FAQ: Will our concrete floor protect against static?

While bare concrete—i.e., a concrete floor that hasn’t been sealed—often exhibits some static-dissipative or conductive tendencies, these electrical properties are variable and environmentally dependent. Conductivity is not inherent or consistent in concrete.

Concrete draws its conductivity from moisture in the floor, and its electrical resistance is subject to changing variables, including moisture permeation, geological conditions, subterranean activity, aquifers, weather, and ambient humidity or RH. A concrete floor that’s too conductive during a high humidity summer could be insulative in drier weather later that same year.

More important: Bare concrete does not reliably meet industry standards. ANSI/ESD S20.20, tested using method STM 7.1, recommends electrical resistance below 1 x 10E9 ohms. As concrete dries, its electrical resistance increases, making it less conductive. If a floor with an electrical ohms resistance at or near 10E9 becomes less conductive, it will not meet best practices or ESD industry standards.

Likewise, as resistance decreases, charge dissipation increases. Concrete can absorb vapor from the soil below, lowering its resistance, making the floor dangerously conductive.

The electrical resistance of bare concrete can vary by 2-3 magnitudes in either direction. Inherent dust and particles along with broad performance differentials, caused by uncontrollable site and environmental conditions, make bare concrete an impossible sell to an ESD-savvy customer or any auditor as part of an ISO certification.

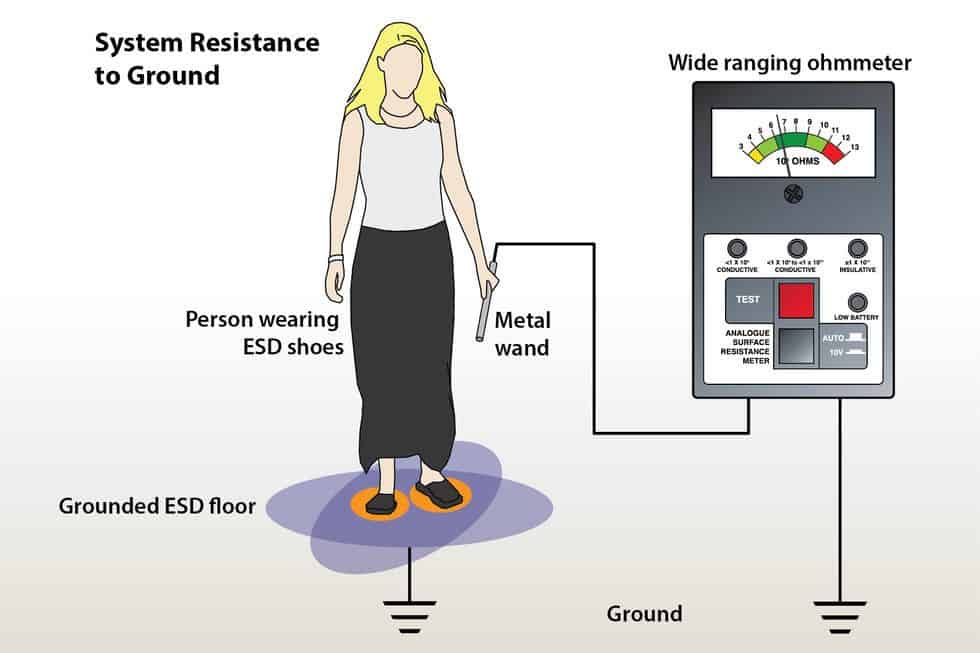

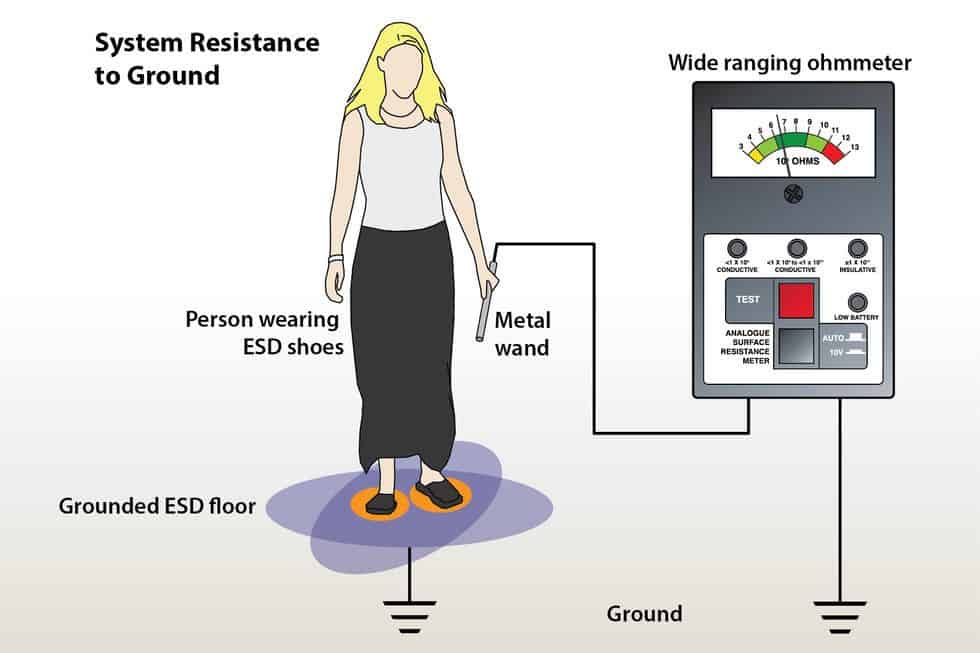

ANSI/ESD STM97.1 System Resistance

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

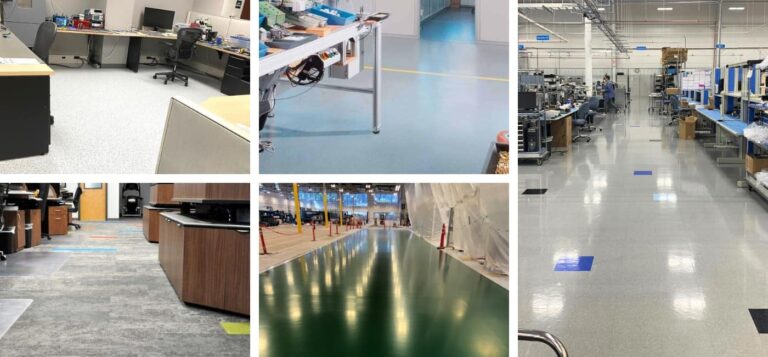

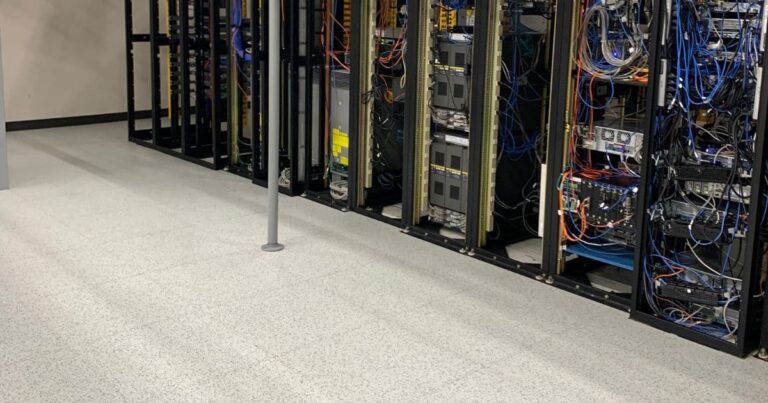

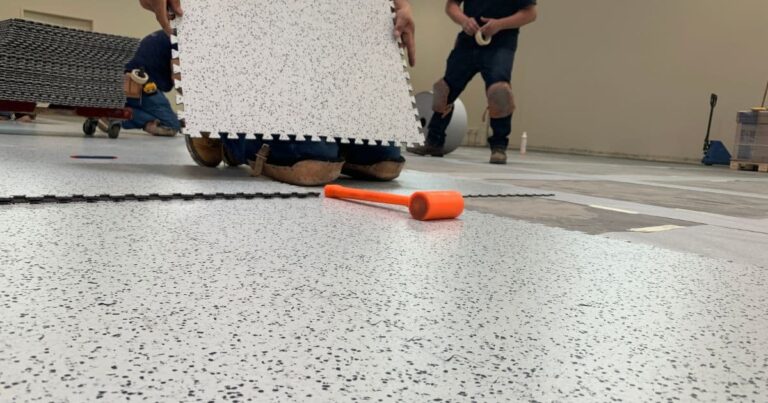

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.