FAQ: How are static-dissipative and conductive properties added to flooring?

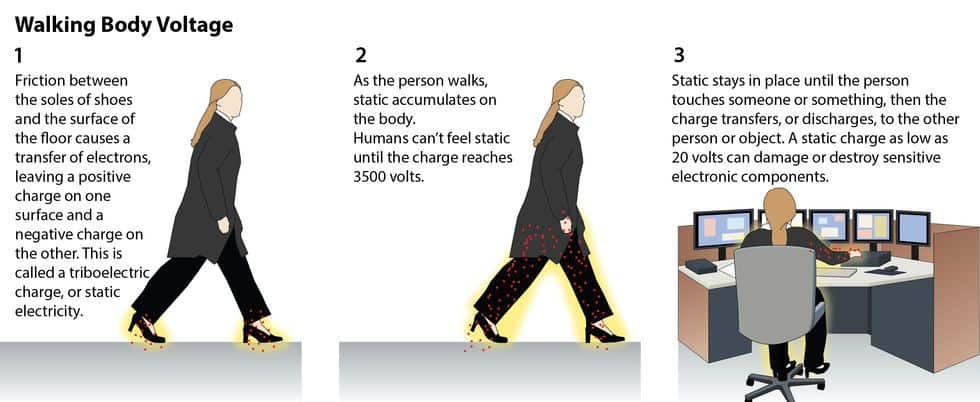

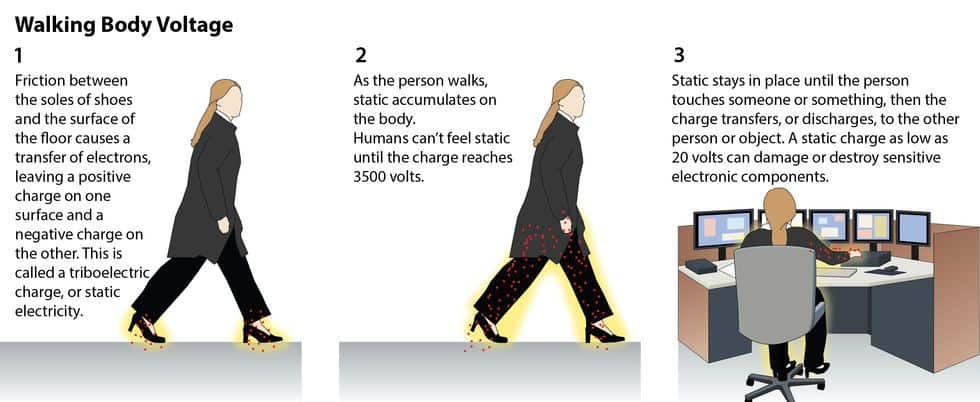

Unlike standard flooring, static control floors promote the flow of electricity—in other words, static charges flow across and through the floor to electrical ground. When people walk across a regular floor, the contact and separation between the floor and the soles of their shoes generates static. Regular flooring, which is electrically insulative – the opposite of conductive—cannot be grounded. As there is nowhere for the static to go, it builds on people and discharges to the first person or object they touch.

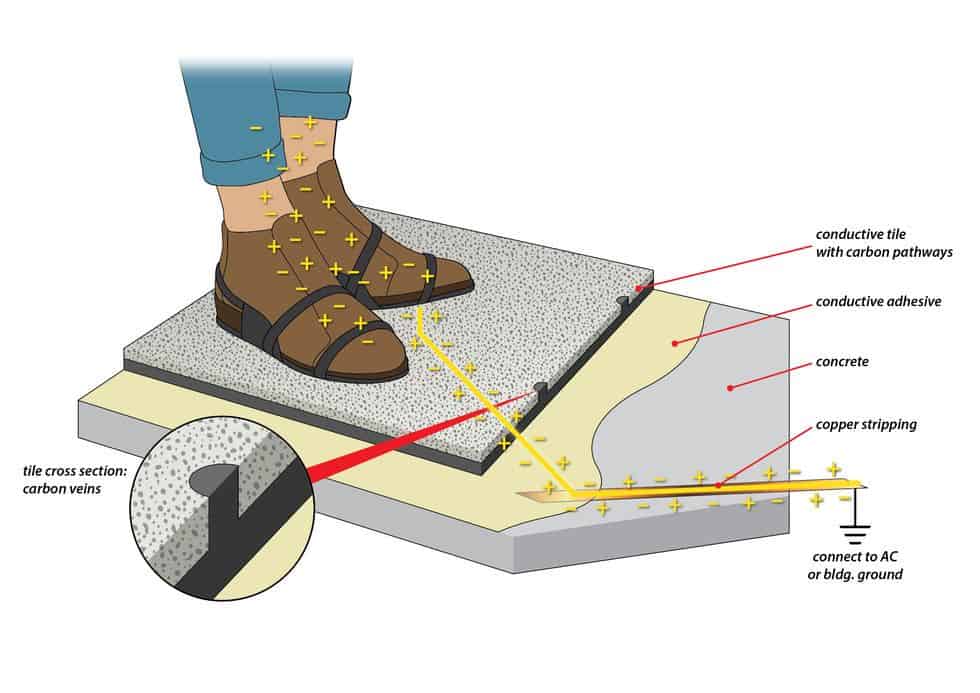

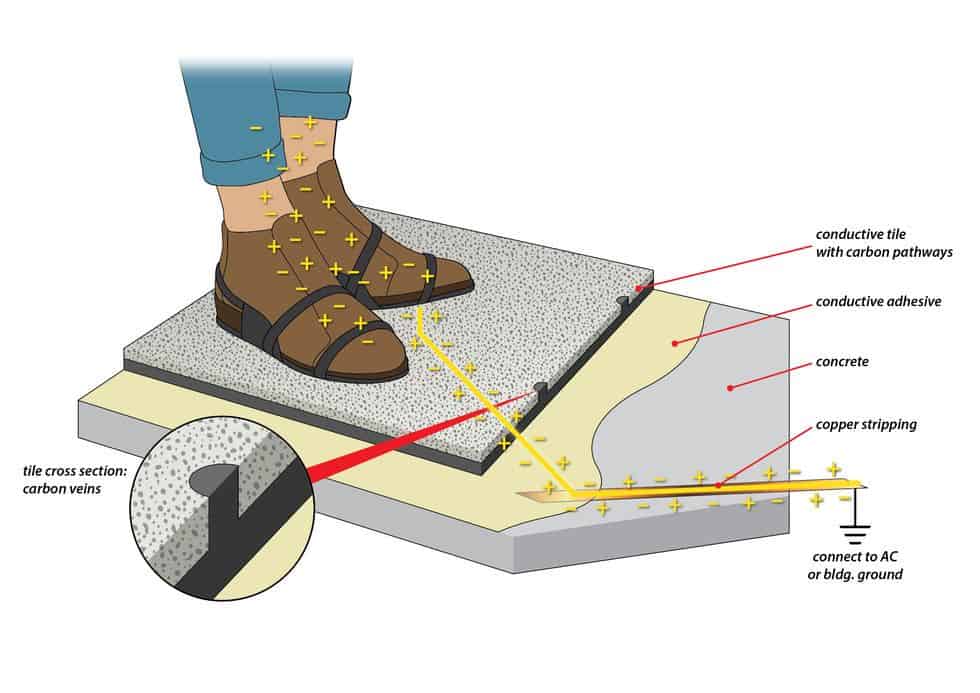

Static-control flooring transports—or dissipates—static electricity and other electrical currents to ground. Because of their conductivity, static-control floors can be grounded.

Most types of flooring can be made into a conductive or static-dissipative floor. The most common way to produce a static-control floor is to add carbon or graphite to the standard flooring formula.

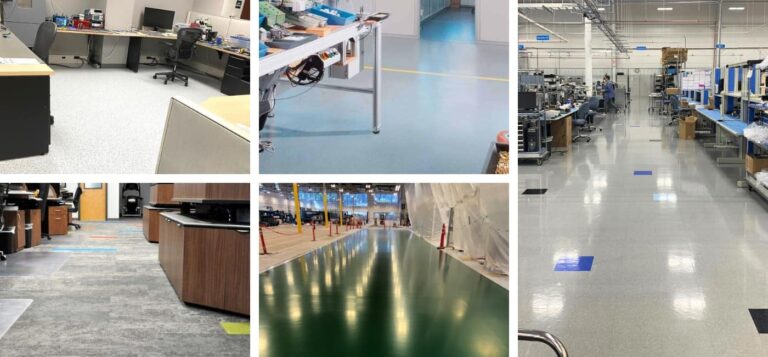

Here are a few examples of how this is done:

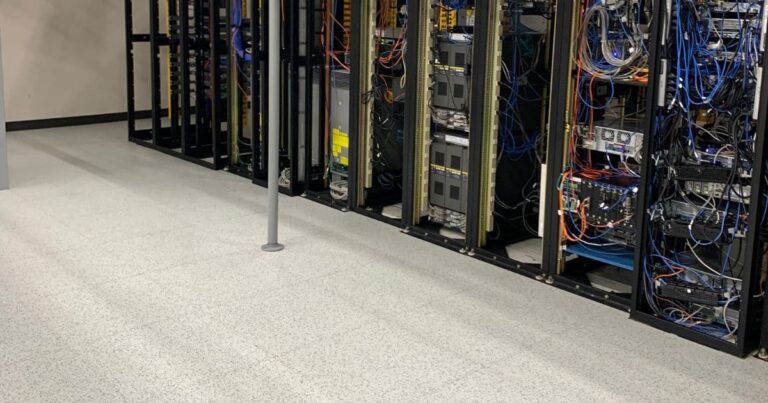

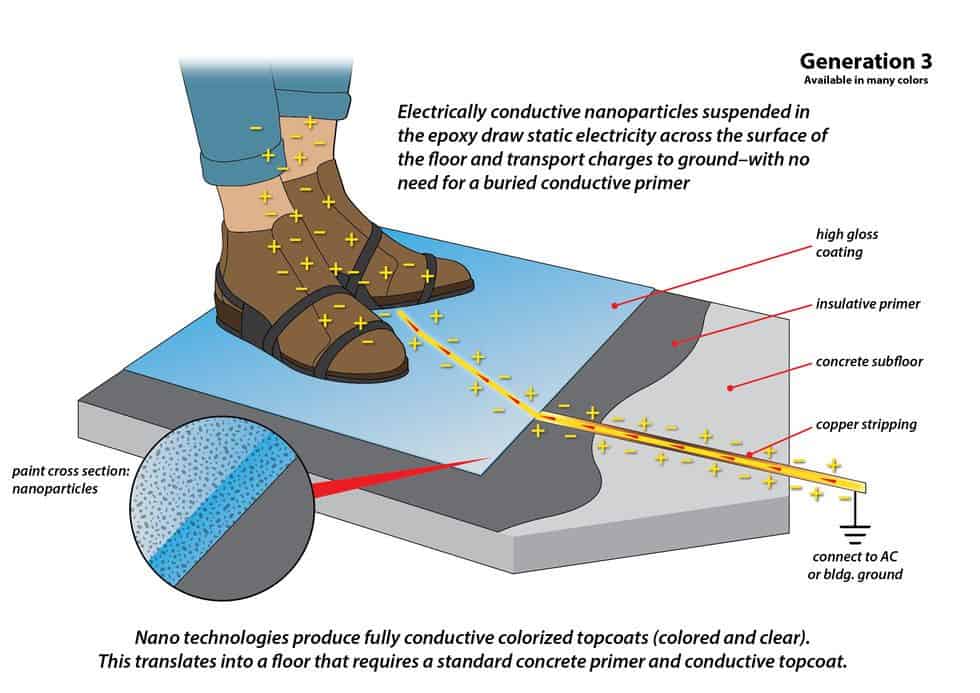

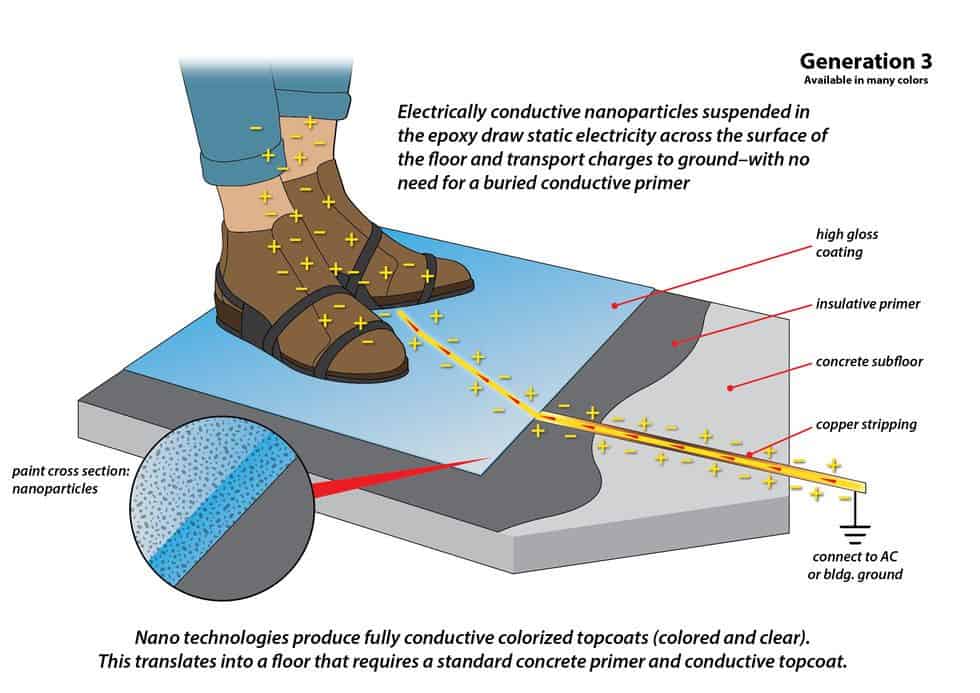

Epoxy floors are made with liquid catalyst-driven resins. Carbon particulate or carbon fibers are added to the epoxy while it is in liquid form. Depending on the percentage of the additive, manufacturers can produce a highly conductive epoxy coating for explosives handling or, by adding slightly less of the additive, create a static-dissipative version for electronics handling applications.

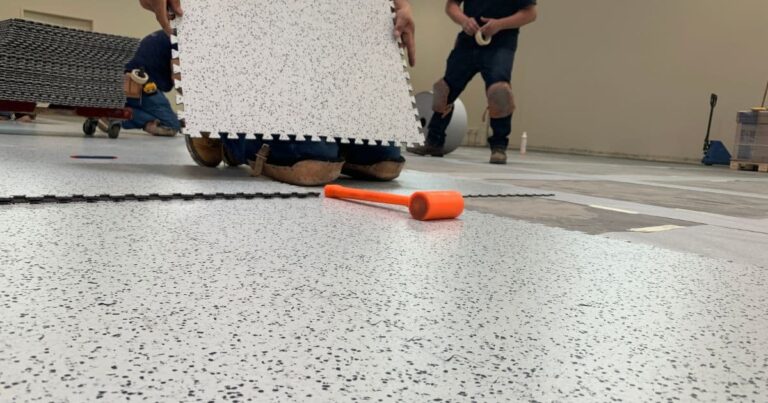

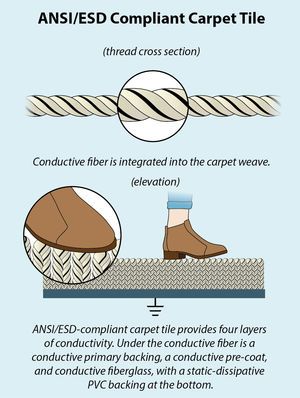

Depending on the type of carbon fiber and the design of the carpet tile, it is possible to control the ohms resistance of the tile and create either static-dissipative or conductive flooring.

Since carpet tiles are rarely used in explosives-handling operations (which require smooth, non-porous washable conductive flooring), most carpet tile applications are for light electronics assembly, labs and end user environments, better suited to the static-dissipative version.

Standard carpet tile, often made with insulative wool or nylon fibers, is a natural static generator. By wrapping carbon-loaded fibers around the tile’s nylon filaments, manufacturers turn a static-generating carpet into a static-control floor.

Depending on the type of carbon fiber and the design of the carpet tile, it is possible to control the ohms resistance of the tile and create either static-dissipative or conductive flooring.

Since carpet tiles are rarely used in explosives-handling operations (which require smooth, non-porous washable conductive flooring), most carpet tile applications are for light electronics assembly, labs and end user environments, better suited to the static-dissipative version.

What is electrostatic discharge (ESD) Flooring?

This video provides an overview of static control flooring options:

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.