Video: Conductors vs Insulators: Does it Matter?

July 31, 2017

To understand basic principles of ESD and ESD flooring, you need to understand electrical conductivity. In this video, we review the difference between conductors and insulators, tell you why conductors and insulators respond differently to static electricity, and explain why conductivity is an important property of static-control flooring.

Visit our Learning Center to find out more about what ESD flooring is and how it works.

For help or advice about choosing an ESD floor, call us on 617-923-2000, email [email protected], or visit our Guide to ESD Flooring Selection.

What is an insulator? What is a conductor? Why does it matter?

Hi, I’m Jennifer Lucchese, Senior Vice President of Staticworx.

And I’m Dave Long, Staticworx founder and president.

The terms insulator and conductor refer to the way a material behaves when electrically charged. Insulators resist the flow of electricity. In conductors, electricity flows freely.

In insulators, electrons are bound tightly to their atoms, restricting their movement. If an insulative material is electrically charged, its stationary particles block the flow of electricity, including static. So the charge stays in place, on the surface of the material. That’s why the rubbery insulative coating around electrical wires prevents shocks.

Plastics, PVC, glass, epoxy, nylon, and dry air are all excellent insulators. The soles of most shoes—often made of rubber, PVC or leather—are also mildly to highly insulative.

Conductors are the opposite of insulators. In conductors, loosely bound electrons move freely from molecule to molecule. If a conductive material becomes electrically charged, its moving particles allow the charge to flow, or dissipate, across the entire surface of the material.

Water, carbon, salt, graphite, and metals—like iron and copper—are excellent conductors. The human body, consisting primarily of water and salt, is also conductive.

Unlike insulators, conductors can be electrically grounded. In transporting electricity, conductive materials provide a pathway for currents to return to earth, or ground.

Let’s do a quick experiment to show you the difference between a conductor and an insulator.

In my hand, I’ve got two discs. One is made of metal and one is made of plastic and the handles are both plastic. In front of me, I have a static meter. What I’m going to do is rub these two discs together, and I’m going to measure them with a static meter.

As you can see, the needle moves all the way to the right when I put the plastic disc in front of the meter. That means there’s a positive charge on here. When I put the metal disc in front of the meter, the needle goes all the way to the left. That means there’s a negative charge on here. By rubbing these discs together, I’ve generated a static charge on both of them, and the charge is opposite between the two different materials.

Now what I’m going to do is find out if I can discharge these discs. So I’m going to take the plastic disc, I’m going to touch it to this piece of ordinary LVT flooring, and as you can see, even though I touched it to that surface, there’s still a charge on it. Now I’m going to take the metal disc and place it on the LVT flooring, and there’s still a charge on it. So we know that these two discs, metal and plastic, cannot be discharged when they touch this type of flooring.

Now let’s take what we call an ESD carpet. This is a carpet that has nylon, that has carbon fibers in it. Let’s take the plastic disc which still has a charge on it. Let’s touch it to the ESD carpet. The charge didn’t go anywhere. Let’s try the metal disc. The charge is gone.

Why did this discharge and not this? The reason this discharged is metal is a conductor, the carpet has conductive elements in it, and when they touch each other, they discharge. On the other hand, the plastic disc is an insulator and regardless of what I touch it to, it’s always going to have a charge because you can’t ground an insulator.

Again, due to their high electrical resistance, insulative materials cannot be grounded. Most ordinary floors are insulators.

When we walk, friction between our feet and the floor covering generates static electricity. The static charge stays on the surface of our body and jumps, or discharges, to the first person or object we touch. A doorknob, for instance. And we get zapped by a static shock.

It takes 3500 volts of static electricity for humans to feel a shock. A tiny charge, as small as 25 volts, can corrupt data, blow headsets, and damage or destroy sensitive electronic components.

To prevent damage or disruption from static—in a data center, FAA control tower, electronics manufacturing plant,or any other place where sensitive electronics are manufactured or handled—

the floor must, first, transmit static charges safely to ground.

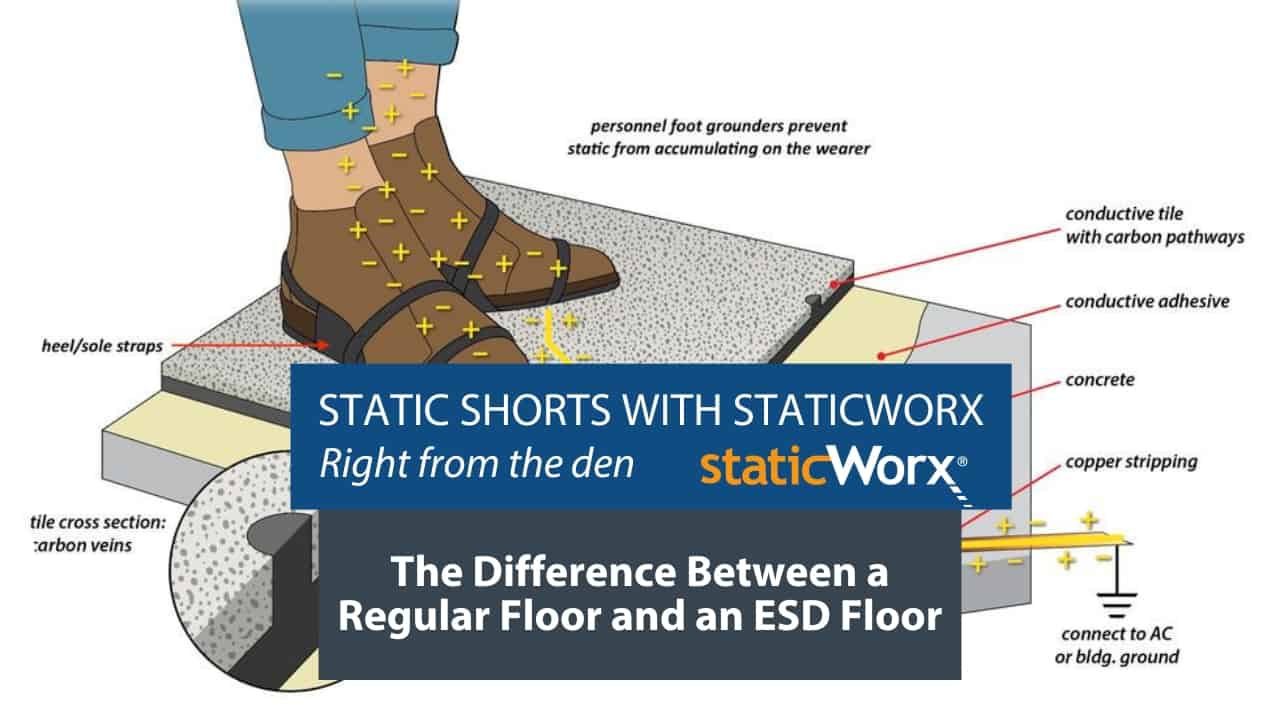

The conductive properties in static-control floors, like the ESD carpet we used in our experiment a few minutes ago, allow static charges to flow from the surface of the flooring material, through the thickness, to the conductive adhesive. The adhesive forms a conductive ground plane under the floor. Static flows across the adhesive ground plane to conductive copper strips, placed along the perimeter of the room. And the copper strips carry the charge to a grounded electrical outlet.

But, remember: electrical resistance is only one property of an effective static-control floor. To prevent static charges from building as people walk, the floor must also have low charge generation.

To learn about charge generation and why inhibiting walking body voltage is crucial to preventing damage or destruction caused by static discharge, give us a call. Or visit our website.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.