Understanding the Hidden Costs of ESD flooring

[20 min read]

THE GIST: Understanding the Hidden Costs of ESD Flooring

Material costs represent only part of the total cost of owning any floor, including an ESD (static-control) floor. To evaluate the full, long-term cost of the floor, it’s important to consider the cost of the floor prep and installation, as well as long-term costs to maintain and repair.

- Cost of floor prep and installation vary based on material and condition of the subfloor.

- For new installations, check the condition of the subfloor

- Check whether moisture mitigation or vapor barrier is necessary

- Floor prep may also be determined by material – e.g. an interlocking floor could be installed directly over most surfaces.

- Epoxy

- Low maintenance, durable, handles heavy loads

- Difficult and costly to repair

- Vinyl

- Lowest total cost of ownership – lower material costs, durable

- Floor must be regularly cleaned and buffed and repair costs can vary

- Carpet

- Moderate material costs, easy to maintain and repair/replace

- Durability depends upon fiber geometry

- Not suitable for heavy loads and low chemical resistance

- Rubber

- Highest material cost

- Durable, easy to maintain and repair

“The costs of installing, maintaining, and repairing a floor can add up, to the point that a more expensive, high performing floor … could ultimately cost less than a lower cost alternative. For quality-conscious as well as budget-minded buyers, it makes sense to anticipate and factor all associated costs into the long-term investment.”

Post Sections

Initial outlay is only part of the cost of an ESD floor. To understand the hidden costs of ESD flooring, it’s crucial to evaluate the total cost of owning the floor.

Need additional information about specific ESD products? Learn more about the StaticWorx ESD flooring range.

The hidden costs of some flooring materials can drive up long-term expenses.

In selecting a flooring material to eliminate the risk of electrostatic discharge (ESD), most property owners and facility managers consider price among their key concerns. The cost of ESD flooring materials varies considerably, with inexpensive thin-mil epoxy coatings at the low end of the spectrum, and architectural rubber flooring, which can cost two times as much per square foot installed, at the high end.

A price matrix comparing the materials under evaluation (taking into consideration ESD properties and other key parameters) would seem an easy way to differentiate products. But unless the matrix accounts for the total cost of owning the floor, these simple calculations can be misleading. Peripheral, sometimes unexpected, expenses associated with installation or routine maintenance of the floor can be costly—in some cases, relative to the long-term investment, the price of the material becomes almost irrelevant.

Some uninformed or first-time buyers do not understand the long-term costs of ESD floors. Or the cost of ownership isn’t as urgent a concern as other issues at hand. Sometimes, rather than spend time learning about ESD, property owners or facility managers leave ESD flooring selections to contractors or design-and-build landlords, with no stake in the long-term performance of the floor. Although building contractors usually provide the tenant or owner with a one-year warranty, their primary concern lies in bringing the project in under budget. Often, these construction professionals don’t know what to look for with regards to material quality or ESD compliance.

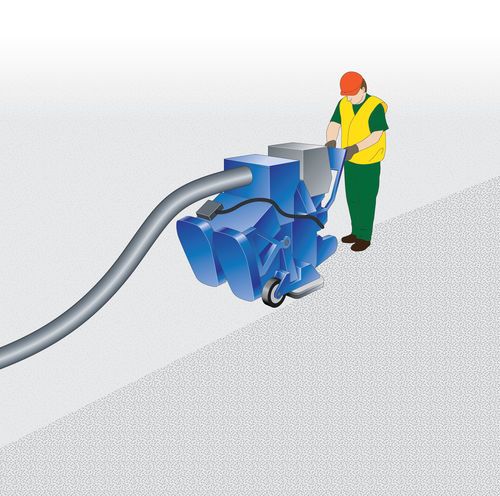

Renovations: Floor Prep and Installation

The total cost of owning any type of floor includes the initial material costs, as well as factors such as floor preparation, installation costs, regular maintenance, and future repairs.

The preparation and installation of an ESD floor differs for new projects and renovations, and also differs based on the material that will be installed. For a renovation project, buyers should ask:

- Does the old floor need to be removed?

- If an existing vinyl floor is more than 20 years old, the adhesive or the tile itself may contain asbestos. Removing a floor containing asbestos falls under EPA regulations, requiring safety precautions, including expensive remediation costs.

- Would it make sense to install the new floor over an existing floor?

- Epoxy floors should not be installed over tile: first, normal dimensional fluctuation (expansion and contraction of the old vinyl) will crack the epoxy. Second, an epoxy coating will telegraph the old seams.

- Vinyl, carpet, or rubber can be installed over old tiles when the intrinsic bond between the old tile and the subfloor is uncompromised.

The conductive adhesive under this ESD vinyl tile installed in California has re-emulsified due to vapor coming through the concrete subfloor. Does the floor have a vapor barrier?

- Subterranean vapor is one of the leading causes of installation failures. Except in rare cases, this is not a visible problem; don’t assume there is no vapor issue just because old flooring seems intact. Performing ASTM moisture tests is the only way to know if vapor could be an issue. Vapor can turn ESD adhesives into sludge, causing them to liquefy and seep through tiles, and the pressure from underground vapor can cause tiles to loosen, bubble or lift.

- An arid local climate does not mean there’s no ground vapor; some of the worst vapor problems occur in dry climates, such as Arizona, Nevada, and California.

- If there is no vapor barrier, will the floor be guaranteed?

- What happens if the floor lifts? Who will be responsible for repair or replacement if the floor fails in a year or two?

- Does furniture need to be moved or the room shutdown in order to lay the floor?

- Epoxy should be poured in small sections and the area cannot be occupied during the installation and curing time, which could take up to a week.

- Vinyl tile can be laid in sections, but heavy objects cannot be rolled over the floor for at least two days, unless the tiles have been installed with a fast-acting pressure sensitive adhesive like GroundTack™.

- Carpet tile can be walked on immediately, if installed with the glue-free GroundBridge™ interlocking installation method.

- Resilient glue-free flooring systems, such as GroundLock interlocking vinyl tile or EclipseGF, a rubber sheet-flooring material that comes with a vapor-resistant, pre-applied adhesive on the backing, can also handle immediate traffic.

New Installations: Evaluating Costs

New installations come with their own sets of costs and concerns. While removing or covering an old floor won’t be a problem, you will need to consider the condition of the subfloor or concrete under the new floor, along with moisture levels and associated moisture mitigation expenses, which can be considerable.

When evaluating the cost of new installations, buyers should ask the following questions:

- What is the condition of the subfloor? Will the floor need to be leveled or patched? Will cracks need to be filled?

- Is the new concrete adequately cured to accept floor coverings? New (green) concrete takes at least 90 days to cure. Because of its initial high water content, conductive adhesives will not adhere to green, hydrated concrete without installing the proper type of topical barrier or base coat.

- Will the floor need a moisture barrier or a special moisture-mitigating curing compound? Both can be expensive.

- Is there a vapor barrier under the concrete? According to the Rubber Institute, moisture levels should be no higher than 3 lb per 1000 sq/ft per 24 hours. Moisture levels are affected by fluctuating environmental conditions and variations in subterranean activities related to water table, drainage, and aquifer.

- A dry climate or absence of seeping water or visible moisture do not mean there’s no problem with vapor. The subfloor should always be ASTM-tested prior to installing a new floor.

- When evaluating the cost of an installation, vapor barriers must be taken into account. Most floors perform poorly or even fail when laid over a subfloor with vapor problems.

- Carpet tile is far more forgiving of moisture than epoxy, vinyl tile, and some rubber materials, and does not encourage molds, so it may be a strong solution under such conditions.

- Interlocking tile and EclipseGF glue-free rubber are also ideal for these installations.

Flooring Comparison: Options Matrix

| Flooring Options | Carpet | Vinyl | Epoxy Gen 2/Gen 3 | Rubber |

|---|---|---|---|---|

| Material Cost | Low | Lowest | Moderate | Highest |

| Durability | Not suitable for heavy loads | Excellent and easy to repair | Excellent – Scratches cannot be repaired | Good |

| Maintenance | Vacuum only | Requires wax or regular buffing | Sweep or mop | Easily cleaned. Mop with soap and water. |

| Installation | Easiest | Average | Average | Average |

| Slip resistance | Greater than 0.6 | 0.5-0.6 | Greater than 0.5 | Greater than 0.6 |

| Chemical resistance | Poor | Good | Superior | Superior |

| Acid, alkali, and solvent resistance | Poor | Good | Excellent | Excellent |

| Sound absorption | Excellent | 4dB | Not sound resistant | 5-19dB |

| Antifatiguing | Excellent | No | No | Good |

| PSI | N/A | 2500 | > 3000 | 600-850 |

| Plasticizer (off-gas) | N/A | Varies – Dependent on manufacturer | None | None |

| Wear layer | N/A | Full thickness | Top Only/Full Thickness | Total thickness |

| Color through, not surface (helps hide scratching) | N/A | No | Yes | Yes |

| Halogen free, no chlorine, no corrosive gases in fire | Yes | No | Yes | Yes |

| Color consistency for projects of any size | Yes | Yes | Yes | Yes |

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Maintenance and Repair

Epoxy

ESD epoxy offers very low maintenance. Like rubber, epoxy requires only regular washing.

Epoxy coatings can be the most durable of ESD floor finishes—offering the look of glass and the hardness of concrete. As epoxy supports heavy loads, it works well in areas with heavy forklift traffic. On the other hand, if dropped on the floor, pointed or jagged tools or equipment can scratch or gouge epoxy coatings, requiring expensive, sometimes complicated repairs.

Costly and Difficult to Repair

Replacement requires professional, specially trained applicators. The entire floor must be recoated, which requires evacuation of all personnel, furniture, and machinery from the area under construction, with shutdowns sometimes lasting upwards of a week.

Routine Maintenance and Durability

ESD epoxy offers very low maintenance. Like rubber, epoxy requires only regular washing.

Epoxy coatings can be the most durable of ESD floor finishes—offering the look of glass and the hardness of concrete. As epoxy supports heavy loads, it works well in areas with heavy forklift traffic. On the other hand, if dropped on the floor, pointed or jagged tools or equipment can scratch or gouge epoxy coatings, requiring expensive, sometimes complicated repairs.

Unlike with vinyl, buffing will not remove scratches and micro-abrasions, caused by casters, in epoxy coatings. Epoxy’s vulnerability to scrapes, gouges, and scratches explains why experienced facilities engineers describe epoxy floors as being at their very best the day before the space is occupied.

Costly and Difficult to Repair

Epoxy is notoriously hard to repair or replace. Due to shading caused by ultraviolet light and normal environmental conditions, it’s nearly impossible to match an older epoxy floor with a new or repair coating.

Replacement requires professional, specially trained applicators. The entire floor must be recoated, which requires evacuation of all personnel, furniture, and machinery from the area under construction, with shutdowns sometimes lasting upwards of a week.

Vinyl

Routine Maintenance

If maintenance costs are well controlled, because of its durability and low material cost, vinyl offers the lowest cost of ownership.

Most suppliers of ESD vinyl discourage waxing the floor, recommending occasional buffing instead. Many janitorial companies, however, believe that it is more profitable for them to use ESD waxes over ESD vinyl floors than to dry buff. Applications of ESD-formulated spray and buff wax can last up to several weeks.

While buffing will shine a vinyl floor, buffed vinyl doesn’t wear as well as a hard finish. Vinyl products contain a matrix of conductive material within the substrate. Regular buffing wears the finish down.

Buffing is also labor-intensive. Although labor costs vary by location, labor can be expensive. And some companies find that, in order to maintain their standards for appearance, the janitorial service must buff the floor weekly. Public spaces, such as grocery stores, show what happens when vinyl surfaces are not kept up.

With waxing, there are several hidden costs and concerns to take into account:

- ESD waxes increase the electrical resistance of conductive vinyl floors. After several coats of ESD floor finish, the conductive floor may no longer measure in the acceptable resistance range. This condition would necessitate removing the built-up ESD wax.

- Strippers are required to remove old ESD wax, which means the area must be evacuated prior to cleaning. The cost of stopping late-shift operations whenever the floor needs buffing should be factored into any cost equation.

Recently, a more effective maintenance method has been developed that provides a high shine, inhibits dirt retention, and has no negative impact on conductivity. The process uses Formula 20.20, a simple spray cleaning emulsion, that is buffed into the floor at relatively low RPM and seals the floor, preventing it from gathering contaminants, which makes the floor easier to maintain.

Removing Damaged Tile

Removing damaged vinyl tiles ranges from easy to difficult, depending on the adhesive holding the tiles. Some repairs require a propane torch to heat the tile. Once heated, the adhesive must be scraped and new adhesive laid down and cured before new tile can be installed. The area under repair must be kept traffic-free throughout the repair and adhesive curing time, which, depending upon the type of tile and adhesive, could range from a couple of hours to a week or more.

Other types of ESD tile are adhered with easy-to-use, fast-acting, pressure-sensitive conductive adhesives like GroundTack™. This type of installation enables easy repairs with no downtime associated with adhesive cure and dry times.

Routine Maintenance

If maintenance costs are well controlled, because of its durability and low material cost, vinyl offers the lowest cost of ownership.

Most suppliers of ESD vinyl discourage waxing the floor, recommending occasional buffing instead. Many janitorial companies, however, believe that it is more profitable for them to use ESD waxes over ESD vinyl floors than to dry buff. Applications of ESD-formulated spray and buff wax can last up to several weeks.

While buffing will shine a vinyl floor, buffed vinyl doesn’t wear as well as a hard finish. Vinyl products contain a matrix of conductive material within the substrate. Regular buffing wears the finish down.

Buffing is also labor-intensive. Although labor costs vary by location, labor can be expensive. And some companies find that, in order to maintain their standards for appearance, the janitorial service must buff the floor weekly. Public spaces, such as grocery stores, show what happens when vinyl surfaces are not kept up.

With waxing, there are several hidden costs and concerns to take into account:

- ESD waxes increase the electrical resistance of conductive vinyl floors. After several coats of ESD floor finish, the conductive floor may no longer measure in the acceptable resistance range. This condition would necessitate removing the built-up ESD wax.

- Strippers are required to remove old ESD wax, which means the area must be evacuated prior to cleaning. The cost of stopping late-shift operations whenever the floor needs buffing should be factored into any cost equation.

Recently, a more effective maintenance method has been developed that provides a high shine, inhibits dirt retention, and has no negative impact on conductivity. The process uses Formula 20.20, a simple spray cleaning emulsion, that is buffed into the floor at relatively low RPM and seals the floor, preventing it from gathering contaminants, which makes the floor easier to maintain.

Removing Damaged Tile

Removing damaged vinyl tiles ranges from easy to difficult, depending on the adhesive holding the tiles. Some repairs require a propane torch to heat the tile. Once heated, the adhesive must be scraped and new adhesive laid down and cured before new tile can be installed. The area under repair must be kept traffic-free throughout the repair and adhesive curing time, which, depending upon the type of tile and adhesive, could range from a couple of hours to a week or more.

Other types of ESD tile are adhered with easy-to-use, fast-acting, pressure-sensitive conductive adhesives like GroundTack™. This type of installation enables easy repairs with no downtime associated with adhesive cure and dry times.

Carpet Tile

ESD carpet tiles are easy to maintain and repair. The material cost is on the lower end of the range and tiles are easily replaced, giving carpet tile a comparatively low total cost of ownership.

Chosen correctly, carpet tile can provide many years of service. When seeking longevity in high-traffic environments, the best designs feature random non-directional patterns. These patterns hide seams and provide a visual appearance that utilizes mixed textures and shapes to prevent wear patterns from showing.

Maintenance

Carpet tiles require regular vacuuming and, depending upon the application, traffic, and environmental conditions, annual (or more frequent) steam cleaning. The labor cost for steam cleaning is relatively low, and regular vacuuming is easy and cheap, especially when handled by in-house personnel.

When evaluating carpet construction and durability, particularly for 24/7 spaces and other heavily trafficked areas, it’s important to understand the role of fiber geometry, measured as modification ratio. The rule of thumb, when looking at durability and long-term appearance, is to avoid mill-branded yarns, typically made in house to cut costs, and stick with carpet tiles using premium yarn from third-party fiber manufacturers, such as Universal, Invista and Aquafil.

The ideal modification ratio for heavy-traffic and 24/7 spaces is less than 2.0.

ESD carpet tile is factory-tested for durability. With the right modification ratio, carpet wears well in medium- to severe-traffic areas, such as mission-critical spaces or call centers. Carpet tile with a high modification ratio is vulnerable to soiling and fiber crush, making it unsuited for high-traffic spaces within manufacturing operations, or in areas like 9-1-1 call centers where roller-caster chairs are used 24 hours per day.

Easy to Repair

Carpet tiles do not require professional installation or repair: modular tiles are easily replaceable by a regular maintenance crew. 18- and 24-in. tiles can be easily removed and replaced into the conductive-releasable adhesive without tools and with no special skills. Carpet adhesive dries in less than an hour and can remain uncovered for several days during installation. Glue-free installations done with a GroundBridge underlayment can be repaired in a matter of minutes by anyone in the building, regardless of flooring experience.

Broadloom carpet and older carpet tile designs had problems with dye-lot variation. Some manufacturers now use a computer-generated process to match yarn colors. The dye lots are called mergeable, meaning new carpet purchased in the future will match the existing carpet tile, and individual tiles can be replaced without having to recarpet the entire room. Keeping a small supply of carpet tiles on hand ensures uniformity, as well as immediate replacement.

Finally, always pay attention to design. Far and away the most low-maintenance carpet tile has what we call “random non-directional” (RND) patterns. RND designs can be laid in any order or direction, and hide wear and seams, increasing the lifecycle of the carpet by about 40%.

ESD carpet tiles are easy to maintain and repair. The material cost is on the lower end of the range and tiles are easily replaced, giving carpet tile a comparatively low total cost of ownership.

Chosen correctly, carpet tile can provide many years of service. When seeking longevity in high-traffic environments, the best designs feature random non-directional patterns. These patterns hide seams and provide a visual appearance that utilizes mixed textures and shapes to prevent wear patterns from showing.

Maintenance

Carpet tiles require regular vacuuming and, depending upon the application, traffic, and environmental conditions, annual (or more frequent) steam cleaning. The labor cost for steam cleaning is relatively low, and regular vacuuming is easy and cheap, especially when handled by in-house personnel.

Durability

When evaluating carpet construction and durability, particularly for 24/7 spaces and other heavily trafficked areas, it’s important to understand the role of fiber geometry, measured as modification ratio. The rule of thumb, when looking at durability and long-term appearance, is to avoid mill-branded yarns, typically made in house to cut costs, and stick with carpet tiles using premium yarn from third-party fiber manufacturers, such as Universal, Invista and Aquafil.

The ideal modification ratio for heavy-traffic and 24/7 spaces is less than 2.0.

ESD carpet tile is factory-tested for durability. With the right modification ratio, carpet wears well in medium- to severe-traffic areas, such as mission-critical spaces or call centers. Carpet tile with a high modification ratio is vulnerable to soiling and fiber crush, making it unsuited for high-traffic spaces within manufacturing operations, or in areas like 9-1-1 call centers where roller-caster chairs are used 24 hours per day.

Easy to Repair

Carpet tiles do not require professional installation or repair: modular tiles are easily replaceable by a regular maintenance crew. 18- and 24-in. tiles can be easily removed and replaced into the conductive-releasable adhesive without tools and with no special skills. Carpet adhesive dries in less than an hour and can remain uncovered for several days during installation. Glue-free installations done with a GroundBridge underlayment can be repaired in a matter of minutes by anyone in the building, regardless of flooring experience.

Broadloom carpet and older carpet tile designs had problems with dye-lot variation. Some manufacturers now use a computer-generated process to match yarn colors. The dye lots are called mergeable, meaning new carpet purchased in the future will match the existing carpet tile, and individual tiles can be replaced without having to recarpet the entire room. Keeping a small supply of carpet tiles on hand ensures uniformity, as well as immediate replacement.

Finally, always pay attention to design. Far and away the most low-maintenance carpet tile has what we call “random non-directional” (RND) patterns. RND designs can be laid in any order or direction, and hide wear and seams, increasing the lifecycle of the carpet by about 40%.

Rubber

As regular washing is sufficient, rubber is the easiest and most cost-effective product to maintain.

Vulcanized rubber, used in ESD tiles and sheet flooring, requires minimal upkeep. Rubber flooring is manufactured under high pressure, with the material tightly cross-linked, making it impervious to dirt retention. Unlike vinyl, rubber contains no plasticizers. Plasticizer migration, akin to material evaporation, is the cause of porosity in all kinds of plastic and vinyl flooring. Free of plasticizers, rubber never becomes porous, making it is easier to clean than vinyl.

As regular washing is sufficient, rubber is the easiest and most cost-effective product to maintain.

Durability

Physical characteristics such as elasticity enable a rubber floor to handle abusive applications in which pallet jacks and forklifts often dent or crack more-brittle materials.

Ergonomics and Liability

Rubber provides a softer walking surface than ESD vinyl or epoxy, making it an ideal material in areas where personnel are required to be on their feet for long periods of time.

Rubber’s inherent high coefficient of friction meets all ADA requirements, reducing the possibility of slips and falls associated with hard, slippery, or super-shiny floors. Given that employee falls cost employers $70 billion in medical and worker’s compensation expenses each year, its slip-resistant properties alone make rubber a good value. Rubber also has the same coefficient of friction whether wet or dry.

Durability

Physical characteristics such as elasticity enable a rubber floor to handle abusive applications in which pallet jacks and forklifts often dent or crack more-brittle materials.

Ergonomics and Liability

Rubber provides a softer walking surface than ESD vinyl or epoxy, making it an ideal material in areas where personnel are required to be on their feet for long periods of time.

Rubber’s inherent high coefficient of friction meets all ADA requirements, reducing the possibility of slips and falls associated with hard, slippery, or super-shiny floors. Given that employee falls cost employers $70 billion in medical and worker’s compensation expenses each year, its slip-resistant properties alone make rubber a good value. Rubber also has the same coefficient of friction whether wet or dry.

Highest Rated ESD Flooring Material

A study conducted over a two-year period by Lucent Technologies (completed in 1996) rated rubber flooring highest when subjective and non-bottom-line factors such as appearance, ergonomics, and ease-of-care were part of the selection criteria.

Conclusion

The cost of the flooring material is only the first of many expenses associated with owning any floor, regular or ESD. The costs of installing, maintaining, and repairing a floor can add up, to the point that a more expensive, high performing floor, such as conductive (EC) rubber, could ultimately cost less than a lower cost alternative. For quality-conscious as well as budget-minded buyers, it makes sense to anticipate and factor all associated costs into the long-term investment.

If selection of an ESD floor is left in the hands of design-and-build construction specialists, short-term factors such as low material price and speed of installation will always prevail. When flooring is selected without calculating total cost of ownership—including unexpected installation costs, routine maintenance, and repair or replacement of damaged floors or floor tiles—it’s the property owner or facility manager who’s left holding the bag.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.