Installing a New ESD Floor Over an Existing Floor—without shutting down the space

[16 min read]

Post Sections

A new ESD floor can be installed over an existing surface without move time or shutdown. Below we set out how and which questions to ask to find the best flooring option.

Need additional information about specific ESD products? Visit our product section.

You run a 9-1-1 dispatch center, data server room, flight tower, or a critical manufacturing operation, and you need to replace an existing floor with a new static-protective surface. Whether for public safety and welfare, to meet a production deadline or quota, or because interruptions are cost-prohibitive, you can’t afford to shut down the space for even a day.

What do you do?

You have a number of very good options, including ESD carpet tile, which can be laid directly over most existing floors with or without the use of adhesives; self-adhering conductive rubber, which can be laid over an existing floor if it’s in reasonably good shape, or interlocking ESD vinyl tiles that can be laid over the old floor and simply snap into place.

Each option has positive attributes, as well as limiting factors. To determine which floor is the right one for your facility, there are a handful of questions you need to answer:

1. What are the electrical requirements for your application? The requirements for ESD floors used in electronics manufacturing and handling differ from requirements for FAA flight towers, and telecom, networked computer, and data center spaces.

2. What type of footwear will be worn in the space? A corollary to number 1. A floor that performs well when everyone in the space is required to wear special ESD footwear could generate static in an application, such as a call center or 9-1-1 dispatch operation, in which people wear regular street shoes.

3. What is the condition of the existing floor or subfloor you will be covering? If the existing floor is a concrete, epoxy or vinyl surface in reasonably good condition, you’ll have more options than you will if you need to go over a cracked, uneven or broken surface.

4. What type of adhesive will the new floor require? To avoid shutdown, you’ll need an adhesive that sets up instantly. Or you could request a glue-free installation.

Electrical Requirements

Electrical requirements for ESD flooring are industry-specific and depend largely on the type of shoes people typically wear in the space.

There are two types of electrical requirements:

- electrical resistance: resistance tests predict the rate of static dissipation, measured by the capacity of a floor to resist or stop the flow of electricity;

- body voltage or charge generation—charge generation tests measure the amount of static (in volts) generated when people walk on the floor.

Electronics manufacturing and handling spaces—which require and enforce the use of ESD-protective footwear (heel, toe or sole straps or ESD shoes)—can generally tolerate lower resistance levels than end-user environments where people wear regular street shoes.

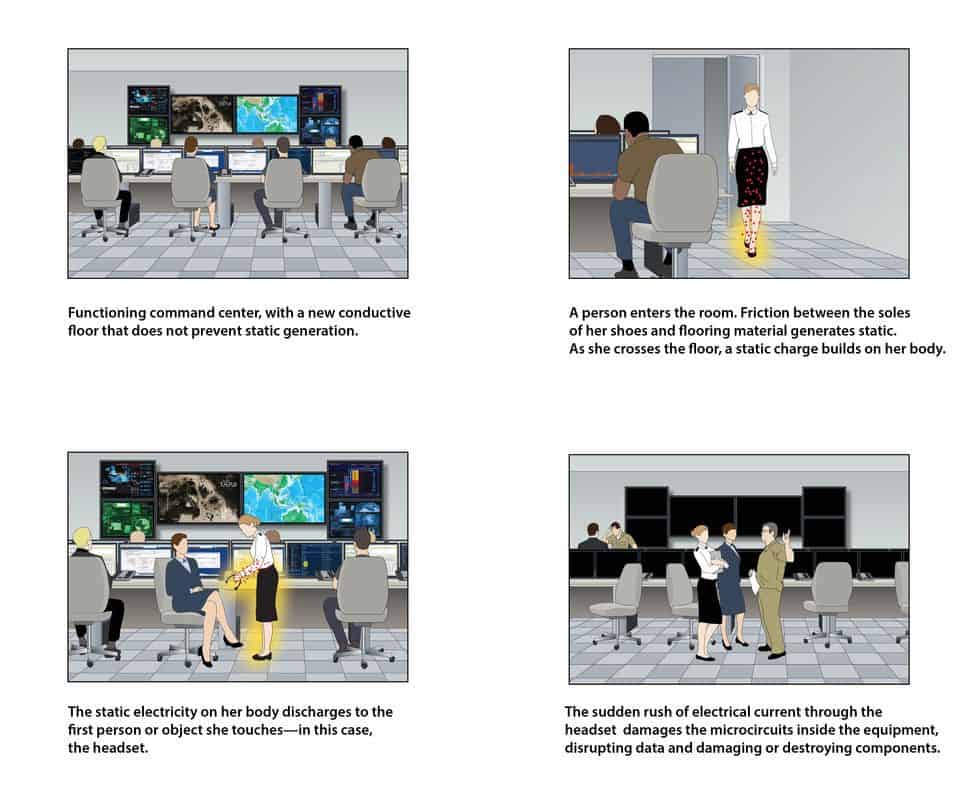

In end-user environments where people are not required to wear ESD-protective footwear—e.g., most data storage or server rooms, mission-critical call centers, 9-1-1 dispatch operations, flight control towers, university labs, and so on—only floors made with low charge-generating materials should be used.

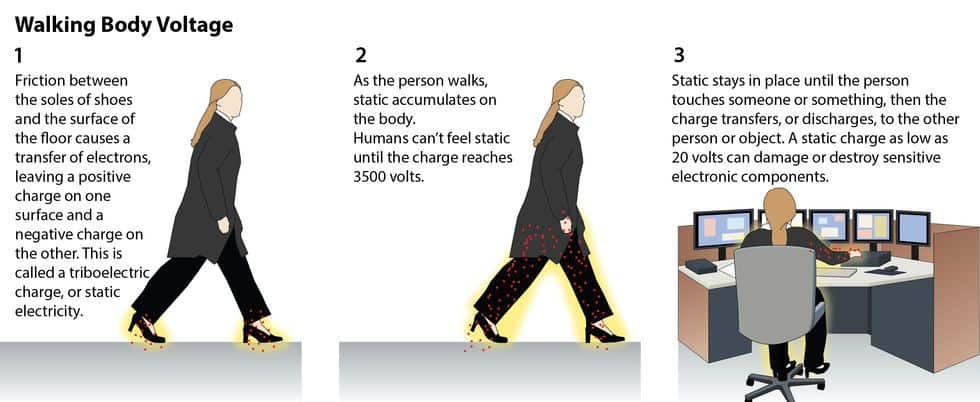

Walking Body Voltage—aka Charge Generation

Charge generation is not the same as electrical resistance, or conductivity.

When people walk across a floor, the friction between the floor and the soles of their shoes generates static electricity. As they continue to walk, static accumulates on the body. These static charges are called Walking Body Voltage.

Like all electrical currents, static seeks its quickest path to ground. If a static-charged person touches a networked computer or other electronic component, the static on his or her body will discharge—like a tiny lightning bolt—to the equipment. This sudden rush of current can damage the component’s internal circuitry, disrupting data, causing malfunctions, even destroying equipment.

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Standards

Electronics manufacturing and handling: Electronics manufacturing and handling facilities follow two main parameters laid out in ANSI/ESD S20.20:

- Electrical system resistance: The electrical resistance of the flooring material and flooring system—conducted with a test subject standing on a mockup installation—must measure ≤ 1.0 x 10E9 ohms.

For safety reasons at the low end of the conductivity range, and to avoid performance failure at the high end (time, temperature, and relative humidity can make a floor less conductive) StaticWorx recommends 1.0 x 10E5 to 1.0 x 10E8.

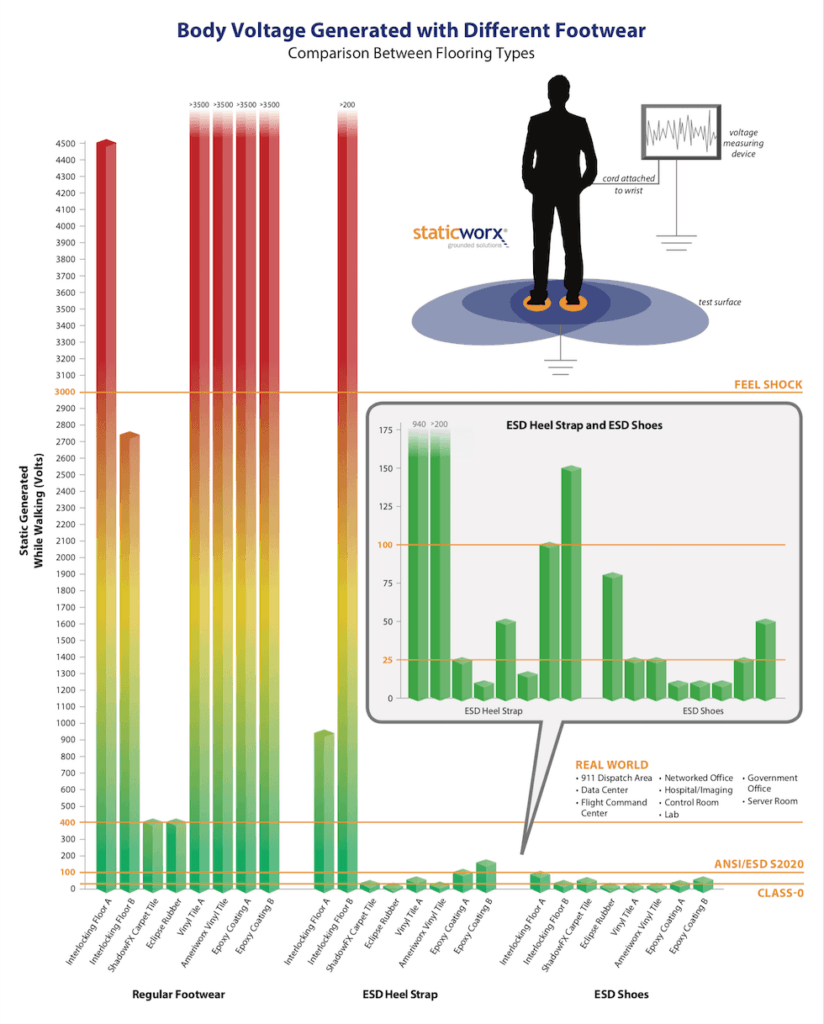

- Walking Body Voltage (charge generation): On a person walking across the floor wearing ESD-protective footwear, an ESD floor must generate no more than 100 volts of static electricity.

In spaces that manufacture or handle ultra-sensitive equipment or devices, the floor should generate no more than 20 volts of static.

Telecom, Call Centers and Dispatch Operations, Data Server Spaces, and FAA flight towers: Each environment follows its own industry standards. Telecom spaces are regulated by Motorola R56 and ATIS 0600321. Data Server Rooms follow an IBM standard. And FAA flight towers follow FAA 019f.

Electrical resistance:

- IBM: 1.5 x 10E5 – 1.0 x 10E10 ohms

- See above, regarding resistance over 1.0 x 10E9

- ATIS, Motorola, FAA: 1.0 x 10E6 – 1.0 x 10E9

Conductive materials have an electrical resistance < 1.0 x 10E6 (one million ohms).

Minimum resistance for control towers and telecom spaces is 1.0 x 10E6. Installing a floor with a resistance measurement that barely meets the minimal requirement leaves no wiggle room should conditions in the environment change.

Walking Body Voltage

Like the pre-ANSI S20.20-2014 standard, standards organizations for telecom, call center and dispatch operations, FAA, and data centers have not set body voltage requirements. Because static-protective footwear is typically not worn in these spaces, low charge-generating flooring materials should always be used; i.e., materials such as ESD carpet* or conductive rubber, that prevent static from building as people walk on the floor.

- Assuming the ESD carpet tile meets industry standards.

Footwear

Before selecting any static-control floor, it’s important to determine the type of footwear people will wear in the environment. Electronics manufacturing and handling facilities, which adhere to the parameters outlined in ANSI S20.20, require the use of ESD-protective footwear, such as conductive heel, toe or sole straps, or ESD shoes. The conductive elements in ESD footwear bond with the conductive particles in an ESD floor, discharging static to ground and preventing static from building as people walk.

The soles of standard—regular, non-ESD—street shoes, on the other hand, generate a great deal of static when they come into contact with most walking surfaces, including some ESD floors. Static-control vinyl and epoxy, for example, whether conductive or static dissipative, will generate charges on people wearing regular shoes—high enough to cause a damaging ESD event.

In end-user environments—such as telecom spaces, critical call centers, 9-1-1 dispatch operations, flight control towers, data storage centers, university labs, etc.—where people working in or walking through the space wear regular footwear, it’s imperative that the floor itself does not generate static charges.

Low Charge-Generating Materials

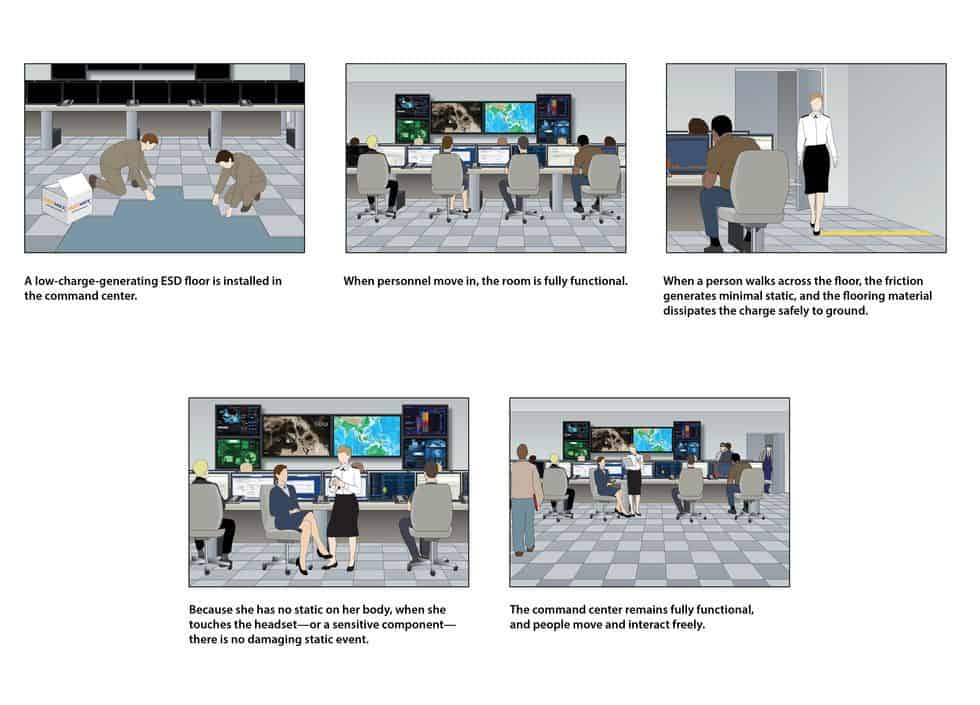

The best low-generating surfaces for spaces that cannot be shut-down for installation are static-dissipative carpet tile or conductive (EC) rubber flooring.

Unlike vinyl and epoxy, whose base materials contain insulative (static-generating) plasticizers (vinyl) or polymers (epoxy), ESD carpet and rubber generate very low charges on people when they walk on the floor—wearing any type of shoes, including static-protective footwear or regular street shoes.

- ESD Carpet

- Conductive (EC) Rubber

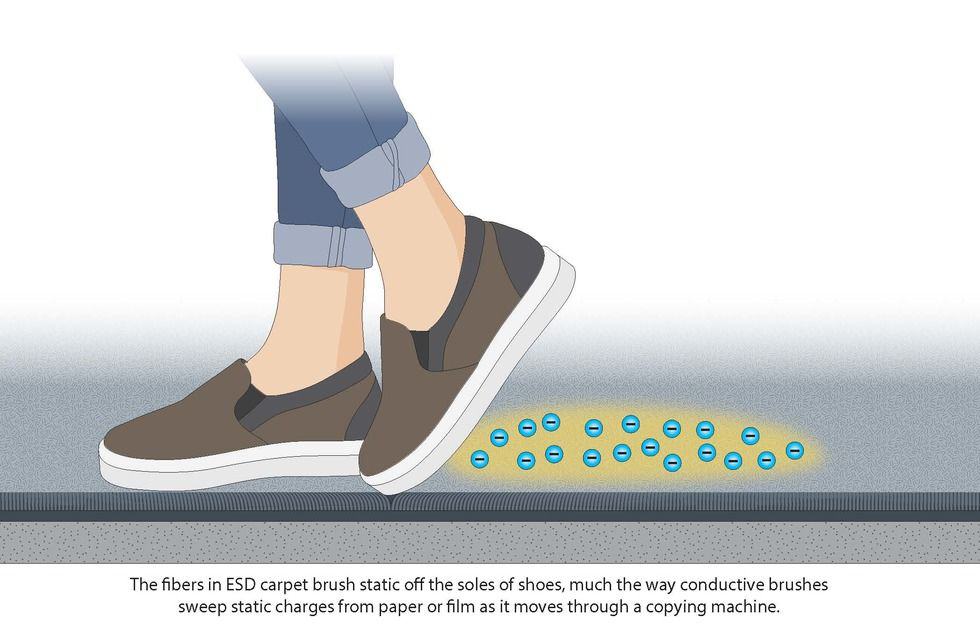

The conductive fibers in ESD carpet brush static away from shoe soles and conduct charges to ground. Think of the static-control brushes inside a copy machine, brushing static off a sheet of paper as it slides through the copier. ESD carpet works in a similar way.

Because the chemical makeup of rubber is sufficiently close to the soles of most street shoes—in other words, they have a similar electrical potential—conductive (EC) rubber is a naturally low static-generating material.

EC rubber performs well in ESD-protected environments that mandate the use of grounded footwear. It is also highly effective at preventing static in areas where grounded footwear is not or cannot be used—places such as mission-critical command centers, computer labs, 9-1-1 call centers, and flight towers.

In a recent ASHRAE-sponsored study of ESD flooring options for data centers, rubber was found to be the most effective ESD floor at any relative humidity with any type of footwear.

The graph below compares the body voltage (static charge) generated when people walk on different types of ESD floors, wearing static-protective shoes, conductive heel straps, and regular (non-ESD) street shoes. As you view the graph, bear in mind that electronic equipment is sensitive to charges of 1000 volts and lower (in some cases as low as 20 V, depending upon the speed and sensitivity of the component).

Condition of Subfloor

What is the condition of your subfloor?

- Is it clean, smooth, and dry? Epoxy, aged concrete or vinyl tile, for instance, that’s free of holes, gaps, or gouges?

- Or is the existing floor broken, battered or gouged?

Most floor tiles and roll goods (in some cases epoxies) can be laid over an existing floor or subfloor that’s in good condition.

If the existing floor or subfloor is gouged, battered, or broken, a resilient material like rubber will telegraph the imperfections.

In electronics applications, where people are required to wear static-protective footwear, imperfect floors could be covered with a hard-surface conductive vinyl or snap-together vinyl tile. In an end-user application, where people typically wear street shoes, these materials will generate static—and thus will not protect against ESD damage. To cover an imperfect subfloor in an end-user environment, ESD carpet may be a better option.

Adhesives and Adhesive-free Installations

- Dry adhesives—Most conductive adhesives cannot be applied over an existing vinyl or epoxy floor. The only compatible types are releasable, epoxy, and dry adhesives.Wet conductive releasable and epoxy adhesives, intended for materials like carpet tile, vinyl tile and rubber are applied using a trowel or spray can. The use of wet adhesives usually requires the work area to be vacated, due to air quality concerns and dry time.Dry adhesives, on the other hand, are permanent and can be walked on immediately. Conductive dry adhesives can be rolled out over any clean, smooth subfloor. They allow instant attachment of tiles to the floor. Normal operations can continue in the room while installation is in progress. There is no “move-in” or “move-out” time.

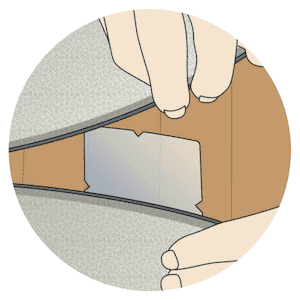

- TacTiles—TacTiles are small adhesive squares that adhere to the corners of carpet tiles and bond the tiles to one-another, enabling a fast-lock tight installation.

TacTiles attach to the corners of carpet tiles. - Self-adhering materials—EC rubber, for example, is available with a pre-installed adhesive backing. Simply peel the protective paper and press the rubber tile onto the subfloor. As with dry adhesives and TacTiles there is no downtime.

EC Rubber with a factory-installed adhesive backing. - Snap-together flooring—Snap-together floors are composed of static-dissipative or conductive vinyl (PVC) and snap into place over the existing floor or subfloor. As noted above, vinyl generates static and should not be used in environments where people wear regular (non-ESD) street shoes.

Snap-together vinyl floor tiles.

Whatever your needs—assuming you do your homework and ask the right questions—you can find a suitable ESD floor that can be installed over an existing surface, without shutting down operations.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Further Reading

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.