Learn the differences between ESD solid vinyl tile and interlocking ESD tile. The post compares specs, installation, maintenance and intangibles.

5 Ways to Save $ on an ESD Floor - Without Settling For a Floor That’s Ugly or Doesn’t Perform

10 min read, 4 min videos

No matter how you slice and dice a project, an ESD floor is a major investment. For most specifiers, buying smart while saving money is a critical strategy, mandated from above. The sixty-million-dollar question is always, how do you invest judiciously – i.e., use money wisely without ending up with a product that forever looks like a compromise or provides borderline performance?

In other words, how do you value engineer an ESD floor, without ending up with a dud?

The simple answer is twofold: buy a quality floor and beware of hidden costs baked into the project. Unlike some low-budget materials that look ugly and/or provide temporary protection that wears off over time, a quality ESD floor will look great, last years, and consistently perform within specifications. Investing in a quality floor may not save money upfront, but will save over the life of the floor with less frequent replacement, lower maintenance cost, and reliable ESD protection.

Another way to buy smart is to consider and budget for hidden costs, in subfloor prep, installation, and material choices – as well as for expenses associated with evacuation and lost or delayed production. These costs, more than most, can knock a real hole in your bottom line.

Here are five ways to get the ESD floor you want while keeping undue costs under wrap:

ESD Floors to fit every budget. Call now!

1. Choose a flooring product that you can install directly over your old floor.

The labor involved in tearing up and disposing of an old floor can add significantly to the cost of a new floor. Not to mention the costs if you discover that the old floor contains regulated substances such as asbestos, requiring hazmat disposal. Choosing a material that can be installed directly over an old floor can eliminate demolition and potentially reduce the 5 to 8 dollars per square foot that demolition adds to the cost of a project.

While thin-mil and soft-surface materials certainly have their place in the flooring world, these materials telegraph even subtle imperfections. Glue-down floors require subfloors that are smooth, flat, clean and dry. To cover a damaged or imperfect floor – cracked tiles, ragged surfaces, spalled concrete, etc. – choose a floor like GroundLock Extreme with enough thickness and rigidity that the old floor essentially disappears. Depending upon the condition of the old floor, ESD carpet tile may also be a good choice.

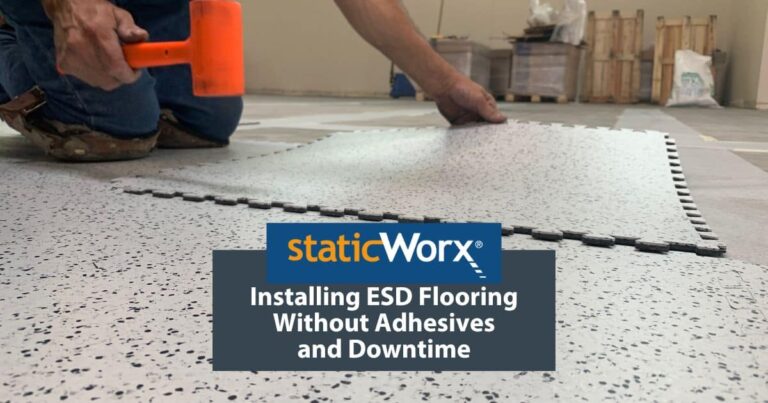

If you’re a commercial tenant investing in leased property, glue-free carpet tile and GroundLock interlocking tile can often be installed directly over the old floor and taken with you when you leave. Both floors will stay put as long as you need them to. If you change locations, they can be picked up and reinstalled in a new space. That’s a saving!

The labor involved in tearing up and disposing of an old floor can add significantly to the cost of a new floor. Not to mention the costs if you discover that the old floor contains regulated substances such as asbestos, requiring hazmat disposal. Choosing a material that can be installed directly over an old floor can eliminate demolition and potentially reduce the 5 to 8 dollars per square foot that demolition adds to the cost of a project.

While thin-mil and soft-surface materials certainly have their place in the flooring world, these materials telegraph even subtle imperfections. Glue-down floors require subfloors that are smooth, flat, clean and dry. To cover a damaged or imperfect floor – cracked tiles, ragged surfaces, spalled concrete, etc. – choose a floor like GroundLock Extreme with enough thickness and rigidity that the old floor essentially disappears. Depending upon the condition of the old floor, ESD carpet tile may also be a good choice.

If you’re a commercial tenant investing in leased property, glue-free carpet tile and GroundLock interlocking tile can often be installed directly over the old floor and taken with you when you leave. Both floors will stay put as long as you need them to. If you change locations, they can be picked up and reinstalled in a new space. That’s a saving!

2. Choose a floor that is impervious to moisture.

Moisture in the subfloor, with proper mitigation costing $2.50 to $7.50 per square foot, can add thousands or more to the cost of a new floor installation. Even facilities in arid desert areas like California or at high elevation in places like Colorado can be affected by subterranean vapor emissions that, without proper moisture mitigation, can turn adhesives into a sticky, oozing mess. A simple ASTM 2170 moisture test will determine if vapor will be a problem and should always be performed before installing a new floor.

Materials like GroundLock Extreme and Eclipse Glue-free (GF) rubber are impervious to moisture. This means either floor can be installed directly over a subfloor with moisture problems with no negative effect to the flooring material. While both materials are more expensive than some other products, the time and expense spared by not having to install a moisture barrier can save a bundle and you end up with a premium product.

Moisture in the subfloor, with proper mitigation costing $2.50 to $7.50 per square foot, can add thousands or more to the cost of a new floor installation. Even facilities in arid desert areas like California or at high elevation in places like Colorado can be affected by subterranean vapor emissions that, without proper moisture mitigation, can turn adhesives into a sticky, oozing mess. A simple ASTM 2170 moisture test will determine if vapor will be a problem and should always be performed before installing a new floor.

Materials like GroundLock Extreme and Eclipse Glue-free (GF) rubber are impervious to moisture. This means either floor can be installed directly over a subfloor with moisture problems with no negative effect to the flooring material. While both materials are more expensive than some other products, the time and expense spared by not having to install a moisture barrier can save a bundle and you end up with a premium product.

3. Choose a floor that can be installed directly over an imperfect subfloor.

Cracked, crumbled or green concrete? Concrete contaminated with bond-breakers from tilt-up construction? Repair or replacement of a damaged or imperfect subfloor can set a project back weeks if not months. When calculating the cost of a new floor it’s easy to overlook the time and expense of subfloor repair and wind up behind schedule and over budget.

Not all flooring materials can be installed over an imperfect subfloor. As you would with installations over an old floor, look for new flooring materials like GroundLock Extreme with enough thickness and rigidity to lay flat and camouflage any imperfections beneath the surface. The trick is to select flooring materials that are both dimensionally stable and more than 5 millimeters thick.

4. For operational spaces, choose a floor that can be installed 24/7.

One of the highest costs of installing a new floor in an existing space is evacuation and lost production time. While stakeholders may recognize these costs, they are often – incorrectly – considered a fixed reality no matter what floor is used. Because these costs are rarely included in the planning or bidding processes they are omitted from the true cost of the project. Yet moving in and out of a space and lost production are crucial to a company’s bottom line. In fact, in 24/7 call centers moving and temporary relocation often exceeds the entire cost of a new floor. What if you didn’t need to move at all?

Materials like ShadowFX ESD carpet tile can be installed as a floating floor using TacTiles, requiring no adhesive, which means no odor and no drying time. GroundLock Exteme interlocking tile is also adhesive-free and is so quick and easy to install that many facilities choose DIY installation; like ESD carpet tile, GroundLock can be installed over almost any subfloor. Eclipse glue-free (GF) conductive rubber is self-adhering and impervious to moisture. All three products – ShadowFX carpet tile, GroundLock Extreme interlocking tile, and StaticWorx Eclipse GF rubber – can be installed 24/7 with no disruption and no downtime.

5. Choose carpet tile that doesn’t show wear patterns.

Because some carpet can wear poorly in walkways, call centers with moveable chairs, and production areas, people sometimes hesitate to use carpet, particularly in these high-traffic spaces. In addition to wear and tear, repair tiles can be hard to match with originals, requiring the facility to maintain significant amounts of attic stock to be used in case of repair. Some low-budget carpet starts to look worn after a year and begs for replacement by three to five. This adds significantly to the cost of a product with a moderate initial price point.

Carpet tile styles installed in random, non-directional patterns create a monolithic floor that is quick and easy to install, allowing for lower installation costs, and hides wear and tear, extending the life of the carpet. While the upfront cost of a quality product like ShadowFX ESD carpet tile may be a little higher than some less expensive carpet tiles, its longer life cycle translates to lower costs in the long-term. Mergeable dye lots mean individual tiles can be replaced without worrying about matching older lots. Should a tile be damaged, it’s easy to lift and replace individual tiles without tearing up the entire floor. With GroundBridge conductive underlayment and TacTiles joining the tile edges, you get an adhesive-free installation 24/7 with no downtime and without vacating the space.

With random non-directional installation and mergeable dye lots, the floor is quick and easy to install, lowering the cost of initial installation, and individual tiles are easy to lift and replace without looking like a repair was ever made in the first place.

Because some carpet can wear poorly in walkways, call centers with moveable chairs, and production areas, people sometimes hesitate to use carpet, particularly in these high-traffic spaces. In addition to wear and tear, repair tiles can be hard to match with originals, requiring the facility to maintain significant amounts of attic stock to be used in case of repair. Some low-budget carpet starts to look worn after a year and begs for replacement by three to five. This adds significantly to the cost of a product with a moderate initial price point.

Carpet tile styles installed in random, non-directional patterns create a monolithic floor that is quick and easy to install, allowing for lower installation costs, and hides wear and tear, extending the life of the carpet. While the upfront cost of a quality product like ShadowFX ESD carpet tile may be a little higher than some less expensive carpet tiles, its longer life cycle translates to lower costs in the long-term. Mergeable dye lots mean individual tiles can be replaced without worrying about matching older lots. Should a tile be damaged, it’s easy to lift and replace individual tiles without tearing up the entire floor. With GroundBridge conductive underlayment and TacTiles joining the tile edges, you get an adhesive-free installation 24/7 with no downtime and without vacating the space.

With random non-directional installation and mergeable dye lots, the floor is quick and easy to install, lowering the cost of initial installation, and individual tiles are easy to lift and replace without looking like a repair was ever made in the first place.

For most of us, saving money is always a priority. We can cut costs with a sledgehammer, saving in the short-term only to experience problems downstream. Or do it smartly, evaluating all expenses – above and beyond initial material costs – and reap the rewards of value over time.

About StaticWorx, Inc

All StaticWorx posts are written by our technical team and based on industry standards and specifications, test data, independent lab reports and other verifiable data. We provide ESD training and offer CEU credits to architects. If you’re interested in an ESD training session or architects’ ESD workshop, give us a call: 617-923-2000.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

More Blog Posts

To maintain performance, ESD floors require specially formulated products. We offer tips on what to consider when choosing cleaning supplies.

Static-dissipative floors transport harmful static charges to ground. Dissipative is also a term for flooring with a specific, measurable electrical resistance.

StaticWorx recognized as one of the fastest growing private companies in the U.S. 2023 marks StaticWorx fourth appearance on Inc. 5000 list.

Conductive and dissipative flooring protect electronics by transporting charges to ground, conductive at a quicker rate, dissipative slower & more controlled.

We explain the 3 main ways to test an ESD floor: Electrical resistance; body voltage & ESD audits, with advantages and reasons for each.

Three critical factors—application, industry standards & footwear—help you choose the best ESD floor, while ensuring the safety & efficiency of your operations.

StaticWorx Founder and President Dave Long shares three of his recommended reads: Quit, How to Change, and The Goal.

There are leadership qualities StaticWorx strives to embody every day, with every product, throughout each project.

What’s the difference between static control and static resistant? Or anti-static flooring? Find out more in our blog post.

A major part of any ESD control program is getting proper flooring in place. How can one replace a floor without generating any debris? Learn more.

A well-designed, comprehensive, fully realized program is a must for manufacturers serious about ESD control. Learn why ESD programs fail.

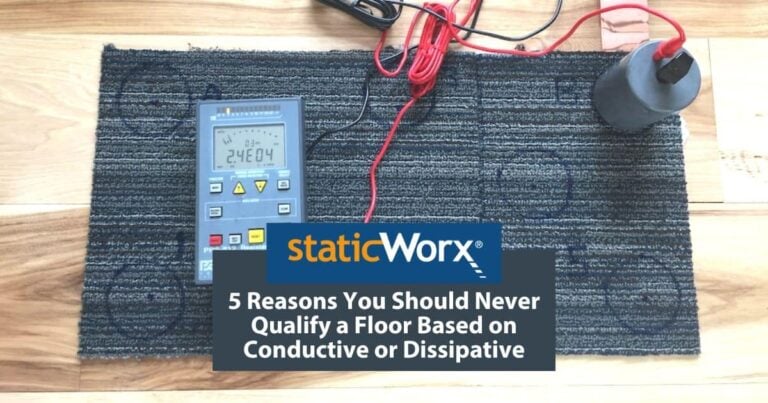

ESD Floors should never be specified based on the descriptive terms conductive or static dissipative. Always base ESD specs on verifiable metrics. Find out why.

<a class="eael-grid-post-link" href="https://staticworx.com/case-studies/esd-flooring-failure-incorrect-testing/" title="Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods">Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods

To comply with relevant ESD standards, test electrical properties using methods outlined in ESD S20.20. For best results require testing by an independent lab.

<a class="eael-grid-post-link" href="https://staticworx.com/installing/esd-flooring-installation-bond-test-manufacturer-oversight-critical/" title="Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success">Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success

If the vapor barrier fails to adhere to the subfloor, tiles will lift. Bond test and manufacturer oversight are crucial to ESD floor installation success.

<a class="eael-grid-post-link" href="https://staticworx.com/technical-info/conductive-static-dissipative-flooring-difference/" title="Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer">Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer

What’s the difference between conductive and static-dissipative flooring? Facts, analogies and images illustrate the difference in easily understood terms.

Qualifying an ESD floor helps ensure you get the floor you paid for. Find out why you should always qualify according to ESD S20.20

Qualification is the first step in selecting an ESD floor. Learn how to perform resistance tests to be sure the floor meets electrical & safety standards.

Will bare concrete control static? Learn why concrete floors are unreliable & what precautions to take if you must work on a bare concrete floor.

A look at how the StaticWorx cartoon, 'Conductive Flooring Does Not Mean Antistatic Flooring,' was conceived and created.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.