7 Common Mistakes in Selecting ESD Flooring

[23 min read, 7 min videos]

THE GIST: 7 Common Mistakes in Selecting Static-Control Flooring

ESD standards vary across industries. This and a lack of technical knowledge can make choosing an ESD floor confusing. In this post, we describe the 7 mistakes we most often see in the field. These mistakes prevent the buyer from selecting the right ESD floor for a particular application – or leave the buyer vulnerable to flooring failure and/or deficiencies in warranty coverage. In this post, we offer information and advice to help you avoid those common mistakes.

Misuse of terms: technical terms like conductive, dissipative, antistatic are not the same, and ESD flooring is a generic term without a universally agreed-upon meaning.

- Solution: Before writing a spec be sure you’re familiar with the terminology. If not, research the terms in our glossary or any recognized ESD glossary.

- Relying on the Internet: Information found on the internet is not always true.

- Solution: Ask questions; require lab data or other verifiable information.

- Using an unfamiliar flooring contractor: to save money, people sometimes hire an unknown contractor or a flooring installer they found on an internet search.

- Solution: Hire locally. Local contractors, interesting in doing all of the client’s flooring work, may be more reliable than a one-off installer. Installing ESD flooring is not black magic: it’s essentially the same as installing a regular floor.

- Heavy reliance on warrantees: buyers forget to read the fine print and are surprised to find they’re not covered for certain problems or flooring failures.

- Solution: Evaluate the supplier’s integrity and financial stability. Ask questions, call references, check bond and insurance information.

- Overlooking site conditions: often, flooring failures are the direct result of poor site conditions – e.g. contaminated concrete and moisture vapor drive.

- Solution: before installing the floor, test and evaluate the subfloor; never ignore defects or marginal vaporreadings.

- Overlooking total cost of ownership: initial material and installation costs are only part of the total cost of the floor. Maintenance, installation and repair can add up.

- Solution: Before purchasing an ESD floor, evaluate durability and long-term electrical performance. Consider cost of maintenance and repair over time.

- Specifying the wrong product: ESD standards vary across industries. And to perform properly, some ESD floors require the use of special ESD footwear.

- Solution: Refer to industry standards. Test the floor according to standard test methods and be sure it meets industry-specific standards. Evaluate footwear: test and qualify ESD floors as a flooring system – i.e., test the flooring material with the subject wearing any shoes to be worn in the space.

ESD standards vary across industries. This and a lack of technical knowledge can make choosing an ESD floor confusing. In this post, we describe the 7 mistakes we most often see in the field. These mistakes prevent the buyer from selecting the right ESD floor for a particular application – or leave the buyer vulnerable to flooring failure and/or deficiencies in warranty coverage. In this post, we offer information and advice to help you avoid those common mistakes.

Misuse of terms: technical terms like conductive, dissipative, antistatic are not the same, and ESD flooring is a generic term without a universally agreed-upon meaning.

- Solution: Before writing a spec be sure you’re familiar with the terminology. If not, research the terms in our glossary or any recognized ESD glossary.

- Relying on the Internet: Information found on the internet is not always true.

- Solution: Ask questions; require lab data or other verifiable information.

- Using an unfamiliar flooring contractor: to save money, people sometimes hire an unknown contractor or a flooring installer they found on an internet search.

- Solution: Hire locally. Local contractors, interesting in doing all of the client’s flooring work, may be more reliable than a one-off installer. Installing ESD flooring is not black magic: it’s essentially the same as installing a regular floor.

- Heavy reliance on warrantees: buyers forget to read the fine print and are surprised to find they’re not covered for certain problems or flooring failures.

- Solution: Evaluate the supplier’s integrity and financial stability. Ask questions, call references, check bond and insurance information.

- Overlooking site conditions: often, flooring failures are the direct result of poor site conditions – e.g. contaminated concrete and moisture vapor drive.

- Solution: before installing the floor, test and evaluate the subfloor; never ignore defects or marginal vaporreadings.

- Overlooking total cost of ownership: initial material and installation costs are only part of the total cost of the floor. Maintenance, installation and repair can add up.

- Solution: Before purchasing an ESD floor, evaluate durability and long-term electrical performance. Consider cost of maintenance and repair over time.

- Specifying the wrong product: ESD standards vary across industries. And to perform properly, some ESD floors require the use of special ESD footwear.

- Solution: Refer to industry standards. Test the floor according to standard test methods and be sure it meets industry-specific standards. Evaluate footwear: test and qualify ESD floors as a flooring system – i.e., test the flooring material with the subject wearing any shoes to be worn in the space.

Always ask about the advantages and disadvantages of the materials under consideration. After all, no ESD flooring product is perfect or universally applicable for every application.

Post Sections

Most ESD flooring failures and liabilities stem from 7 avoidable mistakes. Find out what they are & how you can easily escape these common pitfalls.

Need additional information about specific ESD products? Visit our product section.

In the past, ESD floors, designed to serve a utilitarian purpose in static-sensitive work spaces, were available in a handful of unattractive colors. Today, manufacturers produce a variety of ESD flooring materials, in attractive colors and designs inspired by nature.

Great to have so many choices! But, with myriad options, selecting the right static-control floor can be confusing for the novice, and sometimes even for experienced engineers or architects.

Choosing the wrong floor can be worse than having no static protection at all.

Part of the confusion stems from the fact that different environments require different solutions. Conductive vinyl, for example, works well in an electronics manufacturing services (EMS) environment, where standard operating procedures mandate the diligent use of static-control footwear. In mission-critical data or call centers, there are no mandates to control footwear. Minus ESD footwear, the same vinyl floor will actually generate enough static to corrupt data, blow headsets, and damage sensitive electronic components.

Further complicating matters is a general lack of knowledge about static-control specifications and standards—exacerbated by the trove of information (reliable as well as not) and contradictory data available on the web. No wonder designers and specifiers often make the same common mistakes when selecting static-control flooring materials.

Mistake #1: Unfamiliarity with Static-Control Terms

In sales pitches and marketing materials, sellers use a number of terms to describe static-control flooring: conductive, dissipative, antistatic, and ESD being the most commonly misused. Often used as if they were synonymous, these terms are not interchangeable.

Designating a flooring material as antistatic does not necessarily mean the floor can be grounded. Some so-called “antistatic” materials, such as low kV computer-grade carpet, inhibit static generation but lack the conductive properties necessary to ground the floor.

Note: The term “antistatic” has recently lost favor to the more accurate term “low charge generating“.

Calling a floor “ESD flooring”–a generic term encompassing all types of static-control floors—is the same as saying, we need a floor because we have an ESD problem.

Solution

Before writing a specification, designers and specifiers should have a fundamental understanding of static-control terminology. Referencing one of the numerous ESD industry glossaries should eliminate most of the confusion regarding simple terminology.

Definitions for the following key terms can be found in our Static-Control Glossary.

DO familiarize yourself with static-control flooring terminology and have at least a general understanding of standards and specifications.

Mistake #2: Believing Internet Hype

The Internet is only as good as the researcher doing the research. Too many people assume that, if it’s published on the web, it must be true. Remember: any individual can publish anything on his or her own website, whether or not the information is accurate.

Solution

Ask Questions

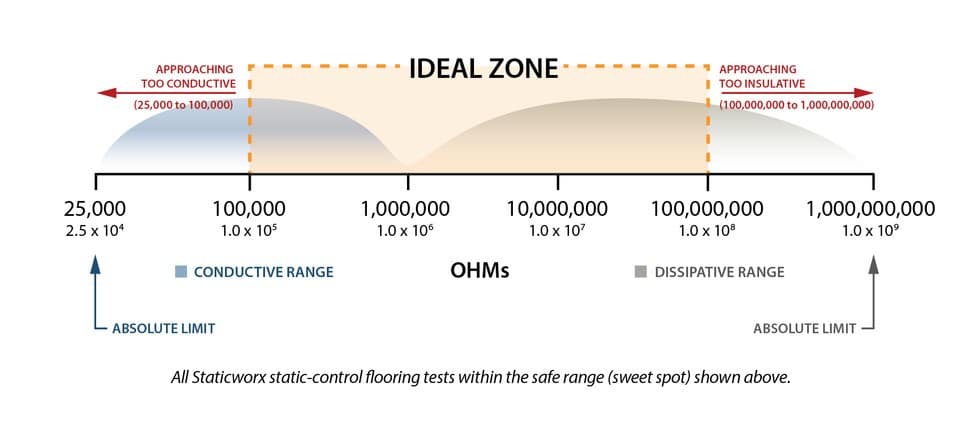

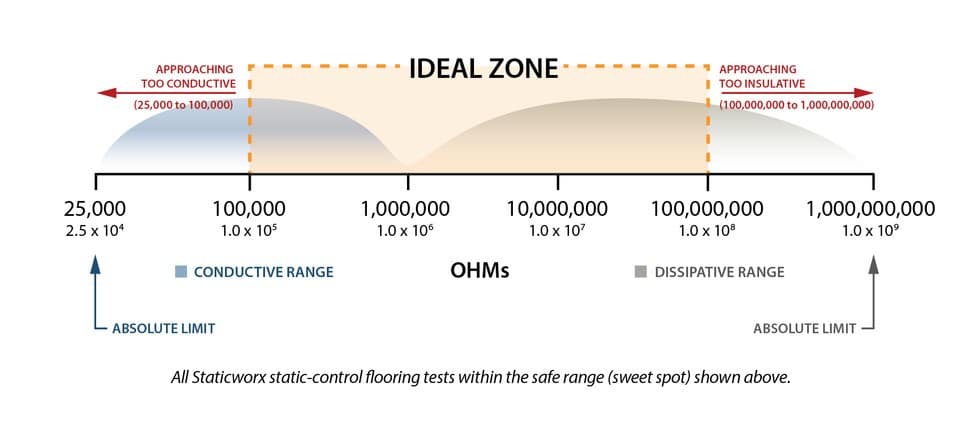

Beware of any claims that are not supported with independent, objective references to standardized test methods that count, quantify, qualify, differentiate or identify performance parameters by some objective, universally accepted scale or longitudinal performance criteria. For example, if you read, “this floor is best for extreme static-control applications due to its high level of conductivity,” ask the supplier for the lab data supporting the claim. Most grounding standards view higher levels of conductivity as a disadvantage, because a high conductivity poses an unnecessary danger to personnel working in the area.

Remember: Stating that an ESD floor will meet ANSI/ESD S20.20 is not a legitimate stand-alone claim. ANSI/ESD S20.20 is a process document, not a test standard.

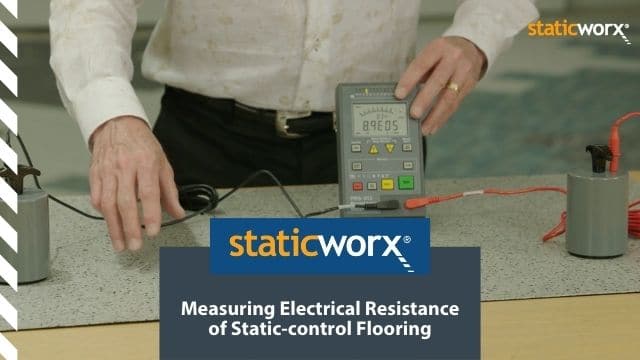

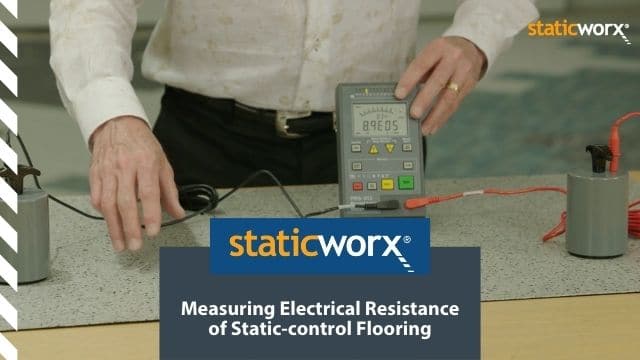

Specifications are meaningless unless they’re derived from respected, reliable, objective sources. The two most important ESD test methods for qualifying flooring are:

Ask Questions

Be aware of hyperbole and meaningless platitudes. Question any source that describes products as having infinite conductivity, offers “unparallelled” performance, or says any property will last “forever.” If a claim seems inconsistent with information you see elsewhere or strikes you as too good to be true, it probably is.

Beware of any claims that are not supported with independent, objective references to standardized test methods that count, quantify, qualify, differentiate or identify performance parameters by some objective, universally accepted scale or longitudinal performance criteria. For example, if you read, “this floor is best for extreme static-control applications due to its high level of conductivity,” ask the supplier for the lab data supporting the claim. Most grounding standards view higher levels of conductivity as a disadvantage, because a high conductivity poses an unnecessary danger to personnel working in the area.

Remember: Stating that an ESD floor will meet ANSI/ESD S20.20 is not a legitimate stand-alone claim. ANSI/ESD S20.20 is a process document, not a test standard.

Specifications are meaningless unless they’re derived from respected, reliable, objective sources. The two most important ESD test methods for qualifying flooring are:

- ESD STM7.1-2013–This standard test method provides procedures for measuring the electrical resistance of floor materials used for the control of electrostatic charge and discharge. It also provides test methods for the qualification of floor materials prior to their installation or application, as well as test methods for acceptance and monitoring of floor materials after installation or application.

- ESD STM97.2–Floor Materials and Footwear— This document establishes test methods for the measurement of the voltage on a person in combination with floor materials and static-control footwear, shoes or other devices.

Voltage Measurement Tested in Combination with a Person. No ESD flooring material should allow the generation of more than 100 volts when tested in conjunction with a person wearing controlled (conductive) footwear. When evaluating flooring for mission-critical applications, tests should be conducted with the human subject wearing all types of conventional footwear (athletic shoes, work boots, leather shoes, etc.) to be worn in the space.

Scrutinize and Cross-check Data.

ESD flooring test results referencing ESD Association standards should be available from an independent test lab. When evaluating performance data, the results of independent lab reports should always be viewed as more credible than supplier-generated data and descriptive performance claims found in marketing materials.

The same is true for articles, blog posts or website editorials that offer opinions and comparisons. When evaluating technical information, look for articles that originally appeared in respected industry journals. Unlike the information in website advertorials, published articles are subjected to professional editorial review before they are published.

Do look for independent test reports and articles published by respected trade journals or industry associations, including National Emergency Number Association (www.nena.org), and EOS/ESD Association (www.esda.org).

Mistake #3: Using an Unfamiliar Flooring Installer

Some buyers believe they can save money or gain technical advantages by hiring a static-control flooring installer or contractor they found in a Google search. Mistakenly, they believe a web company, perhaps marketed as specializing in static-control, will know more than a conventional and local flooring contractor about installing flooring in their facility. In fact, the opposite is typically the case.

Most general contractors would never hire an unfamiliar installer, for a number of reasons. First, there’s no reason to hire a sub-contractor they don’t know or have never worked with. Other than following simple grounding procedures and using conductive adhesives, there is little difference between installing conventional flooring and static-control flooring.

Laws vary. In some states, it’s permissible to hire laborers who are not bonded and have no worker’s compensation insurance. Other states, including West Virginia, California, Nevada, Oregon and Arizona, do not permit construction labor by unlicensed, out-of-state contractors.

In a litigious society, it doesn’t make sense to use a contractor with no regional office or local representation. What happens if there are problems after the job has been completed? Who will handle ongoing installation, warranty work, and repairs?

Few installations are complete after the last tile is placed or grounding strips are bonded to building steel. Often, tiles are damaged by moving equipment and must be reinstalled.

If the installer leaves as soon as the floor install has been completed, who will certify its static-control properties?

The certification of electrical properties should not be finalized for at least several days after the installation is complete—i.e., when the floor or adhesive is fully cured.

And what about insurance?

According to the National Safety Council, slips, trips and falls are one of the most common and costly workplace incidents—costing businesses $11 billion in 2014 alone.

Again, some states do not require contractors to provide worker’s compensation insurance. No cost savings from hiring out-of-town laborers could possibly compensate for damages from one accidental liability claim filed by an employee who, for any reason, was injured after tripping over a poorly installed tile.

Solution

Hire Locally

As with any construction project, it usually makes sense to hire locally. Local contractors are reliable in part because they’re interested in obtaining all of their customer’s flooring business, not just in a one-shot deal involving a few thousand feet of conductive flooring.

ESD flooring installation is not some kind of black art. ESD floors are no more difficult to install than ceramic flooring, regular carpet or conventional tile. In many cases, larger electronics manufacturers utilize members of their own in-house facilities department for their static-control flooring installation. Grounding is simple, new carbon-free conductive adhesives are easy to spread, and clean-up is usually done with soap and water.

DO ask flooring manufacturers for names of local, approved and experienced installers. If the manufacturer can’t confidently recommend an installer, find a different manufacturer.

Hire Locally

As with any construction project, it usually makes sense to hire locally. Local contractors are reliable in part because they’re interested in obtaining all of their customer’s flooring business, not just in a one-shot deal involving a few thousand feet of conductive flooring.

ESD flooring installation is not some kind of black art. ESD floors are no more difficult to install than ceramic flooring, regular carpet or conventional tile. In many cases, larger electronics manufacturers utilize members of their own in-house facilities department for their static-control flooring installation. Grounding is simple, new carbon-free conductive adhesives are easy to spread, and clean-up is usually done with soap and water.

DO ask flooring manufacturers for names of local, approved and experienced installers. If the manufacturer can’t confidently recommend an installer, find a different manufacturer.

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Mistake #4: Relying Too Heavily on Warranties

While it’s reassuring to have a long-term warranty in hand, many buyers forget to read the fine print. Assuming the warranty covers the life of the floor, they figure they’ll be compensated for any problems encountered down the road. But what good is a lifetime warranty if it excludes the most common causes of product failure? Lifetime warranties on some popular brands of carpet exclude pile crush, for instance—the single biggest reason carpets fail.

The financial stability of the warrantor is another factor buyers sometimes overlook. Warranties are only as good as the financial backbone of the warrantor (sometimes their supplier as well). Any warranty becomes null and void if the supplier is out of business a few years after the floor was installed—when problems typically arise. If the supplier is no longer in business, what happens if the floor begins delaminating or losing conductivity?

Although asking for references seems like a good idea, references are only as good as the objectivity and experience of the company or individual providing the reference. As with evaluating a job applicant, due diligence could save a lot of money downstream.

Solution

The best insurance against future problems is not just a long-term warranty, but rather, a detailed evaluation of both the product and the contractor under consideration.

When evaluating a supplier’s integrity and financial stability, consider doing the following:

- Ask how many years the supplier has been in business: A supplier with many successful years of service may be more stable than a new business, indicating that their warranty might have some value.

- Ask for a factory visit. You can learn a lot about a vendor by investigating their supply chain. How many steps are they removed from the actual source? Are they the source? Is there one factory or do they deal with suppliers like a deck of cards, working with whichever manufacturer offers them the most value at the moment?

- Find out if the contractor can be bonded: Insurance companies will only provide bonds to contractors with solid financial and performance history. Comparing a contractor’s bond rate with that of other contractors will usually reveal information that won’t show up on a simple reference or credit check.

- When evaluating a prospective flooring supplier, ask about old installations: Most customers are happy when their floor is new. That’s why it’s important to check satisfaction levels two to three years after the floor has been installed.

DO thoroughly evaluate your supplier. Call references, check credit history, check the suppliers bond and insurance information, and ask about old installations.

Mistake #5: Failing to Investigate Site Conditions

These tests can be arranged by the flooring supplier and should be performed by a local, certified contractor. Often, contaminated slabs can be salvaged by double shot-blasting. Moisture problems can be alleviated by installing topical moisture barriers, moisture resistant sheet flooring or roll-type underlayments such as Kovara.

Solution

Before agreeing to a firm price from any flooring contractor, ask the following questions:

- What is the condition of the subfloor? Will the floor need to be leveled or patched? Are there cracks that need to be filled?

- Is the concrete ready for use? New (green) concrete takes a minimum of 90 days to cure and often longer. Because of its high moisture content, conductive adhesives will not adhere properly to new (green) concrete without some type of coating or vapor-mitigation system.

According to experts in the resilient flooring industry, the moisture levels of a subfloor should be no higher than 75% RH, per ASTM 2170 in sutu probe test method. - Do environmental/site conditions necessitate a moisture barrier or special moisture-mitigating curing compound? Along with the subfloor, environmental conditions of the building site—the conditions under and around the subfloor—should also be evaluated. Moisture varies according to fluctuating environmental conditions, topography and variations in subterranean activities related to water table, drainage, and aquifer.

While seemingly obvious, moisture is not always immediately evident: Certain dry environments, in places like Colorado, Arizona and California, experience some of the worst vapor problems in North America.

When evaluating flooring costs, the potential need for vapor barriers must be taken into account. While moisture mitigation can be costly, installing a moisture barrier after the floor fails will far exceed the costs of alleviating problems upfront. - Perform ASTM F-2170 – Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In-Sutu Probes: This test shows the relative humidity of the concrete slab over time. The maximum relative humidity should be below 75%.

- Perform ASTM F-1869 – Standard Test Method for Measuring Moisture Vapor Rate of Concrete Subfloor Using Anhydrous Calcium Chloride: The maximum allowed transmission rate is 3 pounds per 1000 square feet per 1,000 square feet.

- Perform ASTM-D4263 – Plastic Sheet Test: This is a visual test – not quantifiable – that may provide an indication of the presence of moisture.

DO test and evaluate every sub-floor properly—regardless of previous experience—before flooring is installed, and never ignore defects or marginal moisture vapor readings. If the building will be purchased or leased, it’s a good idea to perform this testing prior to signing any real estate agreements.

Mistake #6: Overlooking Total Cost of Ownership

The initial material and installation costs are only part of the total cost of owning a static-control floor. Every floor, whether standard or ESD, requires some kind of maintenance and repair. Over five years, these maintenance and repair costs can be significant. Calculated over the long-run, a less expensive floor may actually cost a lot more than a pricier option.

- Vinyl floors are the most difficult and costliest to maintain. Vinyl is extremely durable and, in most cases, requires minimal repair; however, maintenance could be pricey.

Beware of any claims that describe vinyl floors as having special factory-applied glazes that never need to be waxed. Never-needs-wax usually means always-needs-buffing. Regular buffing is just as costly as waxing. - Carpet tile requires periodic vacuuming and yearly wet or dry extraction. In clean areas, such as data centers and control rooms, carpet tile maintenance is extremely low. While regular maintenance is cheap and easy, all carpet is vulnerable to chemical and solder spills, a common occurrence in certain areas in electronics manufacturing facilities.

In a 24/7 mission-critical space, carpet tile will take a beating unless it is rated for severe abuse. In these spaces, carpet tiles should only be used if they are TARR rated for “severe traffic.” Many ESD carpet tiles are only TARR-rated for heavy traffic. This is inadequate for use where personnel sit in roller-caster chairs 24 hours per day.

Additionally, pay close attention to the carpet fiber modification ratio. Modification ratio estimates a fiber’s performance by how “round” it is. The rounder the fiber, the lower the modification ratio, the better it performs. This ratio enables buyers to determine dirt retention and subsequent wear properties of a carpet and, by extension, estimate how well the carpet will wear and how long it will last. In 24/7 mission-critical spaces with moderate soiling, use carpet with an MR less than 2.5.

And not even the most durable commercial carpet will stand up to heavy soil or abuse from solder or chemical spills, common in certain operations within electronics manufacturing facilities. - Epoxy floors need regular washing and gouges are extremely difficult to repair. Epoxy is notoriously hard to repair, and repairs can be particularly disruptive in occupied spaces, due to the three-day process of removal, installation and drying. Epoxies are sensitive to ultraviolet exposure, causing the color to soften and fade in well-lit areas, making an installed epoxy floor difficult, if not impossible, to match.

Epoxies are also vulnerable to micro-abrasions from chair casters at work stations.

Unlike vinyl tile, epoxy gloss cannot be restored by buffing. - Rubber is the easiest and least expensive material to maintain, with the lowest total cost of ownership. Rubber is extremely durable and requires minimal maintenance. As rubber is plasticizer-free and non-porous, it will not capture dirt—but the floor still needs occasional scrubbing with a single disc machine or it will become dull. However, rubber floors that have not been maintained over long periods can be restored to look like new.

- Adhesives impact the cost of repair. Certain conductive adhesives dry quickly, while others, such as epoxy-type adhesives, take 24 to 72 hours to fully cure. Adhesive curing times can impact repairs and, with downtime, drive up repair costs considerably.

Solution

The way the floor is maintained directly impacts its lifecycle and appearance, as well as its ability to eliminate static electricity. Before purchasing a static-control floor, evaluate the material’s durability and long-term electrical performance—and be sure you understand exactly what maintenance people will encounter. Results are usually best when the people who will occupy and maintain the space are involved in the final flooring selection.

DO consider the long-term costs of repairing and maintaining your static-control floor.

Mistake #7: Specifying the Wrong Product

Every static-control flooring application presents some unique challenge. For example, 9-1-1 call centers and FAA flight towers rely heavily on sensitive electronic equipment that is extremely vulnerable to static electricity. A static event could cripple their mission-critical operation, jeopardizing public safety and security. For this reason, designers of these 24/7 mission-critical spaces do not hesitate in specifying some form of static-control flooring.

It is all-too-easy to select the wrong flooring material, particularly if the supplier is unclear about the capabilities and deficiencies of a particular ESD floor. For safety reasons, for instance, most mission-critical grounding standards—e.g. Motorola R56 and FAA 019f—prohibit the use of conductive carpet around electrified equipment. Other static-control flooring materials—conductive vinyl, HPL, and computer-grade carpet, for example—either do not inhibit static generation or cannot be grounded, thus will not prevent random static discharge; nevertheless, they are often incorrectly specified for these critical applications.

Forgetting to Account for Footwear

Independent lab studies using ANSI test methods show that vinyl, HPL, and epoxy will not prevent static—unless every person in the space uses special static-control footwear. In a real-world environment, where people are not required to wear special ESD footwear (e.g. a data center), these materials do not—and cannot possibly—prevent damaging events caused by random static discharge.

Rubber and carpet, on the other hand, are ideal ESD flooring solutions for mission-critical spaces. ESD rubber and ESD carpet inhibit static generation on moving personnel—regardless of the type of footwear they’re wearing.

To solve static problems in a mission-critical environment, the floor must be groundable as well as low charge generating—in other words, the floor must safely discharge static to ground and provide static mitigation with or without the use of static-control footwear.

To meet these guidelines, floors should be evaluated for body voltage generation, and tested with both controlled and uncontrolled footwear, using ESD STM97.2 methodology.

Due to electrical safety concerns, most mission-critical grounding standards forbid any type of conductive flooring. To adhere to minimum resistance requirements, beware of product data sheets that describe a flooring material as having a wide resistance range—such as 2.5 x 10E4 – 1.0 x 10E8 ohms—running a vast spectrum, from highly conductive to static dissipative. Resistance measurements can be negatively affected by environmental conditions and even vary from tile to tile; products specified with a wide resistance range should be carefully scrutinized and potentially avoided.

Solution

Always ask about the advantages and disadvantages of the materials under consideration. After all, no ESD flooring product is perfect or universally applicable for every application.

Because ESD is an invisible phenomenon, it’s impossible to know the floor isn’t working properly to eliminate static—until, that is, a computer crashes or some other event occurs.

Remember that applications differ in their static-protective requirements. Be sure the floor you select is the right floor for your application. If you’re not sure, ask a static-control expert for help.

Require the flooring manufacturer or their representative to test the floor and warrant in writing that the floor meets the industry standard that was specified. However, beware of claims that a product “exceeds” a standard. Some salespeople argue that a more conductive floor exceeds the performance of a slightly less conductive floor.

Example: Per FAA 019f for airports or Motorola R56 for 9-1-1 dispatch areas, ESD carpet must measure > 1.0 x 10E6 – < 1.0 x 10E9 ohms. Floors with lower resistance measurements (higher conductivity) may not be used in these applications. In electronics manufacturing and Class-0 applications, per ANSI/ESD S20.20, the floor, in combination with ESD footwear, must generate no more than 100 volts of static.

Be sure you require the right test method for your specific application.

Do It Right the First Time

As we all know, it is much easier and less expensive to install a floor in an unoccupied space than it is to remove and reinstall a floor in an occupied building. In most cases, when the wrong floor was installed it’s because the proper homework was not done up front.

Idiosyncratic and constantly changing requirements of technology businesses challenge the expertise of even the most capable building professionals. Technically trained static-control specialists should be enlisted to help decipher and explain ESD terminology and jargon. Both suppliers and installers should be properly vetted, and references should be checked carefully. When selecting a floor, consider the long-term investment, evaluating the total cost of ownership, based on maintenance requirements and anticipated repairs.

Most important, be sure the ESD floor you choose is the right floor for your application.

Left solely in the hands of construction companies that build on “spec,” black-and-red factors like low price and speed of installation will always prevail over more important criteria like performance, appearance, and cost of ownership. Fortunately, sufficient technical resources exist to prevent the selection of the wrong ESD flooring material.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.

Misuse of terms: technical terms like conductive, dissipative, antistatic are not the same, and ESD flooring is a generic term without a universally agreed-upon meaning.

Misuse of terms: technical terms like conductive, dissipative, antistatic are not the same, and ESD flooring is a generic term without a universally agreed-upon meaning.