FAQ: Why should the adhesive be more conductive than the ESD flooring material?

In any ESD flooring installation we need to look at several factors.

- Does the floor meet ANSI/ESD or ATIS grounding requirements?To meet ANSI/ESD S20.20, resistance should measure below 10E9.

To meet ATIS, resistance should be 10E6 or above. - Is the system inherently or potentially unsafe due to electrical safety issues, such as over conductivity, improper installation or misapplication?

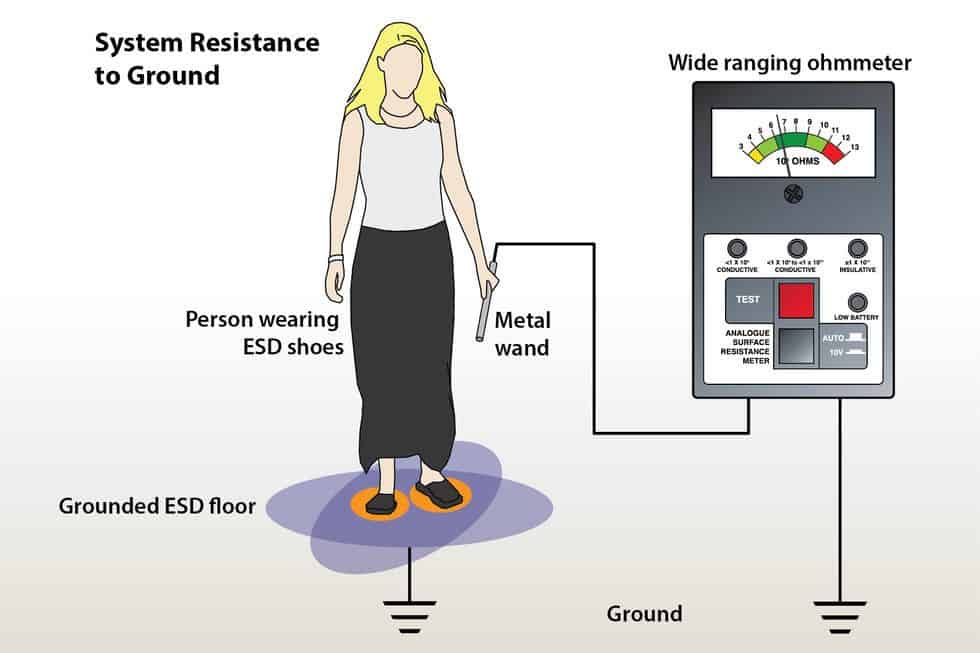

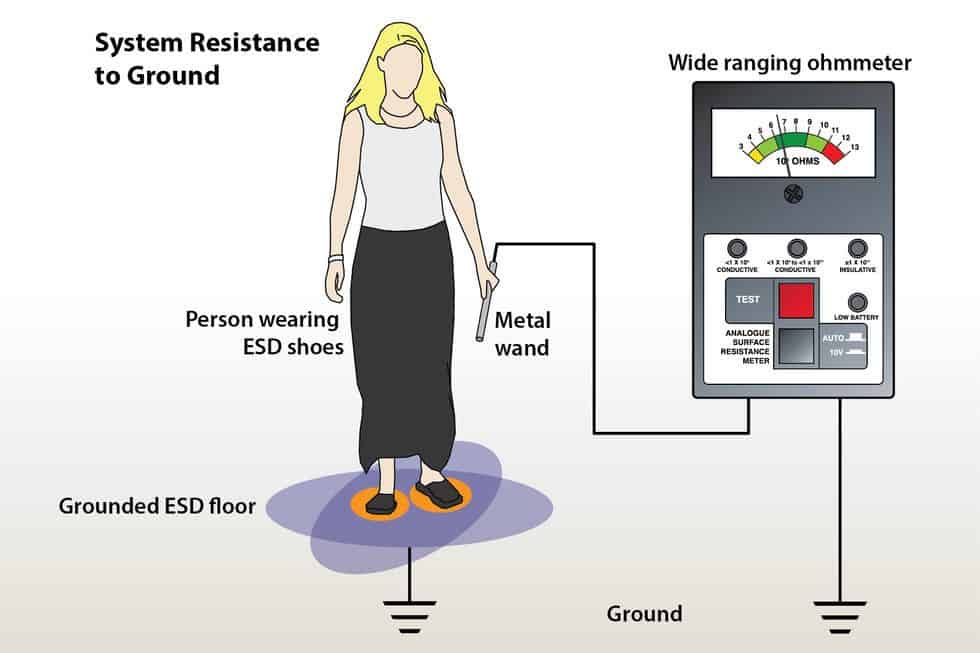

The first variable we investigate is what we call system resistance. System resistance is the ohms resistance of the floor, the adhesive and the ground connection. System resistance will always measure equal to or greater than the most resistant—least conductive—component in the chain.

Important: To direct all electricity downward to ground, as intended, the adhesive must be the most conductive (least resistant) element in the flooring system.

The flooring surface should always most resistant (lease conductive) component in the system.

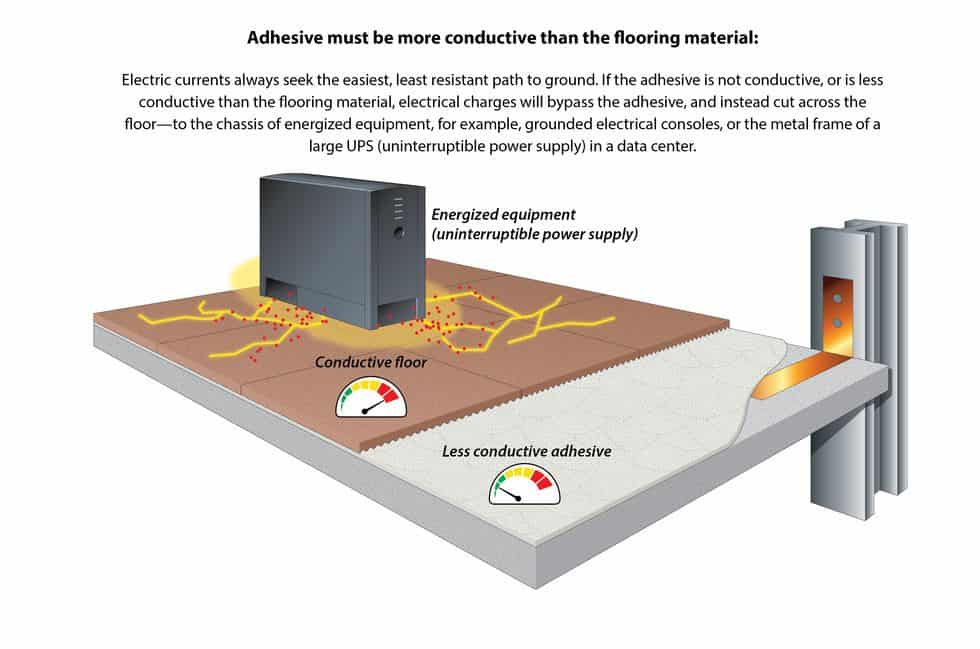

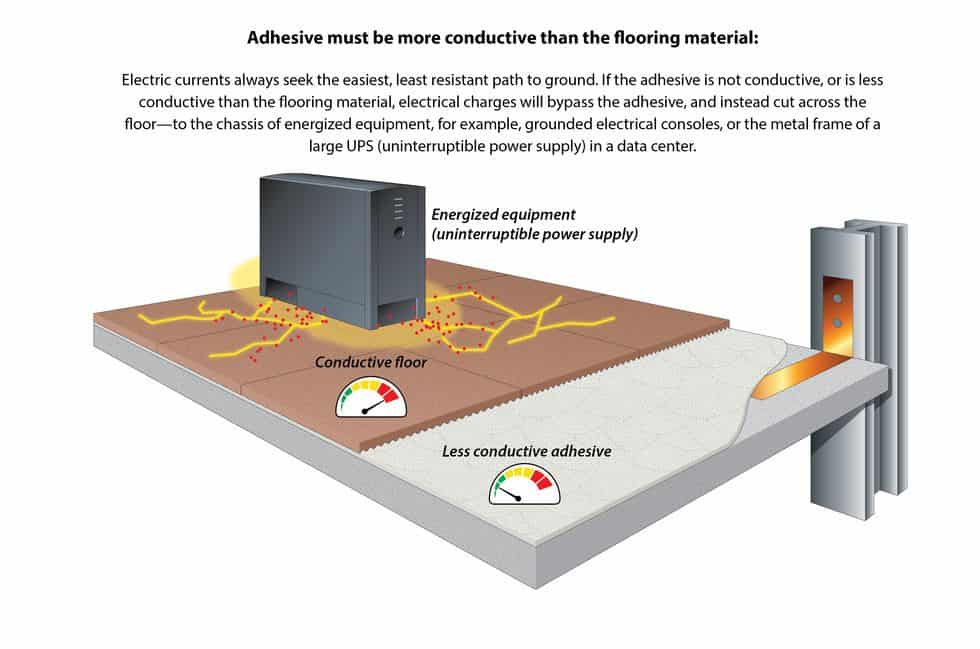

Using an adhesive that’s not conductive or is less conductive than the flooring material could pose a safety hazard.

If the adhesive is not conductive, or the adhesive underlayment is less conductive than the flooring material, electrical charges could bypass the adhesive, preferring the less resistive route, across the top of the floor—to the chassis of energized equipment, for example, or grounded electrical consoles, or the frame of a large UPS (uninterruptible power supply) in a data center.

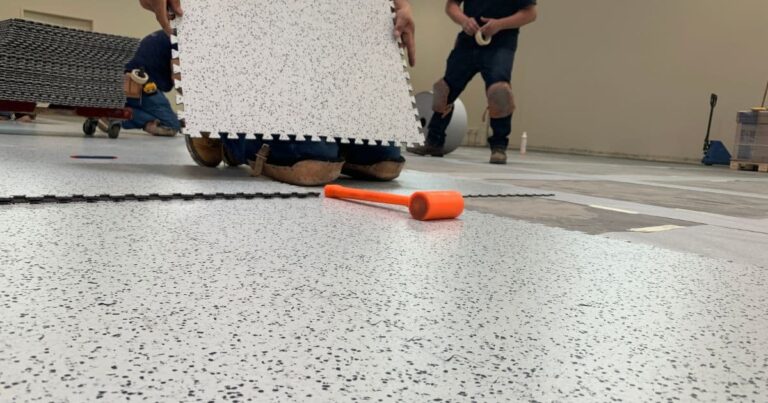

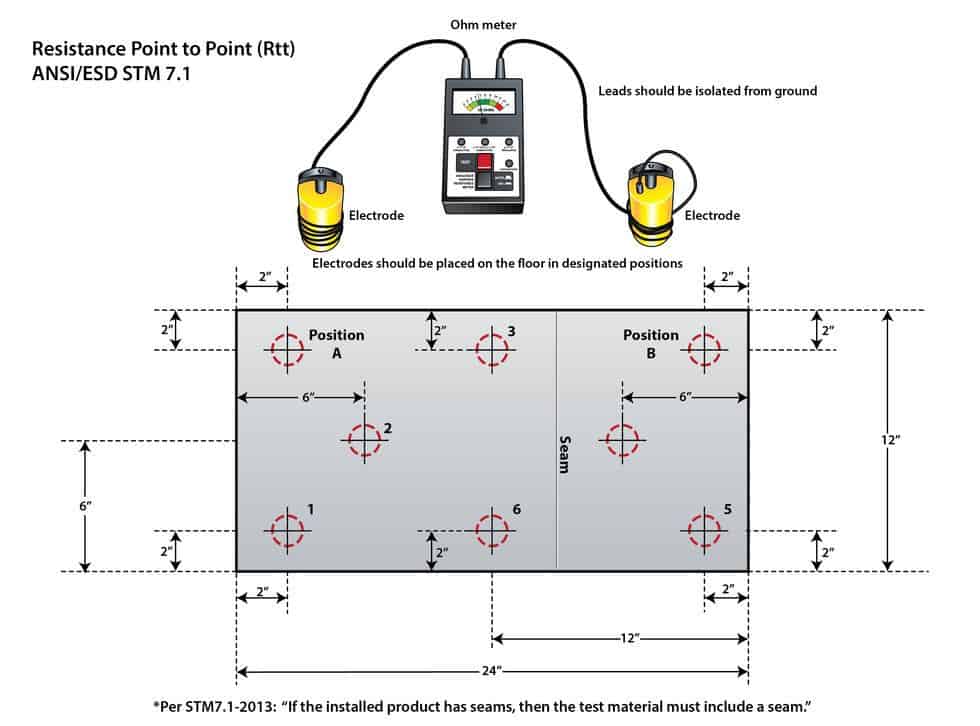

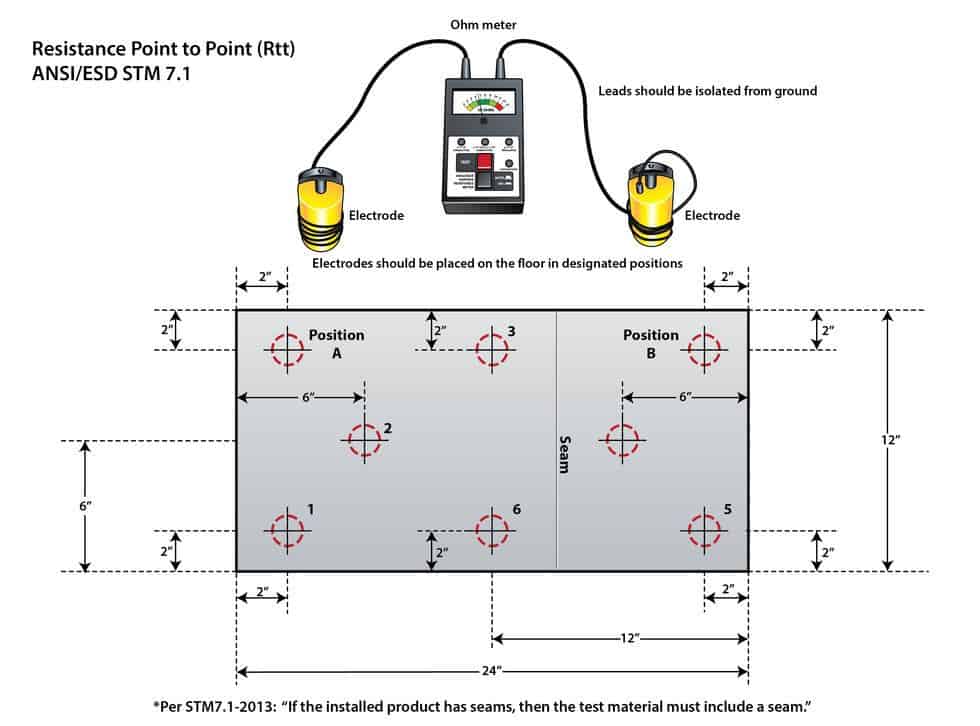

Note to specifiers: A simple audit with an ohm meter can expose this potential problem. We suggest that the flooring material be tested for point-to-point resistance—across the same floor tile. This will indicate whether or not the surface of the flooring material falls within the proper resistivity range.

After the flooring is installed, to verify that it’s properly grounded, test point-to-ground resistance—that is, from the tile to the copper ground strip, or whatever attachment was used to ground the floor.

Remember: system resistance is always equal to or greater than the most resistive element in the chain—so an adhesive that’s not conductive or is less conductive than the flooring material will raise the overall system resistance.

If point-to-point resistance is lower than the point-to-ground resistance—which, again, would happen if the adhesive were not as conductive as the tile—there may be cause for safety concerns.

For this reason, it is best to install tiles with a point-to-point resistance above 100,000 (1 x 10E5) ohms.

Remember: system resistance is always equal to or greater than the most resistive element in the chain—so an adhesive that’s not conductive or is less conductive than the flooring material will raise the overall system resistance.

If point-to-point resistance is lower than the point-to-ground resistance—which, again, would happen if the adhesive were not as conductive as the tile—there may be cause for safety concerns.

For this reason, it is best to install tiles with a point-to-point resistance above 100,000 (1 x 10E5) ohms.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

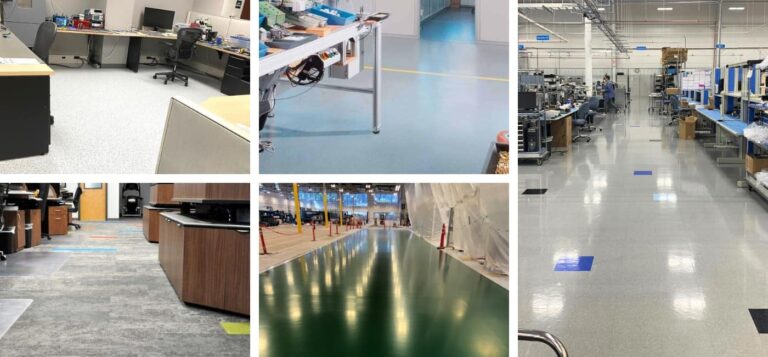

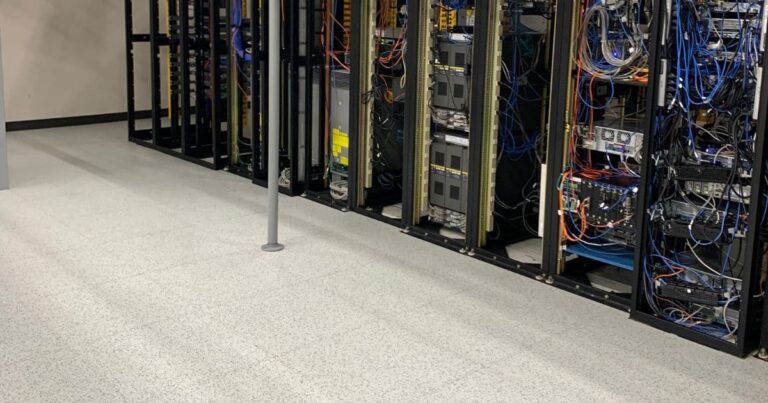

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.