FAQ: Is it possible for a conductive floor not to meet ANSI/ESD S20.20?

First, floors do not meet ANSI/ESD S20.20. S20.20 is a process document, citing recommended electrical parameters based on the measured results of ANSI standard test methods (STM).

But, yes, a floor can fail to meet those electrical parameters. First, the system resistance could be higher than the resistance of the flooring material. That is, a material may fall within the acceptable range when tested alone, but fail when the entire flooring system is tested. (Explanation below.)

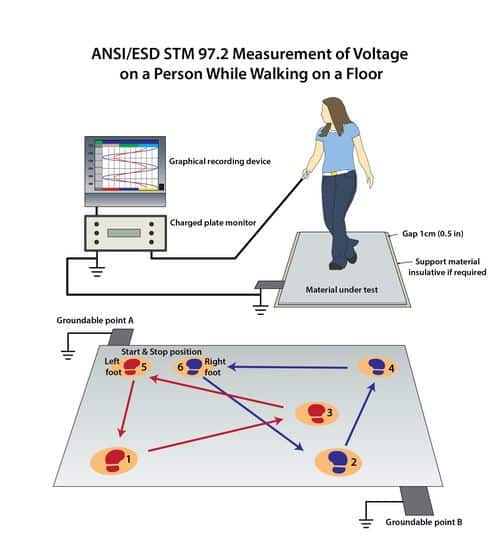

Second, previous versions of S20.20 included only resistance testing. S20.20 also requires that the floor generate no more than 100 volts of body voltage, tested per STM 97.2. A floor can pass resistance tests, yet fail body voltage tests.

Electrical Resistance (measured in ohms)

Under ANSI/ESD S20.20, the resistance to ground (RTG) of a flooring material must measure at or below 1 x 10E9 ohms, or 10E9 Ω.

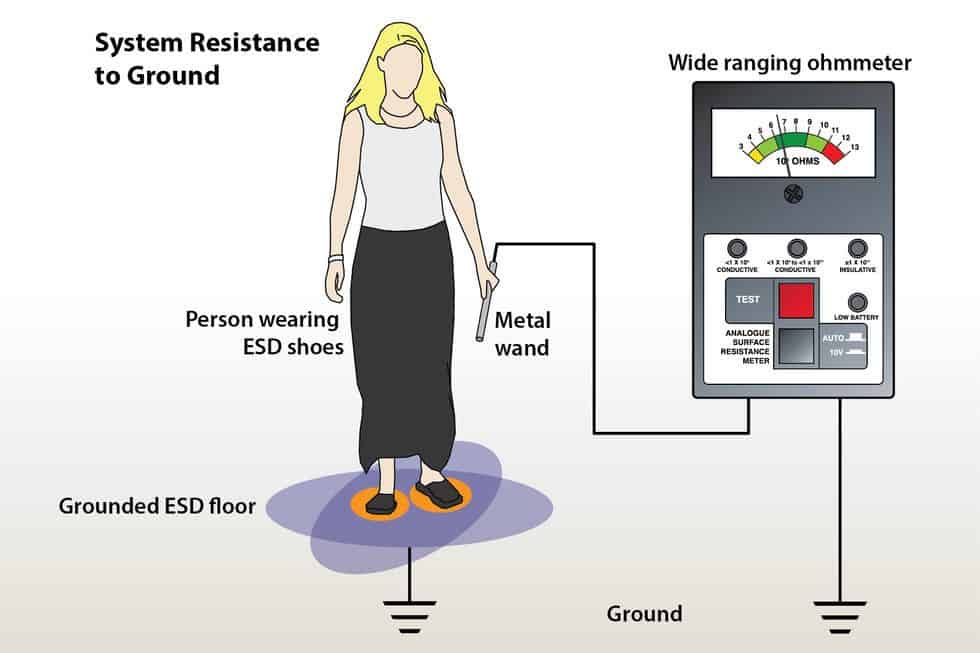

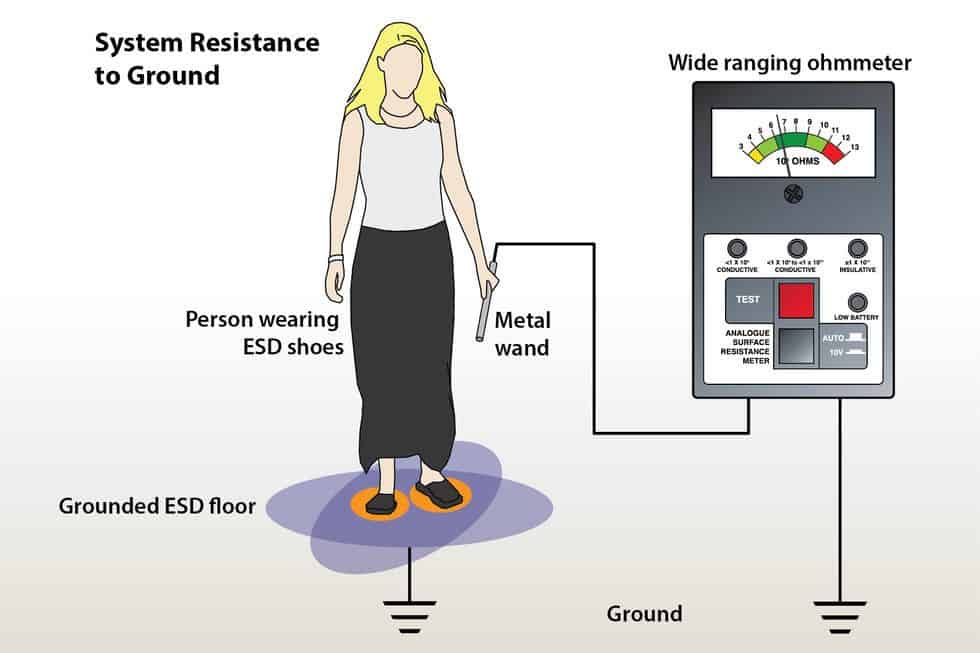

If RTG exceeds 1.0 x 10E8, the resistance of the flooring system—i.e., the aggregate resistance of a person, the footwear the test subject is wearing, the flooring, and the connection to ground—may not be able to compensate for potentially higher resistive properties of, for example, certain types of ESD footwear. As each element in the system has some electrical resistance, the complete system could measure well above 1.0 x 10E9.

Measuring resistance through a person and footwear (as opposed to testing only the floor, using two five-pound weights) yields a different resistance value than you’d get with just the 5-pound NFPA probes. Again, it would be difficult, if not impossible, for a flooring material measuring in the upper end of the static dissipative range (> 1.0 x 10E8) to be part of a total system—person, footwear, potential floor contamination—measuring less than 1.0 x 10E9. The math just may not work.

Body Voltage/Charge Generation (measured in volts)

In 2014, the ESD industry changed their standard to include charge generation—also called walking body voltage—that is, the static that accumulates when people walk on the floor.

Charge generation is the result of a material’s tribo-charging properties. Charge generation and resistance are two separate properties; resistance does not correlate to charge generation.

Most static-dissipative epoxy coatings—and even some conductive floors—are incapable of preventing body voltages from exceeding 100 volts. Since the goal of ANSI/ESD S20.20-2014 is to prevent body voltages above 100 volts, it is impossible to categorically state that all static-dissipative and conductive floors measuring less than 1.0 X 10E9 will automatically meet ANSI/ESD S20.20-2014.

In fact, the opposite is true. Many conductive and static-dissipative floors measuring below 1.0 x 10E8 fail body voltage testing.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

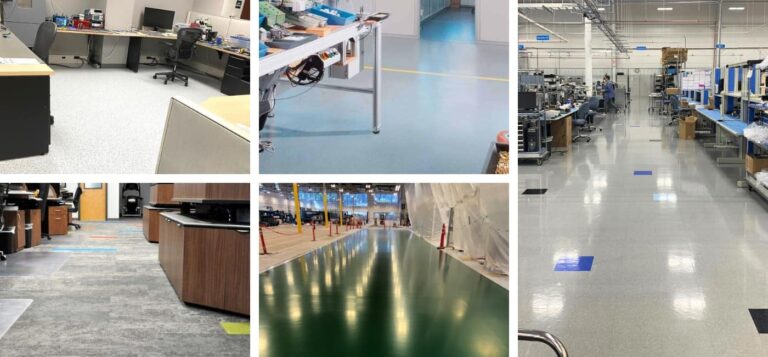

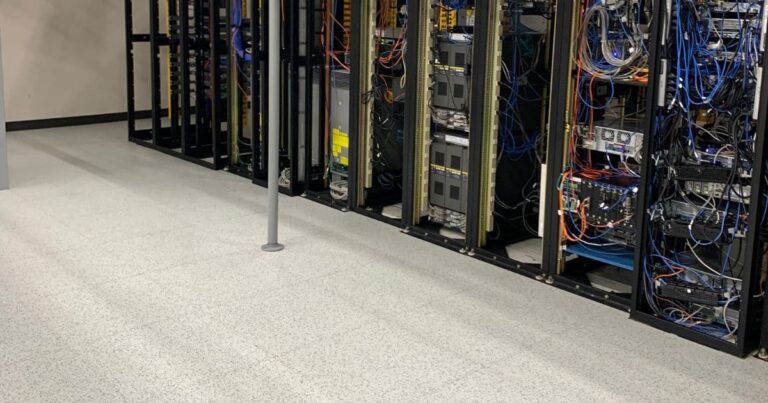

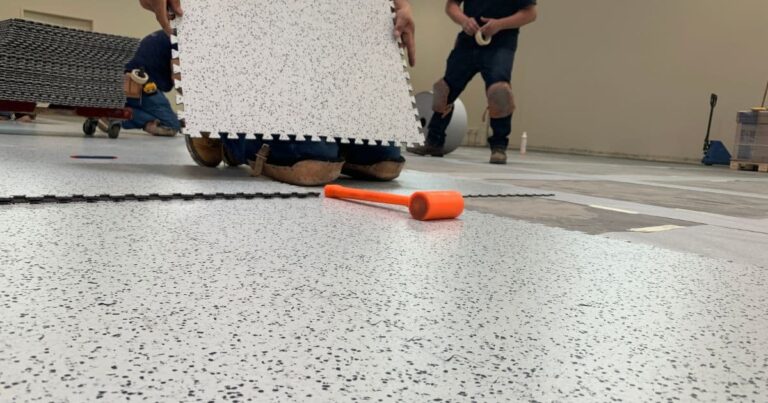

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.