know and questions you should ask. Always, always, always specify floors based on industry standards – never on terms or descriptions.

If you know what shoes people will wear, resistance and body voltage standards specific to your industry, and you’re familiar with standard test methods used to determine these attributes, you’re good to go.

If you need more information or would like help with your project, call us today: 617-923-2000.

About StaticWorx, Inc

All StaticWorx posts are written by our technical team and based on industry standards and specifications, test data, independent lab reports and other verifiable data. We provide ESD training and offer CEU credits to architects. If you’re interested in an ESD training session or architects’ ESD workshop, give us a call: 617-923-2000.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

More Blog Posts

To maintain performance, ESD floors require specially formulated products. We offer tips on what to consider when choosing cleaning supplies.

Static-dissipative floors transport harmful static charges to ground. Dissipative is also a term for flooring with a specific, measurable electrical resistance.

StaticWorx recognized as one of the fastest growing private companies in the U.S. 2023 marks StaticWorx fourth appearance on Inc. 5000 list.

Conductive and dissipative flooring protect electronics by transporting charges to ground, conductive at a quicker rate, dissipative slower & more controlled.

We explain the 3 main ways to test an ESD floor: Electrical resistance; body voltage & ESD audits, with advantages and reasons for each.

Three critical factors—application, industry standards & footwear—help you choose the best ESD floor, while ensuring the safety & efficiency of your operations.

StaticWorx Founder and President Dave Long shares three of his recommended reads: Quit, How to Change, and The Goal.

There are leadership qualities StaticWorx strives to embody every day, with every product, throughout each project.

No matter how you slice and dice a project, an ESD floor is a major investment. This blog post examines five ways to keep undue costs down.

A major part of any ESD control program is getting proper flooring in place. How can one replace a floor without generating any debris? Learn more.

A well-designed, comprehensive, fully realized program is a must for manufacturers serious about ESD control. Learn why ESD programs fail.

ESD Floors should never be specified based on the descriptive terms conductive or static dissipative. Always base ESD specs on verifiable metrics. Find out why.

<a class="eael-grid-post-link" href="https://staticworx.com/case-studies/esd-flooring-failure-incorrect-testing/" title="Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods">Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods

To comply with relevant ESD standards, test electrical properties using methods outlined in ESD S20.20. For best results require testing by an independent lab.

<a class="eael-grid-post-link" href="https://staticworx.com/installing/esd-flooring-installation-bond-test-manufacturer-oversight-critical/" title="Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success">Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success

If the vapor barrier fails to adhere to the subfloor, tiles will lift. Bond test and manufacturer oversight are crucial to ESD floor installation success.

<a class="eael-grid-post-link" href="https://staticworx.com/technical-info/conductive-static-dissipative-flooring-difference/" title="Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer">Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer

What’s the difference between conductive and static-dissipative flooring? Facts, analogies and images illustrate the difference in easily understood terms.

Qualifying an ESD floor helps ensure you get the floor you paid for. Find out why you should always qualify according to ESD S20.20

Qualification is the first step in selecting an ESD floor. Learn how to perform resistance tests to be sure the floor meets electrical & safety standards.

Will bare concrete control static? Learn why concrete floors are unreliable & what precautions to take if you must work on a bare concrete floor.

A look at how the StaticWorx cartoon, 'Conductive Flooring Does Not Mean Antistatic Flooring,' was conceived and created.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.