Learn the differences between ESD solid vinyl tile and interlocking ESD tile. The post compares specs, installation, maintenance and intangibles.

5 Reasons You Should Never Qualify a Floor Based on Conductive or Dissipative

11 min read

Conductive and Static-dissipative are descriptive terms. These terms describe electrical resistance categories with wide variation, and NO industry flooring standards are based solely on these descriptions.

End-user applications like PSAPs, critical call centers, and FAA flight towers require the use of floors measuring above 10E6 (1.0 x 106), which fall into the dissipative range. But the standard is based on the metric, NOT solely on the static-dissipative descriptor.

The Gist: Never Qualify an ESD Floor Based on Conductive or Dissipative

- Flooring standards and specifications should be based on precise metrics. That is, ESD floors should be specified based on science - not categories.

- There is no universally applicable ESD flooring standard. The right floor is based on industry specific requirements.

- Specifications should follow industry guidelines, understanding that ESD flooring standards differ across industries.

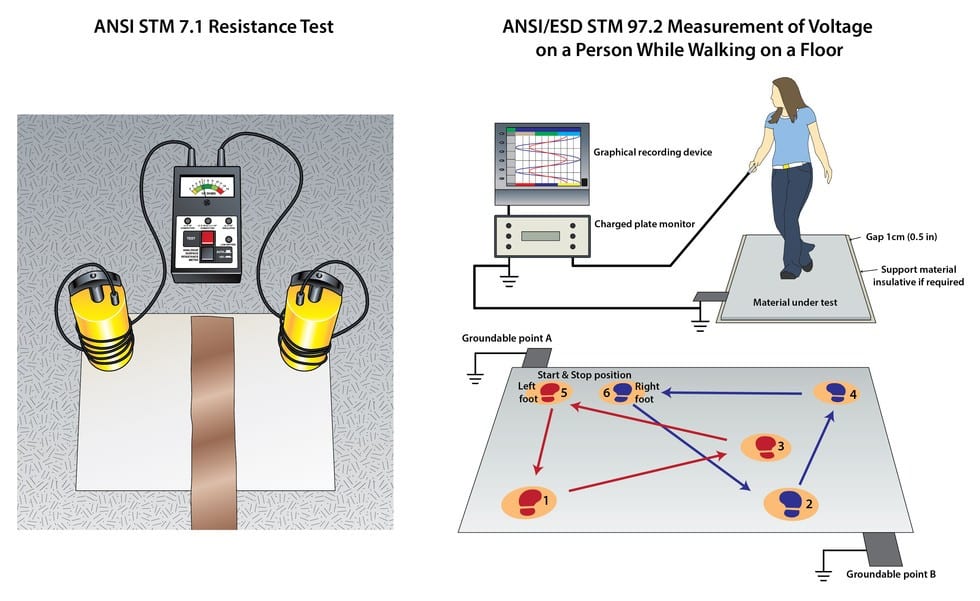

- And all floors under consideration should be tested for resistance and charge generation, following the guidelines in ANSI/ESD S7.1 and S97.2.

“Specifying a floor that’s conductive or dissipative – without specifying metrics – is a mistake. Overly conductive floors could cause a potential safety risk, while some dissipative floors could transport charges too slowly to prevent static build up. Optimal resistance falls within a range, encompassing both conductive and dissipative, and eliminates floors with measurements that compromise safety or performance.”

Electronics manufacturing and handling applications, following ESD S20.20:

Electrical resistance must measure ≤ 1.0 x 10E9

Static generation must be < 100 V or < 20V for Class-0.

End-user spaces, following Motorola R56 and ATIS-0600321 for telecommunications and PSAPs, and FAA 019f for flight towers and spaces using flight tower equipment:

Electrical resistance must measure > 1.0 x 10E6

Static generation must be < 500 V

Takeaway: It’s crucial to know the metrics and specific standards for your industry – and test all ESD floors under evaluation – before you make your flooring selection.

The number 1 question we hear: Should I specify a conductive or static-dissipative floor?

We’d love to give you an easy answer, requiring minimal thought on your part. The fact is, ESD flooring specifications should not be based on descriptors – in other words, you should never base your specs solely on whether the floor is conductive or dissipative.

To repurpose a Nike tagline, “Just don’t do it.”

Where the terms originated

The terms conductive and static dissipative were hijacked from standards related to material handling trays, tabletops and other static-control packaging materials (e.g. bags). Their use with regards to ESD flooring is arbitrary and problematic.

The problem is, to meet the electronics industry standard ANSI/ESD S20.20* the floor has only to measure below 1.0 x 10E9. This means, conductive and static-dissipative flooring meet the standard for electronics manufacturing and handling applications.

- Please note: While S20.20 is a widely known and referred-to standard, the resistance and safety standards for environments such as telecom spaces, PSAPs, flight towers and other end-user spaces are different. 20.20 has no jurisdiction in these spaces.

Because S20.20 allows conductive AND dissipative floors, describing a floor based on those terms creates an unnecessary level of complexity for people writing specifications

The Metrics

Here’s how the terms are applied to flooring materials:

Floors measuring < 1.0 x 10E6 ohms are considered conductive.

Floors measuring ≥ 1.0 x 10E6 and ≤ 10E9 ohms are considered dissipative.

While these terms describe numerical ranges, the ranges are extremely wide – and the terms are not metrics. Conductive and static dissipative are descriptors. Metrics – what you actually need to know to specify a floor – are measured numbers and – because standards are not uniform, – whether the numbers meet standards for your application.

Floors should never be specified based solely on whether they’re conductive or dissipative. Flooring specifications should always be evidence-based, using measured and repeatable performance metrics.

Again, floors should never be specified based on conductive or dissipative descriptors.

Here’s why:

1) Standards aside for a moment - due to differences in material characteristics and manufacturing processes, neither conductive nor dissipative flooring materials are universally preferred.

Sometimes, a conductive material is better.

Conductive vinyl, for instance, has more conductive veins on its surface than dissipative vinyl and the veins are spaced closer together.

The base material in all ESD vinyl floors is a static generator. If someone walked on a static dissipative vinyl floor wearing heel straps – due to the small contact area between the heel strap and floor – chances are good that the unprotected part of the shoe sole would rub against the non-conductive portion of the floor, generating static.

With more conductive veins in conductive vinyl, there is a better chance of the heel strap making an electrical connection with the veins in the floor.

With other materials, static dissipative may be better.

Carpet is the opposite: for end-user facilities – like PSAPs, critical call centers, and FAA flight towers* – carpet (typically used in these facilities) must measure in the static-dissipative range. in fact, to address electrical safety considerations, standards for these applications prohibit conductive flooring materials.

- Conductive carpet is fine for electronics applications where everyone is required to use ESD footwear with built-in resistors and mandates are enforced.

Takeaway: there’s no universally applicable rule saying a conductive or static dissipative material is better. Specifying a floor based solely on these descriptors would be a mistake that could result in poor performance – including, though not limited to, insufficient static protection or violation of safety requirements.

2) Conductivity – a floor’s ability to dissipate static charges - can change.

The resistivity of flooring materials is inherent (cannot change). Electrical resistance, however – in other words, how quickly or slowly the floor transports electrical charges – can fluctuate, due to manufacturing, maintenance, and environmental factors.

For instance, floors that gain conductivity from chemical additives introduced in the manufacturing process can become less conductive as liquid additives rise to the surface and leach into the air. Similarly, floors – such as some vinyl materials – that gain conductivity from waxes or finishes lose conductivity as the finish wears off.

Fluctuations in relative humidity (moist or dry air), which add or take moisture away from the material can also change the electrical resistance of a floor. Dirt and debris, by preventing contact between the floor and shoe sole or conductive footwear, can also change electrical performance.

In all of these scenarios above, without regular resistance testing there’s no way to know when measurements have changed or if the floor is still performing properly.

You may start with a floor that’s conductive or dissipative only to discover that the electrical resistance changed after it’s in use or installed in the environment.

Basing specifications on metrics—testing the resistance of the material in the qualification (pre purchase) phase, in a controlled chamber at the required 15% RH, then testing post-installation in the environment – will ensure that the floor meets required metrics and rule out potential fluctuations based on environmental conditions.

Takeaway: Electrical resistance can change over time due to manufacturing, maintenance or post-manufacturing conditions or due to ambient humidity or dirt and debris in the environment. To be sure the resistance of your ESD floor measures in the acceptable range, it’s essential to test during the qualification phase as well as after it’s installed.

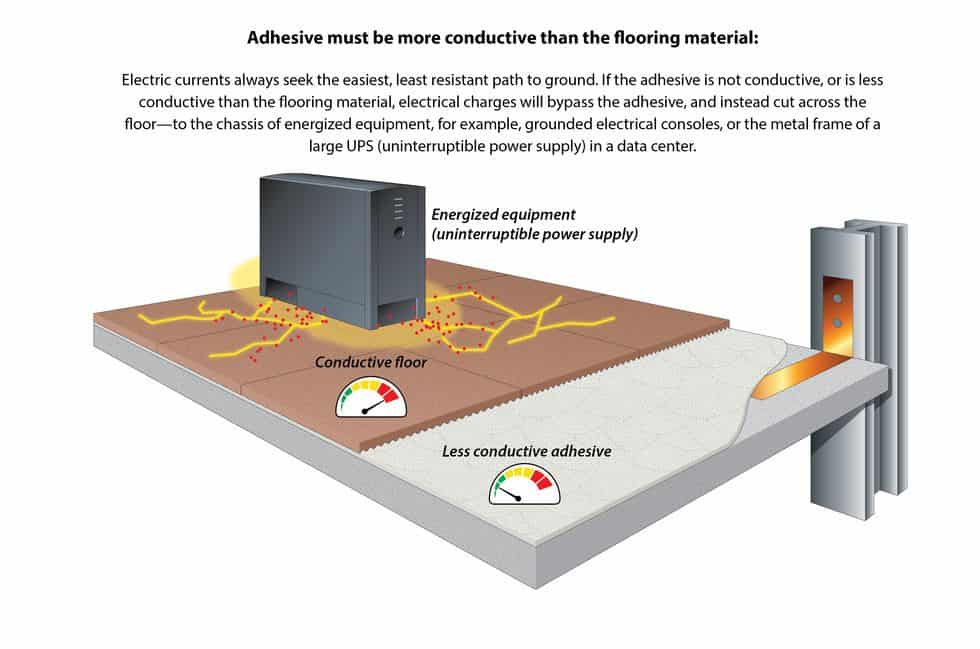

3) Using a less conductive adhesive can cause electrical resistance to appear higher.

Using an adhesive that’s less conductive than the surface of the flooring material will raise the RTG (resistance to ground) and system resistance* of the floor. That’s because system resistance measures the entire system – surface and other layers of the flooring material, footwear, and adhesive.

If a flooring material measures, say, 2.5 x 10E4 and the underlying adhesive measures 1.0 x 10E8, the system resistance would likely read in the static dissipative range (> 1.0 X 10E6). The resistance of the flooring surface, however, remains unchanged. Despite artificially higher readings, the floor itself – and its surface – is still highly conductive.

This is a problem – why?

Adhesive that’s less conductive than the flooring material acts as a resistive barrier. In the case above, the less conductive adhesive could mask a potentially unsafe condition. If flooring was installed in an empty room this would not be a problem. However, the moment the surface of overly conductive carpet tiles is populated with grounded equipment – such as consoles and server racks- the equipment-to-carpet contact will provide an alternate (less resistant) path to ground. This condition would render the entire floor non-compliant.

For this reason, organizations like the FAA require multiple types of resistance testing: surface resistivity, point to point resistance and resistance to ground measurements. This multi-faceted approach reveals any alternate low-resistance paths to ground that would otherwise create a non-compliant installation.*

- System resistance measures the electrical resistance of the flooring/footwear system – i.e., floor, adhesive and footwear.

- Surface resistivity measurements determine the resistive properties in a unit of measurement called ohms per square.

- Point to point measurements determine the properties of electrical paths between points within the same tile and between different tiles.

Takeaway: Always test the resistive properties of the flooring surface.

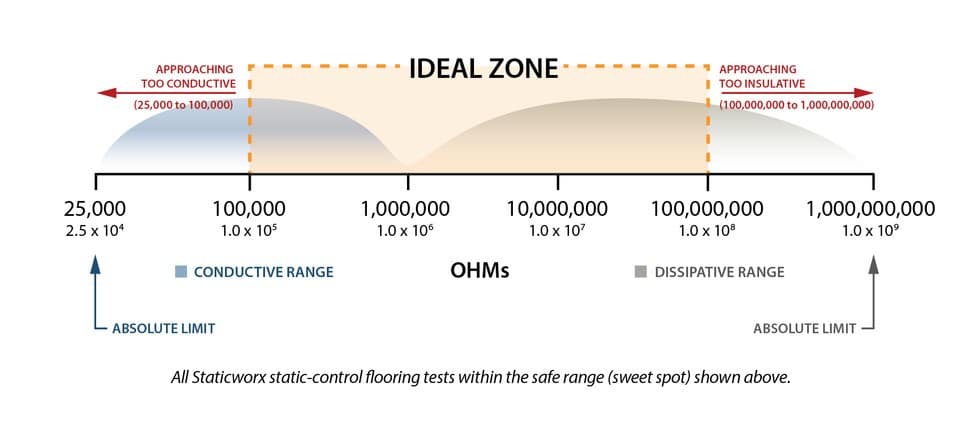

4) The “Sweet Spot”: Optimal electrical resistance falls within a range that encompasses both conductive and dissipative measurements.

Optimal Electrical Resistance is a range. At StaticWorx, we call that range “The Sweet Spot.”

Any floor measuring < 1.0 x 10E9 meets the S20.20 standard; this does not mean any floor measuring < 1.0 x 10E9 offers optimal static protection. In fact, floors with electrical resistance on either end of the acceptable spectrum can create problems.

If resistance is too low – < 1.0 x 10E5 – electricity could flow too quickly and, under certain circumstances, pose an electrical hazard. That’s why standards for telecom, safety dispatch operations, flight towers, and other end user spaces, where people could make contact with electrified equipment, require floors to measure at least 1.0 x 10E6. Industry standards for these spaces prohibit floors measuring below this threshold.*

- Standards Motorola R56 and ATIS 0600321 (for telecom spaces) and FAA 019f (FAA flight towers and spaces that use flight tower equipment).

- Some safety standards deal with this problem by deeming any floor in the conductive range as electrically unacceptable. Because of this sort of categorizing, we lump materials that measure in the < 10E5 in the same conductive category as materials measuring 9.9 X 10E5. Less than 10E5 is probably unnecessarily conductive and possibly unsafe for certain situations. But 9.9 x 10E5 is close to 10E6.

As noted above, fluctuations in RH, topical waxes, debris and other environmental conditions can raise (or lower) conductivity. If RH is low or dirt accumulates, a floor measuring > 1.0 x 10E8 could lose enough conductivity to render it ineffective.

For all of these reasons, we always recommend specifying within a resistance range that we call “The Sweet Spot” – i.e., between 1.0 x 10E5 and 1.0 x 10E8. This range is neither too low, nor too high. This Goldilocks-approved Sweet Spot is just right.

Takeaway: Specifying a floor that’s conductive or dissipative – without specifying metrics – is a mistake. Some conductive floors could cause a potential safety risk. And some dissipative floors could transport charges too slowly to prevent static build up. Optimal resistance falls within a range that encompasses both the upper conductive range and the mid dissipative range, and eliminates floors with measurements that compromise safety or performance.

5) Conductivity is only one part of the ESD flooring equation.

To prevent random static discharge and protect electronic components from harm due to ESD events, the ESD floor must also reduce/inhibit charge generation.

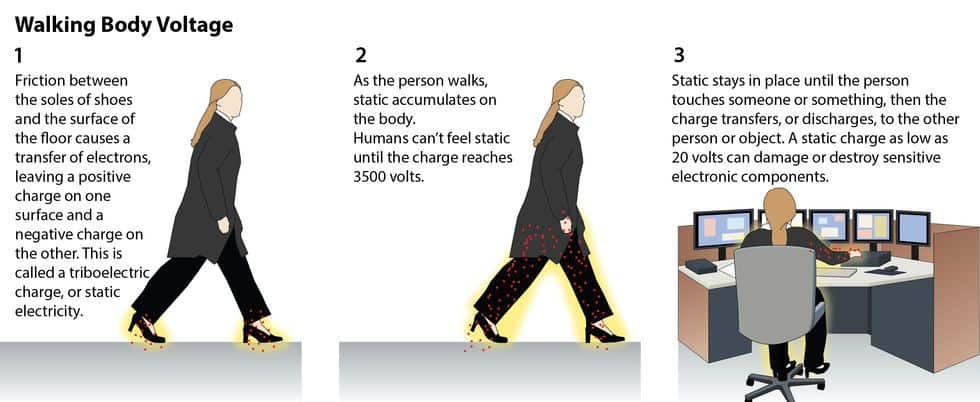

When people walk on a floor, the contact and separation – or friction – between the soles of their shoes and the floor generates static charges. As they walk, charges build on their body. Like all electrical charges, static seeks a path to ground. When a charged person touches someone or something, the charge jumps from them to the other person or object. This transfer of electrical current is called an electrostatic discharge (or ESD) – and it’s this discharge that harms electronic circuitry.

Conductivity enables a floor to transport static charges to ground. But conductivity is separate from charge generation. To protect against unwanted ESD events, the floor must prevent static from building on people as they walk – i.e., prevent static charge generation.

Some conductive floors generate static

Some conductive – even highly conductive – floors generate static electricity. ESD vinyl and epoxy, for instance, are made from charge-generating base materials. The floor may be conductive, but unless every person in the space wears ESD footwear (heel straps, toe straps, or ESD shoes), the floor will generate harmful static charges.For this reason, it’s crucial to also test any/all floor/s under consideration for charge generation. Charge generation tests use a static field meter and follow the guidelines outlined in ANSI/ESD STM 97.2.

Here are acceptable measurement charge generation limits by application type:

End user applications = < 500 volts ( .5kV )Electronics manufacturing and handling applications = < 100 volts (.1kV)

Class-0 electronics = < 20 volts (.02 kV )

Takeaway: Conductivity is only one part of the ESD flooring equation. The floor must also prevent static generation when people walk. Even some highly conductive floors can generate static. That’s why it’s crucial to also test for charge generation.

Industry standards are based on metrics – not descriptors

There are NO industry standards that require the use of conductive or static-dissipative flooring materials – with the requirements stated solely in those terms.

Motorola R56 and FAA 019f do require static-dissipative flooring: floors with electrical resistance measurements above 10E6 are static dissipative. But ESD flooring standards are ALWAYS stated in metrics. They never refer solely to the descriptors.

So…

Bottom Line: It’s important to know the metrics and test the floor -before you make your selection – to be sure any floor under consideration meets your required metrics.

Resistance and Body Voltage (Charge Generation) Tests

Resistance and static generation (body voltage) guidelines

Electronics manufacturing and handling applications follow the guidelines in S20.20:

Electrical resistance must measure < 1.0 x 10E9

Static generation must be < 100 V or < 20V for Class-0.

End-user spaces follow their own standards: Motorola R56 and ATIS-0600321 for telecommunications and PSAPs, and FAA 019f for flight towers and spaces using flight tower equipment:

Electrical resistance must measure > 1.0 x 10E6

Static generation must be < 500 V

Bottom Line: ESD flooring should be based on metrics and specified with precision.

- Flooring standards and specifications should be based on precise metrics. That is, ESD floors should be specified based on science – not categories.

- Specifications should follow industry guidelines, understanding that ESD flooring standards differ across industries. There is no universally applicable ESD flooring standard.

- All floors under consideration should be tested for resistance and charge generation, following the guidelines in S7.1 and S97.2.

Final thought: When descriptors are used as opposed to numerical metrics the discussion assumes that all parties have the same understanding on the definition of the terms they are discussing. In practice, most designers and specifiers do not actually know that static dissipative and conductive flooring are differentiated based on a flooring material’s electrical resistance measured in ohms. To avoid confusion in semantics, static control flooring electrical properties should be stated in numerical terms.

About StaticWorx, Inc

All StaticWorx posts are written by our technical team and based on industry standards and specifications, test data, independent lab reports and other verifiable data. We provide ESD training and offer CEU credits to architects. If you’re interested in an ESD training session or architects’ ESD workshop, give us a call: 617-923-2000.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

More Blog Posts

To maintain performance, ESD floors require specially formulated products. We offer tips on what to consider when choosing cleaning supplies.

Static-dissipative floors transport harmful static charges to ground. Dissipative is also a term for flooring with a specific, measurable electrical resistance.

StaticWorx recognized as one of the fastest growing private companies in the U.S. 2023 marks StaticWorx fourth appearance on Inc. 5000 list.

Conductive and dissipative flooring protect electronics by transporting charges to ground, conductive at a quicker rate, dissipative slower & more controlled.

We explain the 3 main ways to test an ESD floor: Electrical resistance; body voltage & ESD audits, with advantages and reasons for each.

Three critical factors—application, industry standards & footwear—help you choose the best ESD floor, while ensuring the safety & efficiency of your operations.

StaticWorx Founder and President Dave Long shares three of his recommended reads: Quit, How to Change, and The Goal.

There are leadership qualities StaticWorx strives to embody every day, with every product, throughout each project.

No matter how you slice and dice a project, an ESD floor is a major investment. This blog post examines five ways to keep undue costs down.

What’s the difference between static control and static resistant? Or anti-static flooring? Find out more in our blog post.

A major part of any ESD control program is getting proper flooring in place. How can one replace a floor without generating any debris? Learn more.

A well-designed, comprehensive, fully realized program is a must for manufacturers serious about ESD control. Learn why ESD programs fail.

<a class="eael-grid-post-link" href="https://staticworx.com/case-studies/esd-flooring-failure-incorrect-testing/" title="Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods">Blog Post: Case Study: ESD Flooring Failure, Incorrect Testing: Always Qualify Your Floor Using ANSI/ESD Test Methods

To comply with relevant ESD standards, test electrical properties using methods outlined in ESD S20.20. For best results require testing by an independent lab.

<a class="eael-grid-post-link" href="https://staticworx.com/installing/esd-flooring-installation-bond-test-manufacturer-oversight-critical/" title="Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success">Blog Post: ESD Flooring Installation:

Bond Test and Manufacturer Oversight Are Critical to ESD Flooring Success

If the vapor barrier fails to adhere to the subfloor, tiles will lift. Bond test and manufacturer oversight are crucial to ESD floor installation success.

<a class="eael-grid-post-link" href="https://staticworx.com/technical-info/conductive-static-dissipative-flooring-difference/" title="Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer">Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer

What’s the difference between conductive and static-dissipative flooring? Facts, analogies and images illustrate the difference in easily understood terms.

Qualifying an ESD floor helps ensure you get the floor you paid for. Find out why you should always qualify according to ESD S20.20

Qualification is the first step in selecting an ESD floor. Learn how to perform resistance tests to be sure the floor meets electrical & safety standards.

Will bare concrete control static? Learn why concrete floors are unreliable & what precautions to take if you must work on a bare concrete floor.

A look at how the StaticWorx cartoon, 'Conductive Flooring Does Not Mean Antistatic Flooring,' was conceived and created.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.