FAQ: Why not buy cheaper VCT tile?

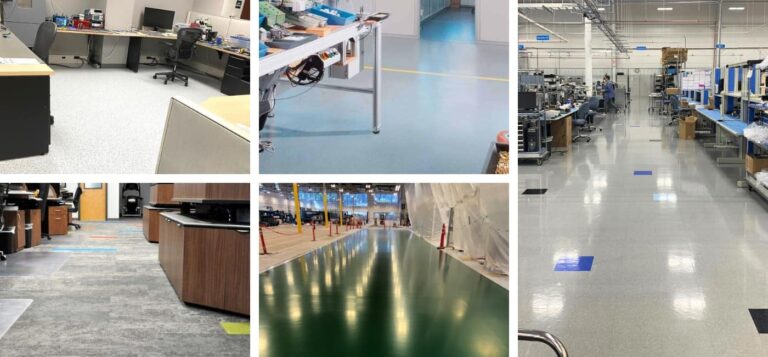

VCT tile vs. SVT tile: lifetime cost vs. effectiveness

Vinyl Composition Tile (VCT), such as static-dissipative vinyl (SDT) is comprised of ordinary static-generating PVC, in combination with fillers like clay and limestone, and a chemical, known as an amine, to provide static-dissipative properties. While amines make the floor groundable, regular VCT is highly static generating.

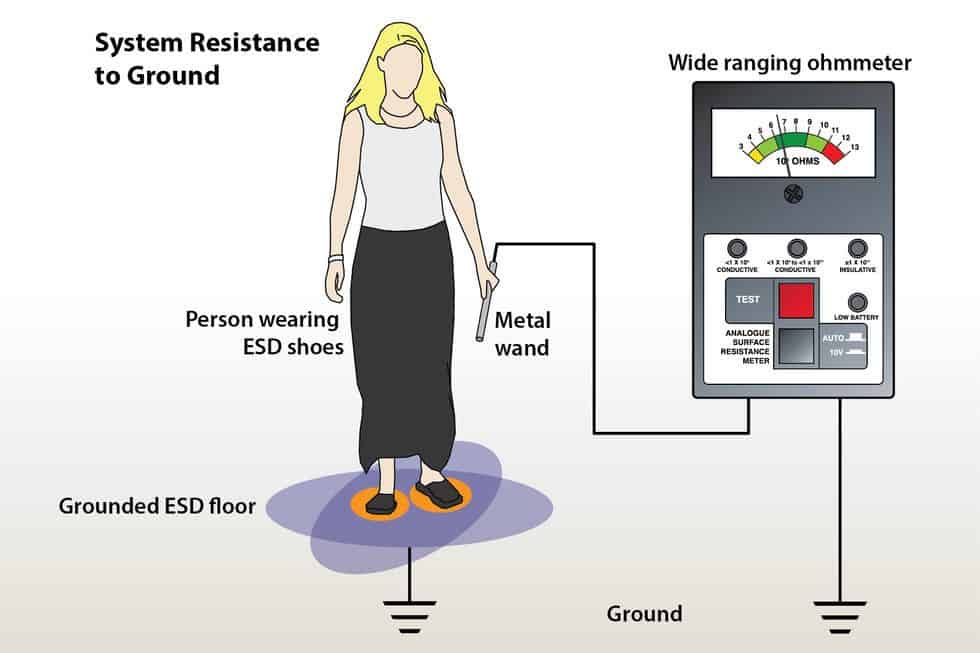

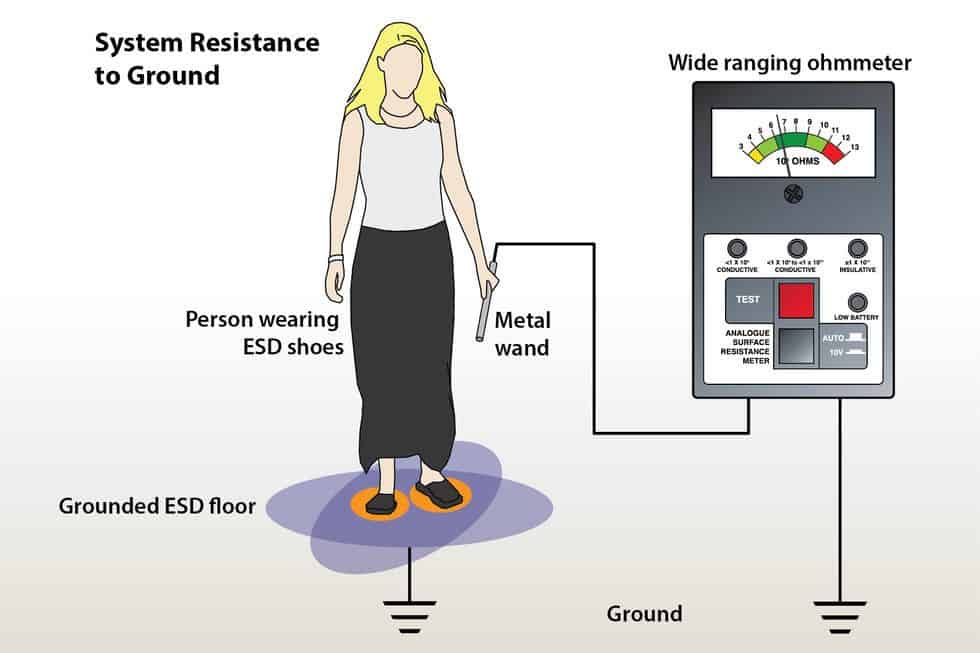

When shoe soles contact and separate from VCT as people walk, static builds. To prevent static from building on people or objects—such as rolling carts or chairs—the floor must be waxed regularly, with three to five coats of antistatic polish. And everyone who walks on the VCT floor must wear special static-protective footwear—ESD shoes or conductive heel or toe straps, a requirement that is routine in electronics manufacturing facilities, but would be difficult if not impossible to enforce in most mission-critical spaces.

Vinyl Composition Tile (VCT), such as static-dissipative vinyl (SDT) is comprised of ordinary static-generating PVC, in combination with fillers like clay and limestone, and a chemical, known as an amine, to provide static-dissipative properties. While amines make the floor groundable, regular VCT is highly static generating.

When shoe soles contact and separate from VCT as people walk, static builds. To prevent static from building on people or objects—such as rolling carts or chairs—the floor must be waxed regularly, with three to five coats of antistatic polish. And everyone who walks on the VCT floor must wear special static-protective footwear—ESD shoes or conductive heel or toe straps, a requirement that is routine in electronics manufacturing facilities, but would be difficult if not impossible to enforce in most mission-critical spaces.

Cost

The initial cost of VCT is low. The ESD wax necessary to keep the tile from generating static is expensive. Maintenance costs quickly accumulate, negating any money saved on the original VCT. In other words, while the initial investment is small, the total, or long-term, cost of ownership is much higher than products requiring less maintenance.

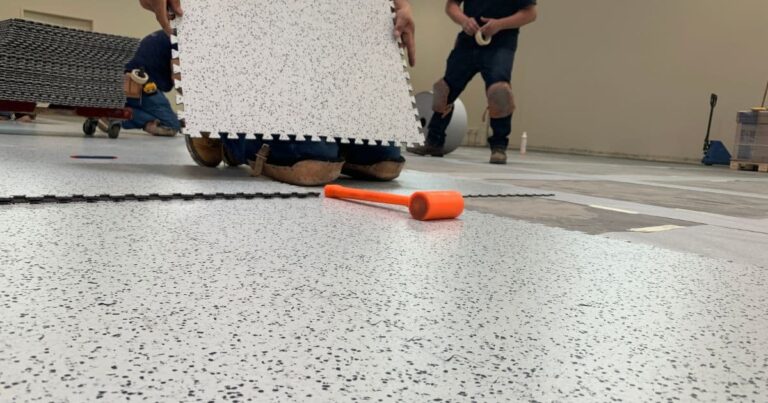

Conductive solid vinyl ESD tile (SVT) has a higher initial price tag, but SVT, uniform throughout the thickness of the tile, requires only periodic buffing to maintain its appearance.

Static-Control

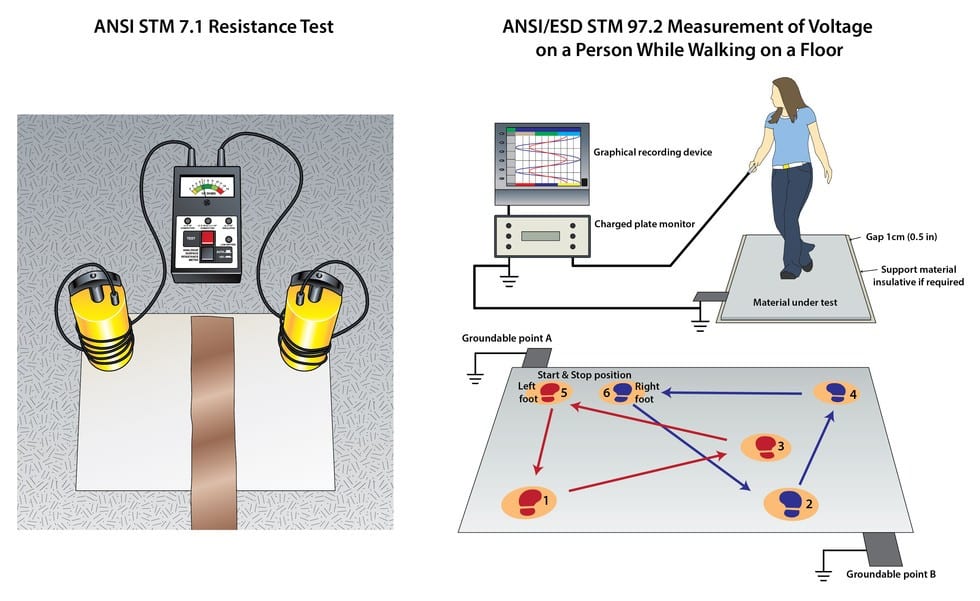

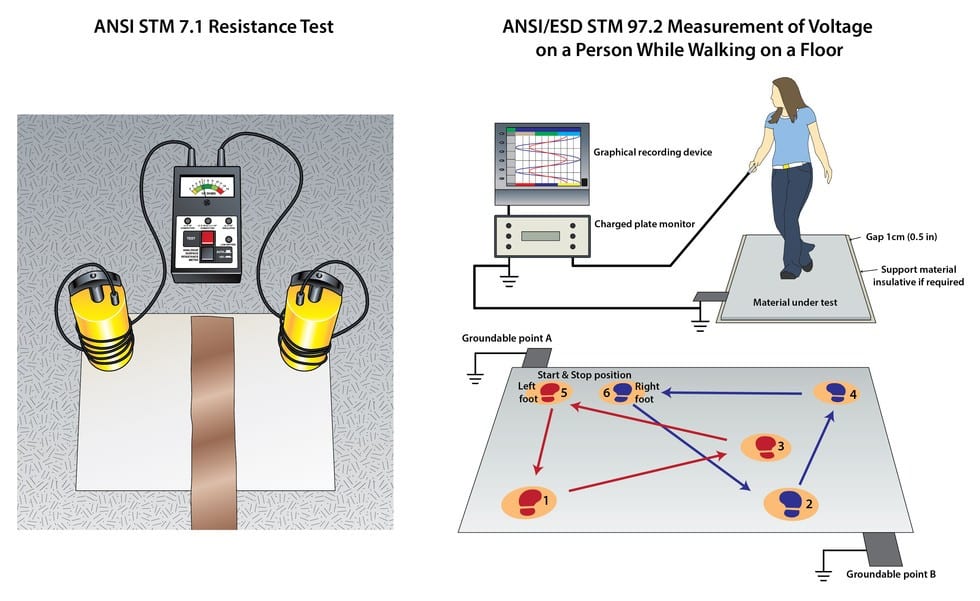

ANSI/ESD S20.20 requires a system resistance measurement below 1.0 X 10E9 ohms. System resistance is the aggregate resistance of the person, footwear, flooring, floor coatings like waxes and polish, and the connection to ground. As the primary ESD flooring surface, the ESD wax must measure well below one billion ohms (< 1.0 X 10E9) at all times. Manufacturers of ESD wax, however, guarantee a measurement of < 1.0 x 10E10 ohms only on newly applied waxes.

ANSI/ESD S20.20 also requires a walking body voltage, tested per STM 97.2, to measure under 100 volts—a standard static-dissipative VCT tile does not and cannot meet this criterion.

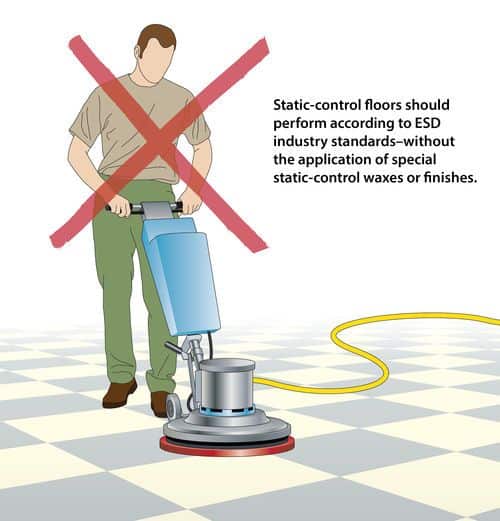

Permanent Static Control

Any ESD flooring material that gains electrical properties from antistatic sprays or special waxes does not provide permanent static protection. Once the coating wears off, the floor loses its static-protective properties, exposing electronics to the hazards of random static discharge. There is no visible indication that the wax or polish is no longer performing. Unless the maintenance crew or someone in the facility is committed to testing the floor on a regular basis, there’s no way to know when the floor has stopped functioning. For peace of mind, it’s best to avoid these materials.

This article, published by In Compliance Magazine, details the key 2014 revisions in ANSI/ESD S20.20.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

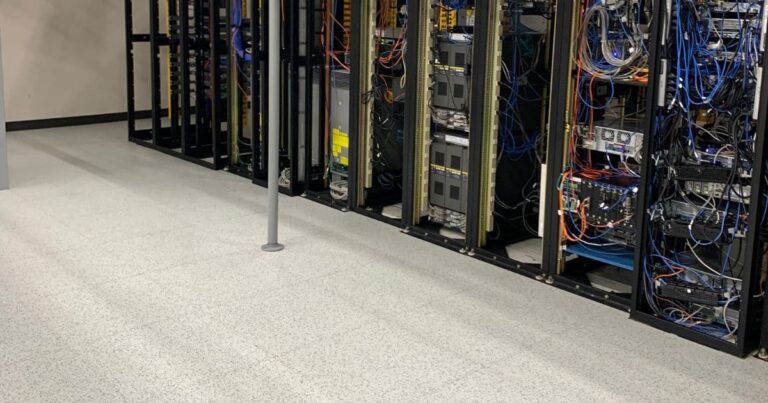

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.