MaCom: GroundLock interlocking tile installed in operational cleanroom

"Even though we absolutely need a conductive floor in our cleanroom, we can't afford contaminating our HVAC system with dust and odors from flooring installation processes like shotblasting, concrete repair and skim coating. We'd have to build a back-up cleanroom before we would even consider installing a new floor."

Facility Manager,

Defense Electronics

Installing ESD Flooring in an Existing Operational Cleanroom with Minimal Impact on Contamination and Production

Some facilities planners, concerned about contamination or potential scheduling delays, dismiss the thought of installing electrostatic discharge (ESD) safe tile in operational clean spaces. Installing a new ESD floor—also known as an antistatic floor or static-control floor—often includes the difficult task of removing the old floor first. Ripping up old flooring, grinding concrete, and pouring epoxies and leveling compounds in a functional cleanroom would be a production manager’s worst nightmare.

The alternative is a temporary production shutdown during demolition and flooring installation which may be an even worse proposition. Horror stories abound about companies expecting a one-week installation schedule for shutting down manufacturing and moving equipment into rented trailers, only to watch one week become 10, 15, and even 20 days.

That’s why space planners with an eye on risk management ask for installation methods that will neither disrupt production nor potentially corrupt their controlled environments.

Reasons for Installing ESD Flooring in Occupied Areas

Let’s start with why a facility manager of a functioning cleanroom would want or need to replace an ESD floor.

Regardless of the issues involved, one does not replace an existing floor unless it is absolutely necessary. Floors are only replaced when the existing flooring, usually a seamless epoxy or tile, becomes incompatible with ongoing needs. In a cleanroom or clean manufacturing facility, there are four main reasons why this happens:

-

The existing floor, while conductive, may not meet stringent cleanroom criteria.

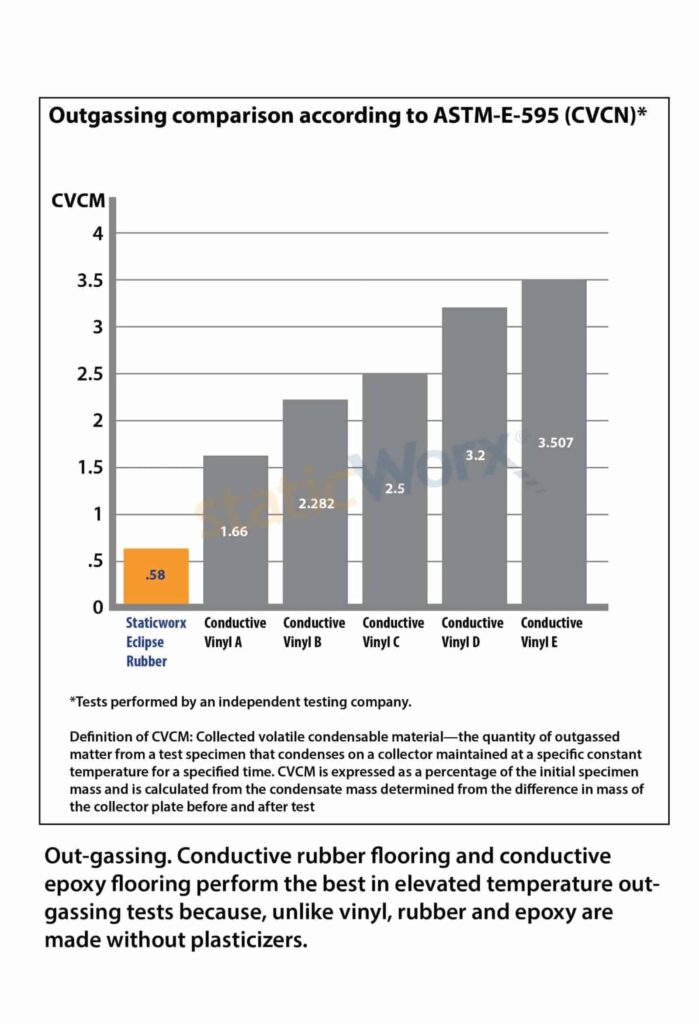

Some PVC/vinyl tile is known for out-gassing and plasticizer migration. The material outgassing/migration from the floor can contaminate electro-optics or giant magnetoresitive (GMR) head manufacturing processes.

-

The existing flooring material is improperly bonded to the concrete and has become a safety or maintenance problem.

This problem could be the result of any number of issues including vapor drive (in other words, moisture problems), alkalinity from the concrete subflooring or poor installation of the original floor.

-

The existing floor is cleanroom compatible, but it has no static-control properties.

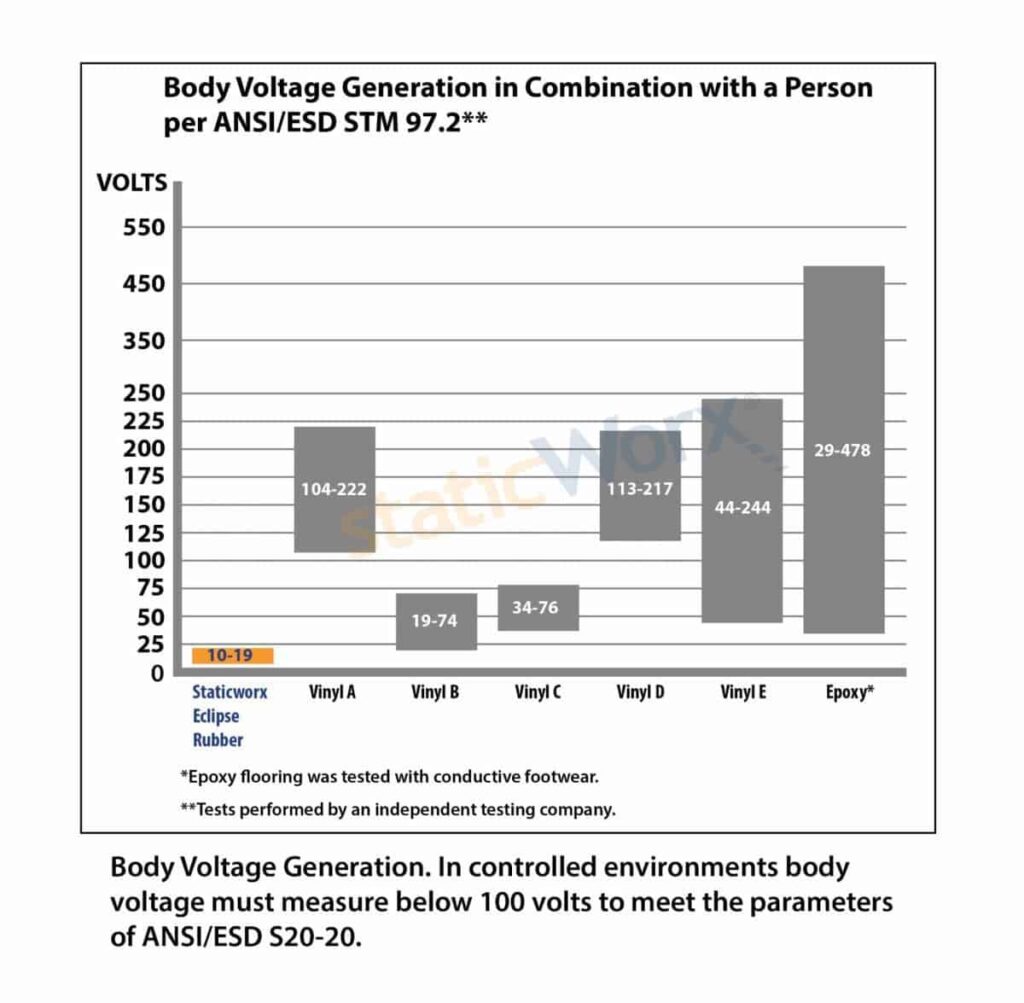

It may not meet the recommended minimum requirements of an ESD prevention program like those described by the ESD Association documents ANSI/ESD S20.20 [Protection of Electrical and Electronic Parts, Assemblies and Equipment] and ANSI/ESD STM97.2 [Floor Materials and Footwear – Voltage Measurement in Combination with a Person].

For example, the present floor may generate over 100 volts of static when people wearing conductive footwear walk from one place to another or the floor and footwear system resistance may exceed 1000 Megohms to ground.

-

The current floor does not meet minimum standards for static control without the use of ESD waxes or dissipative floor finishes.

ESD floor finishes are invisible and exhibit temporary characteristics. Because they are indistinguishable from standard floor finishes, waxes and other maintenance-sensitive ESD solutions, verification requires testing the floor on a regular basis using an ANSI/ESD STM7.1-complaint resistance system.

Relying on maintenance chemicals for ESD protection can give customers, particularly those who demand rock-solid quality control, the impression that their supplier has little concern for quality. Chemicals can be degraded by low-humidity ambient conditions or heavy traffic; 3rd party janitorial services may wax at irregular intervals or inadvertently apply a standard (non-ESD) wax or finish. Topically-applied finishes also wear off. Quality-sensitive clients realize their parts could be compromised if the ESD performance of the floor is degraded by any of these factors.

ESD Flooring Options for Cleanrooms

In any of the four replacement scenarios above, before any serious plans are made or dismissed it’s smart to begin with a broad evaluation of ESD flooring alternatives. Any thoughtful evaluation should begin with an investigation involving process compatibility, and then an examination of the risks/rewards of installing a new floor based on successfully dealing with obstacles such as shutdowns, equipment movement, loss of production, contamination, odor containment and other considerations.

It’s usually advisable to create a decision matrix or to assign points to various attributes when comparing options. Of course most of the options will be quickly dismissed based on contamination-control parameters or unsatisfactory electrical properties (point to point resistance, and voltage on a person wearing specific footwear).

Below is a reasonable list of possible flooring materials:

Various ESD flooring options

- Conductive paint

- ESD floor finish or conductive wax

- Conductive/dissipative carpeting and carpet tile

- Conductive/dissipative seamless flooring including epoxies, urethanes and quartz floors

- Strategically located conductive mats and runners

- Conductive/dissipative vinyl tile and vinyl sheet flooring

- Conductive/dissipative rubber tile and rubber sheet flooring (typical or glue free)

- Interlocking vinyl or rubber flooring (floating floor)

- Raised flooring covered with antistatic HPL

- Raised flooring with panels covered with options 7 or 8

Properly installed and adequately maintained, many of these options will provide some level of static protection in an electronics handling application. However, electrical performance is only one variable within the decision matrix.

Options 1, 2, and 3 can be eliminated purely based on inherent contamination control liabilities: Most ESD paints, option 1, flake, delaminate and – because these floors are usually somewhat porous – ultimately generate dust. ESD waxes and floor finishes, option 2, generate dust and fine particulates from abrasion caused by traffic and standard janitorial practices like buffing. Waxes provide only temporary static protection; ensuring ESD performance requires periodic stripping and maintenance. And any carpet or textile-based flooring, option 3, despite their static-control performance, naturally captures and accumulates particles and eventually becomes a dirt generator.

Option 4, resinous flooring (epoxy or urethane) is rarely installed in occupied spaces due to odors, drying times and dust generated during floor preparation. After installation, epoxies and urethanes must cure for 24 to 72 hours which may make them undesirable flooring materials in any occupied space that must be turned over quickly. Epoxies are also difficult to repair in a cleanroom without closing off the area with plastic shrouds and air exhausts during grinding and reapplication process.

Floor mats and runners, option 5, are typically used as stop-gap solutions until a more permanent flooring material is identified. Floor runners offer limited protection because they ground static charges on people or carts only if and when the latter are in direct physical contact with the runner or mat. This limitation means that the cleanroom will lack contiguous grounding. The resulting islands or zones of ESD protection force a continued reliance on expensive shielded packaging of static sensitive (ESDS) parts.

Ensuring continuous ESD protection also requires redundant grounding through the combination of wrist straps and ground cords (which inhibits mobility). Wrist straps must be connected and disconnected every time parts are removed from packaging or transported through ungrounded areas.

Although options 9 and 10, raised floor, are the de facto standard in most wafer fabrication areas, raised floors may be an expensive overkill for many cleanroom applications. Other than offering access to wires and cables and air exchange, there is little advantage to a cleanroom raised floor system.

Having eliminated other flooring materials, let us explore options 6, 7 and 8.

Will Conductive Footwear Be Required?

Understanding the difference between ESD rubber and ESD vinyl

Most ESD floors are purchased with the assumption that conductive footwear will be used judicially. However, an ESD prevention program, like any comprehensive control process, is only as good as its weakest link. In the case of ESD prevention, the weak link almost always involves compliance – i.e., the failure of personnel to adhere to rigid policies. It would be reckless to make assumptions regarding compliance without first conducting a serious reality check: Will every employee actually wear conductive footwear while he or she is physically present in the ESD-protected cleanroom?

Compliance is particularly important when comparing the performance of ESD vinyl with conductive rubber. Numerous independent testing [1] has documented that without the use of conductive footwear, conductive vinyl floors offer little or no benefit. People wearing uncontrolled footwear on conductive or dissipative vinyl flooring will generate static just as they would on any standard insulative vinyl floor. Walking body voltages (WBV) in excess of 3000 volts [2] can be measured on people walking on conductive vinyl when standard cleanroom booties and conventional footwear are worn without heel straps.

If compliance to ESD process controls is in doubt, it may be prudent to install a conductive rubber floor. Some rubber flooring products exhibit both conductive and antistatic properties; vinyl can only be made conductive/dissipative, not antistatic. Although employees should always wear controlled footwear in the ESD Protected Area (EPA), conductive rubber floors inhibit the generation of static charges regardless of footwear.

What is antistatic?

The term antistatic refers to a condition where static generation is inhibited during contact and separation with another material. Anti static flooring can either be static dissipative or conductive. However, not all static-dissipative or conductive flooring is antistatic. ESD floors can be conductive and still generate enough static to cause a harmful ESD event.

Note: the term antistatic has been replaced by the more accurate term: low charge generating. Low charge-generating materials prevent static from accumulating on people or objects.

| Flooring Option | Performance – Should be tested per requirements of ANSI/ESD S20.20 | |

| With Conductive Footwear | Without Conductive Footwear | |

| Dissipative Vinyl | Based on manufacturer | No static mitigation properties |

| Conductive Vinyl | Usually excellent | Limited antistatic properties |

| Dissipative Rubber | Usually excellent | Good antistatic properties |

| 2-layer Conductive Rubber | Excellent static mitigation properties – usually best in class | Extremely antistatic |

Adhering to Old Flooring Installation Method:

ESD tiles or sheet flooring

The second most time-consuming aspect in standard flooring installations is waiting for adhesives to dry and cure before the new floor is fit for traffic and equipment movement. This 48 to 72 hour step is eliminated by selecting flooring materials and cleanroom-compatible adhesives that bond immediately. Conductive pressure-sensitive adhesives like StatBond Permanent PS are VOC free and they are now formulated with high shear strength.. They can be spread directly over old well-secured tile or on top of intact epoxy coatings. Since these adhesive dry and develop a high tack in one hour or less, the new ESD floor can facilitate foot traffic almost immediately after installation.

One large medical electronics manufacturer used conductive release adhesives to install small segments of ESD rubber flooring over old vinyl tile until the entire facility was covered. This installation occurred over a six week period until all 25,000 feet were covered with ESD flooring. The entire process was done without interrupting traffic or production and since the tile could be walked on right away, minimal labor was required for equipment movement. Larger pieces of equipment were moved just a few feet and then repositioned immediately after tiles were placed on the adhesive. And the best attribute of this installation method is the lack of odors, so the installation was done during normal manufacturing hours.

Floating Installation Method

Despite the obvious costs of tile removal and reinstallation, facility managers are usually as concerned about meeting project deadlines as they are about maintaining budgets. One additional day of shutdown could potentially cost their company more dollars than the entire expense of new flooring and labor. It is well known that delays from unanticipated events are an everyday part of any construction project.

In the case of flooring, demolition will often reveal invisible unforeseen problems like moisture vapor or damaged concrete that must be addressed before any new flooring can be installed. Improper handling of these problems could add days or even a week to an installation schedule that was already overly optimistic. These risks are the main reasons companies limp along with a marginal ESD prevention plan rather than take the chance of ripping up what could become their own Pandora’s Box.

The single biggest obstacle in installing new flooring is dealing with the removal of old flooring. This issue is painlessly solved by leaving the old or failed floor in place and covering it with new subflooring.

Glue-free Rubber

With EclipseGF (glue-free) rubber there is no need for pre-installation testing of subfloors for vapor, no buckets of glue, troweling or cleanup – allowing for easy installation over almost any subfloor with no downtime. Self-sticking EclipseGF can be applied directly over most surfaces, including wood, steel, concrete and epoxy. Simply trim, peel the protective adhesive, roll out – and you’re done.

Interlocking Tiles: Vinyl or Rubber

Interlocking flooring like GroundLock™ Extreme (vinyl tile) can be installed directly over almost any surface regardless of the root cause of the floor’s failure. This floating subflooring system can be installed without the use of adhesives or chemicals. The only tools required are a rubber mallet and a tile cutter. To avoid contamination, floating subflooring tiles can be cut outside of the cleanroom and then brought inside where they are snapped together.

Understanding Moisture Problems

The most dreaded words a flooring contractor can say to a client are “you have a concrete moisture/vapor problem.” In laymen’s terms a moisture problem means that water vapor is passing from the ground below the building through the concrete subflooring. These vapors combine with the alkaline chemistry of concrete and over time will destroy and undermine the bond between flooring materials and concrete.

Unfortunately, this type of moisture is not visible in the form of a visually high water table or pooling of water droplets on the floor, so without testing is easily missed.

Before fully cured concrete is covered or sealed, moisture vapor easily passes through without a problem. Moisture vapor typically remains undetected until it becomes trapped in the concrete subflooring when a non-permeable membrane like rubber, vinyl or epoxy flooring is installed. Over time, vapor pressure increases against the tile or epoxy until the flooring breaks away causing delamination from the concrete.

Despite the availability of moisture-indicating test kits that can assist in predicting (and preventing) this difficult problem, moisture-related issues are usually discovered after a flooring installation failure. In the case of cleanroom floors, “discovery” typically occurs months and sometimes years after installation when the room is fully occupied and cannot be shut down without severe consequences. This is one reason it may be prudent to install over an existing flooring versus removing the old floor.

After small sections of flooring begin failing, the problem quickly spreads. The resulting mess can cripple a manufacturing operation. Tiles become loose, air entrainment bubbles develop in the tile or epoxy coatings followed by eventual black liquids oozing through cracks and seams. The failing floor becomes a safety hazard and traffic obstacle. Repairs are almost impossible because water vapor continuously rehydrates the repaired area, often before the new installation has had the opportunity to cure.

After the problem first emerges, most companies that have experienced this problem find themselves replacing compromised sections on an ever increasing basis. The standard permanent “fix” for moisture problems usually does not get used since it would require a complete shutdown due to demolition and reinstallation of flooring. A permanent fix entails ripping up the failed floor, shot blasting the concrete, repairing imperfections, installing a moisture vapor barrier and then reinstalling new flooring. The cost for this cure could run as high as fifteen to twenty dollars per square foot depending on working conditions, and this is exclusive of the cost of shutdowns, equipment moving and auxiliary support.

Eliminating Moisture Problems with Rolled

Vapor Barrier Installation Method

Sometimes old tiles are so poorly adhered due to moisture, it is best to simply remove them. Philips Medical, an ultrasound manufacturer had just installed ESD vinyl tile in a new cleanroom. With brand new HEPA filters already operating and equipment ready for move-in, they discovered the new floor was poorly adhered and lifting. The root cause was quickly identified as vapor permeation over 90% per ASTM 2170 testing.

The contractor had less than 5 days to remove the floor and replace it. StaticWorx provided a full package starting with a non-invasive method for eliminating vapor problems. The vapor barrier was supplied in self-adhering rolls. This type of vapor barrier is a composite of multiple materials that seal off moisture, prevent dimensional changes and provide an ideal bonding surface for StaticWorx Statbond PS adhesive. The entire removal and reinstallation of 800 feet required only 3 days start to finish. And the best part – the clean room air quality was undisturbed and the entire job is covered by one warranty for vapor, physical characteristics and compliance to ANSI/ESD S20.20.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.