ESD Footwear: What Is It and When Is It Necessary?

[16 min read]

Post Sections

Without special footwear, some ESD floors cannot prevent static discharge. Learn why, how options differ, and how footwear interacts with flooring materials.

Need additional information about specific ESD products? Learn more about the StaticWorx ESD flooring range.

Preventing Static: ESD Flooring the First Line of Defense

Regular floors are insulators. This means they can’t be grounded. With a regular floor, static charges stay on its surface. They have nowhere to go. They’re stuck. Instead of providing a path to ground, regular floors create charges on people as they walk across the floor.

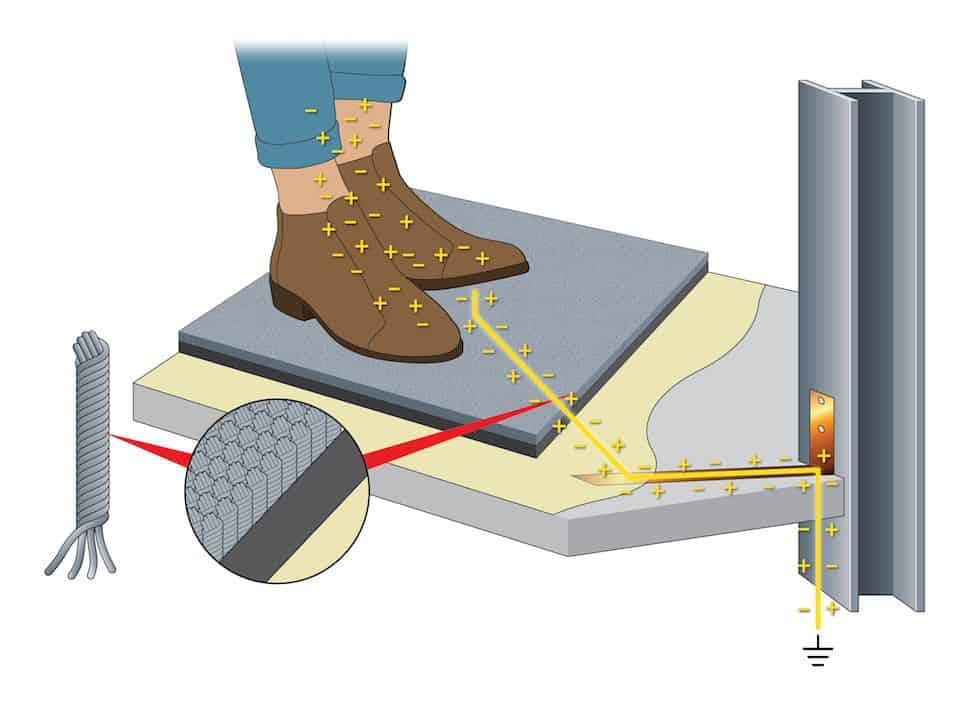

With ESD floors, conductive elements are added to the flooring material in the manufacturing process; these conductive elements draw static downward, away from the surface of the ESD floor, through the thickness of the material, across the underlying conductive ground plane, to copper strips connected to ground.

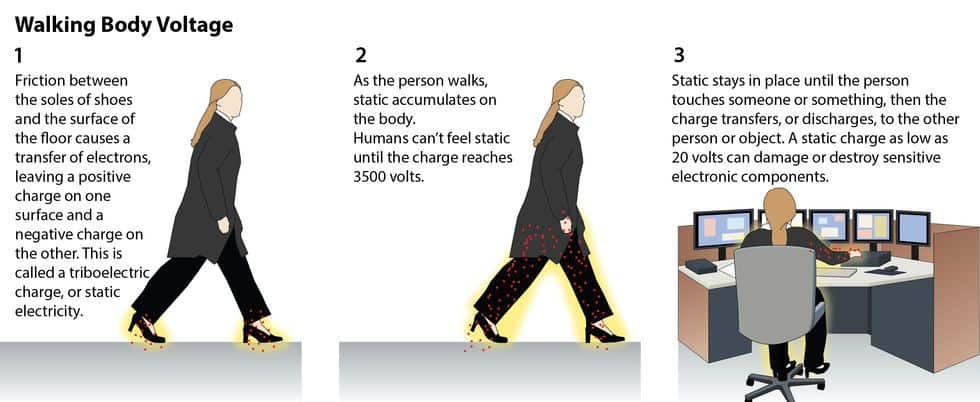

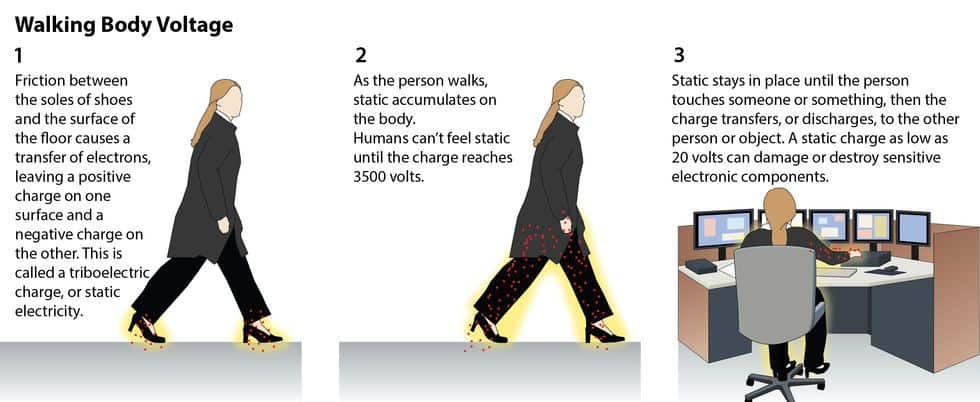

While conductivity is vital to protecting static-sensitive electronics, providing a path to ground does only part of the job. When people walk across the floor, the friction between the soles of their shoes and the surface of the floor generates a triboelectric—or static—charge, called walking body voltage. This is true of regular, as well as with certain—in some cases, very effective—static-control floors.

The charge stays in place until the person touches someone or something, then releases to that person or object. This sudden rush of electrical current, called an electrostatic discharge, or ESD, can wreak havoc in any environment where sensitive electronics are manufactured, handled, or used.

ESD floors are designed to discharge static electricity to ground and eliminate charges from building as people walk—protecting electronics and electronic equipment from damage caused by ESD.

Footwear and Charge Generation

To prevent damage caused by random static events, an ESD floor must perform two functions:

1) Provide a safe and effective pathway to ground;

2) Prevent the generation and accumulation of static when people walk on the floor.

The type of footwear used in the space also affects charge generation. Shoes with PVC soles, for instance, generate more static than shoes with leather soles. Because of its triboelectric propensities, leather is naturally low-charge generating; leather also absorbs moisture, which acts as a conductor to reduce static charges.* However, the anti-static tendency of leather is not reliable; in lower humidity ranges, leather shoes are not always anti-static.

Say “static,” and most of us think about static cling or the pesky zing we get from doorknobs. In fact, static is an invisible threat. To feel a static shock, the charge must be at least 3500 volts. But a charge as low as 20 volts can disrupt data or damage or destroy the microcircuits inside electronic components.

To prevent damage caused by random static events, an ESD floor must perform two functions:

1) Provide a safe and effective pathway to ground;

2) Prevent the generation and accumulation of static when people walk on the floor.

Without the use of special ESD footwear—heel straps, toe straps, sole straps or ESD shoes—some static-control floors meet only the first requirement: they do not prevent static from accumulating as people walk.

The type of footwear used in the space also affects charge generation. Shoes with PVC soles, for instance, generate more static than shoes with leather soles. Because of its triboelectric propensities, leather is naturally low-charge generating; leather also absorbs moisture, which acts as a conductor to reduce static charges.* However, the anti-static tendency of leather is not reliable; in lower humidity ranges, leather shoes are not always anti-static.

That’s why, when selecting an ESD floor, it’s crucial to determine what type of shoes people will wear in the environment—and, if the floor is not low charge generating, mandate the use of ESD footwear.

What is ESD Footwear?

Footwear is the meeting point between the floor and a person walking on the floor. When shoe soles come into contact with the floor, the conductive elements in ESD footwear form an electrical bond or bridge between a person’s body and the carbon veins in static-dissipative or conductive floors, discharging static to ground.

Used in conjunction with floors, such as static-dissipative or conductive vinyl, that do not inhibit static generation, ESD footwear prevents static generation when people walk.

ESD footwear comes in several forms: heel straps, toe straps, sole straps, and shoes. Benefits and performance vary, with buyers selecting footwear based on their needs and priorities.

Heel Straps

Heel straps are inexpensive and can be used with regular footwear. For those with a tight budget or transient workforce, who may not wish to invest in costlier ESD shoes, or with workers reluctant to wear industrial-type footwear, heel straps are a good choice.

Heel straps are inexpensive and can be used with regular footwear. For those with a tight budget or transient workforce, who may not wish to invest in costlier ESD shoes, or with workers reluctant to wear industrial-type footwear, heel straps are a good choice.

Advantages

- Inexpensive

- Unobtrusive

- Comply with ESD standards when used with many types of ESD floors

Disdvantages

- Partial contact with the floor

- Small conductive surface area

- Compliance difficult to monitor

- Do not comply with ESD standards when used with certain types of ESD floors

Toe Straps

Like heel straps, toe straps are inexpensive and can be used with regular footwear. Typically worn with high- or thin-heeled shoes, conductive toe straps create an electrical contact point between the floor and sole of the shoe.

Like heel straps, toe straps are inexpensive and can be used with regular footwear. Typically worn with high- or thin-heeled shoes, conductive toe straps create an electrical contact point between the floor and sole of the shoe.

Advantages

- Inexpensive

- Unobtrusive

- Can be worn with high- or thin-heeled shoes

- Comply with ESD standards when used with many types of ESD floors

Disdvantages

- Partial contact with the floor

- Small conductive surface area

- Compliance difficult to monitor

- Do not comply with ESD standards when used with some types of ESD floors

Sole Straps

Less expensive than ESD shoes, conductive sole straps provide the same full electrical contact with the ESD floor—even when the feet are partially lifted or one foot is off the ground. If a person is squatting, for instance, the heels of his or her shoes are generally lifted, rendering heel straps ineffective. With sole straps, conductive contact would still occur through the toes of the shoes. The surface area of ESD sole straps is also large enough to make electrical contact even on floors with a low density of conductive particles.

Continuity ensures constant protection.

Less expensive than ESD shoes, conductive sole straps provide the same full electrical contact with the ESD floor—even when the feet are partially lifted or one foot is off the ground. If a person is squatting, for instance, the heels of his or her shoes are generally lifted, rendering heel straps ineffective. With sole straps, conductive contact would still occur through the toes of the shoes. The surface area of ESD sole straps is also large enough to make electrical contact even on floors with a low density of conductive particles.

Continuity ensures constant protection.

Advantages

- Inexpensive

- Unobtrusive

- Full contact with ESD floor

- Excellent static protection

- Comply with ESD standards when used with many types of ESD floors

Disdvantages

- Compliance difficult to monitor

ESD Shoes

Easiest type of footwear to use

ESD shoes are superior to heel, toe and sole straps in that shoes are easier to put on, so more likely to be used properly. Shoe straps can slip or slide, be attached incorrectly, or—if the conductive band is incorrectly inserted—straps can fail to make electrical contact with the skin.

Compliance is easy to monitor.

ESD footwear should never be worn outside the facility. Upon entering the workspace, people should be required to put on static-protective heel, toe or sole straps, or change to ESD shoes. Requiring people to change shoes makes compliance relatively easy to police. With the ESD symbol on the back or side of the shoe, ESD shoes are easy to spot in the work area. As they’re bigger and bulkier, ESD shoes are also easier to see than heel, toe or sole straps.

Full, continuous contact with the ESD floor

In terms of static protection, ESD shoes are similar to conductive sole straps: both types of ESD footwear provide full contact with the ESD floor, and protect against static even when one foot is off the ground or the feet are partially lifted. Continuity ensures constant protection.

Easiest type of footwear to use

ESD shoes are superior to heel, toe and sole straps in that shoes are easier to put on, so more likely to be used properly. Shoe straps can slip or slide, be attached incorrectly, or—if the conductive band is incorrectly inserted—straps can fail to make electrical contact with the skin.

Compliance is easy to monitor.

ESD footwear should never be worn outside the facility. Upon entering the workspace, people should be required to put on static-protective heel, toe or sole straps, or change to ESD shoes. Requiring people to change shoes makes compliance relatively easy to police. With the ESD symbol on the back or side of the shoe, ESD shoes are easy to spot in the work area. As they’re bigger and bulkier, ESD shoes are also easier to see than heel, toe or sole straps.

Full, continuous contact with the ESD floor

In terms of static protection, ESD shoes are similar to conductive sole straps: both types of ESD footwear provide full contact with the ESD floor, and protect against static even when one foot is off the ground or the feet are partially lifted. Continuity ensures constant protection.

Advantages

- Full contact with ESD floor

- Superior static protection

- Compliance easiest to monitor

- Comply with ESD standards when used with many types of ESD floors

Disdvantages

- Expensive

- Personnel must change shoes

- Some brands do not provide adequate conductivity to meet system resistance requirements

- May not comply with ESD standards when used with some types of ESD floors

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

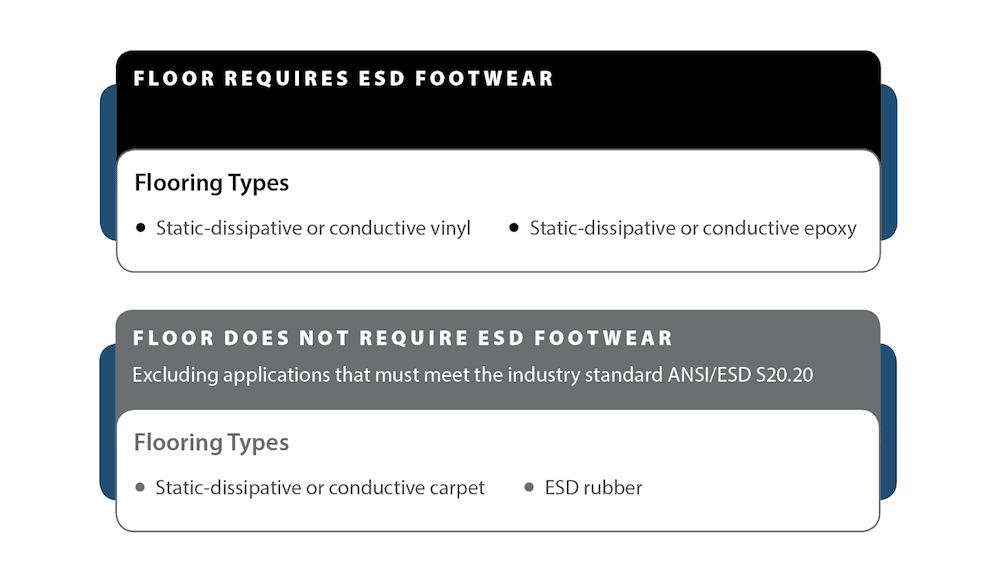

Flooring Materials and ESD Footwear

Standard, non-ESD flooring

As noted above, regular, non-ESD flooring is an insulator and cannot be grounded. Special ESD footwear will neither ground nor prevent static generation on regular, non-ESD floors.

ESD Vinyl and Epoxy

With ESD Footwear

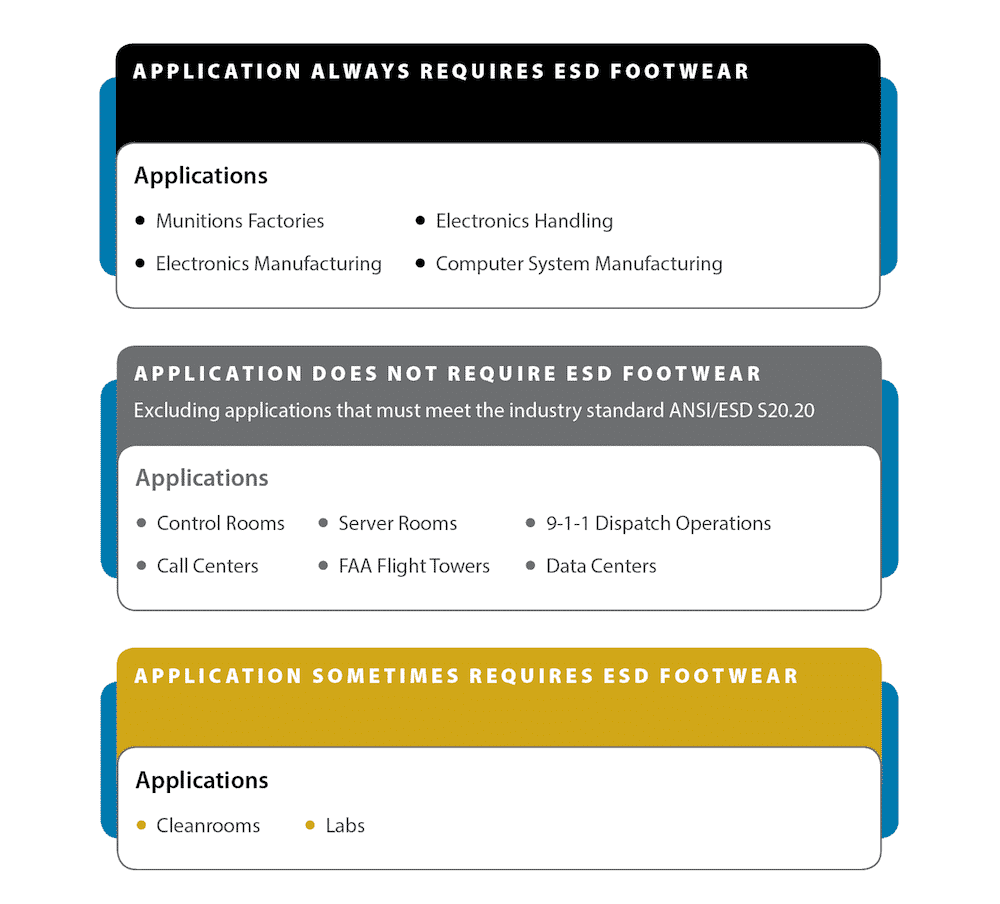

Some very high performing static-control floors—conductive vinyl, for example—are made from ordinary static-generating materials (in this case, regular vinyl) with a small distribution of carbon or graphite particles. The floor is groundable and the embedded conductors provide a safe pathway to ground. Because the material itself generates static, ESD vinyl does not reduce walking body voltage on a person wearing ordinary footwear.

For the floor to be effective, protocols must be in place mandating that every person in or passing through the environment wear static-protective footwear religiously.

This does not mean conductive vinyl is an inferior product. It means that static-control vinyl works best in applications, such as electronic manufacturing and assembly, where footwear and traffic are tightly controlled and regularly monitored.

ESD epoxy, recommended for applications requiring extreme durability—where forklifts are used, for example—is highly susceptible to static. For this reason, ESD epoxy should never be used without tightly enforced protocols requiring the use of ESD footwear.

With Street Shoes

In environments, such as server rooms, 9-1-1 dispatch operations, FAA flight towers, or mission critical data centers, where there are no protocols for ESD footwear—or in environments where protocols are in place but footwear is not regularly monitored or mandates can’t be enforced—and people wear regular street shoes, ESD vinyl and epoxy will not prevent static buildup and should not be used.

ESD Carpet and Rubber Perform Well With or Without Special ESD Footwear

In environments where people wear regular footwear, static-dissipative carpet tile and ESD rubber are the best ESD flooring choices. Static-control carpet and ESD rubber provide a safe pathway to ground while also reducing walking body voltage—regardless of footwear.

Because of their ability to provide redundancy—a.k.a. belt and suspenders—ESD rubber and carpet are also superior choices for electronics manufacturing facilities. If footwear protocols are haphazardly followed, ESD rubber and carpet still provide a high level of protection that ESD vinyl and epoxy are incapable of providing.

Independent research and lab testing found conductive rubber to be the only ESD flooring material that protects against static regardless of footwear.

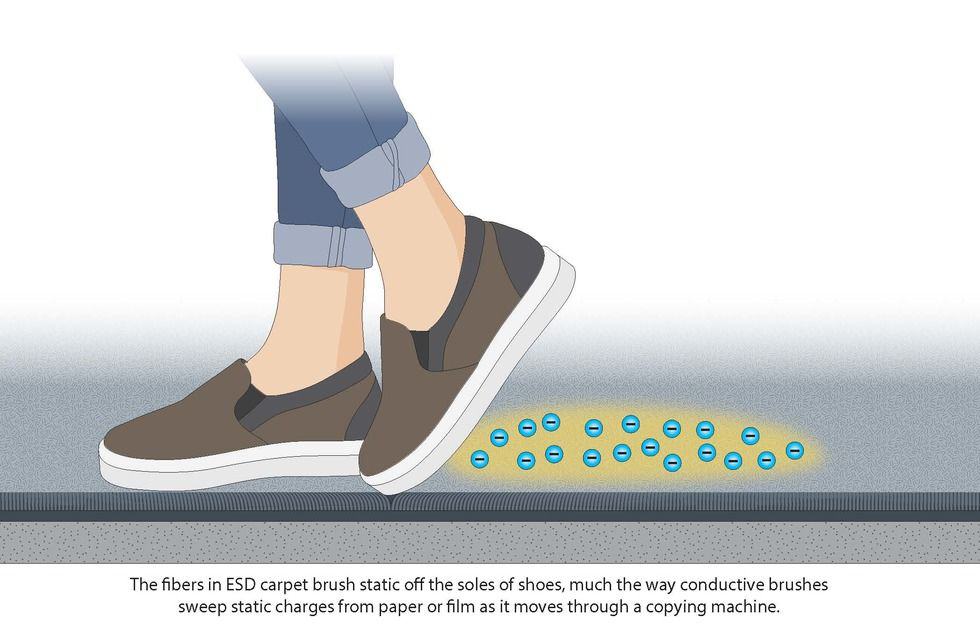

Static-Dissipative Carpet Tiles

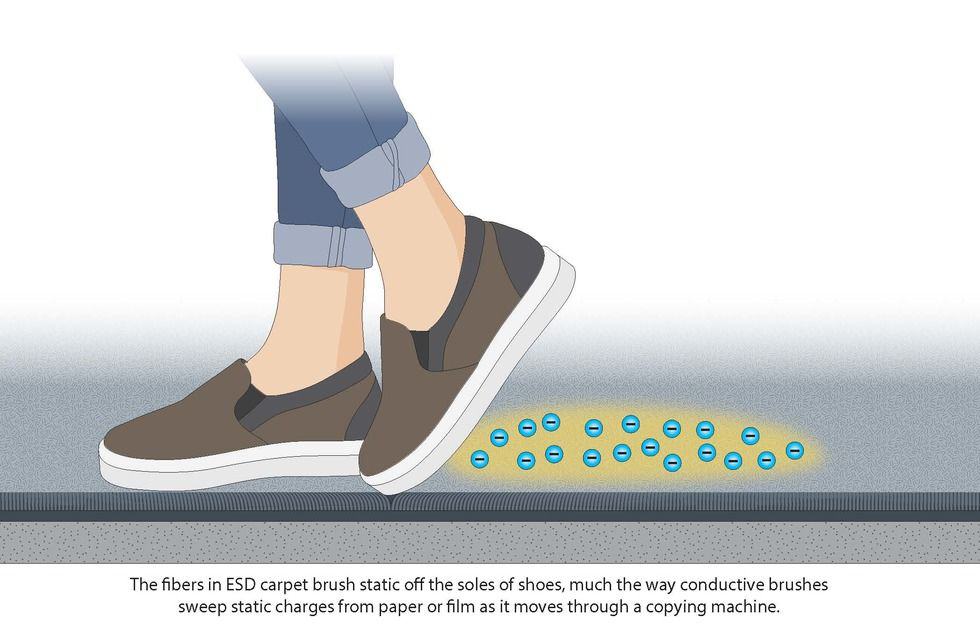

Static-dissipative carpet tiles contain thousands of dissipative fibers that sweep static off the soles of shoes as people walk, and direct the charge safely to ground—much the way small brushes eliminate static on high-speed copiers as paper is fed into the collator.

ESD Rubber

Static-dissipative rubber is a naturally low static generator. Because rubber is similar to the material used in the soles of regular shoes—and since similar materials generate minimal static when they interact—ESD rubber also inhibits static without the need for special footwear.

ESD Footwear: Essential to Meet Electronics Industry Standard ANSI/ESD S20.20

For electronics manufacturing and assembly applications, industry standards require that resistance to ground (RTG) including the person, footwear and floor be < 1 billion ohms or ≤ 1.0 X 10E9, and the static generated in a standard walking body voltage test (while wearing special ESD footwear, per ANSI/ESD STM97.2) < 100 volts.

With regular footwear, rubber and carpet minimize static generation. But when people walk on the floor wearing regular street shoes, these materials do not keep charges under 100 volts. Since 100 volts is the maximum allowable charge, all electronics applications involving ANSI/ESD S20.20 require the use of ESD footwear.

ESD Footwear by Flooring Type and Applications

ESD Footwear by Flooring Type and Applications

Footwear by Application

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.