7 Myths About ESD Flooring

[14 min read, 12 min videos]

Post Summary

A general lack of technical knowledge has led to widespread misunderstanding and misinformation in the ESD industry. Learn the truth behind 7 common myths.

- Myth 1: The more conductive a floor is the more efficient it is.

- Myth 2: The terms static dissipative and conductive are different, with different purposes.

- Myth 3: If a floor is conductive, it won’t generate static.

- Myth 4: If a floor is too conductive, using a less conductive adhesive will solve the problem.

- Myth 5: NFPA 99 is the same as ANSI/ESD S7.1.

- Myth 6: As long as resistance to ground (RTG) measures under 10E9, no other test is required.

- Myth 7: Conductive and antistatic are interchangeable terms

Need additional information about specific ESD products? Learn more about our ESD flooring products

As do all businesses, the static-control industry has evolved over the years. As research and experience support new findings, new technologies emerge, and ways of doing things change. Unfortunately, not everyone keeps up with technical changes. Compound the problem with long obsolete information—still found on some supplier’s websites—equating static-control performance with the conductivity of a flooring material—and people start scratching their heads.

Below we’ve outlined 7 myths about static-control flooring, some of which have persisted since the dawn of static control, with their myth-busting explanations.

Myth 1: The More Conductive a Floor is the More Efficient It is.

When we describe an ESD floor as conductive—or dissipative—we are referring to its ability to promote the flow of electricity and ground a static charge. During the manufacturing process, conductive additives—like carbon—are integrated into the flooring material. These conductors form an electrical pathway, drawing static from the surface of the floor, through its thickness, to the underlying conductive ground plane, to ground.

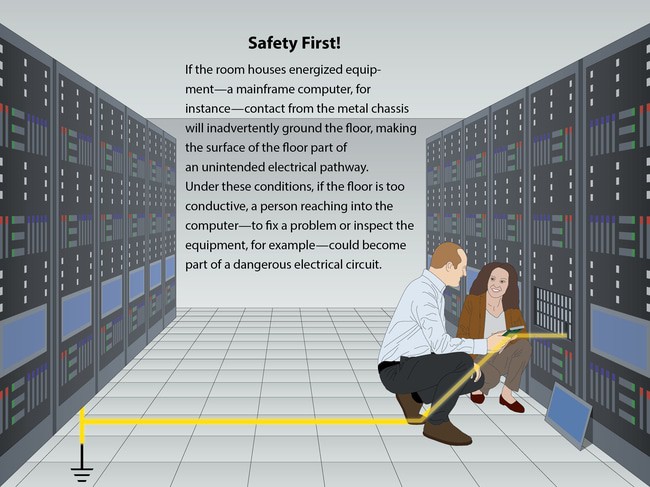

Logically, it may seem that the faster static dissipates to ground the better, but that’s not the case. In end-user spaces, such as 24/7 call centers, 9-1-1 dispatch operations, flight towers, data server rooms, and other environments where people are not required to wear special ESD-protective footwear, an overly conductive floor could pose a safety risk.

As we know, electricity—including static electricity and live-line voltage—seeks its fastest path to ground. Suppose a technician standing, sitting or kneeling on an overly conductive floor came into contact with live voltage while servicing equipment. Though this rarely happens, if the floor were too conductive, electricity would flow through the body part touching the electrified tool or equipment, through the body where it’s in contact with the floor, inadvertently exposing the person to a serious electric shock.*

A less conductive floor will still adequately dissipate static, but the flow of live electricity will be slower. Rather than racing across the surface of the floor, the current would be reduced by the floor’s intrinsic resistance.

For protecting electronics or electronic equipment, there is no advantage to excessive conductivity. As long as the resistance of the flooring material measures below 1.0 x 10E9, the requirement outlined in ANSI/ESD S20.20, the floor will adequately discharge static to ground.

Notes:

- Because some floors can lose conductivity over time (due to environmental and other mitigating factors) StaticWorx does not recommend flooring materials with a resistance of over 1.0 x 10E8.

- High conductivity is generally not a risk for electronics manufacturing and handling applications because everyone in the space is required to wear special ESD-protective footwear (toe, heel or sole straps or ESD shoes). The built-in resistor in ESD footwear provides the wearer with some protection against electric shocks.

- A floor can be conductive and still generate harmful static charges. (Further information below.)

Before selecting a highly conductive flooring material, it makes sense (along with evaluating any perceived benefits) to weigh the potential risk.

Due to concerns about safety (listed above), the FAA (in FAA 019f) and Motorola R56 prohibit the use of conductive floors near energized equipment.

Those materials with a surface resistivity less than 1.0 x 10E5 ohms per square when tested per ANSI/ESD STM11.11 shall be considered conductive. Conductive ESD control materials shall not be used for ESD control work surfaces, tabletop mats, floor mats, flooring, or carpeting where the risk of personnel contact with energized electrical or electronic equipment exists. (FAA 019f – 5.8.3.1 Static Conductive Materials)

Carpeting or floor tiles within an equipment room or dispatch center, including raised flooring, should have a resistance to ground measurement of between 10E6 and 10E9 ohms when measured using the test method of ANSI/ESD STM7.1-2001 or later. (Motorola R56 – C.3.3 Flooring)

Myth 2: The Terms Static Dissipative and Conductive are Different, with Different Purposes.

Static dissipative and conductive are terms used to describe a floor’s ability to promote the flow of electricity.

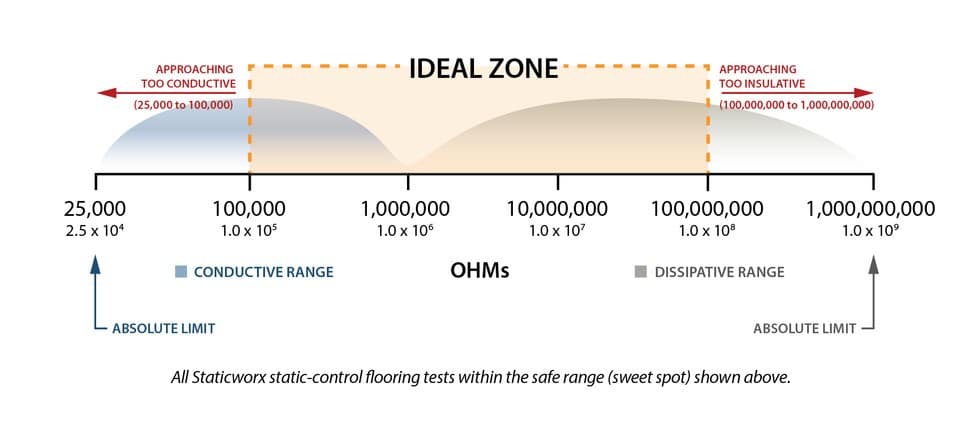

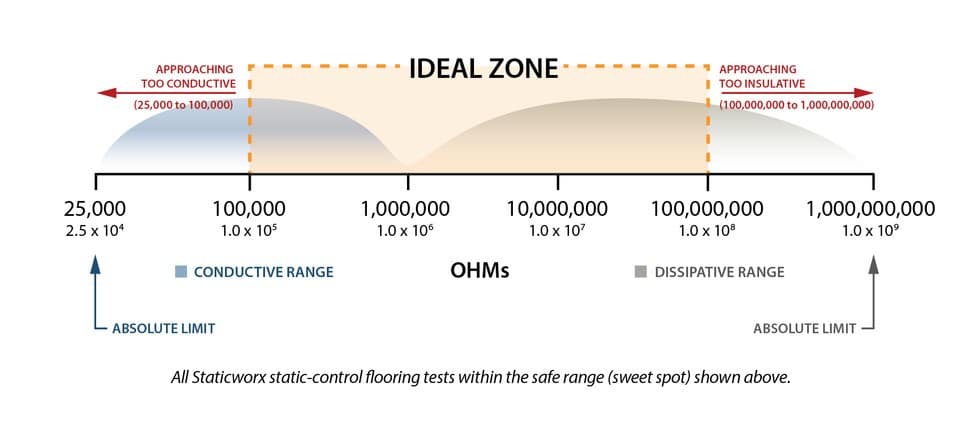

When evaluating an ESD floor, we test not its conductivity, but the opposite: resistance, or the floor’s capacity for stopping, or resisting, the flow of electricity. ANSI/ESD S20.20, the standard set by the ESD Association, requires an ESD floor to have an electrical resistance of under 1 x 10E9, or 1,000,000,000 ohms. While S20.20 does not specify a low-end resistance, for best practices the historical minimum resistance has always been no lower than 2.5 x 10E4, or 25,000 ohms.

Floors at the higher end of the range are considered dissipative. Floors at the lower end of the range are conductive. Somewhere in the middle, they meet.

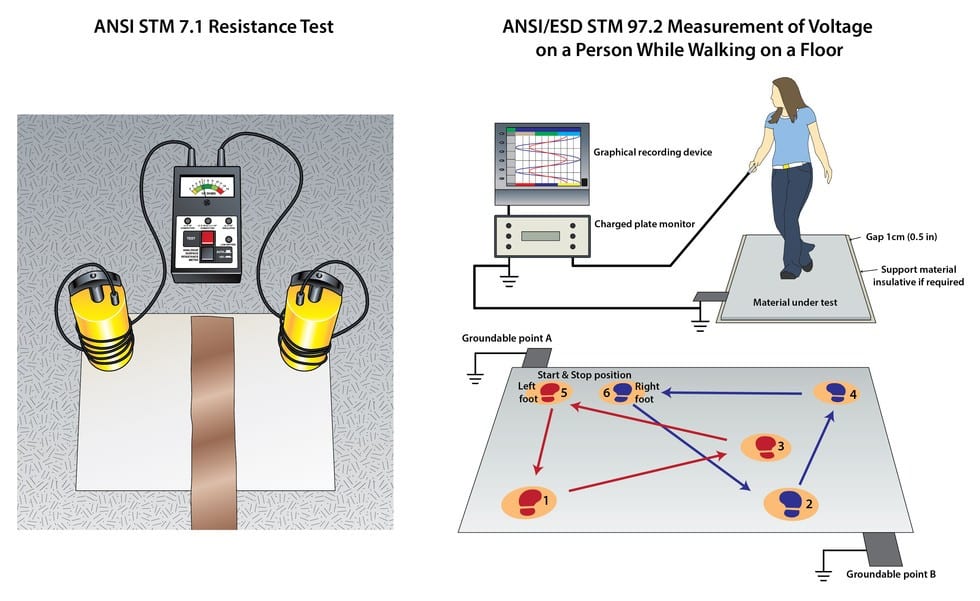

Per test method ANSI/ESD STM7.1 the meeting place occurs at 1 x 10E6, with any reading over 1,000,000 ohms deemed dissipative, and equal to or below 1,000,000 ohms conductive.

This demarcation is a holdover from earlier days, when the terms were coined to describe the electrical performance of floor mats, table tops, and other static-control materials. Their application to floors was arbitrary and has created much unnecessary confusion over the years. Fortunately, the ESD Association, the overseers of ANSI/ESD STM7.1 test method, now approves a floor’s resistance as long as it measures less than 1.0 X 10E9. This means that they approve floors in the static-dissipative and conductive ranges.

Strictly in terms of a floor’s ability to ground static charges, any floor with a resistance under 1 x 10E9 will dissipate static charges adequately. The optimal resistance reading is actually in the middle of the two ranges—that is, between 1 x 10E5 and 1 x 10E8.

Myth 3: If a Floor is Conductive, It Won't Generate Static.

Conductivity and low charge generation are unrelated electrical properties.

Conductivity refers to a floor’s ability to conduct electricity—or draw static from its surface and discharge it to ground. To evaluate conductivity, we test resistance, the floor’s capacity to stop, or resist, the flow of electricity.

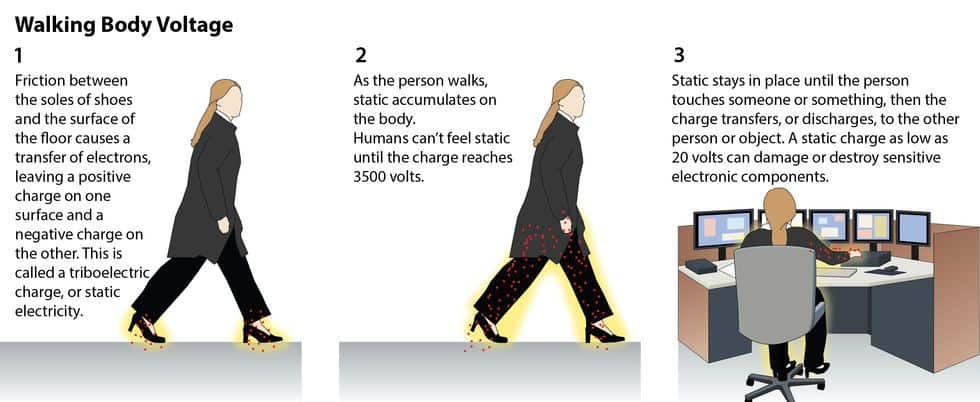

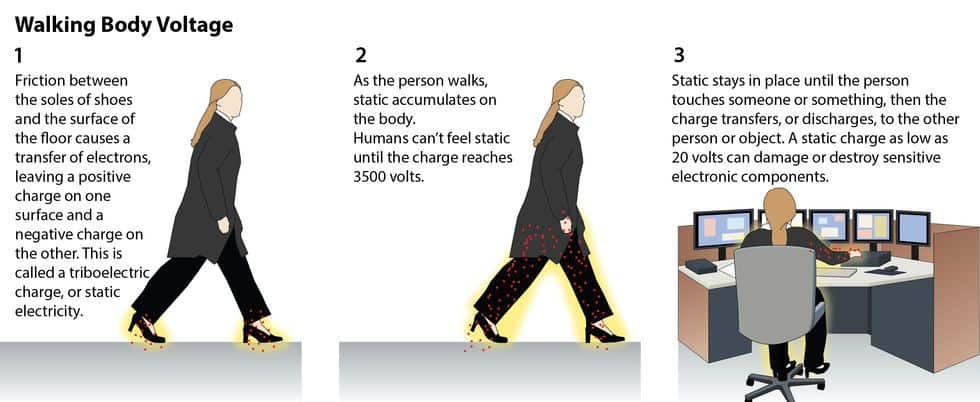

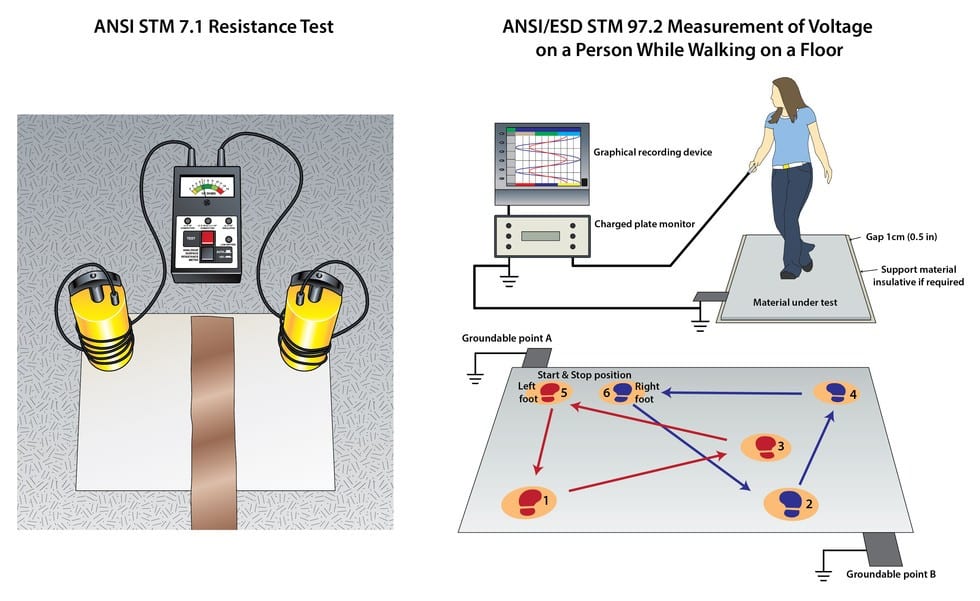

Charge generation occurs when people walk across the floor. The friction between the soles of shoes and the surface of the floor causes one material to accept electrons, the other to give up electrons. This electrical imbalance results in a static charge. This static charge is called walking body voltage.

This charge, or walking body voltage, stays in place until the person touches someone or something, then jumps to that person or object. This release is called an electrostatic discharge, or ESD. A static discharge so small that a person can’t even feel it can damage or destroy electronic components.

Some ESD floors—conductive vinyl, for instance—do an excellent job of discharging static to ground. But unless every person in the facility wears some sort of static-control footwear (heel straps, toe straps, or ESD shoes), conductive vinyl will not prevent charges from building as people walk.

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Myth 4: If a Floor is Too Conductive, Using a Less Conductive Adhesive Will Solve the Problem.

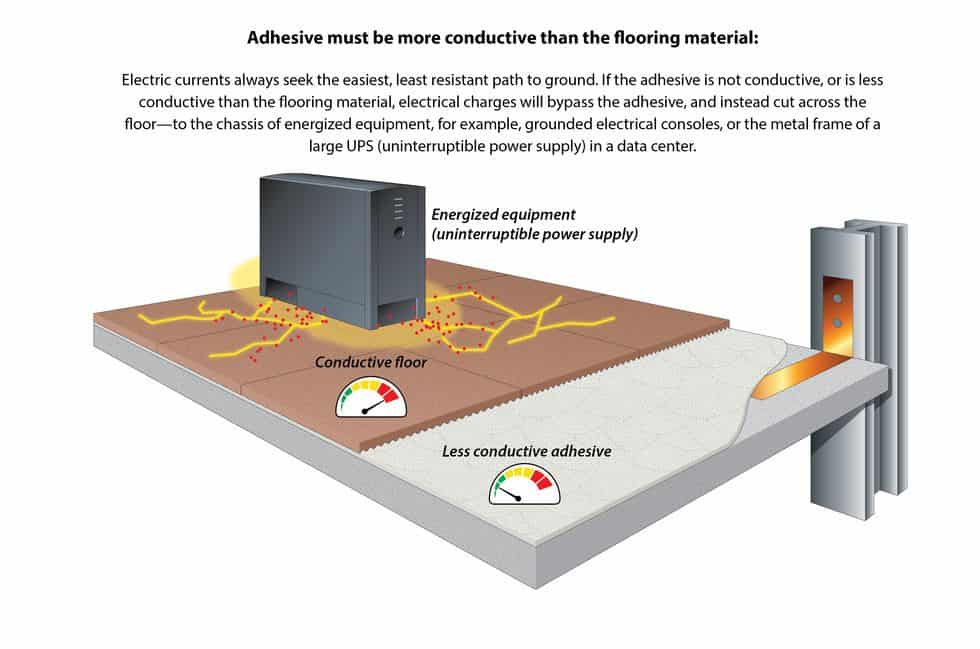

In order to safely draw static charges downward, to ground, the floor should always be the least conductive element in the ESD flooring system.

The conductive adhesive under the tiles form a conductive ground plane, unifying the conductive properties throughout the installation. Static flows from the surface through the thickness of the floor, to the conductive adhesive; across the ground plane to copper strips connected to ground.

If the adhesive is less conductive than the flooring material, stray or unintended line voltages could cut across the surface of the floor, potentially causing safety concerns in applications involving energized equipment.

Myth 5: NFPA 99 is the Same as ANSI/ESD S7.1.

NFPA 99, with roots in the 1950s, was written by the National Fire Protection Association to guide healthcare services in minimizing the hazards of fire, explosion, and electricity in their facilities. In 2015, the NFPA 99 committee deleted references to conductive flooring from the standard.

The resistance test for NFPA 99 is similar to the test for ANSI/ESD 7.1, in that both measure electrical resistance—or a floor’s capacity to resist, or reduce, electrical charges.

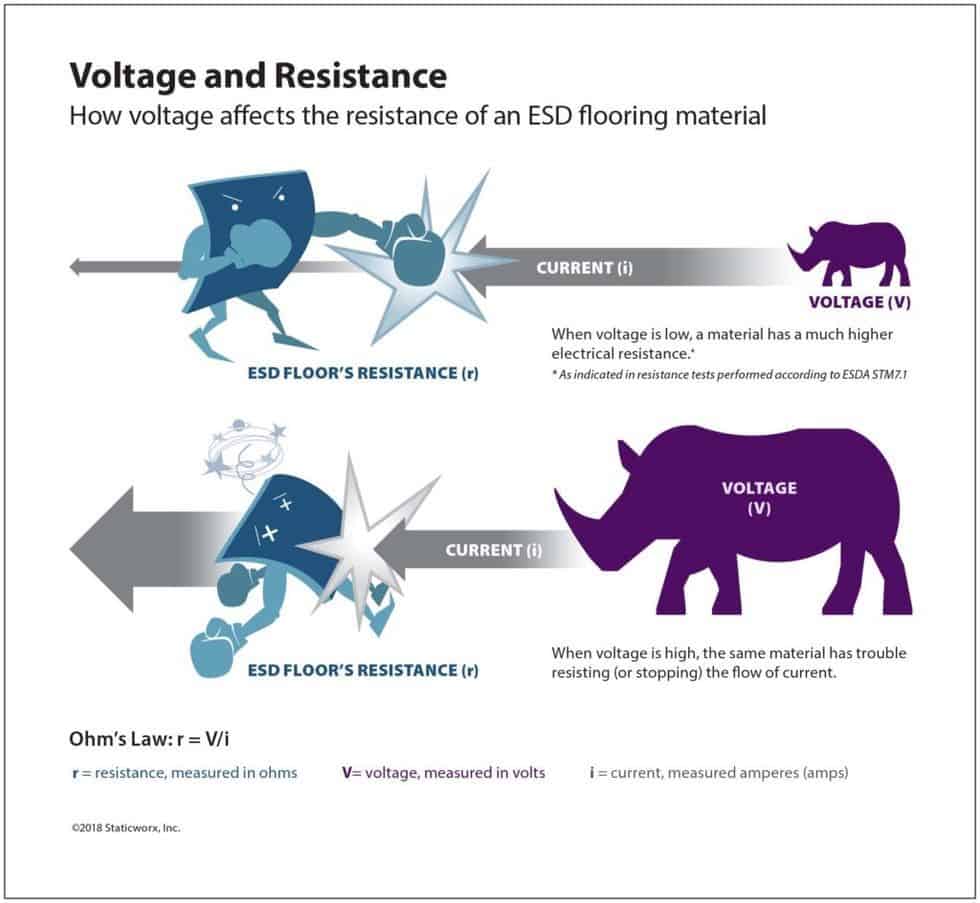

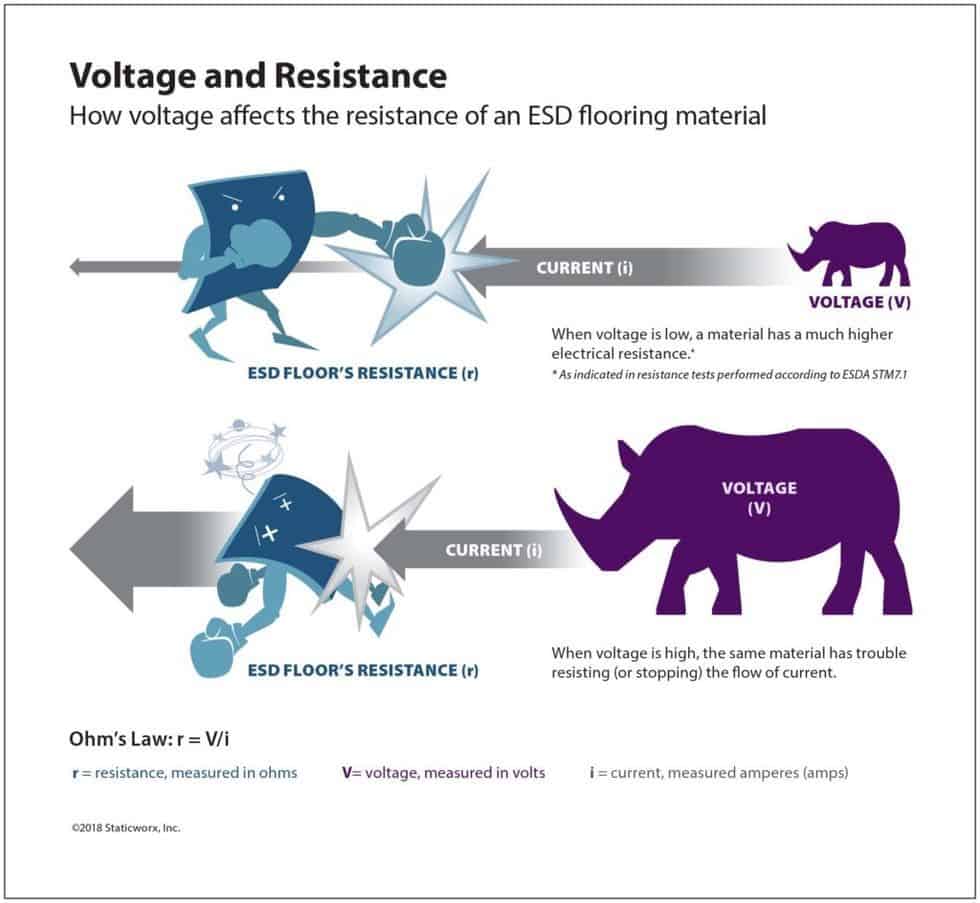

To meet the now-defunct NFPA 99 standard, the electrical resistance of the floor had to measure no less than 2.5 x 10E4, or 25,000 ohms—with one serious caveat: the test for NFPA 99 had to be performed with 500 volts AC current, applied by an ohm meter. ESD 7.1 measurements are conducted at only 10 volts—one-fiftieth the voltage applied in the test to meet NFPA 99.

Why does it matter?

Because the higher the voltage, the lower the resistance. The more voltage you apply, the less capable the floor is of stopping or inhibiting the flow of electricity.

Myth 6: As Long as Resistance to Ground (RTG) Measures Under 10E9, No Other Test is Required.

See Myth #3: Resistance is only one parameter of an ESD floor.

A fully operational ESD floor performs two equally important functions:

- It promotes the flow of electricity, discharging static to ground;

- It prevents or inhibits static generation on people as they walk.

Ensuring that the floor meets both parameters requires three separate tests: both resistance to ground and system resistance—to test for conductivity. And a Walking Body Voltage test, to measure charge generation.

Some floors—conductive vinyl, for instance—have perfectly compliant resistance measurements, but without the use of ESD footwear, fail the charge generation test. You wouldn’t know this without conducting resistance and walking body voltage tests. That’s why it’s crucial to do both.

Myth 7: Conductive and Antistatic are Interchangeable Terms.

Antistatic is an older term, currently out of favor, that refers to a floor’s ability to prevent or inhibit static from building as people walk. Today we call this “low charge generation.” Conductivity and low charge generation are two distinct, unrelated properties of an ESD floor.

To learn more about conductivity and charge generation, see Myth #3.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.