Learn the differences between ESD solid vinyl tile and interlocking ESD tile. The post compares specs, installation, maintenance and intangibles.

Is Bare Concrete Static-Safe?

10 min read

Whether or not bare concrete prevents static is a common question—and one any facility manager with a concrete floor should ask. If bare concrete grounded and inhibited static reliably, with measurable results, it would certainly be an inexpensive ESD flooring option.

First, let’s be clear about the material: by bare concrete, we mean breathable—in other words, concrete that has not been sealed. Sealers are typically made with an acrylic, polyurethane, or regular (non-ESD) epoxy base—all insulative, static-generating materials.

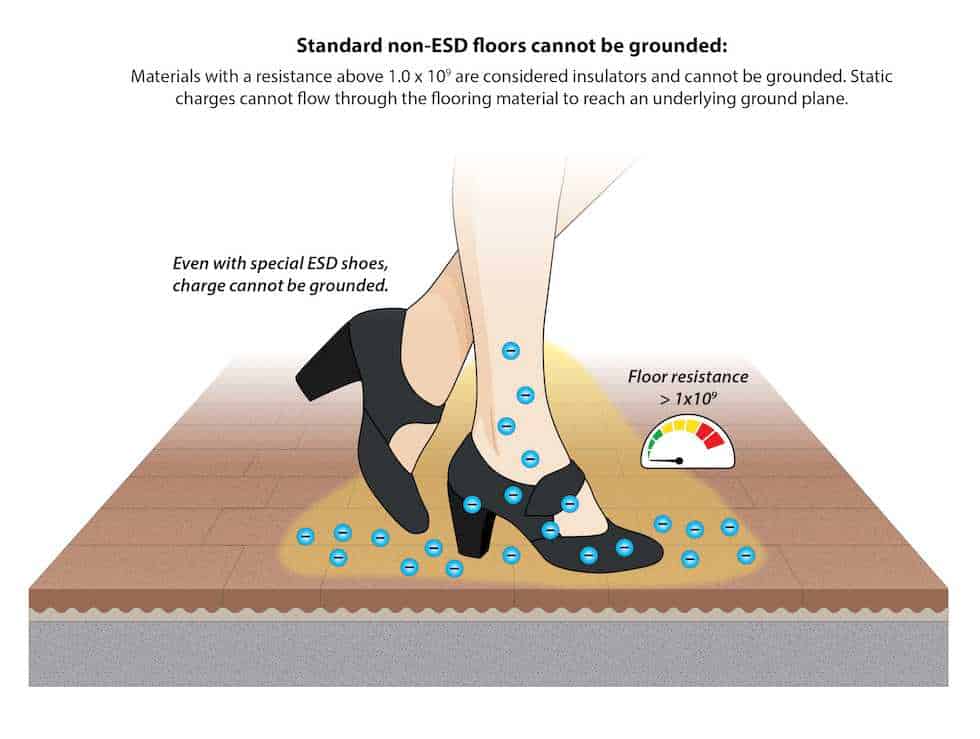

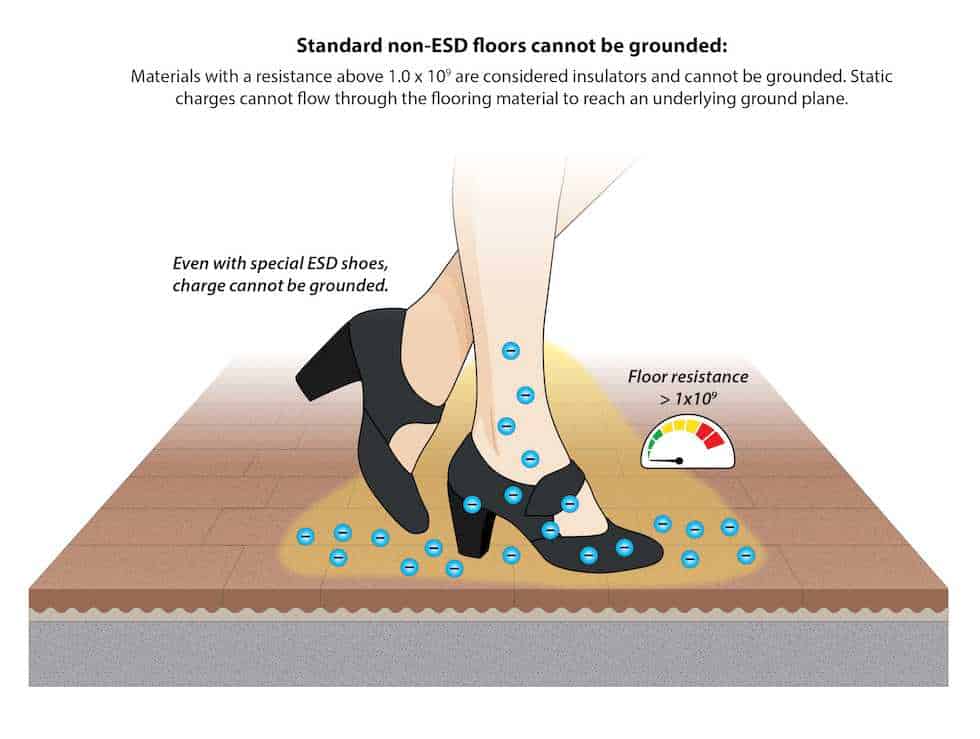

Once the concrete is sealed, it too becomes an insulator. Glass, plastics, dry air, and wood are all examples of insulators. Insulators block the flow of electrical current. Because electricity can’t move through them, insulators—like sealed concrete—cannot be grounded.

Environmental Considerations

A bare concrete floor below grade can create an unsuitably damp environment. Above grade, a bare concrete floor will generate particles, likely contributing to constant contamination and poor air quality. That’s why concrete is almost always sealed.

Technical Terms

What is an anti-static or static-free material?

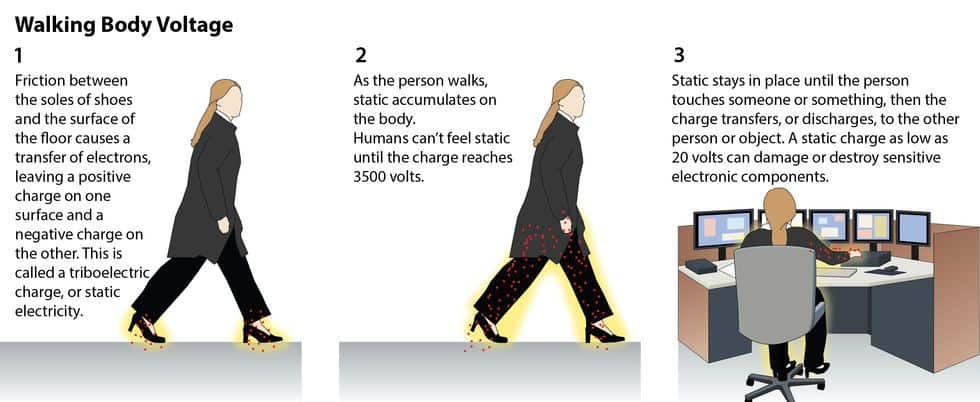

The terms “static-free” and “anti-static” simply mean the material in question will not contribute to triboelectrification. Triboelectrification, or tribocharging—is the result of frictional contact between two materials with different electrical potentials.

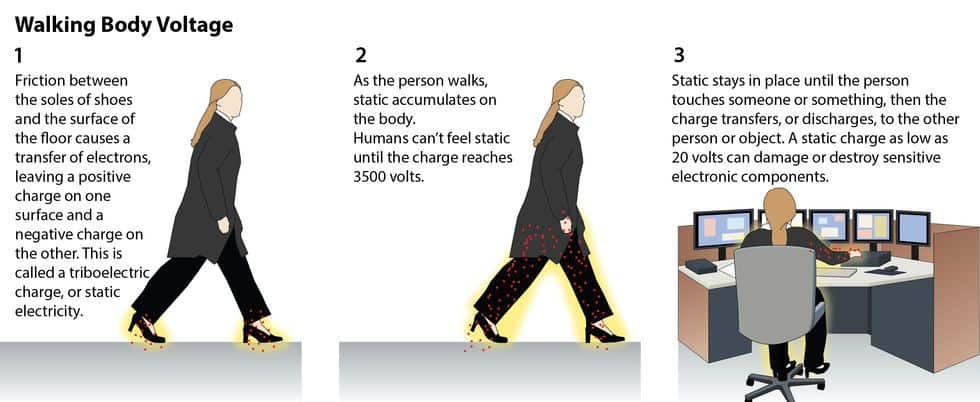

When people walk—or chairs or carts roll—across a floor, the frictional force between the two materials (the shoe soles or casters rubbing against the floor) strips electrons from one material and transfers them to the other. The material that gave up electrons is left with an overabundance of protons, or a positive charge. The material that accepted electrons is left with too few protons, or a negative charge. This electrical charge stays in place—in other words, static—and continues to accumulate as the person/object moves across the floor.

The static that accumulates on the body as people walk is called “walking body voltage.”

The electrification that results from frictional contact is called charge generation.

Walking Body Voltage = the static charge that accumulates on the body when people walk.

Charge generation = the static charge that results from frictional contact.

Like all electrical current, static seeks its quickest path to ground. When the charged person or material comes into contact—or within close enough range to another person or object—the static charge jumps, like a tiny lightning bolt, to the other person or object.

This phenomenon is called electrostatic discharge. The rush of electrical current from an electrostatic discharge—or an ESD event—can damage or destroy the internal circuitry of sensitive electronic components. In electronics manufacturing or handling environments, random ESD events can disrupt production or cause latent product failure. ESD can ignite flammable chemicals. In mission-critical spaces, like data server rooms, mission-critical call centers, 9-1-1 dispatch operations, flight control towers, and other similar spaces, ESD can cause equipment to malfunction, disrupt data, and damage or destroy components.

Electrostatic discharge (ESD) = the static charge that jumps from a charged person or object to another person/object, potentially causing equipment damage and malfunction.

Does an antistatic or low charge-generating floor ground static charges?

Often when people walk on bare concrete, assuming relative humidity is high or there’s sufficient moisture in the concrete, the floor will not generate static on the soles of their shoes. We call floors that generate little or no static “antistatic” or “low charge-generating.”

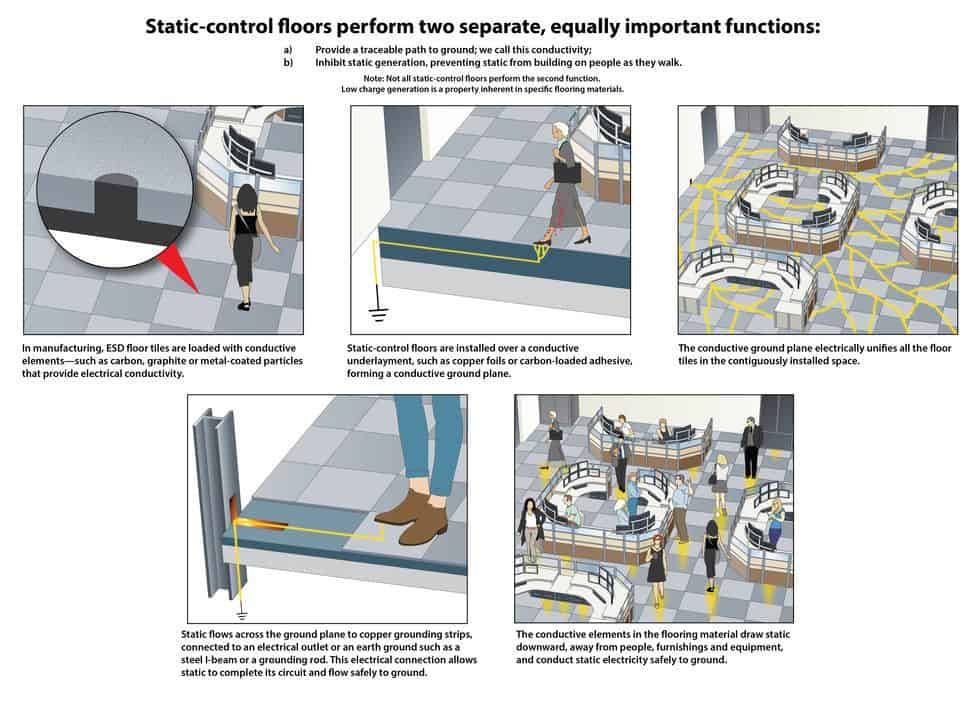

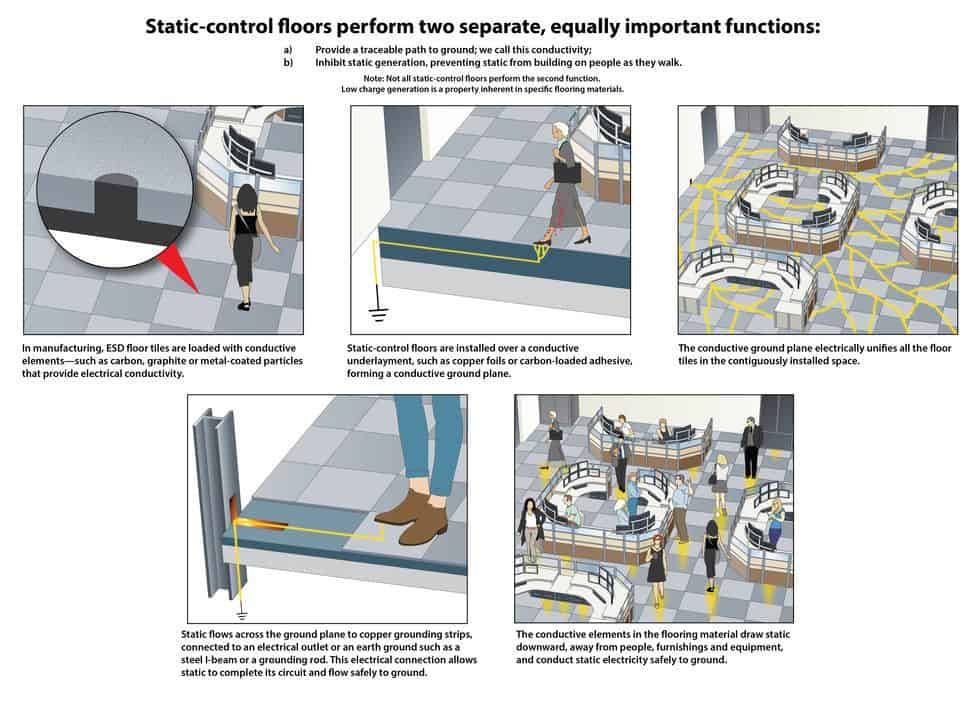

The conductivity or grounding potential of a floor should not be inferred from the term low charge-generating. Charge generation and conductivity are two distinct properties. A floor can be low charge-generating without grounding static charges, and vice versa. A grounded floor can generate enough static electricity to cause a damaging ESD event.

Conductivity and grounding should not be inferred from the term low charge-generating.

Only conductive and static-dissipative materials—in other words, materials that transport electrical current—can be grounded. The fact that concrete exhibits antistatic tendencies does not mean it will dissipate static properly or predictably. The ability to discharge—or dissipate—static charges to ground has to do with the conductive properties of a material.

While bare concrete often exhibits some static-dissipative or conductive tendencies, these electrical properties are not inherent or consistent in concrete, as they are in an ESD floor.

In ESD flooring, conductive elements, like carbon fibers, particles, or filaments, are embedded in the base material in the manufacturing process. The conductive elements are distributed throughout the material, creating a conductive surface. The conductive elements at the surface pull static charges through the thickness of the material to ground.

Conductivity and Environmental Variables

The same is true of concrete. Concrete draws its conductivity from moisture in the environment. Water, including underground vapor, is electrically conductive: i.e., water promotes, rather than resists, the flow of electricity. We measured the conductivity of a concrete floor on a humid summer day and found it to be overly conductive—only to see that same concrete floor measure almost insulative in drier weather later that same year.

Environmentally-dependent, the conductivity of bare concrete relies on numerous variables, including moisture permeation, geological conditions, subterranean activity, aquifers, weather, and ambient humidity (RH). Due to environmental instability, bare concrete will not, and cannot, meet industry standards with any degree of reliability.

Concrete and Electrical Resistance

We evaluate the conductivity of a flooring material by measuring its opposite: electrical resistance. By evaluating the rate at which current passes across the surface of a floor tile, resistance tests—measured in ohms—predict how effectively the floor will resist—or conduct—the flow of electricity to ground.

According to Ohm’s Law, as resistance increases, charge dissipation decreases.

ANSI/ESD S20.20 recommends resistance readings below 1,000,000,000 (1 x 10E9) ohms, using test method STM7.1. As mentioned above, the conductivity in bare concrete comes from moisture in the soil below the slab. As concrete dries (for whatever reason), its electrical resistance increases, making the floor less conductive. That’s why a floor with decent conductivity in humid conditions can be insulative in a drier environment.

The same is true in reverse. As concrete absorbs vapor from the soil, its resistance decreases, potentially turning the concrete floor into a dangerously conductive plane.

If any areas of your factory are used for “hi pot” testing, you should procure and install electrically insulative rubber mats to cover the concrete and protect your personnel from electrical shock hazards.

Advisory

Since the resistance of a bare concrete floor is cyclical, we strongly suggest testing its resistance with an ohmmeter on a regular basis. We also recommend performing ANSI/ESD S97.2 body voltage tests to determine if the concrete floor will maintain walking voltages below 100 volts, as required by ANSI/ESD S20.20.

The electrical resistance of bare concrete can vary by up to 2 orders of magnitude in either direction. Broad performance differentials caused by unpredictable site conditions would be a hard sell to a knowledgeable customer or any auditor as part of an ISO certification.

If you choose to use concrete as your static-protective floor, you should set an absolute minimal flooring resistance—100,000 (10E5) ohms for a factory environment. For end-user spaces, such as mission-critical call centers, server rooms, or 9-1-1 dispatch operations, housing operational equipment, resistance should be no lower than 1,000,000 (10E6) ohms.*

Since the resistance of a bare concrete floor is cyclical, we strongly suggest testing its resistance with an ohmmeter on a regular basis. We also recommend performing ANSI/ESD S97.2 body voltage tests to determine if the concrete floor will maintain walking voltages below 100 volts, as required by ANSI/ESD S20.20.

The electrical resistance of bare concrete can vary by up to 2 orders of magnitude in either direction. Broad performance differentials caused by unpredictable site conditions would be a hard sell to a knowledgeable customer or any auditor as part of an ISO certification.

- While these are StaticWorx recommendations, requirements for the communications and telecom industry and flight control towers are set by independent industry standards: Motorola R56, FAA 019f, and others. For safety reasons, these standards all recommend resistance ≥ 1 x 10E6 in areas where energized equipment is used.

About StaticWorx, Inc

All StaticWorx posts are written by our technical team and based on industry standards and specifications, test data, independent lab reports and other verifiable data. We provide ESD training and offer CEU credits to architects. If you’re interested in an ESD training session or our architects’ ESD workshop, give us a call: 617-923-2000.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

More Blog Posts

To maintain performance, ESD floors require specially formulated products. We offer tips on what to consider when choosing cleaning supplies.

Static-dissipative floors transport harmful static charges to ground. Dissipative is also a term for flooring with a specific, measurable electrical resistance.

StaticWorx recognized as one of the fastest growing private companies in the U.S. 2023 marks StaticWorx fourth appearance on Inc. 5000 list.

Conductive and dissipative flooring protect electronics by transporting charges to ground, conductive at a quicker rate, dissipative slower & more controlled.

We explain the 3 main ways to test an ESD floor: Electrical resistance; body voltage & ESD audits, with advantages and reasons for each.

Three critical factors—application, industry standards & footwear—help you choose the best ESD floor, while ensuring the safety & efficiency of your operations.

StaticWorx Founder and President Dave Long shares three of his recommended reads: Quit, How to Change, and The Goal.

There are leadership qualities StaticWorx strives to embody every day, with every product, throughout each project.

No matter how you slice and dice a project, an ESD floor is a major investment. This blog post examines five ways to keep undue costs down.

What’s the difference between static control and static resistant? Or anti-static flooring? Find out more in our blog post.

A major part of any ESD control program is getting proper flooring in place. How can one replace a floor without generating any debris? Learn more.

A well-designed, comprehensive, fully realized program is a must for manufacturers serious about ESD control. Learn why ESD programs fail.

ESD Floors should never be specified based on the descriptive terms conductive or static dissipative. Always base ESD specs on verifiable metrics. Find out why.

<a class="eael-grid-post-link" href="https://staticworx.com/case-studies/esd-flooring-failure-incorrect-testing/" title="Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods">Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods

To comply with relevant ESD standards, test electrical properties using methods outlined in ESD S20.20. For best results require testing by an independent lab.

<a class="eael-grid-post-link" href="https://staticworx.com/installing/esd-flooring-installation-bond-test-manufacturer-oversight-critical/" title="Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success">Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success

If the vapor barrier fails to adhere to the subfloor, tiles will lift. Bond test and manufacturer oversight are crucial to ESD floor installation success.

<a class="eael-grid-post-link" href="https://staticworx.com/technical-info/conductive-static-dissipative-flooring-difference/" title="Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer">Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer

What’s the difference between conductive and static-dissipative flooring? Facts, analogies and images illustrate the difference in easily understood terms.

Qualifying an ESD floor helps ensure you get the floor you paid for. Find out why you should always qualify according to ESD S20.20

Qualification is the first step in selecting an ESD floor. Learn how to perform resistance tests to be sure the floor meets electrical & safety standards.

A look at how the StaticWorx cartoon, 'Conductive Flooring Does Not Mean Antistatic Flooring,' was conceived and created.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.