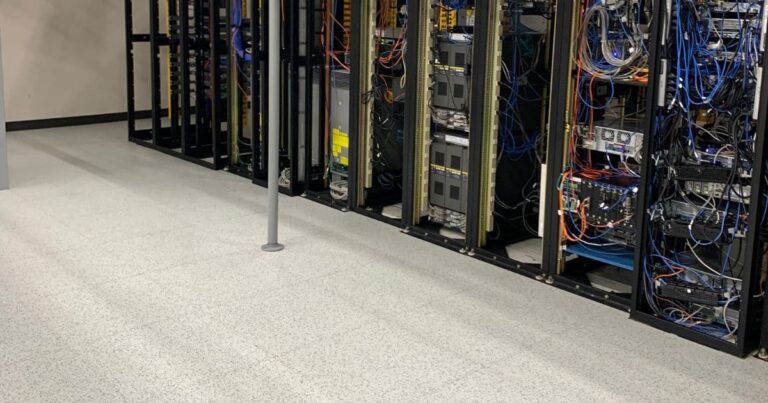

FAQ: Is ESD epoxy appropriate for a small server room?

We need to caution about the limitations of static-dissipative or conductive epoxy coating in a data center/server room application.

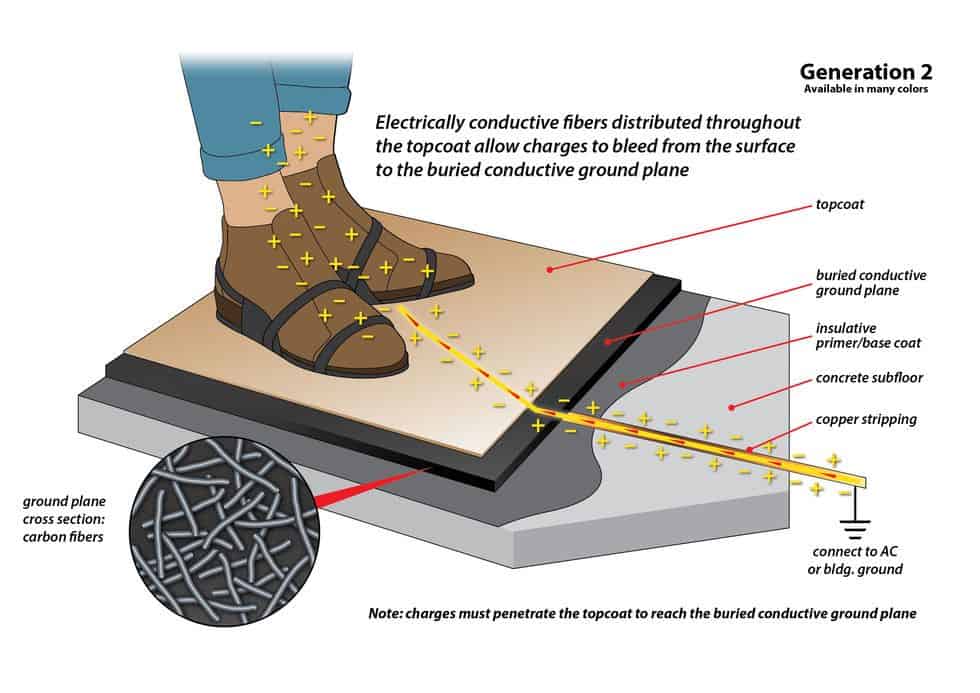

ESD coatings eliminate static by providing a path to ground. Conductivity is achieved by adding conductive fibers or carbon and graphite particulate. The fibers and particulate create an electrical bridge through a material that, otherwise, is an insulating static generator.

Conductivity is only one of the two critical static control properties provided by a coating.

Most epoxy is not a low charge-generating material. ESD epoxy coatings will eliminate static only if they are used in conjunction with special static-preventive footwear. If people walk on the floor with regular footwear (dress shoes, sneakers, hiking boots etc.), the coating will neither prevent the generation of static nor remove a static charge after it is generated.

To bridge the electrical gap between the human body and the floor, every person walking on the floor would need to wear special ESD footwear at all times. Walking on any ESD coating in street shoes would be the same as walking across a sheet of plastic. The result being the generation of thousands of volts and an increased likelihood of an ESD event.

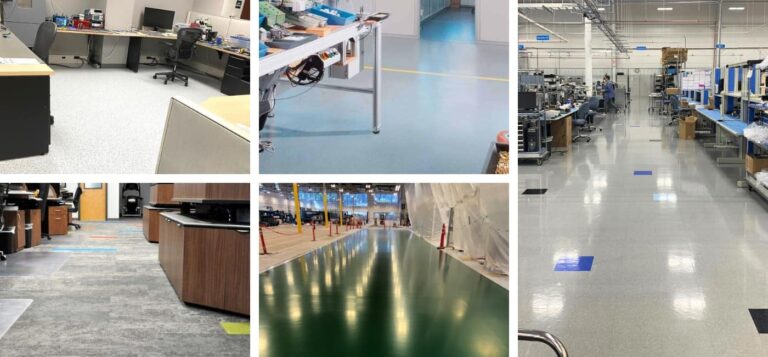

In data centers, we recommend the following conductive materials:

- Conductive rubber;

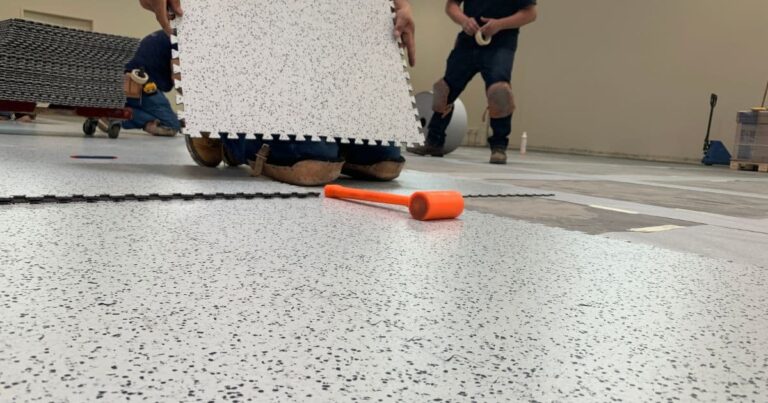

- Conductive epoxy—but only if ESD footwear is mandated and rigorously enforced;

- Conductive vinyl tile—but only if ESD footwear is mandated and rigorously enforced;

- Static-dissipative carpet tile.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.