FAQ: How do I ensure continued conductivity across an ESD tile floor?

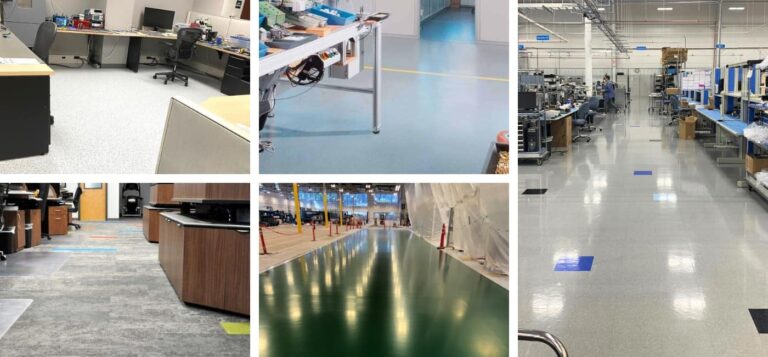

The answer must involve your choice of static control flooring.

First, there are several different types of static control floor covering. All possess different properties and some of the floor coverings have limitations. For example, Armstrong manufactures a product called SDT. Armstrong SDT requires special waxes to make it perform. Some antistatic broadloom cannot be grounded at all because it is not conductive.

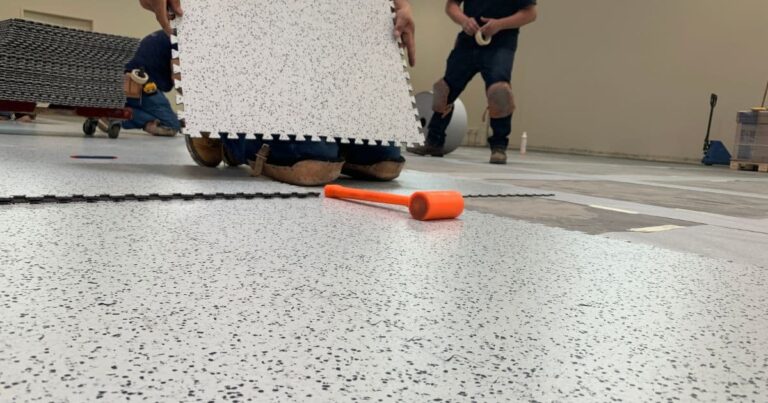

StaticWorx® vinyl tile is a permanently conductive material that requires no special care to remain conductive. Waxes are not needed. Our vinyl tiles can be grounded using a simple 24 inch long, 2 inch wide, copper strip under one tile. We provide the strips as part of our package. The other end of the strip is attached to an electrical outlet using one of the screws in the outlet box.

Only one ground connection is needed per 1000 square feet. The other tiles are bonded via our conductive pressure sensitive adhesive—GroundTack®—which contains conductive coated fibers.

How the Adhesive Works

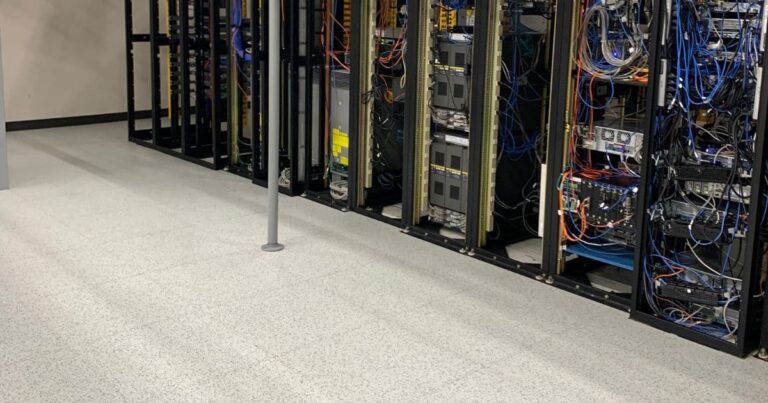

Conductive adhesive provides electrical continuity by creating an electrical bond between ESD flooring tiles. So when a person walks across the floor or slides out of a chair, the built up static is discharged to the static control floor. The static charge follows a path from the floor to the adhesive and is safely and effectively discharged to ground. StaticWorx® Conductive Adhesives are highly conductive and provide excellent continuity across the entire ESD floor. To meet relevant specifications, the conductive adhesive must be attached with copper strips to some form of ground-e.g. Electrical conduit, building steel or a dedicated grounding strip.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.