FAQ: Don't let moisture ruin your ESD flooring installation

We were recently contacted by a client who wanted our opinion about an inexpensive system designed to eliminate moisture vapor in concrete. Measurements using Test Method ASTM F2170 showed moisture levels in the concrete throughout the client’s facility in excess of 95%. At nearly 100% humidity, any ESD floor installed with low-VOC conductive adhesives will fail without some form of moisture mitigation system.

The supplier of the moisture-mitigation system had promised the client that their system would prevent the installation from failing and guaranteed it for the life of the floor. The warranty covered up to “8 pounds” of moisture per the ASTM F1869 calcium chloride test method, stating, “in the unlikely event of any failure resulting from moisture vapor below 8 pounds, XYZ, Inc. will either replace the material or refund the cost of the floor.”

Here’s the problem with this scenario:

- Brand-new, manufactured by a small company, the system had not been thoroughly vetted. The warranty guaranteed performance for “the life of the floor,” but the system hadn’t been in use long enough to justify such a claim.

- A warranty claim could cost 100s of thousands of dollars. Did this small company have the financial backbone to pay out such a claim? It wasn’t clear.

- The manufacturer cited a different ASTM test method than the method the client had used for the first set of tests. If there was a problem, how could the client be sure the method cited by the manufacturer would produce consistent results?

- The guarantee covered only the replacement costs of materials. It did not cover labor. Nor did the warranty compensate for inconvenience or cover any costs associated with lost business due to shutdowns. On a big job, labor can cost as much as or more than the material. And lost business could cost an operational facility 5, 10, or even 50 times more than the cost of an ESD floor.

Moisture is a serious issue, and it’s expensive to solve. It’s even more expensive if not handled with lock-tight solutions up front. If moisture testing indicates a problem, there’s a problem. Don’t be like property owners or facility managers who try to hide from a problem by looking for contrary test results. Remember: there is always a contractor out there who, to gain your confidence – or get the job—will be willing to take on a risk. But will that contractor compensate you fully if the floor fails and needs to be replaced?

If a solution sounds too good—or too cheap—to be true? It probably is.

Please note: StaticWorx is not in the moisture mitigation business. We’re providing this information as a service to the many clients and contractors who use our ESD flooring.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

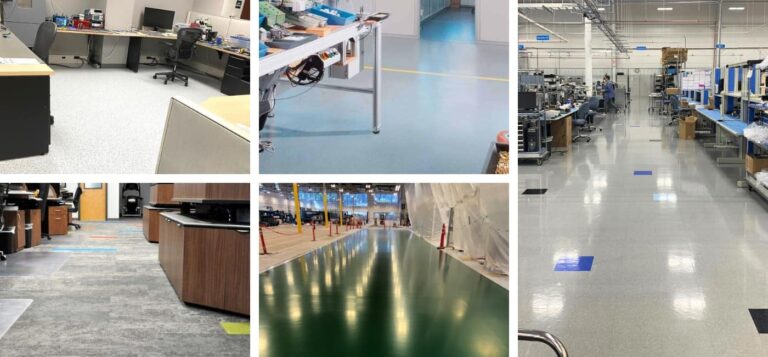

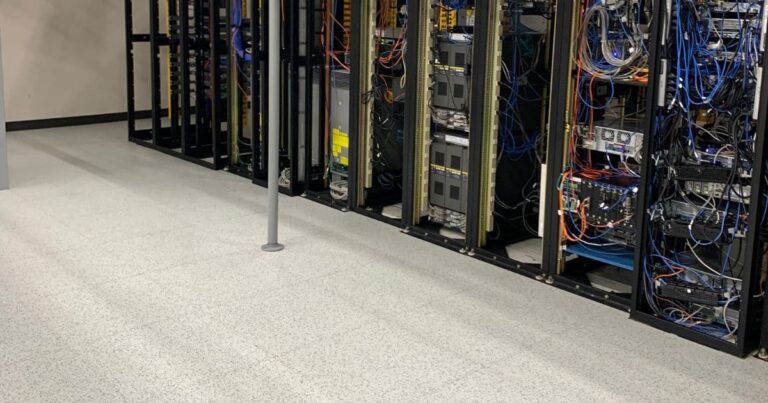

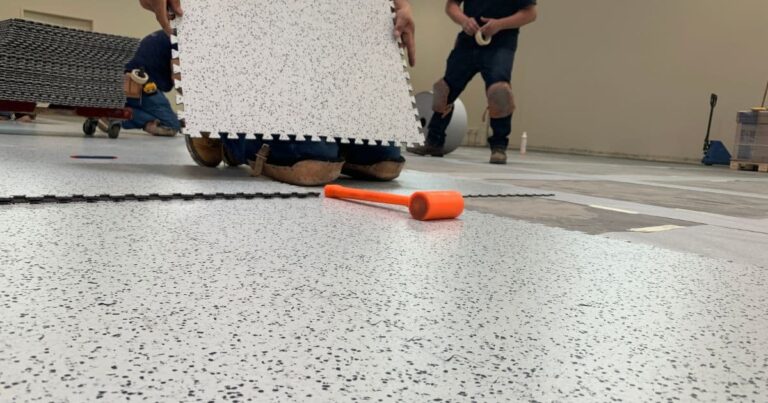

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.