Video: Choosing ESD Carpet Tile for 911 Dispatch & FAA Applications

July 2, 2011

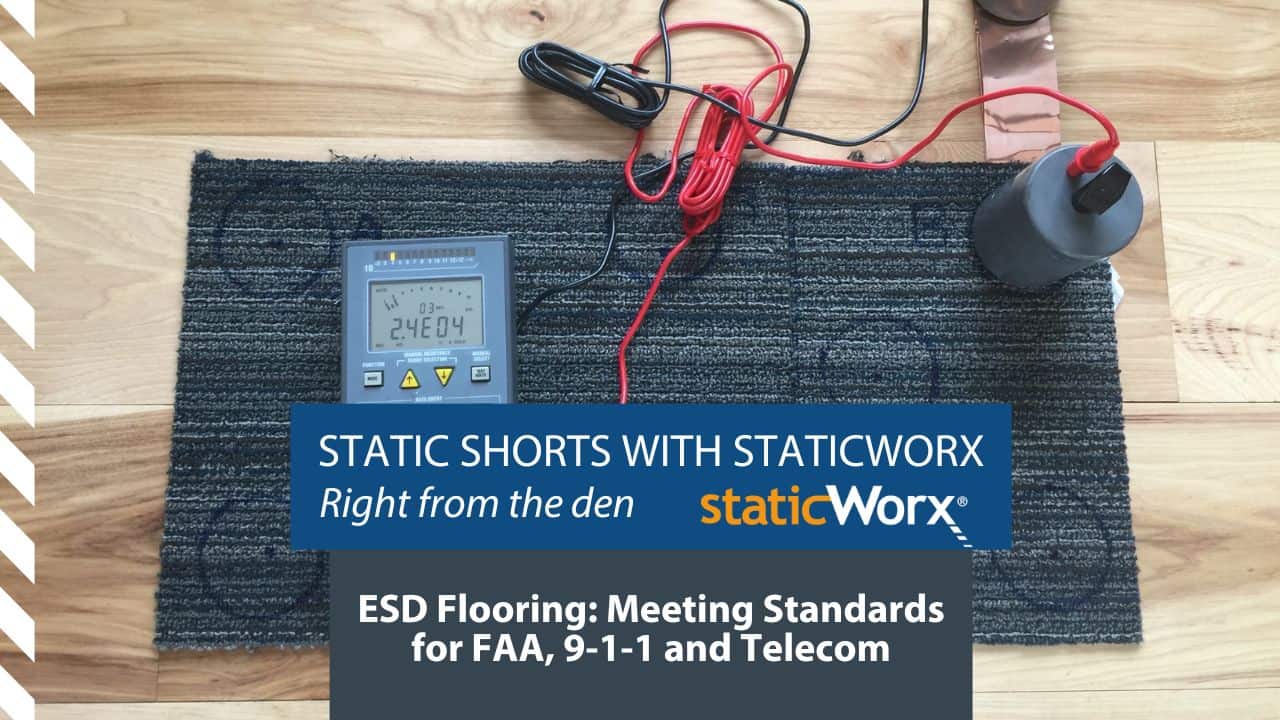

Static dissipative carpet tile is preferred over static conductive carpet tile for installations in end user mission critical environments like call centers and dispatch areas. Grounding standards like Motorola R56, FAA STD 019f and ATIS 0600321 require a carpet’s resistance to exceed 1.0 x 10E6 or 1 million ohms. We generically call this acceptable type of carpet “operational grade carpet” due its suitability for use around operational or energized electronic equipment. Conductive carpet is viewed as unsafe for these operational equipment environments because conductive carpeting could increase the risk of an electrical hazard. A conductive carpet tile is easily recognized due to its unique black colored carbon loaded backing. It is generally described as having a resistance to ground range between 2.5 x 10E4 (25,000) and 1.0 x 10E8 ohms. 2.5 x 10E4 is 100 times more conductive than most end user grounding standards allow.

For help or advice about choosing an ESD floor, call us on 617-923-2000, email [email protected], or visit our Guide to ESD Flooring Selection.

Hi, this is Dave Long from StaticWorx and in this sequence we’re going to be talking about the different types of carpet that are used to prevent static electricity problems.

The first one we’re going to discuss is computer grade static-control carpet and by computer grade carpet, what we’re talking about is very old technology that was originally designed to prevent static shocks on people who worked in computer rooms.

Early on, probably early 1980s, the thought was that if people did not get a shock when they walked across carpet, then the computer equipment in the room was also protected from static electricity. Unfortunately, what we’ve learned since then is that when a person feels a shock it requires 3,500 to 4,000 volts. Computer parts are sensitive to 30, 40, 50, under 100 volts of static electricity so today when we look at computer grade carpet, we actually look at it as totally ineffective because all it really should be called is shock free carpet. You won’t get hurt when you’re walking on the floor.

The second type of carpet that has been put into use for probably the last 20 years is called ESD grade carpet and this is the type of carpet–usually comes in the form of a tile–that you would find in a manufacturing operation. You would find it in a place where they’re handling semiconductor, where they’re repairing computer parts. Generally speaking people wear special footwear and where the people are tested for the conductive properties of their footwear before they walk on the carpet.

The problem with this type of carpet is it has an ohms rating that puts it into the very conductive range but we’re talking about using carpet in a real world environment. We’re talking about people coming in wearing high-heeled shoes, wearing work boots, wearing flip-flops. You’re not in a situation in those environments where you have the ability to know whether you’re safe or not based on any kind of testing, so this has created a need for a third type of carpet.

What we’re calling that third type of carpet is an operational grade carpet, a carpet that can be used around energized equipment and when I say energized equipment, all I’m talking about is something that’s plugged into the wall. Could be a laptop, could be a whole series of consoles surrounding you. You could be working in a flight control tower, you could be working in a command center, a control room, but anything that’s plugged into the wall if it’s static sensitive and you want to protect the equipment at the same time as you’re reducing the possibility of a static discharge, you need to have a floor that prevents static but also allows the person to be safe.

The only difference between operational grade and ESD grade is operational grade has a built-in resistive network. That resistive network prevents grounding from occurring at such a rapid rate that you’re going to find yourself potentially in a circuit where you’re tied too closely to ground.

Not only does a static control floor have to reduce static electricity and look good but it also has to be safe.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.