What is the best antistatic flooring option for data centers and server rooms?

Multiple factors are at play

Choosing static-control flooring for a data center involves a number of considerations. Multiple factors influence success and failure. What type of footwear will people wear while working in the space? Will personnel access open circuitry? What chairs will be used – static free or static generation?

Some ESD flooring materials made with resinous polymers or plasticizers – e.g. ESD epoxy and vinyl– provide maximum benefit when used in combination with controlled ESD-protective footwear. With regular street shoes, these floors can generate charges as people walk on the floor.

In typical data centers, footwear is not – or is usually not – controlled. For this reason it is crucial that you select a floor that will prevent static under the circumstances you anticipate as standard operating procedure in your data center.

Approaching the selection process this way enables you to inhibit static generation on anyone, anytime, regardless of humidity, the sensitivity of your systems or the application and critical nature the equipment represents to your mission or operation.

Generally speaking, the effectiveness of static-control flooring is based on:

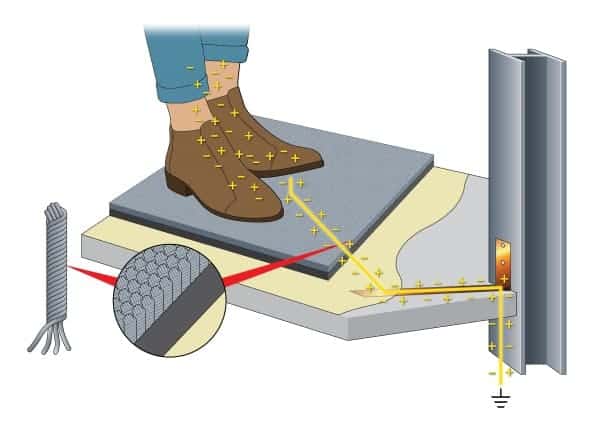

- A floor’s ability to inhibit static regardless of traffic, maintenance, humidity or the type of footwear worn by people occupying the space. This is called preventing body voltage generation aka The Walking Test. Body voltage generation is measured using test method ANSI/ESD S97.2. The test results appear in volts generated and should include measurements with and without static-control footwear to account for real-world situations.

- The intrinsic ability of the flooring system to be grounded. This is also called finding a traceable “ground path.”

This property is measured using test method ANSI/ESD STM7.1. Test results should be obtained on samples that have been preconditioned at humidity levels below 20%. An ideal data center floor will usually measure above 150,000 ohms and always below 1.0 X 10E9 ohms using this test.

When testing ESD carpet, the test should be performed on new and used carpet to determine if traffic and abuse will degrade the groundable path.

Recommended

Recommended floors are not listed in any hierarchical order. The best floor for the space depends upon the specific environmental concerns along with architectural and/or owner objectives.

ESD COATING

Groundworx Ultra generation 3 ESD urethane

Installed cost: $

- High PSI rating enables easy rolling of large systems, pallet jacks and fork lifts.

- Non porous surface is easily cleaned.

- Top coat provides decorative layer and ground plane all-in-one

- Urethane is scratch resistant.

- Available in multiple colors.

Disadvantages: does not attenuate sound, Due to cure time best to install during initial construction vs in operational space.

ESD CARPET TILE

ShadowFX static-dissipative carpet tile

Installed cost: $$.

- Can be installed with releasable adhesive over raised access panels or concrete.

- Will not generate more than ASHRAE body voltage limit of 500 volts with ordinary footwear.

- Significantly attenuates sound from cooling fans.

- Can be installed as a floating floor without adhesive.

Disadvantage: Soft surface, difficult to roll heavy equipment

CONDUCTIVE RUBBER

2-layer Eclipse (EC or GF) Rubber tile and sheet flooring.

Installed cost: $$$$

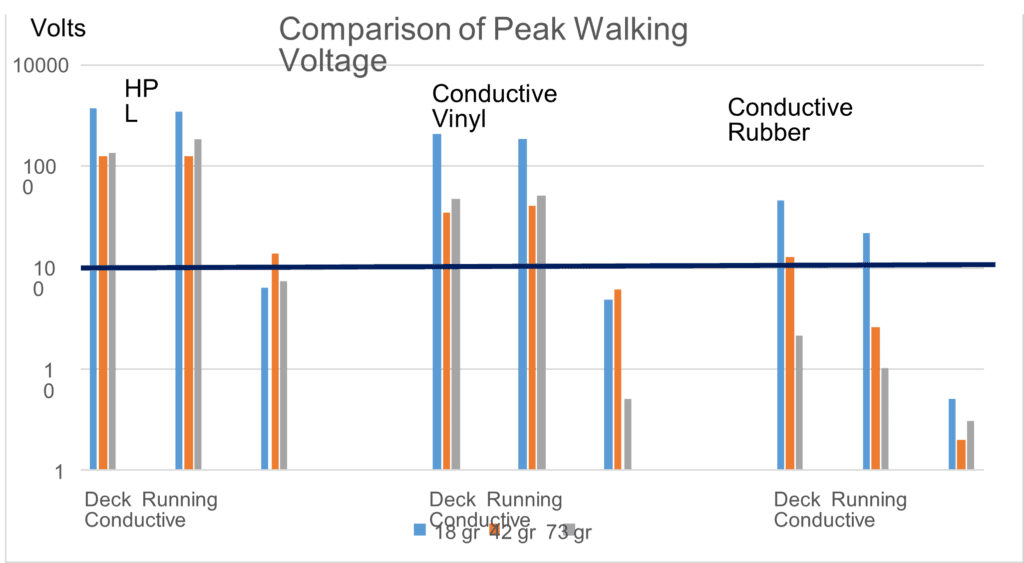

- Best performing static mitigation surface in ASHRAE ESD flooring study.

- Will not generate above ASHRAE body voltage limit of 500 volts with ordinary footwear.

- Can be installed over raised access panel or bare concrete.

- No ESD wax needed

Disadvantage: Initial cost

CONDUCTIVE SOLID VINYL TILE WITH VEIN MATRIX

Ameriworx ESD vinyl tile

Installed cost: $$$

- Hard 2500 PSI surface enables easy rolling of heavy loads.

- Available in attractive colors and patterns.

- No ESD wax ever needed.

- Can be installed over raised panels or bare concrete

Disadvantage: best when used in conjunction with static-protective footwear.

INTERLOCKING CONDUCTIVE TILE WITH HIGH DENSITY CONDUCTIVE PARTICLE DISTRIBUTION

StaticWorx GroundLock Extreme Interlocking (or Lay-flat) tile

Installed cost: $$$$

- Hard 2500 PSI surface enables easy rolling of heavy loads.

- Available in attractive colors and patterns.

- No ESD wax ever needed.

- Can be installed over raised panels or bare concrete.

- No adhesive needed.

- Can be installed in fully operation spaces with zero shutdown.

Disadvantage: expensive, best when used in conjunction with static-protective footwear.

Static-control Vinyl performs best In Conjunction

with ESD-Protective Footwear

Although static-control vinyl is a significant upgrade over traditional flooring, studies have shown that vinyl is less effective than rubber for static mitigation in environments where street shoes are typically worn.

Above from: Footwear and flooring: charge generation in combination with a person as influenced by environmental moisture by D.E. Swenson : Affinity Static Control Consulting, LLC

Floors Not Recommended

Important Note: The objective of an ESD floor—also known as an antistatic floor or static-control floor—in a data center is to mitigate static generation on personnel – regardless of humidity.

To varying degrees, all of the following floors fail to prevent static generation in all environmental conditions:

HPL, Static dissipative vinyl, ESD polish and SDT vinyl floors that rely on waxes and polish, low kV (also called computer grade) carpet, conductive generation 2 epoxy.

HPL

High pressure laminates are available in standard, static dissipative and conductive grades. None of these 3 grades of HPL mitigates static on ordinary footwear. Even the conductive version allows charge generation above 1000 volts on personnel wearing ordinary footwear.

SDT vinyl tile

SDT vinyl tile requires polish or wax to maintain its dissipative properties. ESD floor finishes wear off and can deteriorate significantly from ambient low humidity and traffic. To ensure compliance with ANSI/ESD S20.20, these must be monitored, using measurement instruments, and wax/finish reapplied regularly when degradation is detected. SDT vinyl costs the same or more than floors with permanent static-control properties.

Static-dissipative vinyl tile and sheet floors

Static-dissipative vinyl tile and sheet floors are significant static generators when walked on with ordinary footwear. When a charged person or object moves across the floor, they fail to provide an acceptable decay time. Conductive casters on ESD chairs make poor electrical contact with these types of floors. Even when used with conductive footwear SD vinyl does not provide optimal static decay properties.

Low kV carpet tile

Low kV carpet tile* does not mitigate or decay static at an acceptable level for use in equipment environments. Low kV carpet has high electrical resistance and cannot be grounded.

- Historically, low kV carpet materials were specified as meeting a standard called the IBM Burroughs test. This is a long outmoded test method that relied on testing the resistance of a floor at 500 volts. Resistance and other static-control parameters should be tested and documented based on ANSI, IEC and ASTM test methods.

Conductive Generation 2 Epoxy.

Conductive floors with a low density distribution conductive granules.

Inadequate distribution of conductive contact points on the surface means these floors cannot provide a reliable ground connection for chairs, carts and machines with conductive casters.

Generally, due to the large contact area of the 5-pound NFPA test probes, these floors will pass a standard resistance test. Statistically, the probes are large enough to make some contact with conductive particles, masking their poor reliability with smaller objects such as chair castors.

These floors perform poorly in walking tests unless the test subject is wearing protective footwear with 100% conductive shoe soles.

CHECKLIST: CHOOSING THE RIGHT STATIC-CONTROL FLOORING

-

Only static-dissipative and conductive floors can be grounded.

- Standard flooring installed with ground strips or conductive adhesive will not offer any static protection.

-

Industry standards for data centers and server rooms require floors to measure above 150,000 ohms (1.5 x 10E5) and less than 1,000,000,000 (1.0 x 10E9).

- Most StaticWorx flooring options (See Recommended) meet this guideline.

-

Any effective static-control floor can be verified with an ohm meter to determine the electrical resistance of the material.

- If the material does not pass the ohm meter test then it cannot be grounded.

-

Static-dissipative and conductive floors should be inherently conductive.

- In most cases, an ESD floor should not require antistatic sprays or waxes to enhance or maintain electrical performance. Topical finishes wear off and degrade. The floor must be monitored closely to ensure compliance with ANSI/ESD S20.20. Dissipative properties are more reliably achieved by the physical composition of the material - not by a maintenance additive or ongoing dependent process.

-

The floor should reduce static electricity regardless of relative humidity.

- Ask the supplier specifically about performance in very dry conditions (See ASHRAE study).

-

The floor must inhibit static buildup in real world conditions without special static-free shoes or shoe straps and eliminate static with special footwear.

- When in doubt, ask for independent test data verifying this property. It should be available.

- The data should be derived from installed floors and from low humidity lab tests of new flooring.

-

Never assume that a shock-free environment means a static-free environment.

- A shock-free environment only means that static charges are below 3500 volts. ASHRAE has set 500 volts or .5kV as a limit for static buildup when accessing sensitive equipment.

-

Do the homework up front.

- It is much more costly to remove an ineffective floor and replace it than it is to do it right the first time.

- Any mission-critical space is only as secure as its Achilles' heel.

-

Prepare for tomorrow. Have a plan.

- Smaller means more sensitive! Transistors in microelectronic devices inside data storage equipment are becoming more dense, smaller, faster and more sensitive. In the past 10 years, the industry has evolved from 14nm nodes to 10nm to 7nm to 5nm to anticipation studies that suggest the potential exists for 3nm and below.

As with any potential security breach, it is always best to plan ahead.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.