A Step-By-Step Guide to Choosing an ESD Floor & Ensuring the Success of Your Installation

An ESD floor is a long-term investment. Following a logical, comprehensive process can help to ensure the reliable, permanent ESD protection that’s exactly the right fit for your application.

When ESD floors fail to meet expectations, nine times out of ten it’s for highly preventable reasons:

Top Ten Reasons for Installing the Wrong ESD Flooring

- The specifier or end user did not understand static electricity or ESD problems.

- Decisions were based on an incorrect understanding of ESD terms.

- Stakeholders failed to recognize that flooring is only one component in a static-control system.

- The specifier didn’t realize or neglected to account for the fact that standards vary across industries and applications.

- No one accounted for differences in performances with different footwear.

- No one accounted for site conditions.

- Flooring materials were not tested prior to purchase.

- Some stakeholders were left out of the decision-making process.

- Installation challenges were ignored.

- No one tested or certified the ESD properties of the floor after it was installed.

Skip any one of the big 10s and your floor may not perform as hoped or intended.

At StaticWorx, we go through the same detailed process with every client we work with.

We offer over 20 options. This does not mean we will tell you which floor to buy – that’s your decision. But we will help you figure out which questions to ask. Along the way, we’ll guide you, by providing the objective, evidence-based information you need to help you answer your questions in a way that enables you to meet your goals and objectives and make the right decision for your application and environment.

In each of the following steps—and throughout the selection process—we help you identify the questions you need to ask and, when necessary or requested, help you formulate your answers.

Working with StaticWorx:

Twelve Steps

to a Successful ESD Flooring Installation

STEP ONE: Understand the problem or you can’t find the cure.

- How does static pose a threat?

- Why are you concerned about static discharge?

- What consequences may occur if you fail to address your static problem?

- What are your goals and objectives for static control?

- How will you know the floor has solved your problem? What are your metrics?

STEP TWO: Standards Are Industry and Application-Specific.

Before working with us, many, if not most, clients do not realize that static prevention does not have a one-size-fits-all solution. In fact, electrical standards vary across different industries. At the start of the process, we share standards and specifications and help you understand how standards for your industry differ from the standards for other industries and why it matters.

Here are the pertinent questions:

- Are you an electronics manufacturer?

- Are you an end user of electronic systems?

- Are you installing in data center, 9-1-1 call center or control room?

- Do you know which ESD protection standards apply to your industry?

- Do you understand the difference between anti-static, conductive and dissipative?

- Are you aware that static charge generation differs from conductivity and that each has its own standard test method?

STEP THREE: Problem-Solving Solutions Do Not Work in Isolation.

- What happens when people sit down?

- What happens when they stand back up or move equipment?

- What happens if they wear certain types of footwear

- Will the ESD floor help in all of these scenarios?

To choose the right floor, you need to know the answers to these questions. Because a floor is part of a system or process that is application-specific, solutions must match your application.

STEP FOUR: Understanding Your Site

Neglecting site conditions is one of the primary reasons for physical flooring failures. In step four, we help you to evaluate your environment and understand any challenges you may face.

Among the questions we ask are these:

- Where will you install your ESD flooring?

- Do you own or lease the building where the flooring will be installed?

- Have you done – or does your contractor plan to do – vapor testing?*

- What is the condition of the subfloor? Does it need repairs?

- Do you need your floor to ground carts and chairs or just people?

- Vapor testing is a hot and litigious issue in the floor-covering world. Vapor permeation contributes more than any other factor to tile and floor bonding failures. ASTM vapor tests determine if adhesives may fail when bonded to bare concrete. Most people don’t perform these tests properly. Ask StaticWorx about this.

STEP FIVE: Understanding the Install Process

Are you aware that there is more than one way to install an ESD floor? Or that different flooring materials require different methods of installation?

We help you work through your installation process, by asking the following questions:

- What are the challenges of installing the material/s under consideration?

- What install methods are appropriate for the material and application?

- Would you prefer to use glue or have a glue-free installation?

- What are the advantages or perceived disadvantages of each?

- How much downtime are you facing?

- What sort of floor prep should you do?

- What is the air quality?

- What is the ambient temperature and humidity?

- What are the advantages and disadvantages to covering a pre-existing floor?

STEP SIX: Rounding Up the Stakeholders

Typically, the decision for ESD flooring is left to a particular person or committee. Sometimes it’s an ESD specialist or team; other times, it’s a facilities person; still others it’s an architect, designer or contractor. Because the selection process often involves only this particular person or team, concerns of the people who will work in the environment are sometimes overlooked.

Before you make a decision, we’ll ask you to round up the stakeholders and ask what’s important to them. We can help you design a matrix that takes their concerns as well as all of the issues outlined above into consideration.

Here are questions to consider:

- Is there an internal group that will calibrate the floor at certain intervals?

- Is ergonomics an area that should be addressed?

- Who will take care of the floor?

- Are aesthetics important? Are there visual constraints?

- Is there a need or desire for noise attenuation?

- Will the area be exposed to natural light? (Color as well as certain flooring materials – e.g. epoxy – can be affected by light.)

STEP SEVEN: Writing the Spec

Before selecting the floor, you’ll need to write a specification that takes into consideration your various goals and objectives and addresses all issues, from electrical standards to performance.

If you’re not sure how to write the spec, our team will provide you with objective advice about standards, performance, warranty, maintenance and certification of your new floor. We will help you avoid proprietary language and write your specification so that it meets industry best practices and represents an objective effort to identify potential alternatives .

STEP EIGHT: Choosing the Floor

Now comes the fun part! You’ve asked and answered all of the important questions and narrowed your choices to one or two flooring materials. The next step is to match your choices to your objectives, challenges and concerns, and decide on the best fit for your application.

As most of your questions have been answered by now, we help you with the following:

- Provide lab reports

- Show you how to test your floor

- Provide design samples, including an actual mock-up

STEP NINE: Choosing a Contractor

If you’ve ever hired a contractor for work at your home you know that the right contractor can make all the difference, not only in cost and in getting the job done, but in doing the job right. The fastest or least expensive contractor is not always the right contractor. As we always tell clients, it’s much less expensive to do the job right the first time than to have to do it over.

When hiring a contractor, these are the questions we suggest you ask:

- Is the contractor licensed and insured?

- Is the cost completely transparent? Do you know, for instance, the cost for floor prep?

- How does the contractor handle change orders?

- Is the contractor experienced?

- What is his or her reputation?

- Where is the contractor located? (A local contractor is much more likely to be there for you should you have problems down the road.)

STEP TEN: Writing a Contract

A contract should be envisioned as a template for a deal that’s a two-way street. It should clearly define acceptable materials, disposal, safety policies, start and finish dates, hours of work, environmental controls, warranty, cost, payment and retainage policies. The contract should also include agreed costs for items that may become necessary – such as vapor emission barriers, floor protection, overtime and weekend labor costs, interruptions, and so on.

STEP ELEVEN: Installing the Floor

First and foremost, you need to require your contractor to follow the manufacturer’s installation instructions. We always suggest a short meeting in-person or by phone, Zoom, etc., with the installer, the flooring manufacturer’s rep, the specifier, the end user, the GC and, depending on the situation, the manager of the area where the flooring will be installed.

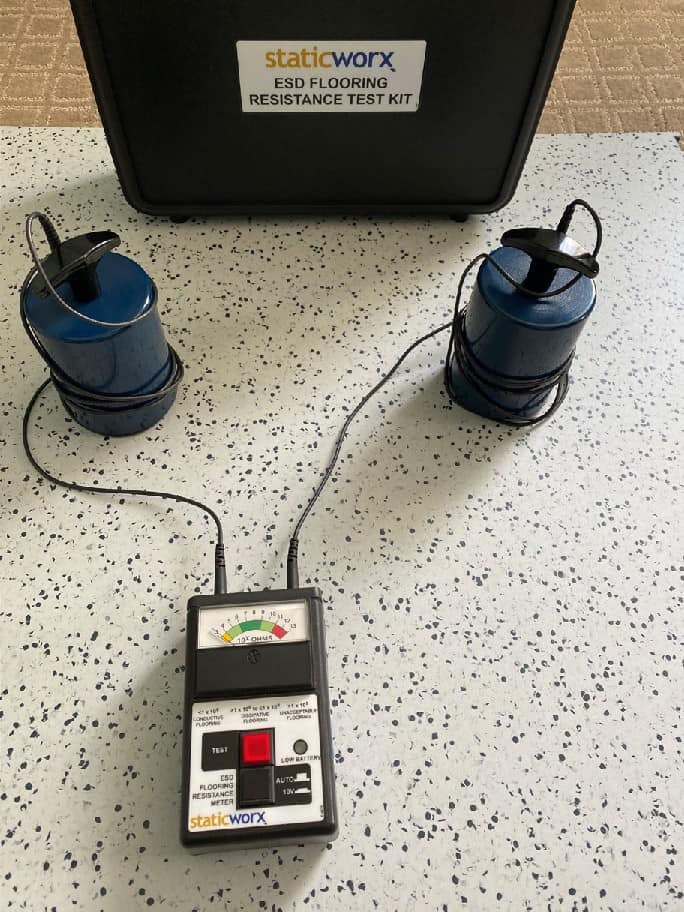

STEP TWELVE: Certification

Ongoing relationships

If we’ve been successful—and we like to think we usually are—you’ll feel comfortable calling us with any questions or concerns. If there are any issues with your floor, we pride ourselves on helping you solve those problems in a way that satisfies you—and your contracting team.

Working with clients is the best, most interesting part of our job. Building and maintaining relationships is the reason we do what we do. That’s why we work so hard to earn your trust.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.