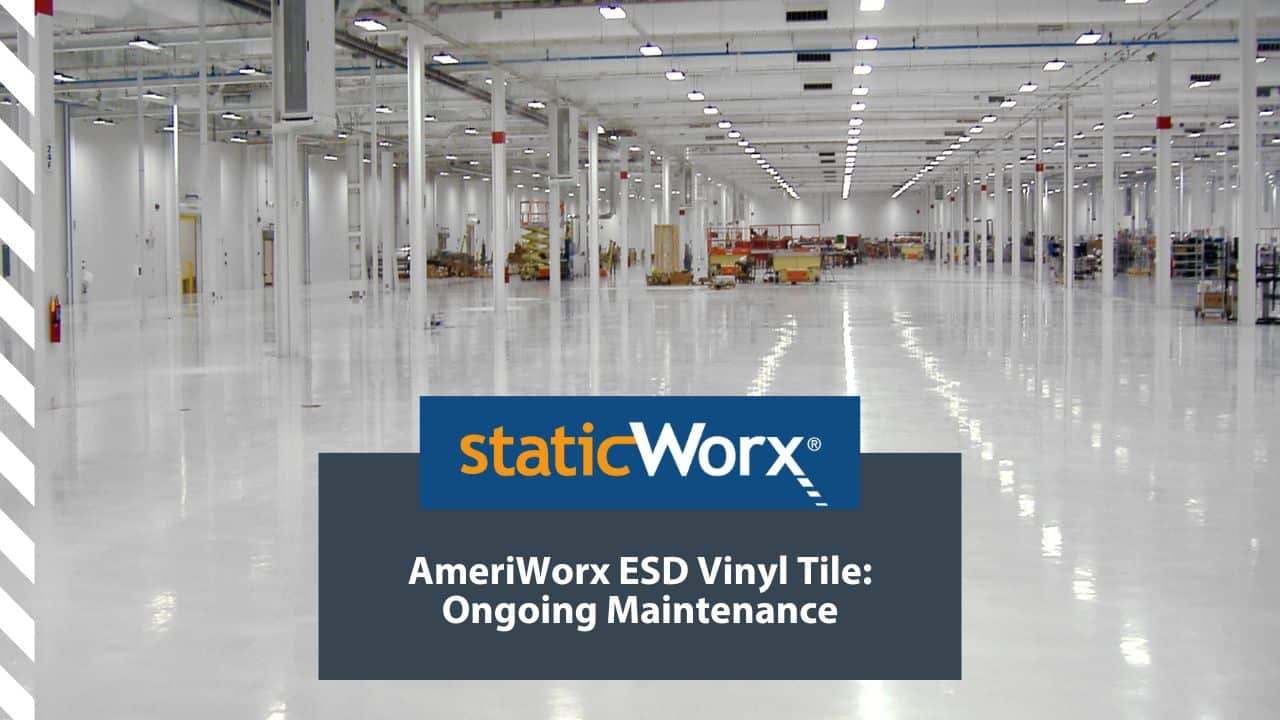

Video: AmeriWorx ESD Vinyl Tile: Ongoing Maintenance

October 30, 2022

Accumulated dirt and debris can insulate your ESD floor from its conductive components and cause your floor to look unattractive and worn. Simple routine maintenance, using StaticWorx ScrubWorx cleaner and Formula 20.20 will keep your ESD floor at optimal electrical performance while maintaining a clean, beautiful, hospital-like shine.

To add luster and restore an old, soiled vinyl floor to like-new condition, simply follow the procedure shown in our post-installation video. This restoration procedure uses StaticWorx EcoScrub degreaser and Formula 20.20.

Learn more about StaticWorx cleaning products.

Learn more about AmeriWorx ESD Solid Vinyl Tile.

View/download the written instructions for AmeriWorx ongoing maintenance procedures.

For help or advice about choosing an ESD floor, call us on 617-923-2000, email [email protected], or visit our Guide to ESD Flooring Selection.

AmeriWorx ESD tile provides excellent electrical protection with an attractive appearance that enhances any working or manufacturing environment.

As with any other floor, ongoing maintenance is required to maintain the visual appearance and clean, hospital-like shine of AmeriWorx vinyl tile. Routine cleaning prevents the buildup of contaminants and debris, which can affect the floor’s electrical performance. While there may be other ways to keep your AmeriWorx ESD floor looking clean, StaticWorx recommends only the use of StaticWorx ScrubWorx and StaticWorx Formula 20.20. Unapproved methods and procedures may cause suboptimal electrical performance and/or poor visual appearance. Frequency of cleaning can be daily, weekly, monthly or quarterly, depending on visual requirements, traffic frequency and other site-specific environmental conditions. Never at any time buff AmeriWorx ESD vinyl tile in excess of 375 RPM. Floors become slippery when wet and care must be taken to prevent accidental slipping or falls. Appropriate barriers to wet areas and warning/caution placards should always be used.

First, sweep or dust mop the floor to remove any large debris. Never use oil-treated dust mops. Dilute StaticWorx ScrubWorx one part cleaner to 64 parts water, two ounces per gallon, with cool, clean water. Damp mop or auto-scrub using a generic red pad. Rinse as necessary, then allow to dry. To achieve a deep, rich luster, simply clean the floor using StaticWorx ScrubWorx. After the floor is completely dry and free of residue and other contaminants, mist a small area with StaticWorx Formula 20.20, with the sprayer on a fine-mist setting. Buff the floor with a generic red or natural hair pad using a slow, even sweeping motion until you obtain the desired appearance. If you follow these recommended procedures, your AmeriWorx ESD tile will look beautiful and last a lifetime.

StaticWorx cleaning and finishing products and buffing pads are available from StaticWorx.

StaticWorx. We Keep You Grounded.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.