ESD Urethane & Epoxy Coatings

“While the floor ultimately looked attractive as well, its success came from intense focus on performance. The customer wouldn’t do it just to make it pretty. They do it for a specific, highly critical part of their application. They’re looking for performance properties, as opposed to decorative or a glossy finish. That’s really the key. That’s why they’re buying it.”

Ron Puszynski, President

Concare

Simplicity Meets Style

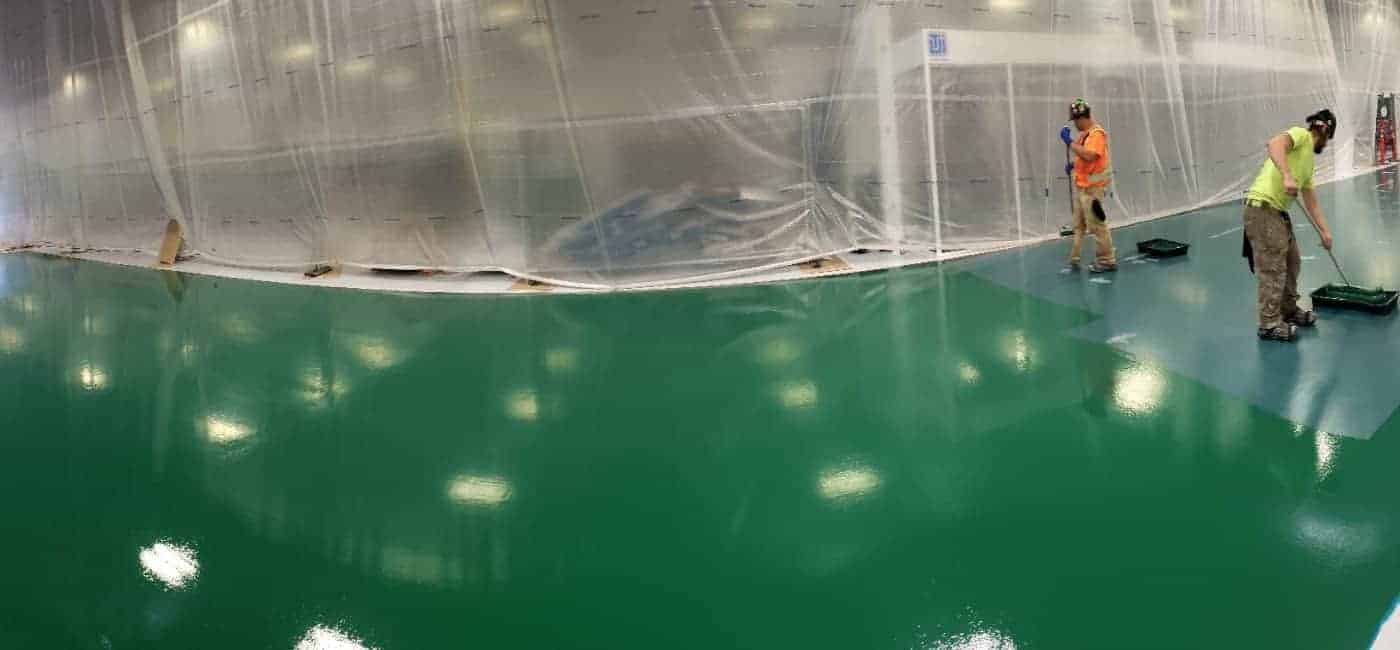

StaticWorx ESD urethane and epoxy coatings protect electronic equipment from damage caused by electrostatic discharge – at the same time sealing your floor so you don’t have to worry about contaminants, germs or bacteria accumulating in cracks, seams or other invisible places.

Coatings are typically applied over a concrete subfloor in electronics manufacturing facilities. We also apply our ESD coatings over existing LVT and VCT flooring – bringing regular, non-ESD floors into ESD compliance and greatly reducing the ongoing cost of maintenance.

Unlike most epoxies, our coatings won’t crack under heavy loads such as forklifts, movable test equipment or hospital beds. Our epoxy and urethane coatings can be installed quickly and easily and are scientifically certified for hospital management.

Like all StaticWorx floors, our ESD coatings meet ANSI/ESD S20.20, NFPA 99 and other applicable industry standards for electronics manufacturing and healthcare applications.

StaticWorx ESD urethane and epoxy coatings protect electronic equipment from damage caused by electrostatic discharge – at the same time sealing your floor so you don’t have to worry about contaminants, germs or bacteria accumulating in cracks, seams or other invisible places.

Coatings are typically applied over a concrete subfloor in electronics manufacturing facilities. We also apply our ESD coatings over existing LVT and VCT flooring – bringing regular, non-ESD floors into ESD compliance and greatly reducing the ongoing cost of maintenance.

Unlike most epoxies, our coatings won’t crack under heavy loads such as forklifts, movable test equipment or hospital beds. Our epoxy and urethane coatings can be installed quickly and easily and are scientifically certified for hospital management.

Like all StaticWorx floors, our ESD coatings meet ANSI/ESD S20.20, NFPA 99 and other applicable industry standards for electronics manufacturing and healthcare applications.

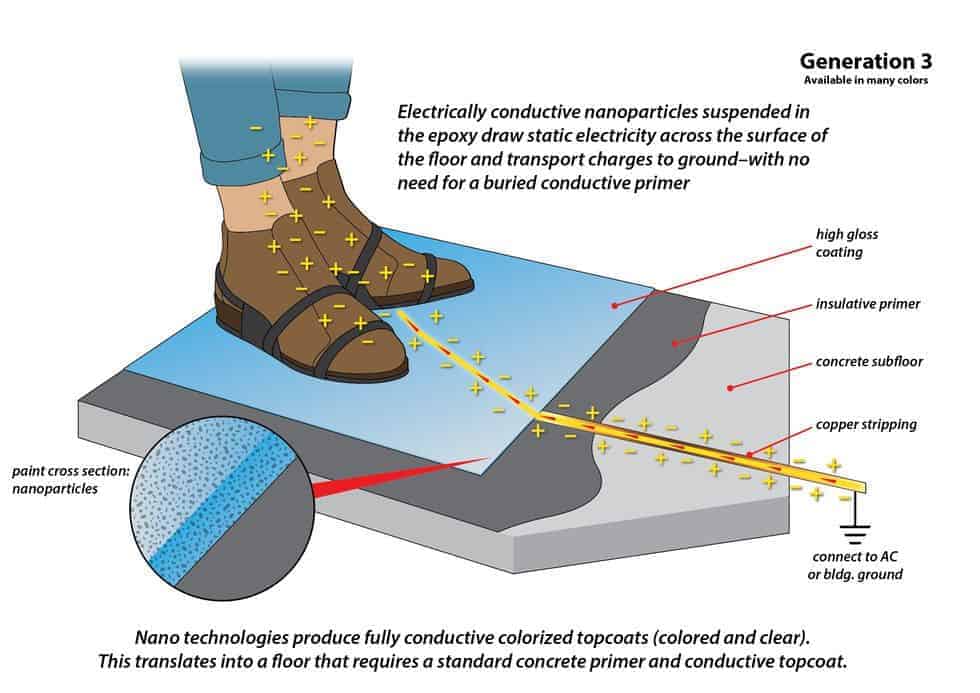

Generation 3 Epoxy Coatings: Eliminate Variables

New additive technologies enable us to produce fully conductive colorized epoxy top coats (colored and clear). This translates into a floor that requires a standard concrete primer, one layer of top coat and no conductive primer layer. This means, the coating is not thickness dependent – thus more reliable than older coatings with a buried ground plane.

Less Vulnerable to Blistering and Vapor

A thinner top coat provides the added benefit of being less vulnerable to blistering and vapor problems from high RH concrete. In most cases Generation 3 floors can be installed at ASTM 2170 RH numbers as high as 95%. This enables installations over relatively new concrete.

Easy Repair

In the event a Generation 3 floor requires a repair in an area that was heavily abused by frequent dragging of wooden pallets with protruding nails, a new top coat can be applied directly over the existing floor. The new surface will become the new path to ground.

Superior Static Control

GroundWorx Ultra meets all aspects of ANSI/ESD S20.20. It can be formulated in either the conductive (< 1.0 x 10E6 ) or the static dissipative (10E6 to 10E9) range.

With the conductivity at the surface, we can provide a coating with extremely low tribocharging properties – used with any ESD footwear at any humidity level.

| ESD COATING | Carbon Black Generation 1 | Multi-layer Epoxy with Conductive Groundplane Generation 2 | ESD Urethane Generation 3 | Epoxy Acrylate Generation 3 |

|---|---|---|---|---|

| Electrical Specification/ ANSI S20.20 | ||||

| Always meets ANSI/ESD S20.20 | Yes | No1 | Yes | Yes |

| Available in dissipative (> 1.0 x 10E6) | No | Yes | Yes | Yes |

| Available in conductive (< 1.0 x 10E6) | Yes | No | Yes | Yes |

| Measures below 100V with heel straps per STM 97.2 | Yes | No | Yes | Yes |

| Measures below 100v with ESD shoes | Yes | Yes | Yes | Yes |

| Material | ||||

| Requires carbon black ground plane | No | Yes | No | No |

| Available in light colours | No | Yes | Yes | No |

| Scratch resistant | No | No | Yes | No |

| Installation | ||||

| Can be installed over sub- or old floors in one coat | Yes | No | Yes | Yes |

| Can be repaired in a single coat | Yes | No | Yes | Yes |

| Gloss finish without use of sealer or wax | No | Yes | Yes | No |

1In qualification testing, multi-layer epoxies that rely on a groundplane fail 97.2 walking body tests with heel straps.

Learn more about about Generation 1, 2 and 3 Epoxy.

Key Benefits of Generation 3 Epoxy Floors

Seamless

Superior Static-Control

Rugged

Slip-resistant

Easy to Install and Maintain

Attractive

“The results were even better than expected,”

Ron Puszynski, President Concare

Applications

(Depending upon selected product)

- Electronic Assembly, Test, Repair and Handling

- Data and Telephony Closets

- BGA Rework

- Shipping & Receiving

- Warehouses

- Leased Spaces

- Pallet Drop Zones

- Box Build

- SMT

- Any space requiring permanent low cost ESD flooring.

- Hospitals

- Medical Manufacturing

- Electronic Assembly, Test, Repair and Handling

- Data and Telephony Closets

- BGA Rework

- Shipping & Receiving

- Warehouses

- Leased Spaces

- Pallet Drop Zones

- Box Build

- SMT

- Any space requiring permanent low cost ESD flooring.

- Hospitals

- Medical Manufacturing

Learn about GroundWorx and Generation 3 Epoxy.

StaticWorx Epoxy and Urethane Coatings

GroundWorx Basics

GroundWorx Basics is a low-cost ESD epoxy coating that’s stronger and more durable than ESD paint. So strong that it resists damage from forklifts and heavy machinery—making it ideal for warehouses, shipping/receiving areas, and manufacturing spaces. If the surface does get scratched, GX Basics is quick, easy and inexpensive to repair.

GroundWorx Basics is a low-cost ESD epoxy coating that’s stronger and more durable than ESD paint. So strong that it resists damage from forklifts and heavy machinery—making it ideal for warehouses, shipping/receiving areas, and manufacturing spaces. If the surface does get scratched, GX Basics is quick, easy and inexpensive to repair.

Learn about GroundWorx Basics.

Download the GroundWorx Basics brochure.

GroundWorx Ultra

Our premium GroundWorx ESD coating, GroundWorx Ultra gives you a beautiful, high- performing static-free surface – for an excellent value at a favorable cost point. With a tensile strength exceeding 6,000 pounds, GroundWorx Ultra is extra durable and can handle forklifts and other heavy loads. GroundWorx Ultra is easy to install and is quick and cost effective to maintain. Learn more about GroundWorx Ultra.

Our premium GroundWorx ESD coating, GroundWorx Ultra gives you a beautiful, high- performing static-free surface – for an excellent value at a favorable cost point. With a tensile strength exceeding 6,000 pounds, GroundWorx Ultra is extra durable and can handle forklifts and other heavy loads. GroundWorx Ultra is easy to install and is quick and cost effective to maintain. Learn more about GroundWorx Ultra.

Learn about GroundWorx Ultra.

Download the GroundWorx Ultra brochure.

StaticWorx/Dr. Schutz Remake

StaticWorx/Dr. Schutz Floor Remake provides you with an attractive, inexpensive way to refurbish or seal your lab, hospital, nursing home, school, university, and other floors. Remake prevents contamination by inhibiting the formation of bacteria. Resistant to chemicals and disinfectants, our PU sealant is easy to clean and maintain – and gives you a clean, hospital shine at a fraction of the cost of a new floor.

Learn about StaticWorx/Dr. Schutz Floor Remake.

Find out about StaticWorx flooring essentials

Learn about the flooring essentials that StaticWorx can supply,

plus our GroundSafe™ Equipment Loaner Program.

Further Reading

READ

- Grounding ESD/Coatings

-

Why Some Epoxy Coatings

Fail Body Voltage Tests -

StaticWorx GroundWorx

Ultra Case History

Grounding ESD Coatings [Read/Download]

There are several ways to ground an ESD epoxy floor – including circuit ground, earth ground, and natural earth ground. Learn more.

Why Some Epoxy Coatings Fail Body Voltage Tests [Read]

There are different ways to produce these coatings and technologies have changed over the years. Many of today’s conductive epoxy coatings fail ESD body voltage tests. Gen 3 epoxies use nanotechnology for an attractive floor, in any color, that meets all ESD standards. Learn more.

StaticWorx GroundWorx Ultra Case History [Read/Download]

For an electronic components manufacturer, electricity is at the heart of business. But static electricity? That’s a very different story. That was the conundrum for Extreme Engineering Solutions (X-ES), which manufactures and tests hardware for the embedded computing market at its headquarters just outside Madison, Wisconsin. The choice for X-ES’s production floor was the HB-97.2 epoxy line [GroundWorx Ultra] from StaticWorx, which includes both an epoxy primer and polyurethane topcoat. Learn more.

Why Some Epoxy Coatings Fail Body Voltage Tests [Read]

There are different ways to produce these coatings and technologies have changed over the years. Many of today’s conductive epoxy coatings fail ESD body voltage tests. Gen 3 epoxies use nanotechnology for an attractive floor, in any color, that meets all ESD standards. Learn more.

StaticWorx GroundWorx Ultra Case History [Read/Download]

For an electronic components manufacturer, electricity is at the heart of business. But static electricity? That’s a very different story. That was the conundrum for Extreme Engineering Solutions (X-ES), which manufactures and tests hardware for the embedded computing market at its headquarters just outside Madison, Wisconsin. The choice for X-ES’s production floor was the HB-97.2 epoxy line [GroundWorx Ultra] from StaticWorx, which includes both an epoxy primer and polyurethane topcoat. Learn more.

LISTEN

Epoxy coatings were introduced in the 1950s to meet the needs of the munitions industry.

Gen 1 coatings were essentially black or dark gray paint, with a conductive surface. They were cheap, easy to repair, and ugly.

Gen 2 epoxies were created in the 60s and 70s for electronics manufacturers, who wanted light, shiny surfaces. Gen 2 was more attractive, but subject to damage over time. With three layers – consisting of a primer, conductive ground plane, and top layer – Gen 2 epoxies can be difficult to install correctly and difficult and costly to repair. ESD performance can also be unreliable.

Current Gen 3, all-in-one coatings, consist of a single layer, with decorative and conductive properties in all-in-one. Gen 3 ESD coatings work extremely well. They’re easy to install and repair and offer superior ESD performance.

WATCH

Eliminate bacteria and contaminants on floor with StaticWorx/Dr. Schutz Remake.

StaticWorx/Dr. Schutz Remake PU Sealant prevents contamination on lab, hospital, nursing home, school floors by inhibiting the formation of bacteria. Resistant to chemical and disinfectants, Remake is easy to clean and maintain – and gives you a clean, hospital shine at a fraction of the cost of a new floor.

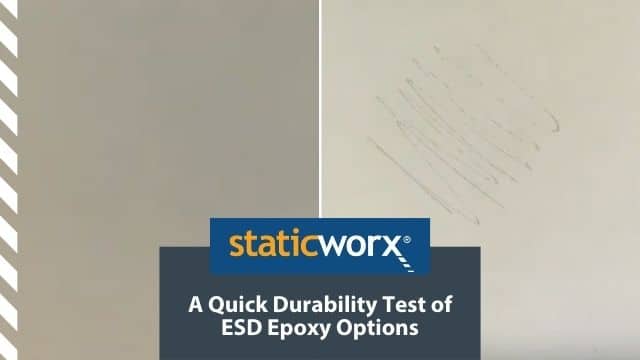

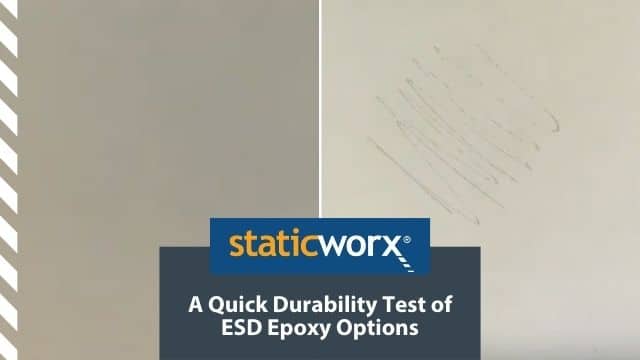

Comparing the scratch resistance of shiny no-wax HB 97.2 (GroundWorx Ultra) with an entry-level Water-Based 2-Part Epoxy-Acrylate Finish.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Unless otherwise stated, standards referenced are the most up-to-date versions.

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Flooring Products

We accept these major credit cards.

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

All rights reserved. © 2008-2024, StaticWorx® GroundSafe™ ESD Flooring. Privacy Policy