What is GroundSafe™ ESD flooring?

GroundSafe™ is a certification program consisting of pre-testing and post-installation testing of the electrical resistance of your ESD flooring (also known as antistatic flooring or static-control flooring). Most people recognize the necessity of pre-installation testing to qualify floors under consideration. Electrical/static-control requirements vary by industry. Testing tells you whether or not the floor meets standards for your industry and measures how safely and effectively the flooring material will transport charges to ground.

GroundSafe™ is a certification program consisting of pre-testing and post-installation testing of the electrical resistance of your ESD flooring (also known as antistatic flooring or static-control flooring). Most people recognize the necessity of pre-installation testing to qualify floors under consideration. Electrical/static-control requirements vary by industry. Testing tells you whether or not the floor meets standards for your industry and measures how safely and effectively the flooring material will transport charges to ground.

GroundSafe™ is a certification program consisting of pre-testing and post-installation testing of the electrical resistance of your ESD flooring (also known as antistatic flooring or static-control flooring). Most people recognize the necessity of pre-installation testing to qualify floors under consideration. Electrical/static-control requirements vary by industry. Testing tells you whether or not the floor meets standards for your industry and measures how safely and effectively the flooring material will transport charges to ground.

GroundSafe™ is a certification program consisting of pre-testing and post-installation testing of the electrical resistance of your ESD flooring (also known as antistatic flooring or static-control flooring). Most people recognize the necessity of pre-installation testing to qualify floors under consideration. Electrical/static-control requirements vary by industry. Testing tells you whether or not the floor meets standards for your industry and measures how safely and effectively the flooring material will transport charges to ground.

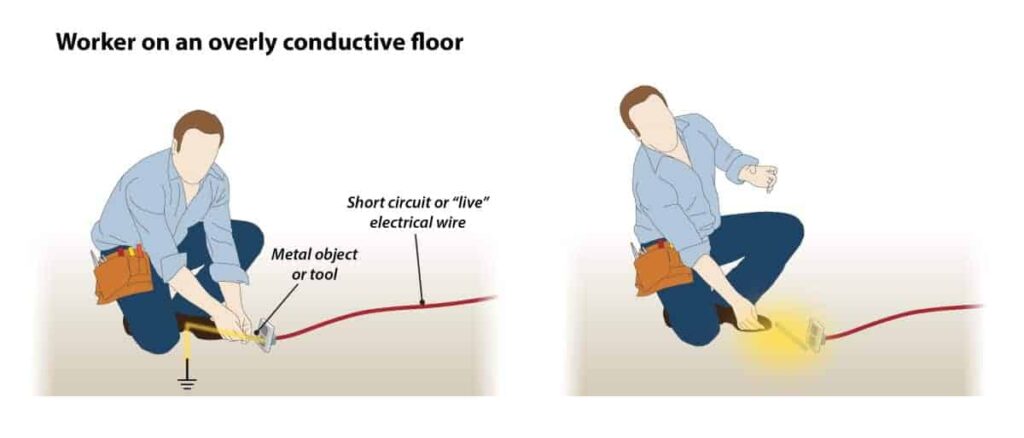

Industry standards, requiring adherence to ASTM F150 and ANSI/ESD STM7.1, also require verification (post installation) testing. Post-installation testing confirms that the flooring system meets standards and buyer expectations. Still, it’s often overlooked. Maybe people are in a hurry to move into the space. Maybe the buyer doesn’t see the value in testing a floor after it’s been installed. Maybe they trust the specifications they were given by the flooring manufacturer. Maybe they believe their qualification tests are enough and the results won’t change. Whatever the reason, the decision-maker likely has no idea how greatly flooring systems are impacted by site conditions such as:

- Grounding methods

- Adhesive dry times

- Amount of adhesive used

- Method of installation

- Relative humidity and dew point

- Vapor in concrete

- The placement of grounded items like consoles and servers on the floor

- Types of subfloors and their resistance to ground

Industry standards, requiring adherence to ASTM F150 and ANSI/ESD STM7.1, also require verification (post installation) testing. Post-installation testing confirms that the flooring system meets standards and buyer expectations. Still, it’s often overlooked. Maybe people are in a hurry to move into the space. Maybe the buyer doesn’t see the value in testing a floor after it’s been installed. Maybe they trust the specifications they were given by the flooring manufacturer. Maybe they believe their qualification tests are enough and the results won’t change. Whatever the reason, the decision-maker likely has no idea how greatly flooring systems are impacted by site conditions such as:

- Grounding methods

- Adhesive dry times

- Amount of adhesive used

- Method of installation

- Relative humidity and dew point

- Vapor in concrete

- The placement of grounded items like consoles and servers on the floor

- Types of subfloors and their resistance to ground

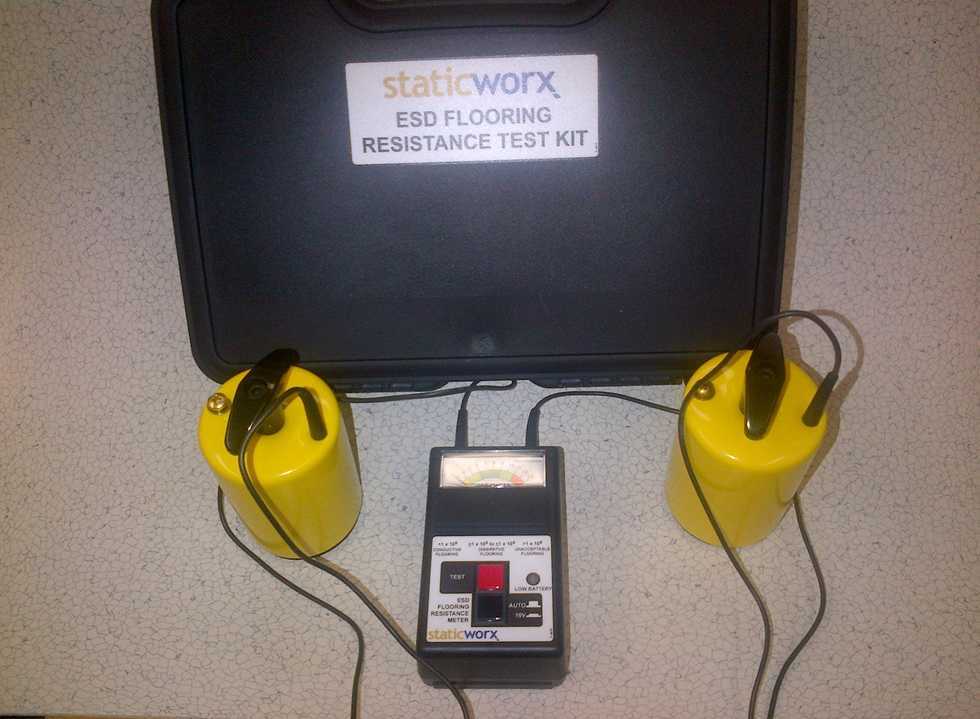

If the flooring system fails to meet your specifications it may not perform as you’d hoped or intended. If, for instance, you specified a static-dissipative floor to meet safety standards for PSAPs, telecom, a flight tower, bank, or any end-user space where people work with or near electrified equipment, you don’t want a floor that’s too conductive. Likewise, if you specified and purchased a conductive floor for an SMT or manufacturing facility, and you have mandates in place requiring the use of special ESD footwear, you want to be sure your floor is conductive.

Too often when a floor fails post-installation testing the floor is ripped up and replaced, with costs recouped via a law suit or settlement – both of which cost time, money, and aggravation.

Manufacturer’s specifications are the results of tests performed in a lab. It’s not enough to simply trust them. Tests need to be performed in a real-world setting.

The lab samples manufacturers use to characterize a floor as conductive or dissipative are small material samples with ground connections installed in a specific manner to suit the flooring manufacturer’s purposes. For example, some manufacturer’s install conductive tiles with static-dissipative adhesive, using a sort of sandwich strategy that has no effect on the flooring material, but can alter system measurements.* In a perfectly dry lab setting it’s very possible that this type of flooring system will appear to measure as static-dissipative – yet installed on concrete in a high-humidity environment, the same floor can measure in the conductive range.

* System measurements take into account flooring material, conductive adhesive or other underlying ground plane, the person walking on the floor, and the shoes she’s wearing.

Where you choose to place the probes also influences the electrical resistance to ground of any ESD floor. Test methods like ASTM F150 and ANSI/ESD STM7.1 are based on testing resistance to ground using the manufacturer’s designated grounding method. That’s because the intent of these tests is to verify results performed in the lab – not look for ways to contradict lab results.

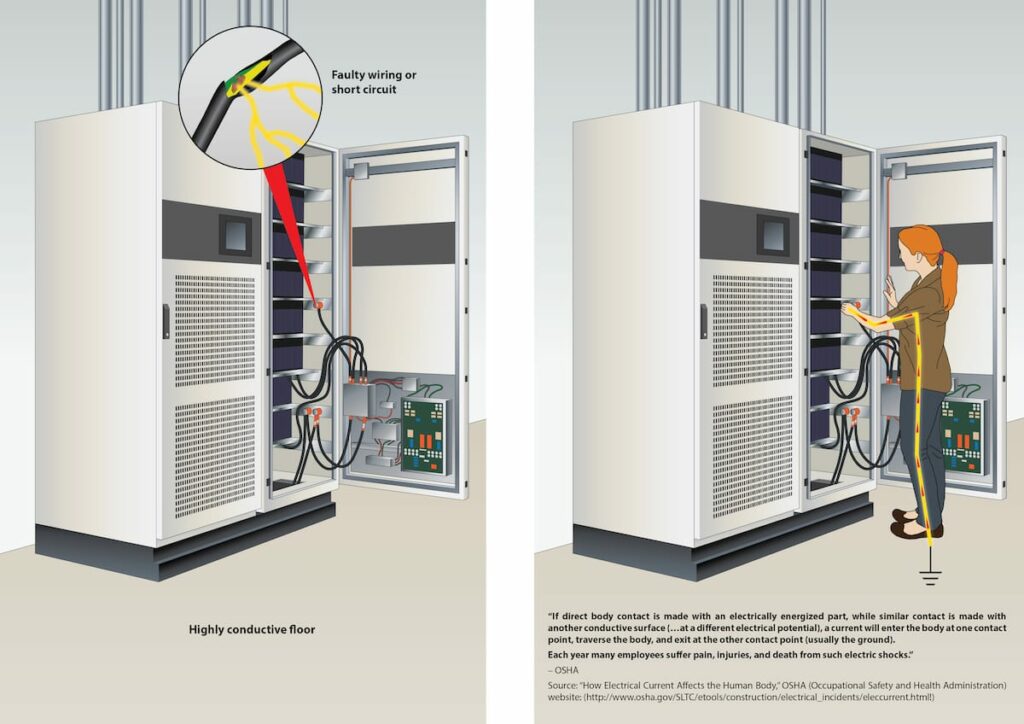

But what if people in your facility work with or near electrified equipment that could become unintentionally grounded? In the floor qualification lab there’s one ground connection: the manufacturer’s. In the real world, it’s highly likely that the manufacturer’s ground is not the only ground connection. Conductive flooring can, in fact, be grounded by the electrical components above it. Resistance values of tiles under grounded equipment is often quite different – and lower – than resistance to ground of tiles in the middle of the space. Doesn’t it make sense, then, to test the resistance to ground of tiles and sections of flooring that lie below and/or beside operational equipment?

Electricity flows through all available paths to ground.

A myth about grounding goes like this: “electricity flows to ground through the path of least resistance.” In reality, electricity flows to ground through all paths – intended and unintended.

Picture a bucket of water with different sized holes at the bottom. Will water leak only from the largest hole? Of course not. It will leak through all holes until the water is gone. The larger the hole, the more water will flow through – nonetheless, water will pass through every single hole.

Ground connections work the same way. Connections with lower resistance transport more electrical current, but current will flow through all connections in proportion to their respective resistance. In other words, electricity will flow through every grounding connection – not just the connection the flooring manufacturer instructed you to use for your verification testing.

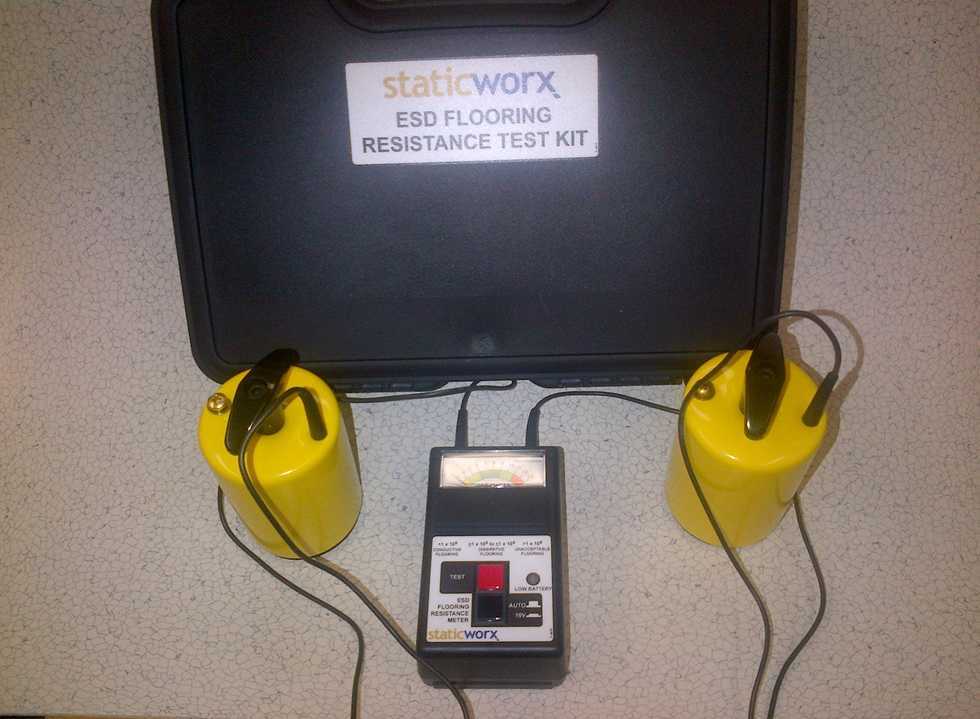

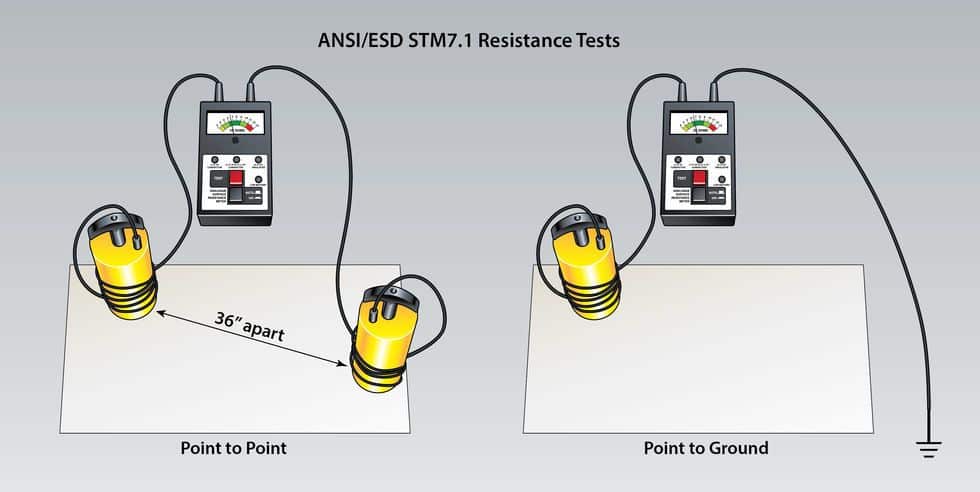

GroundSafe™ post-installation verification testing accounts for all the variables in your space and tells you where and how electricity will find its way to ground. With GroundSafe™ verification, you’ll know for sure whether or not the floor you specified and bought is the floor you received. Through our GroundSafe™ Flooring program, StaticWorx loans test equipment to anyone seeking to verify a StaticWorx floor. If you’re not sure how to perform the tests and would like assistance, we’ll walk you through it – either in person, in writing, or via a Zoom call.

GroundSafe™ post-installation verification testing accounts for all the variables in your space and tells you where and how electricity will find its way to ground. With GroundSafe™ verification, you’ll know for sure whether or not the floor you specified and bought is the floor you received. Through our GroundSafe™ Flooring program, StaticWorx loans test equipment to anyone seeking to verify a StaticWorx floor. If you’re not sure how to perform the tests and would like assistance, we’ll walk you through it – either in person, in writing, or via a Zoom call.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.