Choosing ESD Floors for Cleanrooms

[16 min read]

Post Sections

ESD requirements for cleanrooms differ from other flooring applications. We offer tips and relevant technical details to help you choose the right ESD floor.

Need additional information about specific ESD products? Learn more about our ESD flooring products.

Cleanroom environments are known for the extraordinary measures used to control particles to ultra-clean ISO standards. Ironically, their static-control flooring doesn’t always meet industry standards and specifications.

Understandably, given that ESD prevention is a field most people rarely have a need to research, many engineers and facility managers are frustrated, and sometimes confused, when it comes to selecting static-control floors for their cleanroom.

Making sense of electrical specifications and standards takes time. And selecting the right ESD floor requires detailed attention to a range of issues, from maintenance, durability, ergonomics, safety, and installation procedures, to technical issues— most importantly, how the floor interacts with the footwear people use in the space.

In cleanroom applications, with their stringent controls, the selection process often requires the assistance of outside experts who specialize in ESD, contamination control, ion chromatography, material out-gassing tests, and particle analysis.

Suitable ESD Floors

Depending upon space and site considerations, ESD floors can be installed over old floors, bare concrete, or raised access-flooring panels. Due to concerns regarding contamination and particle-control, only three forms of ESD flooring are generally considered suitable for cleanroom environments: rubber, vinyl, and epoxy.

Key factors to consider in the evaluation and selection process include: electrical performance, footwear, cleanliness, mechanical properties, and ergonomics.

Electrical Performance

To control static, an ESD floor must perform two equally important functions:

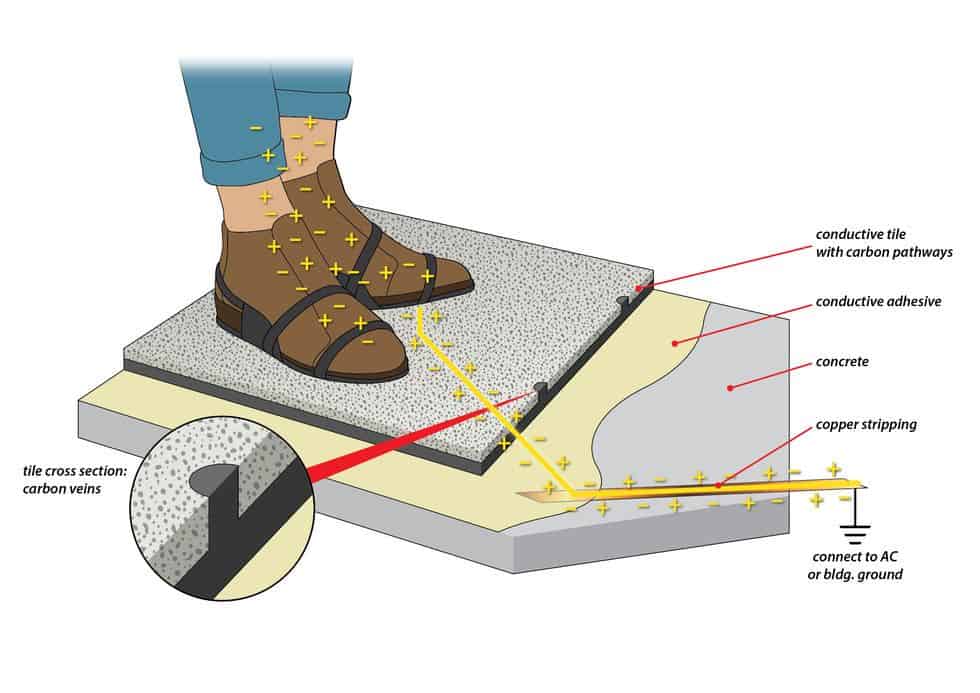

- The floor must provide a safe, traceable pathway to ground.

- The floor must prevent static from building on people as they walk.

Providing a path to ground is a function of the floor’s electrical conductivity. In the manufacturing process, conductive particles are embedded in the material. These conductive particles draw static away from the surface of the floor, through its thickness, to a conductive underlayment—such as conductive adhesive—to ground.

A floor’s conductivity is evaluated based on standard test methods that measure its electrical resistance—i.e., its ability to resist, or stop, the flow of electricity.

Note: Some ESD floors provide an adequate pathway to ground, but—unless every person in the space wears special ESD footwear at all times—will not prevent static generation when people walk. ESD vinyl, for instance, does not prevent static buildup on people wearing regular street shoes. To perform properly, the use of ESD footwear must be mandated and strictly enforced.

Takeaway: An ESD floor must provide a safe, traceable path to ground AND prevent static generation when people walk. Not all ESD floors perform both functions.

Walking Body Voltage

When we walk across a floor, the contact and separation that occurs between the floor and soles of our shoes generates a triboelectric charge, or static electricity. These static charges—called walking body voltage—continue to build on our body as we walk, and discharge to the first person or object we touch.

This electrostatic discharge—or ESD—can damage or destroy sensitive electronics.

Because the triboelectric properties of rubber are sufficiently close to the materials in most shoe soles, ESD rubber generates very little static when people walk. ESD vinyl and epoxy, on the other hand, generate significant charges and should only be used when protocols are enforced mandating the use of static-control footwear.

Takeaway: ESD rubber generates less static than vinyl or epoxy on people in street shoes. When specifying an ESD floor, always factor whether or not ESD footwear will be used into the equation.

Electrical Resistance

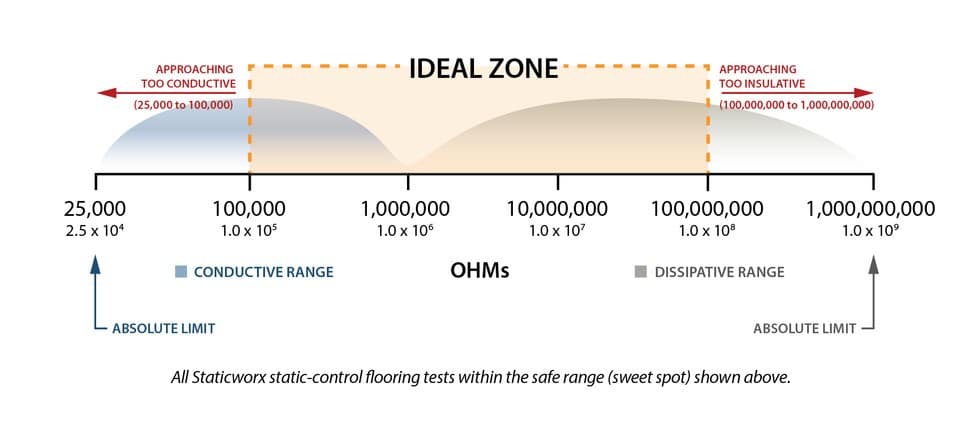

According to the ESD Association, any floor measuring below 1.0 x 10E9 (one billion ohms), using test method ANSI/ESD STM7.1-2015, will adequately control static. Floors measuring above 1 x 10E8, while providing a pathway to ground, drain static slowly and, in some applications, may not provide adequate protection.

Floors measuring below 2.5 x 10E4 are universally considered too conductive for use in spaces that contain energized equipment. Both the FAA and telecom industries (in standards FAA 019f and Motorola R56) prohibit the use of floors that measure below 1.0 x 10E6 in spaces where people are in contact with energized equipment.

The best-performing floors measure within a range we call “the Sweet Spot,” between 1 x 10E5 and 1 x 10E8.

Takeaway: the best floors measure within between 1 x 10E5 and 1 x 10E8 ohms.

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Footwear

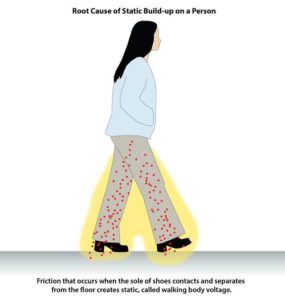

ESD industry standard ANSI/ESD S20.20 requires testing of both the resistive properties (measured in ohms) and the charge-generation properties (measured in volts) of the floor. The latter, called the walking body voltage test, measures the electrostatic voltage generated by the flooring system-i.e., on a person in combination with the flooring material and footwear. This test requires the subject to wear the footwear to be used in the space, and should be repeated to evaluate every footwear/flooring combination.

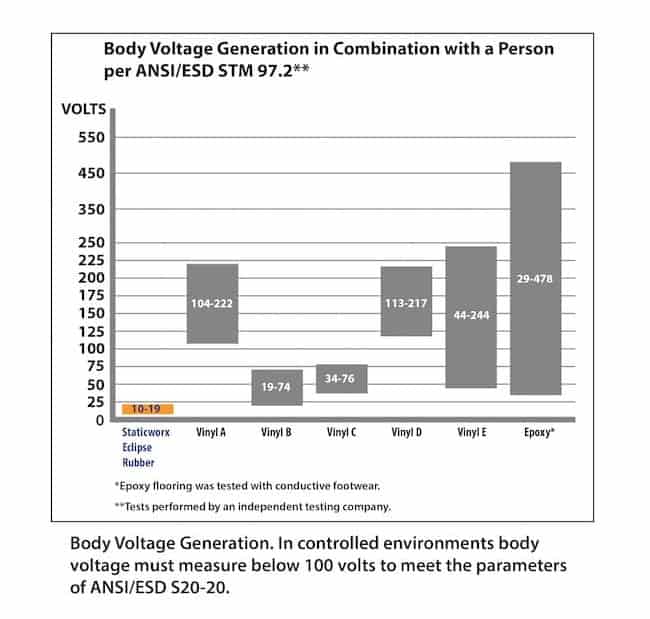

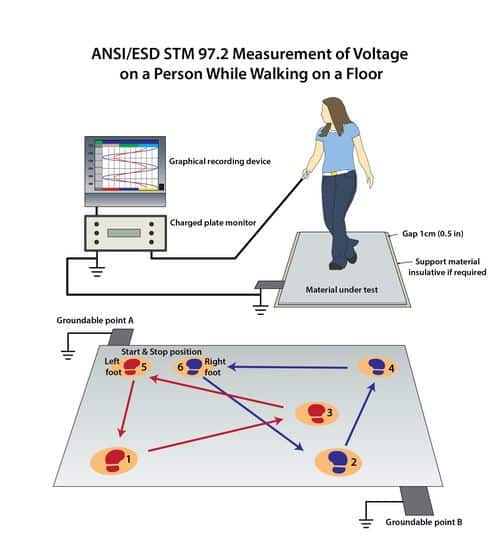

Body voltage generation is evaluated using the standard test method ANSI/ESD S97.2. The test subject is connected to an instrument, called a charged-plate monitor, that measures the static charge generated as the person walks back and forth and side-to-side in a box-step type pattern on the floor.

To meet ANSI/ESD S20.20, the floor cannot generate over 100 volts of static on a test subject wearing approved, static-control footwear. This parameter may be difficult to achieve in cleanrooms, depending upon the contamination requirements.Standard shoe covers, or booties, worn in cleanrooms generate charges in excess of 1,000 volts.

Several suppliers offer disposable as well as permanent static-control shoe covers with conductive or static-dissipative material on the bottom.

Shoe covers should always be tested in conjunction with the grounded floor. In tests conducted by an independent lab, most ESD vinyl and epoxy floors generated well over the 100-volt maximum on test subjects wearing static-control booties and shoe covers. In the same independent tests, with subjects wearing cleanroom-approved ESD shoe covers and booties, ESD rubber generated well under 100 volts.

Because of its material construction and unique triboelectric properties, rubber generates significantly less static than vinyl or epoxy flooring—regardless of footwear.

Takeaway: Test walking body voltage with the subject wearing the specified shoe covers or booties. If the floor measures over 100 volts, consider a different floor.

Cleanliness

In determining the compatibility of cleanroom processes with construction materials such as flooring, primary considerations include out-gassing and particle transfer.

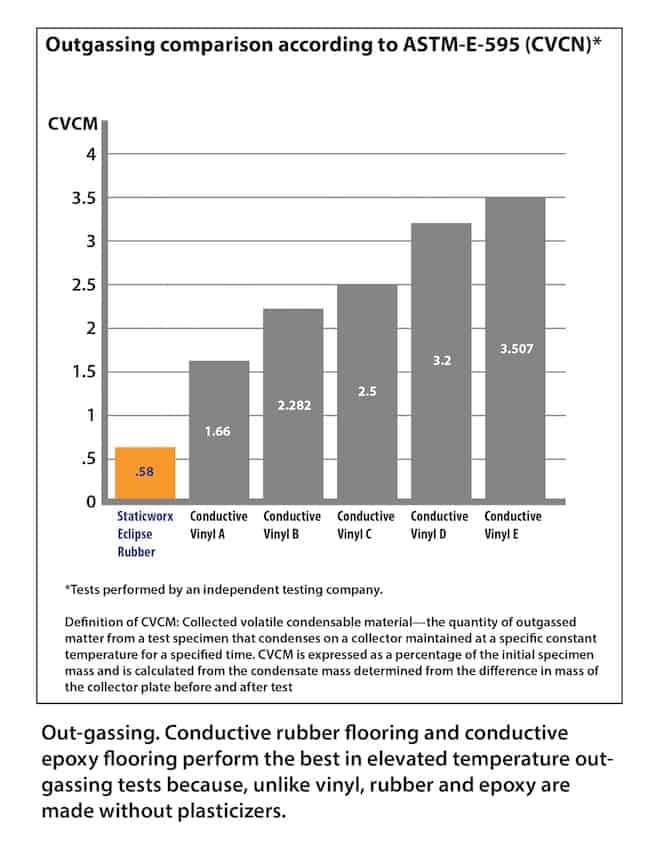

As ESD and contamination-control consultant Carl Newburg, president of Microstat Laboratories/River’s Edge Technical Service in Rochester, Minnesota, explains: “Out-gassing is a measurement of the quantity of volatile chemicals released from a material while it is heated. Condensable volatile residue (CVR), Static Headspace, and Dynamic Headspace are typical tests used to measure out-gassed materials. Test results offer an indication of the material’s tendency to contaminate surfaces in a controlled environment with airborne molecular compounds.”

Most vinyl flooring fails stringent, elevated temperature outgassing tests due to the plasticizers in the material. Plasticizers can migrate out of the flooring material and create significant contamination problems in cleanroom applications, such as optics and MR head manufacturing. Anyone who’s been inside a new car has experienced plasticizer outgassing. As plasticizers migrate from the plastic materials in the car’s interior, they become airborne, producing what we refer to as “the new car smell.”

Without thorough testing, plasticizer migration would be difficult to identity and quantify. While many flooring manufacturers state that their flooring will meet all out-gassing requirements at ambient temperature, most contamination-control experts do not believe that ambient testing is adequate.

Before specifying any floor, we recommend discussing the application with an expert in contamination control and ESD. As a rule of thumb, ESD rubber and epoxy flooring will perform the best in elevated temperature out-gassing tests.

Unlike vinyl, rubber and epoxy are made without plasticizers.

Takeaway: Due to plasticizers in the material, ESD vinyl often fails outgassing tests. Floors that pass elevated-temperature outgassing tests: ESD rubber and epoxy.

Mechanical Properties

Most facilities managers prefer a seamless floor in cleanrooms. For this reason, some specifiers choose epoxy coatings. When installing an epoxy coating, the material is poured in liquid form and applied across the surface of the floor using rollers and squeegees. There are, however, downsides to seamless epoxy coatings: i.e., the aforementioned charge-generating problems and the difficulty and time required to make repairs in the event of damage from scratches or cracking.

Rubber and vinyl can also be installed seamlessly, using a technique called seam welding. Like caulking, seam welding fills in and fuses gaps in sheet flooring or between adjacent tiles. While both tiles and sheet floors can be seam-welded, most specifiers prefer sheet flooring, as there are fewer seams to weld. Welds in rubber floors are less visible than in vinyl, because—unlike vinyl—rubber doesn’t shrink.

Rubber and vinyl floors can be repaired more quickly and easily than epoxy using simple techniques that don’t require abrasive floor preparation. ESD rubber sheet flooring can be installed with fast-drying, pressure-sensitive adhesives that can usually be applied in an operational cleanroom. Some ESD rubber sheet flooring, such as Eclipse GF, already has pre-applied adhesives on the bottom side. A pre-applied adhesive allows for immediate traffic and eliminates almost all the challenges of installing a cleanroom ESD floor.

Pre-applied adhesives allow for foot traffic immediately after the floor is installed.

Takeaway: ESD rubber flooring is easier and faster to repair than epoxy coatings, and poses little to no risk of contamination or odor problems.

Ergonomics

Of rubber, vinyl and epoxy flooring options, rubber offers the most slip-resistant walking surface, wet or dry. Rubber is softer underfoot, and absorbs ambient noise better than hard epoxy and vinyl surfaces.

Takeaway: ESD Rubber is the most ergonomically friendly option. However, its ergonomic properties make the material susceptible to damage from heavy loads.

Simplifying the Selection Process

Selecting static-control flooring for controlled environments requires consideration of a wide array of technical information—and it would be short-sighted to look for shortcuts in the process. In the final analysis, prevention and protection are key.

To prevent ESD problems, select the flooring option that best meets current and anticipated industry specifications. While applications and site conditions vary and specific objectives must be taken into account, industry experts recommend:

- ESD Rubber—rated “ideal.”

- Rubber is the only ESD flooring certified as Class-0 Qualified for ultra-sensitive component handling.

- Rubber also has low body voltage generation.

- Depending upon the application, ESD vinyl tile and epoxy may be suitable.

- Other flooring options are not recommended.

Planning wisely from the get-go prevents costly problems later on. To be sure the floor will perform to industry standards and adequately protect your environment, we encourage ESD audits after the floor has been installed. When selecting ESD flooring for controlled environments, it makes sense to exercise maximum control.

Updated from an earlier article, titled, “Why Static-Control Flooring Is So Important – And How to Find Solutions to Keep You Grounded” by Dave Long, published in the 1/2/12 issue of CE Magazine.

Takeaway: ESD Rubber is the most ergonomically friendly option. However, its ergonomic properties make the material susceptible to damage from heavy loads.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.