Moisture problems are the #1 cause of failed flooring installations....

Read More

Static Bursts (Ep #2): Static-dissipative versus Conductive Flooring

Why Do You Recommend Static-Dissipative Flooring For Some Applications & Conductive For Others?

Have you ever wondered why we recommend static-dissipative flooring for some applications and conductive for others? Shouldn’t both types of flooring work for any application? No, because electrical standards vary by industry.

In episode 2 of Static Bursts, Dave discusses the technical difference between static-dissipative and conductive floors. Standards for flight towers, communications facilities and other end-user applications require flooring with electrical resistance measuring between 1.0 x 10E6 and 1.0 x 10E9. Standards for electronics manufacturing, however, allow for any floor measuring below 1.0 x 10E9. Dave explains why it’s important to know and follow industry standards for the specific application where the ESD floor will be installed.

The Gist: Static-dissipative versus Conductive Flooring

- Static-dissipative and conductive

- For end users

-

For electronics

manufacturing - Charge generation

What do the terms static-dissipative & conductive mean?

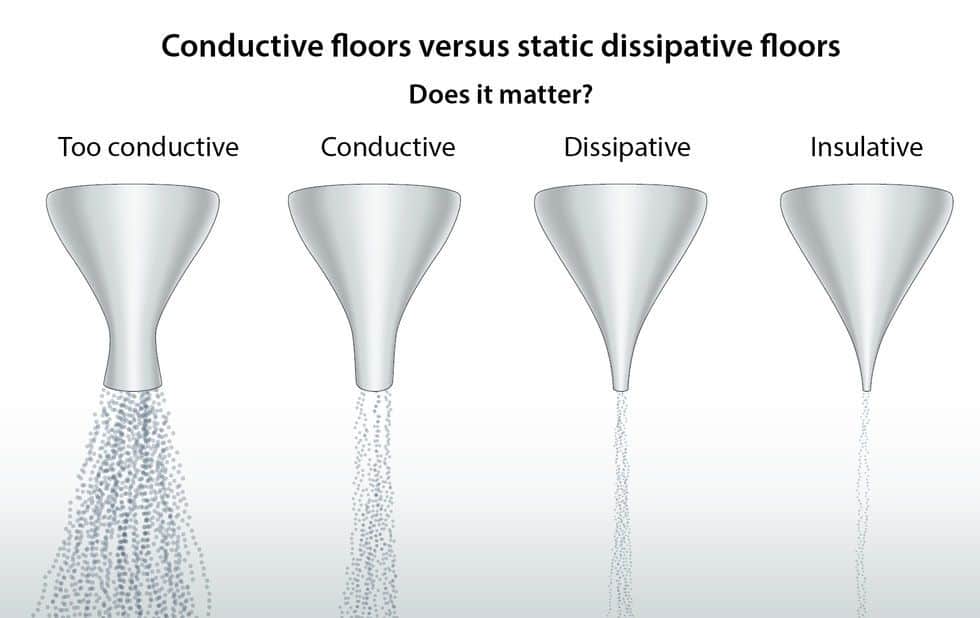

The terms static-dissipative & conductive describe the electrical resistance of flooring materials. Resistance is measured in ohms, following guidelines in STM (standard test method) 7.1.

Dissipative floors measure from 1,000,000 – 1,000,000,000 ohms (1.0 x 10E6 – 1.0 x 10E9)

Conductive floors measure less than 1,000,000 ohms (<1.0 x 10E6).

Why use static-dissipative materials for some applications and conductive for others?

- standards vary by industry.

- strictly enforced protocols in electronics manufacturing allow for a wider range of electrical resistance.

Flooring should always be specified based on particular industry standards.

In any end-user space (where electronics are not manufactured) —flight towers, call or dispatch centers, labs, hyperbolic chambers, data centers, etc.—industry standards require flooring materials to measure between 1.0 x 10E6 – 1.0 x 10E9 – with a minimum resistance of 1.0 x 10E6.

These standards are designed to meet safety protocols.

Will conductive floors work in these applications?

Yes, conductive flooring works, but does not meet industry standards for these applications.

What are those standards?

FAA 019f, Motorola R56, and ATIS 0600321

What if the flooring material exceeds industry standards?

The resistance standard consists of a range. Exceeding the range in either direction would be like exceeding the speed limit: it would not meet the standard.

Why do I need to specify to a standard?

Industry standards are designed to meet safety and other industry protocols. In the case of a post-installation problem, specifying outside the standard increases your professional liability.

For electronics manufacturing environments, specify resistance below 1.0 x 10E9

What standard governs electronics manufacturing?

Electronics manufacturers comply with ANSI/ESD S20.20. This is the best-practice standard for ESD-protected areas and ISO-certified electronics manufacturing and handling facilities.

What is the resistance requirement for S20.20?

To meet ANSI/ESD S20.20, the floor must measure below 1,000,000,000 ohms (1.0 x 10E9). Any resistance from 0 to 1 billion ohms meets the standard.

People working in electronics facilities also work around electrified equipment. Why isn’t low resistance – or greater conductivity – a safety risk for them?

Electronics facilities have protective protocols in place, which are tightly monitored and routinely tested. Before entering the ESD-protected area, for example, every person is required to change into special ESD footwear—heel straps, toe straps, sole straps, ESD shoes. The built-in 1 megohm resistor in ESD footwear protects the wearer from electric shock.

Are there any other standards we should be aware of?

Yes, all floors should also be tested for charge generation. Charge generation (the amount of static generated when people walk), is measured in volts and tested according to STM 7.3.

Floors for end-user spaces should not exceed 500 volts.

Floors for electronics applications should not exceed 100 volts.

Floors for Class-0 electronics should not exceed 20 volts.

What do the terms static-dissipative & conductive mean?

The terms static-dissipative & conductive describe the electrical resistance of flooring materials. Resistance is measured in ohms, following guidelines in STM (standard test method) 7.1.

Dissipative floors measure from 1,000,000 – 1,000,000,000 ohms (1.0 x 10E6 – 1.0 x 10E9)

Conductive floors measure less than 1,000,000 ohms (<1.0 x 10E6).

Why use static-dissipative materials for some applications and conductive for others?

- standards vary by industry.

- strictly enforced protocols in electronics manufacturing allow for a wider range of electrical resistance.

Flooring should always be specified based on particular industry standards.

In any end-user space (where electronics are not manufactured) —flight towers, call or dispatch centers, labs, hyperbolic chambers, data centers, etc.—industry standards require flooring materials to measure between 1.0 x 10E6 – 1.0 x 10E9 – with a minimum resistance of 1.0 x 10E6.

These standards are designed to meet safety protocols.

Will conductive floors work in these applications?

Yes, conductive flooring works, but does not meet industry standards for these applications.

What are those standards?

FAA 019f, Motorola R56, and ATIS 0600321

What if the flooring material exceeds industry standards?

The resistance standard consists of a range. Exceeding the range in either direction would be like exceeding the speed limit: it would not meet the standard.

Why do I need to specify to a standard?

Industry standards are designed to meet safety and other industry protocols. In the case of a post-installation problem, specifying outside the standard increases your professional liability.

For electronics manufacturing environments, specify resistance below 1.0 x 10E9

What standard governs electronics manufacturing?

Electronics manufacturers comply with ANSI/ESD S20.20. This is the best-practice standard for ESD-protected areas and ISO-certified electronics manufacturing and handling facilities.

What is the resistance requirement for S20.20?

To meet ANSI/ESD S20.20, the floor must measure below 1,000,000,000 ohms (1.0 x 10E9). Any resistance from 0 to 1 billion ohms meets the standard.

People working in electronics facilities also work around electrified equipment. Why isn’t low resistance – or greater conductivity – a safety risk for them?

Electronics facilities have protective protocols in place, which are tightly monitored and routinely tested. Before entering the ESD-protected area, for example, every person is required to change into special ESD footwear—heel straps, toe straps, sole straps, ESD shoes. The built-in 1 megohm resistor in ESD footwear protects the wearer from electric shock.

Are there any other standards we should be aware of?

Yes, all floors should also be tested for charge generation. Charge generation (the amount of static generated when people walk), is measured in volts and tested according to STM 7.3.

Floors for end-user spaces should not exceed 500 volts.

Floors for electronics applications should not exceed 100 volts.

Floors for Class-0 electronics should not exceed 20 volts.

“You’ll see things when you look at spec sheets like “exceeds R56,” “exceeds FAA 019f.” You can’t exceed those standards, and the reason you can’t exceed them is they prescribe a range. There’s a minimum and a maximum. How do you exceed that?”

We’ve made it easy to subscribe on your favorite platform!

Dave: Welcome to Static Talks.

I’m your host, Dave Long, founder and president of Staticworx. We make static-control flooring and our podcasts will discuss the threat static electricity poses to business, and how to address those risks.

One of the questions that comes up almost every day is “why do you contradict your own recommendations?” In other words, why do you tell some people the reason you need static-dissipative flooring is such and such, and then tell someone else, you need conductive flooring? And it’s actually something that I think causes a little bit of confusion when people come on our website. It’s confusing for them in general, even if they’re not talking with us. So why do you really need to use a static-dissipative floor sometimes instead of a conductive floor? Let’s start out with the more simple part of it. What is a static-dissipative floor?

A static-dissipative floor is a flooring material that if you were to use an ohm meter, and follow a certain standard, which happens to be ANSI/ESD STM7.1 – which I’m not going to repeat over and over again, I’m just going to call it the test – if you were to do the test on a static-dissipative floor, what you would discover is it that floor measured for electrical resistance less than 1 billion ohms, which is less than 1.0 x 10E9, and greater than 1.0 x 10E6, which we also call one megohm, which we also call 1 million ohms. So a floor that measures with a resistance meter between a million ohms and a billion ohm, we call that a static-dissipative floor.

A conductive floor is a floor that measures less than 1 million ohms, which is the same as saying 1.0 x 10E6. So if it measures less than a million ohms, all the way down to zero, we can call that a conductive floor based on the same test I’ve already talked about.

Rick: So up to a million ohms of resistance is considered conductive flooring and between 1 million and 1 billion ohms is considered dissipative. So how do customers know which to choose?

Dave: So why would you use one of these floors versus the other? Let’s start with why you wouldn’t, because that’s probably more important for the podcast we’re doing right now.

If you’re putting flooring in an FAA flight tower, or a 9-1-1 call center, or a communication room, or a hyperbaric chamber, or any place other than electronics manufacturing, if you look closely at the standards, especially the grounding standards and the code and a lot of other aspects that have to do with the electrical properties of the building – lightning surge protection, that sort of thing – what you’ll discover is that in these areas, because you have energized equipment – in other words, things that are plugged in – those kinds of applications, the standards tell you that you’re supposed to use a floor that has a minimum amount of resistance. That minimum amount of resistance just so happens to be 1 million ohms.

It doesn’t matter which standard you’re looking at for these kinds of spaces because the one thing I can assure you of is there’s a lot of consensus. So the FAA’s newest document, FAA standard 019f, the latest ATIS document, the Motorola R56 document, all of them tell you for these kinds of spaces, that the floor has to have a minimum resistance of 10E6. That doesn’t mean that a floor measuring 10E5 wouldn’t do the job. What it does mean – and that’s this is kind of important if you’re a specifier – is if you’re going to specify a floor, why would you even think about deviating from the norm? The consensus? A floor that measures less than 10E6 will also work but it will not meet or comply.

I’m being very careful in the way I’m saying this because some manufacturers don’t have the engineering or the expertise to explain this in detail. So you’ll see things when you look at spec sheets like “exceeds R56,” “exceeds FAA 019f.” You can’t exceed those standards, and the reason you can’t exceed them is they prescribe a range. There’s a minimum and a maximum. How do you exceed that? If you go over, you’re out of the range. If you go under you’re out of the range. I mean, think about it: you’re driving down your favorite highway, and you’re driving 90 miles an hour, and you get pulled over by your local police or state police and when they tell you, “You’re going too fast,” you say “But officer I was exceeding the range.” You’re going to get a big ticket and they might even get mad at you for saying that.

Rick: So by exceeding a specified range, you would essentially be failing to comply with the standard and the result would be a potentially risky situation.

Dave: Think about what happens if you put a floor in a building, and you wrote a specification, and you knew that you weren’t supposed to write the specification in such a way that it “exceeded the range,” but you did it anyway. Then there’s an incident, there’s a computer burns out, there’s a lightning strike on the building and power goes out and they start looking at everything and for some reason they question your specification. Why would you want to defend that to begin with? You don’t need to. There are products that are built to meet these expectations and those products are the ones that you should specify. So when you’re looking at an end-user space – a place where you’re using computers, a data center, an operation that requires understanding the possibility of someone coming into the building and servicing the equipment – you don’t want to put them in harm’s way and have them kneeling on the floor, changing out circuit boards where the floor’s electrical measurements are more conductive than they should be. So that that’s the answer to the question about why you wouldn’t want to do something.

Let’s talk about why you would want to do something in the conductive range. I’m tasked right now, possibly, with designing a floor for a manufacturing operation where they’re going to build circuit boards. They need, let’s call it 100,000 square feet of flooring and I’ve been told that the floor and the operation itself have got to comply with an ESD standard called ANSI/ESD S20.20. Simply said, that’s the latest version of a document that tells you how to set up a program where you can handle electronic devices – including parts and circuit boards and final assemblies – and meet what would amount to being best practice expectations if you were ever audited for ISO 9000, or whatever the version of ISO it is that you would have to meet.

Rick: So the standard documents specify both an upper and a lower limit to the amount of resistance that’s appropriate for this flooring?

Dave: The one I’m talking about now for electronics: no. In electronics assembly, because there are so many other protocols that are constantly monitored and tested, you don’t need to have a minimum, you just need to have a maximum. The maximum resistance of the floor in electronics manufacturing is 1 billion ohms. That’s it. So everything less than a billion all the way down to zero. That begs the question, why would it be more important to protect people in a space that has this other parameter than a place where people are going to work and put circuit boards together? And the answer is actually pretty simple. They have all kinds of strategic protocols in place, including testing people’s footwear, making people wear special garments, having people wear certain types of wristwear that’s connected to ground with resistors in it, the footwear has resistors – everything in the environment is protected and controlled. The possibility of things happening that would potentially hurt a person are diminished greatly just by the statistical protocols that are put in place.

Rick: Do the standards documents assume that everyone in the space will be wearing some kind of ESD footwear?

Dave: That’s the million dollar question. No. What they assume is that in the kinds of spaces, we’re talking about – call centers, flight towers – you’re going to be wearing whatever kind of footwear you like to wear – you like wearing athletic shoes, you’re wearing dress shoes because after work, you’re going somewhere, you want to look for professional reasons a certain way – those kinds of shoes don’t even have any conductivity. Which brings us to a very important parameter, which is the floor also has to have the ability to prevent or mitigate or inhibit the ability to charge up in the first place. That’s why I complimented your question, because when you put a floor in a particular type of environment, sometimes the conductivity is not as important as the floor’s ability to prevent the charge in the first place.

Let’s go back to the communications applications like the dispatcher operation. Those floors have a minimum resistance at one megohm. Whether they had a minimum resistance of one megohm or 10 megohm really doesn’t matter as much as will that floor add to the generation of static or inhibit the generation of static. Well, we know that because they’re going to be wearing regular shoes in those environments, the floor obviously has to have a place to take a charge but it also can’t contribute to the charge to begin with. We’re not looking for that floor in a dispatcher operation to be a dead short to ground.

However, in an electronics manufacturing application, completely different set of parameters. We’re going to be assuming – because of the way these organizations operate and the standards they have to meet – that when a person arrives at work in the morning or whatever shift they’re working, they are going to have to put on special footwear. The special footwear that they wear will have conductivity also. That could be ESD shoes, it could be an ESD foot strap, it could be a moccasin of some sort. In clean rooms, they wear special booties that have conductive materials on them. But they will be required as part of their protocol before entering what they call them the ESD protected area to wear special footwear. That allows for that type of application in that industry to put together a parameter which states that when the floor is tested, based on a particular method, that when the person is wearing special footwear, they will never generate more than 100 volts. With regular footwear, that wouldn’t even be possible.

That’s why organizations like the FAA put out these ground and surge protection documents and include clauses like you cannot use conductive flooring and the reason you can’t use it is because if that kind of flooring is used around energized equipment and they define energized equipment pretty clearly – it’s things that are electrical, your laptop, your cell phone charger, anything in the room that’s electrical – you could be in harm’s way if the floor’s too conductive. So we take a pretty strong stand on this. I’m not telling you are going to get hurt if you use these materials. What I’m telling you is that because there are alternatives, it makes absolutely no sense to be deviating from standards. We could think of so many different examples and building materials and I know enough about the architectural community to know it’s not a community that intentionally specifies things just to differentiate themselves from what they’re supposed to do, it’s the other way around.

Rick: Do all of the end flooring products on the market protect in the same way from these types of risks?

Dave: When you look at static control flooring, one of the things you might see in a brochure is that it’s the responsibility of the owner or the specifier to determine the suitability of the product. Now, on top of that, some manufacturers will go so far as to make the statement that their product meets or exceeds a certain application. Depending upon your definition of semantics, you might say that if they say “meet” or “exceed” and they name five standards, you’re not really sure which ones they’re meeting or exceeding. I’m not a lawyer. I’m not here to to argue semantics. What I am here to tell you is that if something is supposed to fall between x and y, and it’s either less than x or more than y it doesn’t meet.

We hope you learned something today. If you have questions about the podcast, give us a call at 617-923-2000. Even though we specialize in solving problems with flooring, if you have a question about static discharge, how to install a floor, how to test a floor, we’ll be glad to help you. Thanks for listening.

Dave: Welcome to Static Talks.

I’m your host, Dave Long, founder and president of Staticworx. We make static-control flooring and our podcasts will discuss the threat static electricity poses to business, and how to address those risks.

One of the questions that comes up almost every day is “why do you contradict your own recommendations?” In other words, why do you tell some people the reason you need static-dissipative flooring is such and such, and then tell someone else, you need conductive flooring? And it’s actually something that I think causes a little bit of confusion when people come on our website. It’s confusing for them in general, even if they’re not talking with us. So why do you really need to use a static-dissipative floor sometimes instead of a conductive floor? Let’s start out with the more simple part of it. What is a static-dissipative floor?

A static-dissipative floor is a flooring material that if you were to use an ohm meter, and follow a certain standard, which happens to be ANSI/ESD STM7.1 – which I’m not going to repeat over and over again, I’m just going to call it the test – if you were to do the test on a static-dissipative floor, what you would discover is it that floor measured for electrical resistance less than 1 billion ohms, which is less than 1.0 x 10E9, and greater than 1.0 x 10E6, which we also call one megohm, which we also call 1 million ohms. So a floor that measures with a resistance meter between a million ohms and a billion ohm, we call that a static-dissipative floor.

A conductive floor is a floor that measures less than 1 million ohms, which is the same as saying 1.0 x 10E6. So if it measures less than a million ohms, all the way down to zero, we can call that a conductive floor based on the same test I’ve already talked about.

Rick: So up to a million ohms of resistance is considered conductive flooring and between 1 million and 1 billion ohms is considered dissipative. So how do customers know which to choose?

Dave: So why would you use one of these floors versus the other? Let’s start with why you wouldn’t, because that’s probably more important for the podcast we’re doing right now.

If you’re putting flooring in an FAA flight tower, or a 9-1-1 call center, or a communication room, or a hyperbaric chamber, or any place other than electronics manufacturing, if you look closely at the standards, especially the grounding standards and the code and a lot of other aspects that have to do with the electrical properties of the building – lightning surge protection, that sort of thing – what you’ll discover is that in these areas, because you have energized equipment – in other words, things that are plugged in – those kinds of applications, the standards tell you that you’re supposed to use a floor that has a minimum amount of resistance. That minimum amount of resistance just so happens to be 1 million ohms.

It doesn’t matter which standard you’re looking at for these kinds of spaces because the one thing I can assure you of is there’s a lot of consensus. So the FAA’s newest document, FAA standard 019f, the latest ATIS document, the Motorola R56 document, all of them tell you for these kinds of spaces, that the floor has to have a minimum resistance of 10E6. That doesn’t mean that a floor measuring 10E5 wouldn’t do the job. What it does mean – and that’s this is kind of important if you’re a specifier – is if you’re going to specify a floor, why would you even think about deviating from the norm? The consensus? A floor that measures less than 10E6 will also work but it will not meet or comply.

I’m being very careful in the way I’m saying this because some manufacturers don’t have the engineering or the expertise to explain this in detail. So you’ll see things when you look at spec sheets like “exceeds R56,” “exceeds FAA 019f.” You can’t exceed those standards, and the reason you can’t exceed them is they prescribe a range. There’s a minimum and a maximum. How do you exceed that? If you go over, you’re out of the range. If you go under you’re out of the range. I mean, think about it: you’re driving down your favorite highway, and you’re driving 90 miles an hour, and you get pulled over by your local police or state police and when they tell you, “You’re going too fast,” you say “But officer I was exceeding the range.” You’re going to get a big ticket and they might even get mad at you for saying that.

Rick: So by exceeding a specified range, you would essentially be failing to comply with the standard and the result would be a potentially risky situation.

Dave: Think about what happens if you put a floor in a building, and you wrote a specification, and you knew that you weren’t supposed to write the specification in such a way that it “exceeded the range,” but you did it anyway. Then there’s an incident, there’s a computer burns out, there’s a lightning strike on the building and power goes out and they start looking at everything and for some reason they question your specification. Why would you want to defend that to begin with? You don’t need to. There are products that are built to meet these expectations and those products are the ones that you should specify. So when you’re looking at an end-user space – a place where you’re using computers, a data center, an operation that requires understanding the possibility of someone coming into the building and servicing the equipment – you don’t want to put them in harm’s way and have them kneeling on the floor, changing out circuit boards where the floor’s electrical measurements are more conductive than they should be. So that that’s the answer to the question about why you wouldn’t want to do something.

Let’s talk about why you would want to do something in the conductive range. I’m tasked right now, possibly, with designing a floor for a manufacturing operation where they’re going to build circuit boards. They need, let’s call it 100,000 square feet of flooring and I’ve been told that the floor and the operation itself have got to comply with an ESD standard called ANSI/ESD S20.20. Simply said, that’s the latest version of a document that tells you how to set up a program where you can handle electronic devices – including parts and circuit boards and final assemblies – and meet what would amount to being best practice expectations if you were ever audited for ISO 9000, or whatever the version of ISO it is that you would have to meet.

Rick: So the standard documents specify both an upper and a lower limit to the amount of resistance that’s appropriate for this flooring?

Dave: The one I’m talking about now for electronics: no. In electronics assembly, because there are so many other protocols that are constantly monitored and tested, you don’t need to have a minimum, you just need to have a maximum. The maximum resistance of the floor in electronics manufacturing is 1 billion ohms. That’s it. So everything less than a billion all the way down to zero. That begs the question, why would it be more important to protect people in a space that has this other parameter than a place where people are going to work and put circuit boards together? And the answer is actually pretty simple. They have all kinds of strategic protocols in place, including testing people’s footwear, making people wear special garments, having people wear certain types of wristwear that’s connected to ground with resistors in it, the footwear has resistors – everything in the environment is protected and controlled. The possibility of things happening that would potentially hurt a person are diminished greatly just by the statistical protocols that are put in place.

Rick: Do the standards documents assume that everyone in the space will be wearing some kind of ESD footwear?

Dave: That’s the million dollar question. No. What they assume is that in the kinds of spaces, we’re talking about – call centers, flight towers – you’re going to be wearing whatever kind of footwear you like to wear – you like wearing athletic shoes, you’re wearing dress shoes because after work, you’re going somewhere, you want to look for professional reasons a certain way – those kinds of shoes don’t even have any conductivity. Which brings us to a very important parameter, which is the floor also has to have the ability to prevent or mitigate or inhibit the ability to charge up in the first place. That’s why I complimented your question, because when you put a floor in a particular type of environment, sometimes the conductivity is not as important as the floor’s ability to prevent the charge in the first place.

Let’s go back to the communications applications like the dispatcher operation. Those floors have a minimum resistance at one megohm. Whether they had a minimum resistance of one megohm or 10 megohm really doesn’t matter as much as will that floor add to the generation of static or inhibit the generation of static. Well, we know that because they’re going to be wearing regular shoes in those environments, the floor obviously has to have a place to take a charge but it also can’t contribute to the charge to begin with. We’re not looking for that floor in a dispatcher operation to be a dead short to ground.

However, in an electronics manufacturing application, completely different set of parameters. We’re going to be assuming – because of the way these organizations operate and the standards they have to meet – that when a person arrives at work in the morning or whatever shift they’re working, they are going to have to put on special footwear. The special footwear that they wear will have conductivity also. That could be ESD shoes, it could be an ESD foot strap, it could be a moccasin of some sort. In clean rooms, they wear special booties that have conductive materials on them. But they will be required as part of their protocol before entering what they call them the ESD protected area to wear special footwear. That allows for that type of application in that industry to put together a parameter which states that when the floor is tested, based on a particular method, that when the person is wearing special footwear, they will never generate more than 100 volts. With regular footwear, that wouldn’t even be possible.

That’s why organizations like the FAA put out these ground and surge protection documents and include clauses like you cannot use conductive flooring and the reason you can’t use it is because if that kind of flooring is used around energized equipment and they define energized equipment pretty clearly – it’s things that are electrical, your laptop, your cell phone charger, anything in the room that’s electrical – you could be in harm’s way if the floor’s too conductive. So we take a pretty strong stand on this. I’m not telling you are going to get hurt if you use these materials. What I’m telling you is that because there are alternatives, it makes absolutely no sense to be deviating from standards. We could think of so many different examples and building materials and I know enough about the architectural community to know it’s not a community that intentionally specifies things just to differentiate themselves from what they’re supposed to do, it’s the other way around.

Rick: Do all of the end flooring products on the market protect in the same way from these types of risks?

Dave: When you look at static control flooring, one of the things you might see in a brochure is that it’s the responsibility of the owner or the specifier to determine the suitability of the product. Now, on top of that, some manufacturers will go so far as to make the statement that their product meets or exceeds a certain application. Depending upon your definition of semantics, you might say that if they say “meet” or “exceed” and they name five standards, you’re not really sure which ones they’re meeting or exceeding. I’m not a lawyer. I’m not here to to argue semantics. What I am here to tell you is that if something is supposed to fall between x and y, and it’s either less than x or more than y it doesn’t meet.

We hope you learned something today. If you have questions about the podcast, give us a call at 617-923-2000. Even though we specialize in solving problems with flooring, if you have a question about static discharge, how to install a floor, how to test a floor, we’ll be glad to help you. Thanks for listening.

Further Reading/Viewing

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Other Podcast Episodes

Static Bursts (Ep #3): Why Resistance Tests Alone Are Not Enough to Properly Qualify An ESD Floor

How can you predict whether an ESD flooring material will...

Read MoreStatic Bursts (Ep #4): Avoiding Problems When Installing ESD flooring Over Existing Surfaces

New floors are typically installed over the following pre-existing surfaces:...

Read MoreStatic Bursts (Ep #5): Hidden Costs of Flooring Installations (Part I) – Vapor in the Concrete

Moisture or vapor in the concrete subfloor can cause your...

Read MoreLearning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.