StaticWorx ESD Floors for Government

StaticWorx – the Static Control Experts

StaticWorx helps government clients solve problems caused by electrostatic discharge (ESD). In a government facility, ESD events can disrupt communications, corrupt data and cause electronic systems to fail. StaticWorx ESD flooring—also known as antistatic flooring or static-control flooring—and chair materials prevent static from accumulating as people walk and from building on chairs, equipment and mobile workstations.

ESD flooring and chairs are technical products. To perform properly they must meet standards that are specific to the industry and application. It’s our job to help you select the right ESD products for your application. Known for our technical expertise, we are widely published in industry journals. And we collaborated with The Army Corp of Engineers in creating the UNIFIED FACILITIES GUIDE SPECIFICATIONS UFGS-09 65 36 (November 2010) for Static Control Resilient Flooring including Dissipative and Conductive Vinyl Tile USACE / NAVFAC /AFCESA / NASAC.

Buy America

Our ESD carpet, vinyl, epoxy, and coatings are 100% made in USA and can help you meet your Buy America initiatives.

Lifetime Warranty for Static Control

All StaticWorx conductive and antistatic products meet industry standards for resistance and charge generation and come with a lifetime warranty for static control.

Small Business With a Long History of Serving Government

We are a Vermont-based small business with a long history of providing static-control flooring for local, state, and federal government facilities, as well as foreign governments (e.g. Canadian Mounted Police). We’ve served private government contractors, government facilities such as the FAA, U.S. military bases, on and offshore, as well as U.S. embassies around the globe.

Our clients include: DOD, NASA, USCG, Army Corps of Engineers, Department of Homeland Security, Fort Detrick Medical Command Center, Federal Reserve, Lockheed Martin, Los Alamos National Laboratory, Denali National Park, US Army, US Air Force, US Department of Veteran’s Affairs, Commonwealth of Massachusetts, L3 Communications, DC National Guard, Corpus Christi Army Depot, Tinker Air Force Base, along with local and state police, emergency dispatch PSAPs and FAA flight towers across the U.S.

How We Can Help

StaticWorx offers comprehensive training and technical assistance to help you choose the right floor for your application – and to ensure that any ESD floor you’re considering complies with industry standards & specifications. Our core competencies include: site assessment, new construction, renovation and alteration, maintenance & repair, installation oversight, and installation certification.

Government personnel can buy direct from StaticWorx:

Call 617-923-2000

Email: Kimberly Petraccaro, Director of Government Relations.

Applicable ESD Standards

StaticWorx produces products that meet the following industry standards:

StaticWorx produces products that meet the following industry standards:

Government Applications

- Mission critical areas

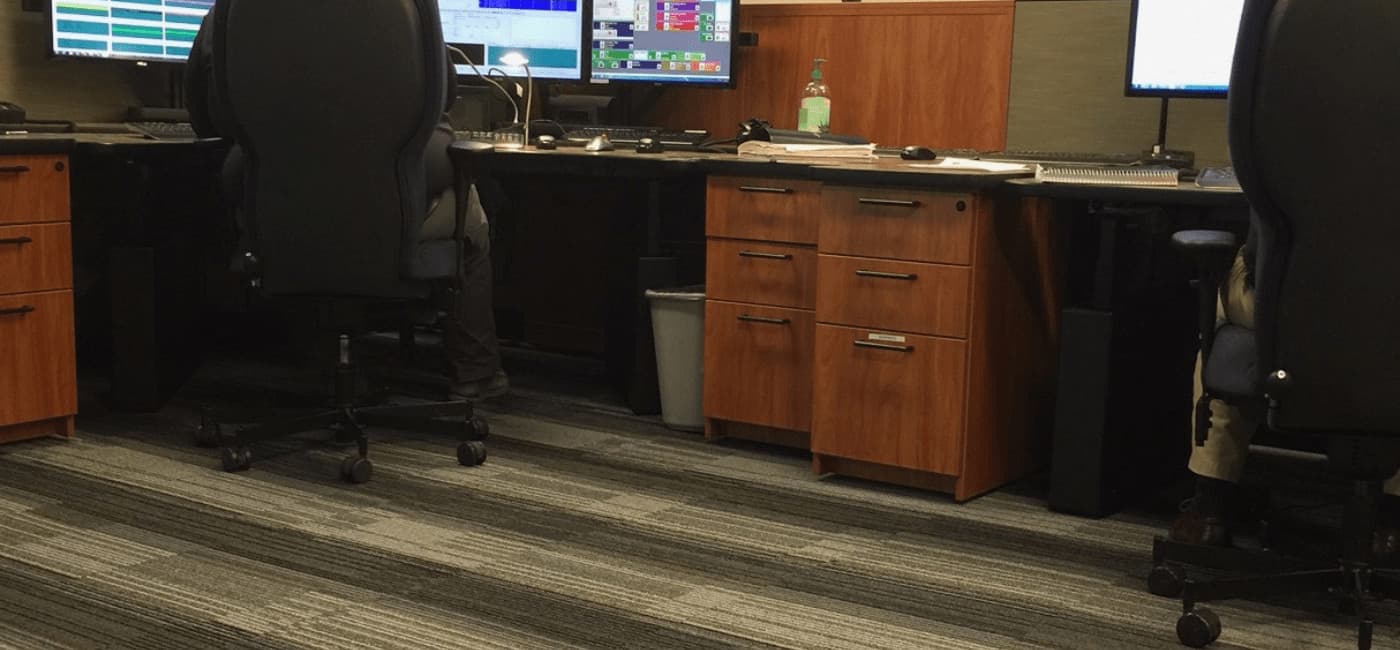

- Public safety 911 communications rooms

- Data centers

- FAA and FAA flight operations

- Military/DOD applications

- Electronics manufacturing and handling

- Explosives manufacturing and handling

- ATCT

- TRACON

- AFSS

- DASR

- ARTCC

- Government CCC facilities

- Military EOCs

- MP and fire dispatch rooms

- NASA command centers

- Engineering labs

- Government data centers (National Archives, IRS, SSA, NSA, FBI, etc.)

- War rooms

- SCIFs

- Communications centers

- Military base electronics labs

- Mission critical areas

- Public safety 911 communications rooms

- Data centers

- FAA and FAA flight operations

- Military/DOD applications

- Electronics manufacturing and handling

- Explosives manufacturing and handling

- ATCT

- TRACON

- AFSS

- DASR

- ARTCC

- Government CCC facilities

- Military EOCs

- MP and fire dispatch rooms

- NASA command centers

- Engineering labs

- Government data centers (National Archives, IRS, SSA, NSA, FBI, etc.)

- War rooms

- SCIFs

- Communications centers

- Military base electronics labs

StaticWorx Products

Overview ShadowFX Static-dissipative Carpet Tile

- Superior Static Protection with an electrostatic propensity of less than .4 kV. Meets:

- D.O.D. HDBK263A, Section 40.1.2 : guidelines for sensitive ESD devices, Class 1.

- FAA-STD-019f Section 3.16.5.2.1.5 - requirements for static-dissipative ESD control floor coverings.

- ANSI/ESD S20.20 Electrostatic Discharge Control Program Standard for electronics manufacturing and handling applications.

- ShadowFX carpet tile is available in modular format, with 6 stock and over 150 available colorways. Aesthetically pleasing designs are easy to install with or without adhesives.

- Lifetime warranty on static-control properties. Also warranted against cupping, doming, curling or dishing.

- Comfortable and ergonomic, ShadowFX carpet reduces leg and back fatigue, improves acoustics and reduces glare - important factors for flight control towers and other mission critical spaces.

- Can be installed one-to-one for access flooring applications.

- ShadowFX carpet tile is available in modular format, with 6 stock and over 150 available colorways. Aesthetically pleasing designs are easy to install with or without adhesives.

- Lifetime warranty on static-control properties. Also warranted against cupping, doming, curling or dishing.

- Comfortable and ergonomic, ShadowFX carpet reduces leg and back fatigue, improves acoustics and reduces glare - important factors for flight control towers and other mission critical spaces.

- Can be installed one-to-one for access flooring applications.

StaticWorx AmeriWorx ESD Vinyl tile, Eclipse conductive (EC) and glue-free rubber, GroundLock interlocking and lay-flat tile and GroundWorx ESD Epoxy may also be used as specified.

Learn More

read

-

What is ESD Flooring, How Does It

Work, and How Do I Choose One? -

Choosing ESD Flooring for

Mission-Critical Spaces -

Standard of Care for Specifying

Floors in Mission-Critical Spaces - Glue-Free ESD Floors

Electrostatic Discharge (ESD) flooring protects electronics from damage caused by static electricity, which accumulates as people walk. Conductive elements such as carbon, graphite or metal-coated particles, distributed throughout the flooring material, give ESD floors electrical conductivity and create an electrical pathway from the walking surface to ground.

According to the National Emergency Number Association, in the U.S. alone, more than 240 million 9-1-1 calls are placed each year. In a 9-1-1 dispatch center—and other mission-critical spaces, such as FAA flight towers, data centers, server rooms, critical-call centers, and networked government offices, such as Social Security, the IRS or Homeland Security, to name just three—static electricity can wreak havoc. In worst case scenarios, electrostatic discharge (ESD) can result in lost calls or misdirected traffic, putting human safety at risk.

Static-control flooring helps prevent random discharge from harming electronic equipment in mission-critical spaces. But if the floor doesn’t meet international industry standards—as well as the standard of care established by the American Institute of Architects (AIA)—dispatchers can’t do their job and callers may be frustrated or, in worst cases, put at risk.

Years of experience suggest that approximately 70% of the static-control floors installed in end-user environments such as 24/7 mission-critical call centers are improperly specified.

Most ESD floors are installed with a conductive adhesive that forms a conductive ground plane under the floor. But in areas requiring access to underfloor wiring or utilities or chemical-free installation, in 24/7 spaces that cannot be shut down, or in spaces that may be repurposed or the flooring redeployed, a glue-free installation may be a better option.

Electrostatic Discharge (ESD) flooring protects electronics from damage caused by static electricity, which accumulates as people walk. Conductive elements such as carbon, graphite or metal-coated particles, distributed throughout the flooring material, give ESD floors electrical conductivity and create an electrical pathway from the walking surface to ground.

According to the National Emergency Number Association, in the U.S. alone, more than 240 million 9-1-1 calls are placed each year. In a 9-1-1 dispatch center—and other mission-critical spaces, such as FAA flight towers, data centers, server rooms, critical-call centers, and networked government offices, such as Social Security, the IRS or Homeland Security, to name just three—static electricity can wreak havoc. In worst case scenarios, electrostatic discharge (ESD) can result in lost calls or misdirected traffic, putting human safety at risk.

Static-control flooring helps prevent random discharge from harming electronic equipment in mission-critical spaces. But if the floor doesn’t meet international industry standards—as well as the standard of care established by the American Institute of Architects (AIA)—dispatchers can’t do their job and callers may be frustrated or, in worst cases, put at risk.

Years of experience suggest that approximately 70% of the static-control floors installed in end-user environments such as 24/7 mission-critical call centers are improperly specified.

Most ESD floors are installed with a conductive adhesive that forms a conductive ground plane under the floor. But in areas requiring access to underfloor wiring or utilities or chemical-free installation, in 24/7 spaces that cannot be shut down, or in spaces that may be repurposed or the flooring redeployed, a glue-free installation may be a better option.

Watch

Listen

The Pitfalls of ESD Flooring Selection: How to Avoid ESD Flooring Failure

Three fundamental mistakes account for a majority of ESD flooring failures: selecting the wrong floor for the application: failure to consider total cost of ownership; failing to test the floor after it’s been installed. Avoiding these mistakes helps ensure success. This first of a two-part series on avoiding ESD flooring failures explains why it’s important to select a floor based on the specific application and details the primary considerations that should be taken into account: assessing the type of footwear people will wear in the space and considering goals and objectives, including how the space will be used.

Installing ESD Flooring: Avoiding Pitfalls

The cost of flooring materials is only part of the total cost of ownership. To calculate the long-term cost of owning a floor, consider installation, maintenance, repairs, and downtime required for maintenance and repair. Aesthetics are another consideration. In this podcast, Dave and Rick describe scenarios that occur when people base flooring decisions solely on the cost of the material. Dave also explains why it’s crucial to test an ESD floor immediately after it’s been installed.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.