Home > Learning Center > ESD Flooring: The Basics > What is ESD Flooring, How Does It Work, and How Do I Choose One?

Home » Learning Center Articles » ESD Flooring: The Basics » Article: What Is ESD Flooring, How Does It Work, And How Do I Choose One?

What Is ESD Flooring, How Does It Work, And How Do I Choose One?

[23 min read, 7 min videos]

THE GIST: What is ESD Flooring?

How Does ESD Flooring Work? How Do I Choose an ESD Floor?

Electrostatic Discharge (ESD) flooring protects electronics from damage caused by static electricity, which accumulates as people walk. Conductive elements such as carbon, graphite or metal-coated particles, distributed throughout the flooring material, give ESD floors electrical conductivity, and create an electrical pathway from the walking surface to ground.

ESD flooring standards are based on an ESD flooring/footwear combination. Some, but not all, ESD floors also prevent charge generation – i.e., static from accumulating as people walk. Thus, it’s critical to determine the type of footwear people will use in the space. When choosing an ESD floor, always test for both electrical resistance (STM7.1) and charge generation (STM97.2).

A floor can be conductive and still generate enough static to damage electronics.

- To be sure you choose the right ESD floor for your application, always evaluate:

- The relevant electrical code

- Industry standards for electrical resistance and charge generation (body voltage)

- Independent test results: resistance (STM7.1); charge generation (STM97.2)

- Footwear used in the space: ESD-protective footwear or regular street shoes

- Any specific requirements for the application

- The demands and constraints of the environment

- Buyer goals and objectives

- A static discharge as small as 20 volts, can damage or destroy microelectronics.

- Static-control floors create a traceable path from the walking surface to ground.

- To measure the resistance of a flooring material, we use test method ANSI STM7.1.

- ANSI/ESD S20.20 requires electrical resistance to measure below 1x 10E9 ohms.

- Motorola R56 and FAA 019f, require 1 x 10E6 ohms and below 1 x 10E9 ohms.

- If people wear street shoes in the space, the floor must also prevent charge generation.

- An ESD floor can be conductive and still generate static (fail to prevent body voltage).

- To evaluate the potential for charge generation, use ANSI STM97.2

Post Sections

Need additional information about specific ESD products? Learn more about our ESD flooring products

What is Static Electricity?

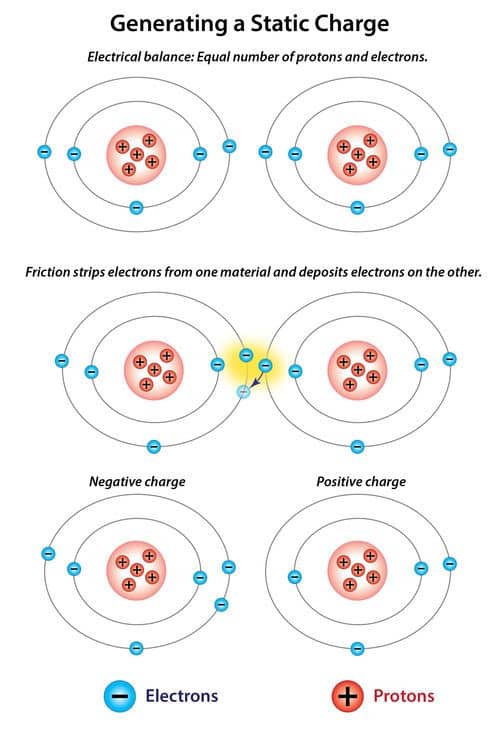

Whenever two materials with different electrical characteristics rub together, or come into frictional contact—you drag a plastic comb through your hair, pet your cat, or walk across a floor—their surface molecules interact, forming an electrical bond.

Separating the materials creates friction. This frictional force pulls electrons away from one material and deposits them on the other, creating an electrical imbalance in both materials.

The material that lost electrons becomes positively charged. The material that gained electrons is left with a negative charge.

The technical term for this phenomenon is tribo-electrification, commonly known as static electricity.

Why is ESD – Electrostatic Discharge – a Problem?

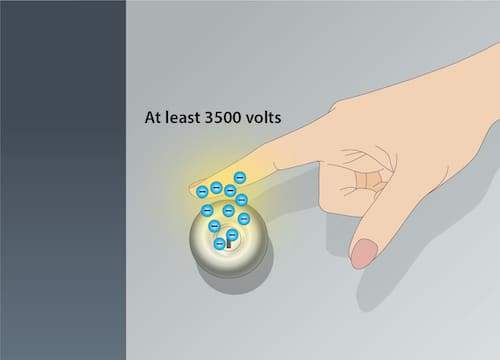

When we think of static in our everyday lives, most of us think nuisance—static cling, particle attraction, irritating static shocks. To perceive these common effects of static electricity—to feel a static shock—the discharge must be at least 3500 volts. Though we may not enjoy feeling a 3.5 kV shock, it’s no big deal—to us.

So sensitive, in fact, that they can be damaged—and data compromised, if not lost or destroyed—by a static discharge as low as 20 volts. Well below the human threshold for perception.

We’ve all, at one time or another, been slowed down, laid-up, or knocked out by a cold. A static discharge of 20 volts is about as perceptible as breathing the germs that cause the common cold. We don’t know they are there—until……….

When we think of static in our everyday lives, most of us think nuisance—static cling, particle attraction, irritating static shocks. To perceive these common effects of static electricity—to feel a static shock—the discharge must be at least 3500 volts. Though we may not enjoy feeling a 3.5 kV shock, it’s no big deal—to us.

Electronic components built or assembled in electronics manufacturing plants, circuit boards, hand-held electronic devices, headsets, and sophisticated computer equipment typically used in labs, hospitals, server rooms, FAA flight towers, 9-1-1 dispatch operations, mission-critical call centers—even in theaters and casinos—contain microelectronic parts that are highly sensitive to minute changes in electrical current.

So sensitive, in fact, that they can be damaged—and data compromised, if not lost or destroyed—by a static discharge as low as 20 volts. Well below the human threshold for perception.

We’ve all, at one time or another, been slowed down, laid-up, or knocked out by a cold. A static discharge of 20 volts is about as perceptible as breathing the germs that cause the common cold. We don’t know they are there—until……….

Why is Static-Control Flooring Needed?

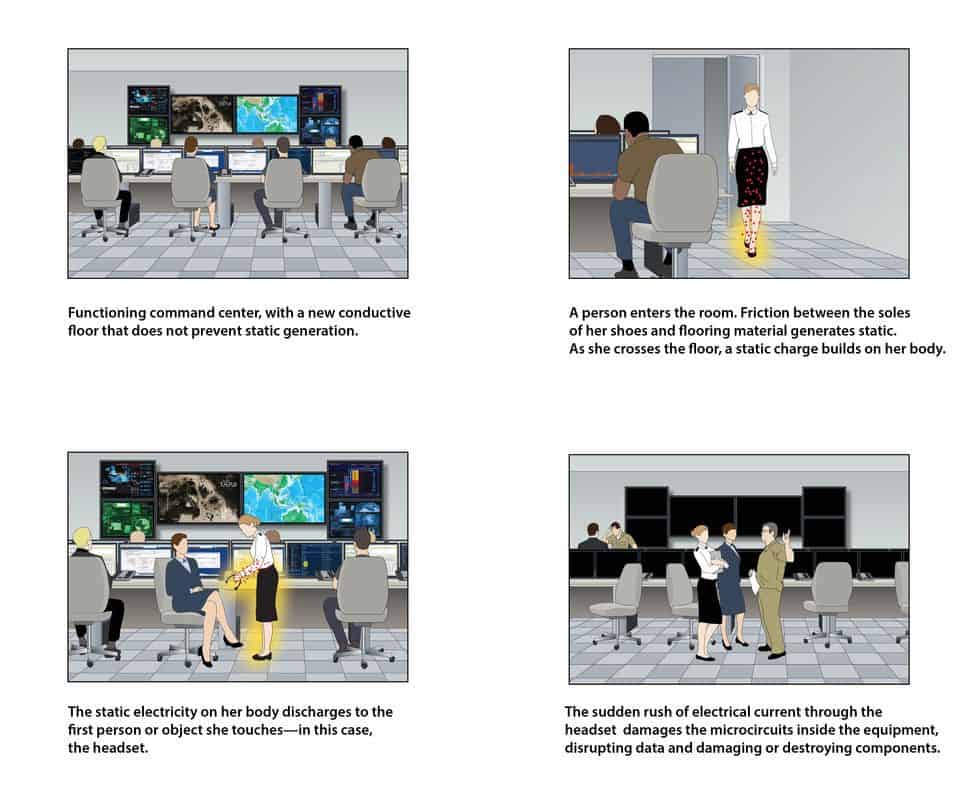

When we walk on certain floors, the friction between the soles of our shoes and the floor generates a static charge.* This static charge stays in place, on the surface of our body, until we touch something, then it jumps or discharges to that person or object.

This release of electricity is called an electrostatic discharge, or ESD. When static discharges to a static-sensitive electronic component, the sudden rush of electrical current can damage or destroy its internal circuitry.

- The voltage and polarity of a static charge is determined by various factors, including the force of friction, triboelectric properties of the materials, relative humidity, etc.

In most workplace environments, the static generated when people walk is the biggest contributor to random ESD events (or problems caused by electrostatic discharge). For this reason, a static-protective floor—or an ESD floor/footwear combination—is the cornerstone of any effective static-control program.

How Does Static-Control Flooring Work?

An effective static-control floor performs two separate, equally important functions:

- Provides a traceable path to ground;

- Inhibits static generation, meaning the floor prevents static from building on people as they walk.

Note: Grounding and conductivity differ from static generation. A grounded/conductive floor can still generate static charges.

Understanding and adhering to these basic requirements is anything but simple.

Some so-called “antistatic” floors do not provide a path to ground.

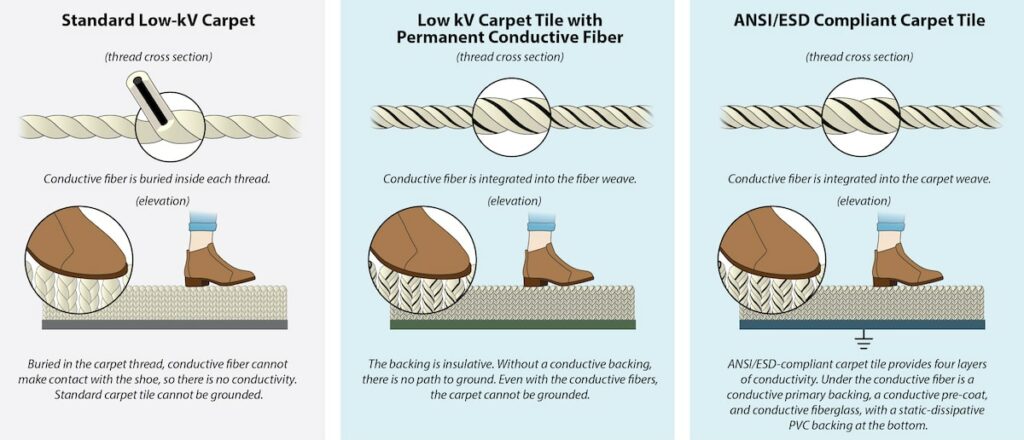

Low kV carpet fibers do not make electrical contact with shoe soles, so the carpet cannot dissipate static charges, and cannot be grounded. Low kV floors merely reduce the amount of static that occurs when shoe soles contact the surface of the carpet.

Designed to prevent nuisance static and nothing more, 3kV antistatic carpet is good only for reducing the ouch when people touch metal objects like a doorknob. A 3.5 kV floor is neither intended nor warranted for reducing charges to the minute thresholds necessary to protect ultra-sensitive electronics.

Some very good static-control floors generate charges.

Many perfectly good static-protective floors fail to meet the second requirement: preventing charge generation.

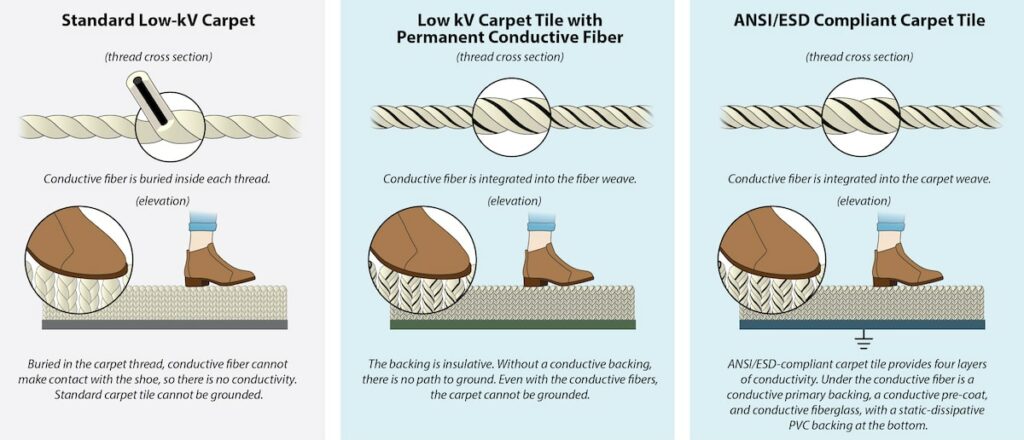

Low charge-generating materials do not generate static when people walk on the floor.

However, whether or not it has conductive veins on its surface, vinyl is not a low charge-generating material. To prevent static, conductive vinyl must be used in combination with special static-protective footwear; otherwise, when people walk, a conductive (or static-dissipative) vinyl floor will generate static.

This doesn’t mean vinyl is a poor option for every application. It does mean, unless footwear controls are in place, requiring every person who comes through the space to wear special, static-protective footwear—and these mandates are diligently enforced—conductive vinyl will not prevent static and won’t protect equipment from damage caused by static discharge.

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

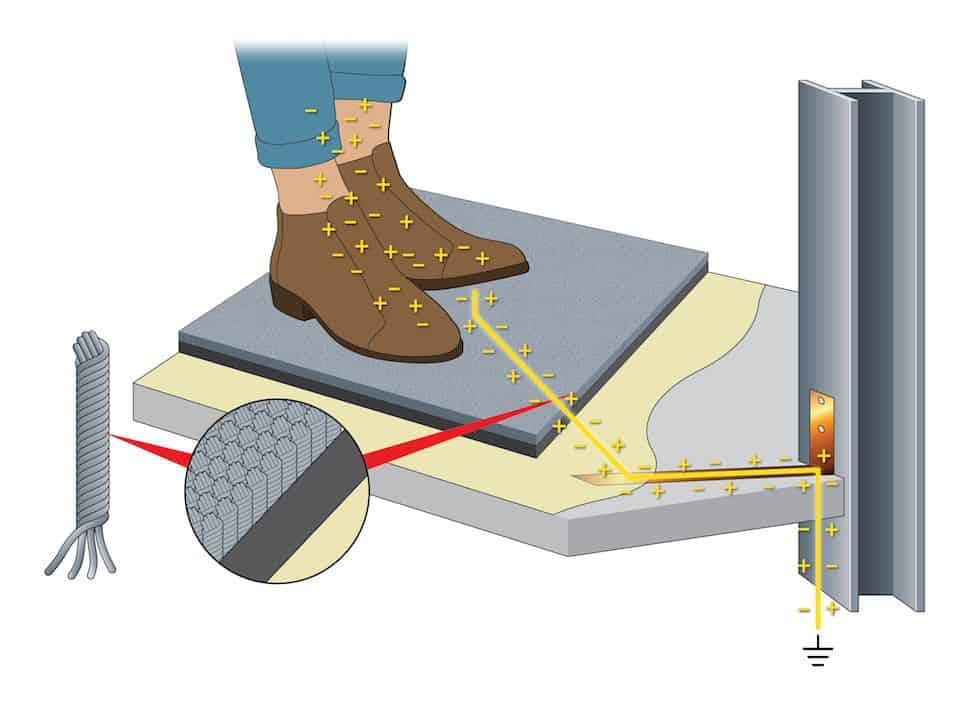

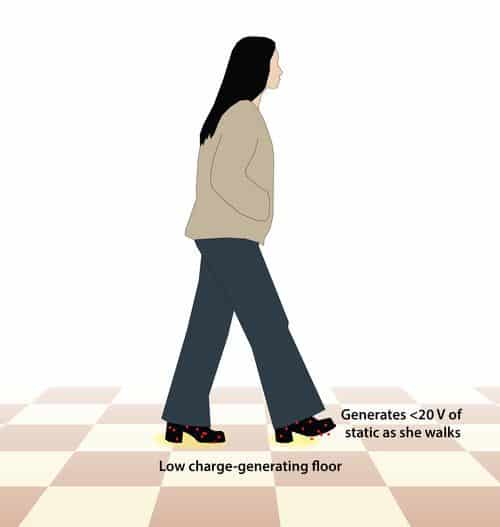

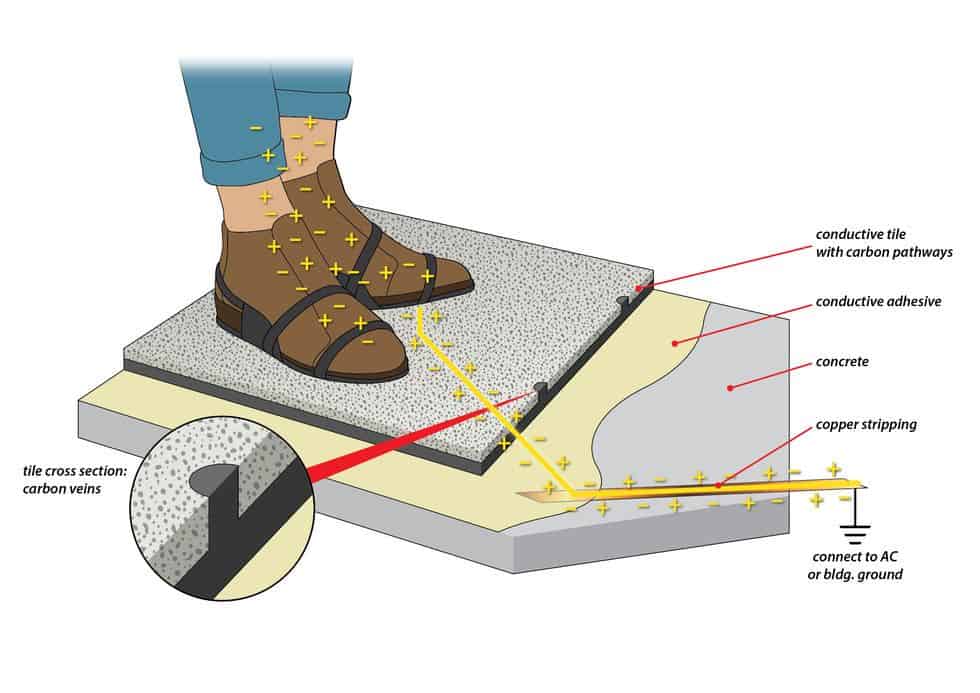

How Does a Static-Control Floor Provide a Path to Ground?

In the manufacturing process, ESD floor tiles are loaded with conductive elements, such as carbon, graphite or particles coated with metals, that provide electrical conductivity. When the floor becomes electrically charged, these conductive elements act as an electrical chain, conducting electricity from the surface of the floor through its entire thickness. Static-control flooring is installed over an electrically conductive underlayment, such as conductive copper foils or carbon-loaded adhesive. The underlayment forms a conductive ground plane that unifies all the contiguously-installed tiles in the room.

Copper grounding strips, attached to the underlayment, are connected to either an electrical outlet or an earth ground such as a steel I-beam or a grounding rod. This electrical connection allows static to complete its circuit and flow safely to ground.

The static generated when people walk on the ESD floor flows at a controlled rate through the conductive elements in the floor, across the underlayment, to the copper strips, to ground.

Instead of remaining on the floor’s surface or moving through humans to whatever they touch, static is drawn downward, toward ground, where it can no longer wreak havoc.

Note: An ESD floor can be grounded, yet fail to provide a safe pathway to ground. How is this possible? Because electricity always seeks its easiest path to ground. If the floor’s surface is more conductive than the underlying adhesive, currents may bypass the adhesive, preferring to cut across the surface of the floor, presenting a possible safety hazard.

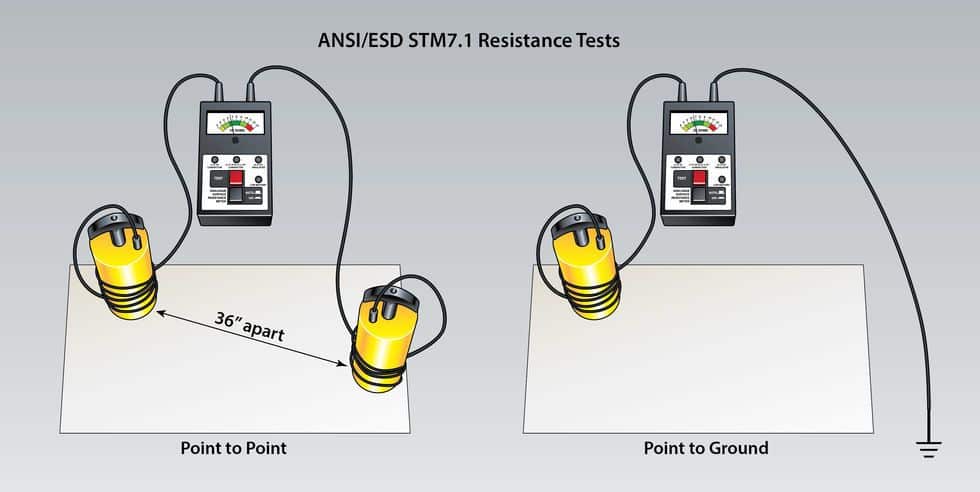

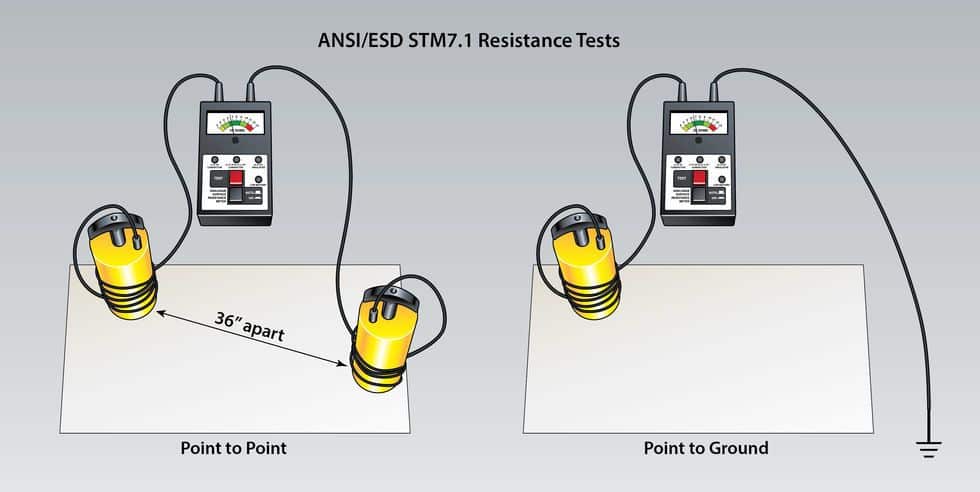

Testing the Electrical Resistance of Flooring Materials

To measure the resistance characteristics of a flooring material, we use ANSI STM7.1. Using two five-pound NFPA probes, this test measures resistance across the surface of a grounded floor tile or flooring material. To meet the ANSI/ESD standard S20.20, the material must measure below 1 x 10E9 ohms.

A minimum resistance is not specified in the standard, because S20.20 requires the use of conductive footwear, with built-in resistors measuring at least 750,000 ohms (7.5 x 10E5). The resistors protect the wearer from electrical shocks, by compensating for an overly conductive floor. However, many testing devices trigger a failure mode if the footwear measures below 750,000 ohms, meaning the protective gateway is insufficient, in which case the wearer would not be allowed on the floor.

To meet Motorola R56 and FAA 019f, the grounding standards for 9-1-1 dispatch areas, telecommunications spaces, and FAA flight towers (where people wear regular shoes without built-in resistors), flooring materials must measure above 1 x 10E6 ohms. This minimum threshold is intended to protect personnel from stray voltages that could cause personal injury on an overly conductive floor.

Why would a person wearing regular shoes be potentially at risk walking on an ESD floor in a telecommunications space?

Unlike controlled environments in electronics manufacturing, spaces like 9-1-1 dispatch areas and flight towers do not have control over footwear or footwear conductivity requirements. This means, people walking in these areas are not screened—as they are in electronics facilities—to determine if their footwear might be too conductive to interact with the environment.

An example of footwear that could be too conductive are leather shoes worn on a wet day. When leather, normally an insulator with no conductivity, absorbs water, it becomes highly conductive. If the wearer happens to step in a puddle on the way to work, the wet shoe would direct any electrical current from its sole to the wearer’s skin. For this reason, the static-control floor should provide intrinsic electrical resistance to compensate for the possibility of a person wearing shoes that are too conductive or deciding to kick off his/her shoes while working in the environment.

Low Charge Generation: Inhibiting Walking Body Voltage

To dissipate static, or draw static charges away from people or objects, the floor in any static-sensitive environment must be grounded. For electronics manufacturing applications that require the use of ESD footwear it’s fine to use charge-generating flooring materials like conductive vinyl. The carbon veins in conductive vinyl tiles form an electrical bond with the conductive materials in ESD footwear, preventing static from building as people walk.

To eliminate charges in spaces such as mission-critical call centers, flight towers, or 9-1-1 dispatch operations, where people wear regular street shoes, the floor must also prevent static charges from accumulating when people walk on the floor; we call these charges “walking body voltage,” and the materials that prevent walking body voltage “low generating materials.”

Command Center With a Conductive Floor that Generates Static

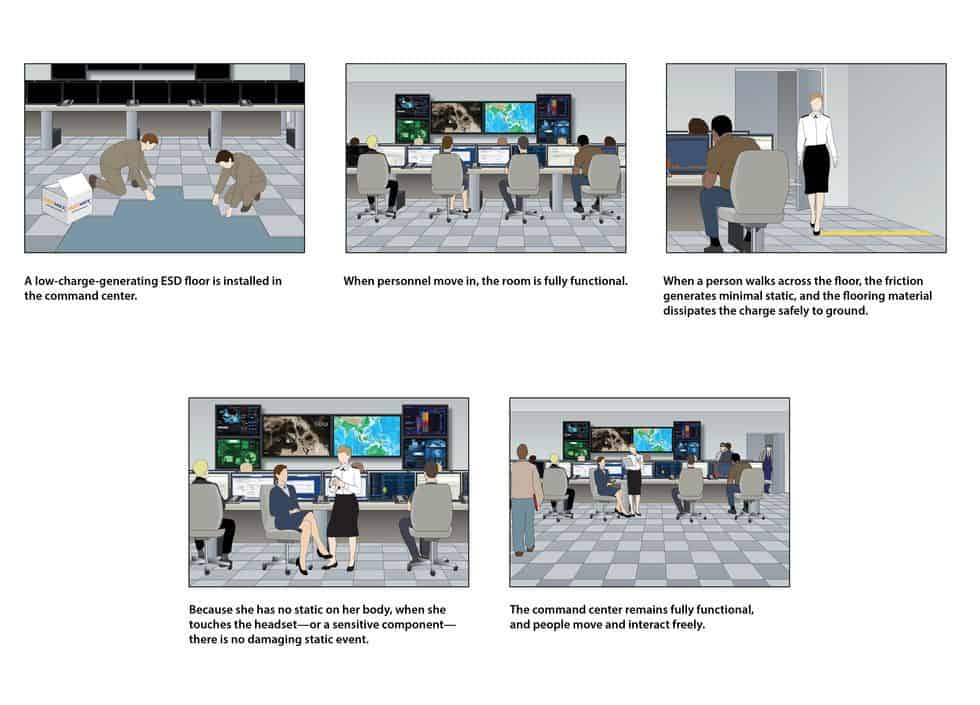

Command Center With a Low Charge-Generating ESD Floor

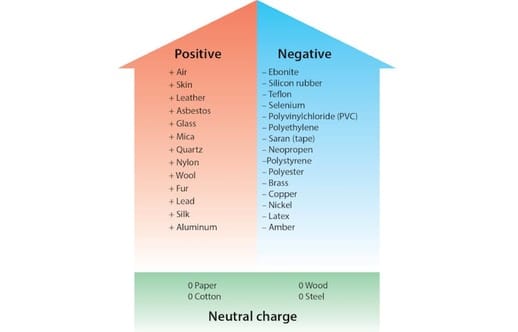

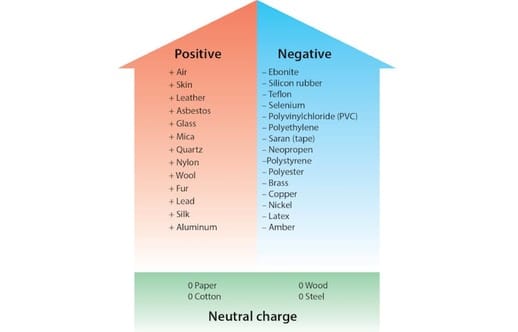

Triboelectric Propensity and Charge Generation

The frictional force (contact and separation) between two materials creates a triboelectric—or static—charge. The polarity (whether a material takes on a positive or negative charge) is determined by the relative properties of the two materials—or which material is more apt to accept or give up electrons. How the materials interact, as well as environmental conditions, such as humidity, also contribute to the effects of triboelectrification.

The chart below ranks materials according to their propensity to become positively or negatively charged.

Why Do Some Static-Control Floors Generate Less Static Than Others?

The ability of flooring material to inhibit static is determined by the triboelectric effects of the material, the way the floor is manufactured, and how the flooring material interacts with the composition of the particular shoes a person is wearing

When two dissimilar materials are rubbed together they generate static. Conductive vinyl, for instance, is comprised primarily of ordinary static-generating plastic compounds, mainly polyvinyl chloride (PVC), with a small distribution of carbon or graphite particles. People wearing ordinary footwear (street shoes) will generate significant static charges while walking on conductive vinyl.

Every documented study has shown vinyl to generate 8 to 10 times the amount of static generated by the same person walking on ESD rubber or static-dissipative carpet tiles.

The corollary is also true: materials with similar triboelectric properties generate minimal static when they interact. The base compound used in two-layer conductive rubber sufficiently resembles the material composition of most shoe soles, so that when people walk, wearing almost any type of footwear, a conductive rubber floor will not generate a charge. Numerous studies conducted by independent labs, such as Fowler Labs, have confirmed that static-control rubber is a low-generating material, regardless of footwear.

Charge generation doesn’t make conductive vinyl a poor choice for static-control flooring. It does mean that vinyl ESD floors should always be used in conjunction with static-control footwear. A conductive vinyl floor will prevent static ONLY if protocols are in place mandating that, at all times, any and everyone on the floor must wear static-control footwear—such as heel straps, conductive shoe covers, or ESD shoes.

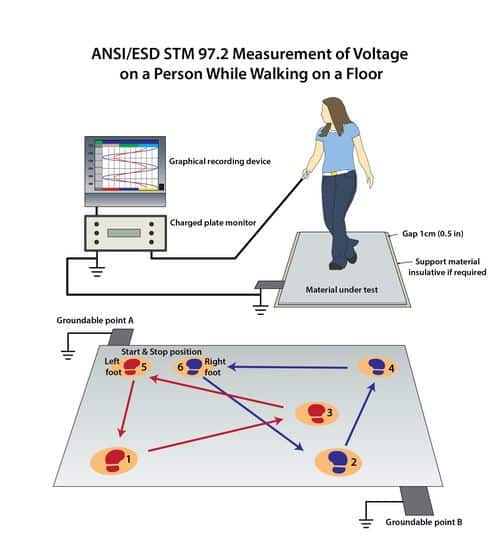

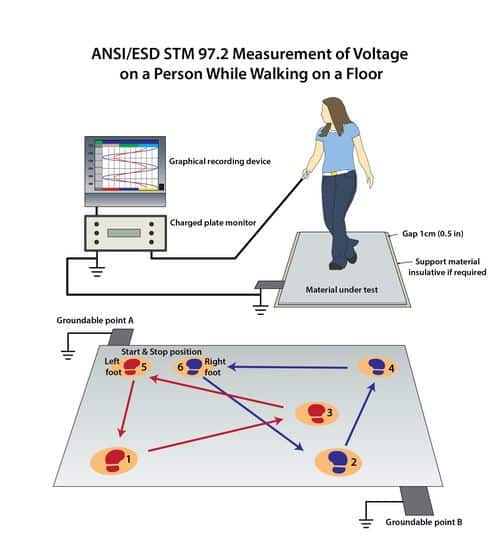

Walking Body Voltage/Charge Generation Test

To evaluate the potential for charge generation, we use ANSI/ESD Test Method 97.2.

This test stipulates that—within reason—the subject is to wear the exact types of shoes that will be worn by people walking on the static-control floor. This means, if anyone in the environment will be wearing street shoes, then the floor should be tested for charge generation on people wearing a variety of street shoes—e.g., athletic shoes, shoes with leather soles, and so on.

To evaluate the potential for charge generation, we use ANSI/ESD Test Method 97.2.

This test stipulates that—within reason—the subject is to wear the exact types of shoes that will be worn by people walking on the static-control floor. This means, if anyone in the environment will be wearing street shoes, then the floor should be tested for charge generation on people wearing a variety of street shoes—e.g., athletic shoes, shoes with leather soles, and so on.

Eliminating Walking Body Voltage

It’s about low charge generation—not conductivity.

Scientific Fact: Level of conductivity—high or low—has no bearing on charge generation. The ability of a static-control floor to prevent static in a particular environment has to do with the material, footwear, and environmental conditions.

Bottom Line: a highly conductive floor does not guarantee low static generation.

How Do I Choose a Static-Control Floor?

Almost every conceivable floor-covering material, including epoxy, vinyl, and rubber, can be manufactured to provide some static-dissipative or antistatic (low charge-generating) properties. The choice of flooring materials should be based on the electrical code, best practice, industry standards and requirements for the specific application, the demands and constraints of the environment, and buyer goals and objectives.

Different applications often require different flooring materials. A floor that works well in electronics manufacturing, with protocols mandating the use of special ESD footwear, will likely not work in a mission-critical space with people wearing regular street shoes.

A single facility may also benefit from the use of more than one flooring material. Material handling areas, for instance, may call for an ergonomically friendly floor like carpet or rubber, while in the warehouse, where it’s common to transport heavy loads, a hard-surface floor like ESD epoxy might be a better choice.

Before selecting any type of ESD flooring, it is crucial to understand how the floor will interface with its environment and the people working in or moving through the space. To find answers, it’s important to ask relevant questions—and listen closely to the responses.

What Type of Footwear Will be Worn in the Space?

Will people who walk on this floor wear grounded heel or toe straps, static-protective shoe coverings, or conductive shoes?

If the answer is no—which, in most cases, it is—then the grounded floor must provide a combination of conductive elements and the capacity to prevent or inhibit static build-up.

| Category | Class-0 | Controlled Environments (ANSI/ESD S20.20) | End-User/Real-World |

|---|---|---|---|

| Maximum allowable resistance | 0 – ≤ 10E9 | 0 – ≤ 10E9 | 10E6 – 10E9 |

| Environment | Controlled/manufacturing ESD-protected areas (EPA) that handle ultra-sensitive devices or will in the future | Controlled/manufacturing ESD-protected areas (EPA) that are not Class-0 | Mission-critical areas that require ESD protection regardless of footwear |

| Applications | -electronics manufacturing service (EMS) facilities -cleanrooms -R&D environments | -microelectronics fabrication -circuit board assembly -manufacturing test and repair of electronics | -9-1-1 dispatch areas -data centers -fight command centers -networked offices -hospital/imaging -control rooms -labs -government offices -server rooms |

| Flooring options with regular footwear | N/A: Regular footwear prohibited; must use ESD footwear | N/A: Regular footwear prohibited; must use ESD footwear | -EC Rubber -ESD Carpet |

| Flooring options with ESD footwear or heel straps | -EC Rubber -ESD Carpet -Conductive Vinyl | -EC Rubber -ESD Carpet -Conductive Vinyl -Some Conductive Epoxy Coatings -Plastic Interlocking Conductive Flooring | -EC Rubber -ESD Carpet -Conductive Vinyl -Static-dissipative Vinyl Tile -Conductive Epoxy Coatings -Static-dissipative Epoxy Coatings -Plastic Interlocking Conductive Flooring -Plastic Interlocking Dissipative Flooring -Conductive High-pressure Laminate |

What is the Environment Like?

Every static-control floor has attributes and drawbacks. ESD epoxy is an extremely hard, durable, high-gloss material, well suited for spaces where forklifts or pallet jacks are commonly used. But sounds echo off the hard surface, creating noise pollution, and epoxy is easily gouged, scratched, marred, and coatings are vulnerable to fading.

Despite its positive ergonomic and charge reduction properties, static-control carpet is also inappropriate in some environments. In heavy-duty manufacturing, for instance, some areas tend to get wet or be contaminated by solder and chemicals. These areas do well with hard-surface flooring materials that are easily cleaned and mopped. Static-control rubber, vinyl, and quartz-filled ESD epoxies are better suited for these wet, high-traffic, messy areas.

Adjacent walkways or cleaner areas in the facility may be carpeted, with special thought and attention paid to layout and design.

| Category | ESD Carpet Tile | ESD Solid Vinyl Tile (Conductive) | ESD Multi-layer Poured Epoxy | Interlocking Plastic Flooring | ESD Rubber |

|---|---|---|---|---|---|

| Ease of finding small parts | Fair | Easy | Easy | Easy | Easy |

| Slip resistance | < 0.6 Meets or exceeds ADA guidelines | < 0.6 Meets or exceeds ADA guidelines | 0.4 – 0.6 Depending on texture | 0.5 – 0.6 | < 0.6 Meets or exceeds ADA guidelines |

| Sound absorption | Excellent | Poor to fair 4 dB | Not sound resistant | Poor to fair | Excellent 5 – 19 dB |

| Anti-fatiguing | Excellent | No | No | No | Good |

| VOC compliant | Yes | Yes FloorScore certified | Yes | Yes | Yes GREENGUARD certified |

| Halogen free – no chlorine or other corrosive gases in fire | No | No | Yes | No | Yes |

| Contributes toward LEED credits | Yes | Yes | No | Yes | Yes |

What are the Performance and/or Maintenance Concerns?

Different floors require different maintenance procedures, which may affect performance—as will neglecting to clean or maintain the floor.

- Epoxy

- Vinyl

- Carpet and Rubber

ESD epoxy requires only regular washing, making it easy to maintain, but epoxy coatings are easily scratched or gouged, and epoxy is notoriously difficult to repair. Because it’s nearly impossible to match a newly repaired spot to the original floor, epoxy coatings are difficult to patch.

As an epoxy floor cannot tolerate traffic until it’s fully cured and completely dry, the entire repair area must be shut down during repair/replacement, for one or two days, to accommodate the repair.

ESD vinyl products offer an efficient, cost-effective, durable static-control option. Conductive solid vinyl tile requires minimal maintenance procedures—it’s easily maintained by regular buffing—and because it can be installed over existing surfaces, vinyl is quick and easy to repair, with short downtime.

Some vinyl tiles require frequent application of special dissipative polishes to maintain their performance. Without the application of special waxes, static-control performance degrades—the only way to know if a polish-reliant floor is performing properly is to commit to and carry out frequent ASTM electrical resistance testing. Often, static-dissipative vinyl composition tile (SDT) is not warranted unless the customer regularly reapplies multiple coats of special antistatic floor polish.

Vinyl manufactured offshore should be checked for dimensional stability and size tolerances. Many offshore-sourced tiles are produced with fillers that outgas and lead to shrinkage, creating gaps that look unsightly, and collect contamination and water, causing delamination. To help prevent shrinkage, tiles produced offshore should be installed with epoxy adhesives.

Static-dissipative carpet and conductive rubber provide excellent long-term static protection and require only simple routine maintenance—vacuuming for carpet; for rubber, washing the floor with a wet mop. Both products are durable and easily repaired, simply by lifting the damaged tile and laying a new tile in its place. Rubber is easily matched and random non-directional (RND) carpet tiles hide wear and can be replaced with no concerns about dye lots.

* When choosing static-control carpet tile always reference application and environment-specific standards like Motorola R56 and FAA 019f. A close technical reading of these industry standards should clearly define the ohms resistance of an appropriate ESD floor.

| Category | ESD Carpet Tile | ESD Solid Vinyl Tile (Conductive) | ESD Multi-layer Poured Epoxy | Interlocking Plastic Flooring | ESD Rubber |

|---|---|---|---|---|---|

| Long-term appearance | Good to excellent | Excellent: surface scratches can be removed by abrasive buffing | Fair: degrades over time, scratches cannot be removed | Excellent: surface scratches can be removed by abrasive buffing | Excellent |

| Wear layer | n/a | No: wear is consistent throughout the thickness of the floor | Yes: minimal | No: wear is consistent throughout the thickness of the floor | No: wear is consistent throughout the thickness of the floor |

| Color throughout thickness (helps hide scratches) | n/a | Yes | No | Yes | Yes |

| Color consistency for projects of any size | Yes | Yes | Yes | No | Yes |

| Durability | Good to excellent | Excellent | Excellent | Excellent | Excellent |

| Handles/withstands heavy rolling loads | Fair | Excellent | Excellent | Good | Good |

| PSI | n/a | 2500 – < 3000 | > 3000 | n/a | 600 – 800 |

| Ease of rolling | Fair | Excellent | Excellent | Good to excellent | Good to excellent |

| Maintenance | Vacuum and wet extraction | Sweep, damp mop, and buff | Sweep and damp mop | Sweep, damp mop, and buff | Sweep, damp mop, and buff |

| Chemical Resistance | Fair | Superior | Superior | Superior | Superior |

| Ease of repair | Easiest | Easy | Most difficult | Easy | Moderate |

How Does Electrical Performance of Static-Control Flooring Materials Compare?

-

Static-Dissipative

Carpet Tile - Conductive Vinyl

- Conductive Rubber

- Conductive Epoxy

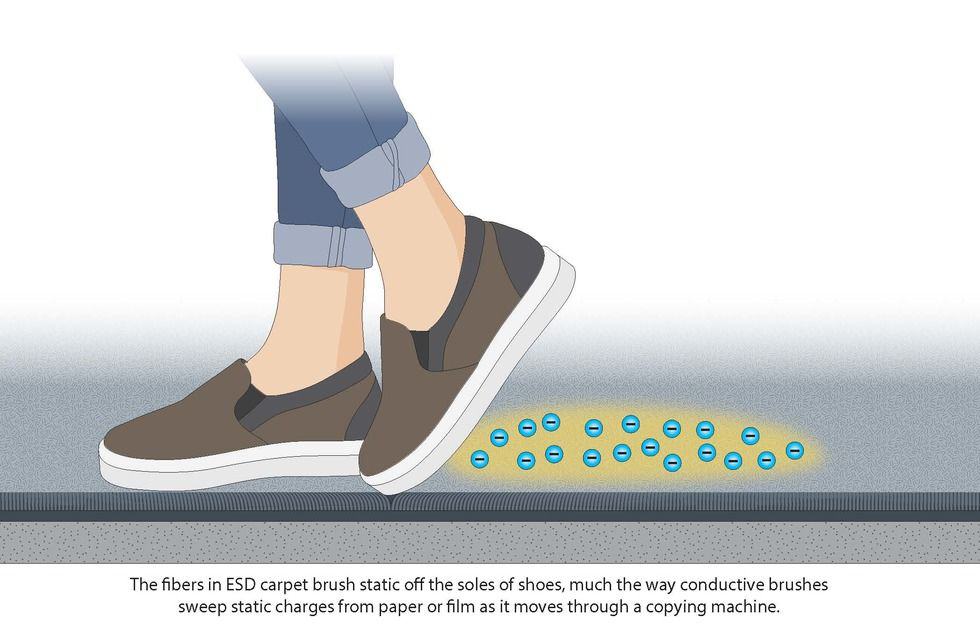

ESD carpet tiles contain thousands of conductive fibers that sweep static off of shoes and safely discharge it to ground, much the same way small brushes sweep static from paper on high-speed copiers as the paper is fed into the collator.

With ESD carpet tile, a low generating material, it is almost impossible to create a harmful static charge—regardless of footwear. That’s because static charges are ionized at the surface of the carpet and conducted directly to ground through a static-dissipative backing and conductive ground plane created by the conductive underlayment or adhesive system.

The embedded carbon veins in conductive vinyl look like a spider web on the surface of the tile. These veins provide a very effective path to ground. Because of its negligible triboelectric performance (meaning it doesn’t inhibit charge generation), vinyl works best in applications, such as electronic manufacturing and assembly, where special ESD footwear is required and where foot traffic and access to the space are controlled and monitored.

Static-dissipative vinyl

Unlike conductive vinyl, with embedded carbon veins, most static-dissipative (SDT) vinyl, made from vinyl composition tile (VCT), gets its static-control performance from special waxes or polishes that wear off over time and must be routinely reapplied.

Conductive rubber is a vulcanized two-layer material with static-control properties distributed across the surface and throughout the thickness of the tile. Rubber’s low charge generation is due to its material composition, which has a unique tribo-electric effect when rubbed against other materials.

Like static-dissipative carpet, conductive vinyl, and ESD epoxy, rubber can be grounded. And, like carpet tile, rubber is a low-generating material, well-suited for electronics manufacturing and handling, as well as end-user applications, such as public safety dispatch centers, research labs, and server rooms, where people will typically wear ordinary footwear.

Prior to 2014, conductive epoxy was a popular ESD flooring option for electronics manufacturing environments. Epoxy is a relatively inexpensive flooring solution. With their hard, rugged surface, epoxy floors allow for easy rolling of heavy carts or forklifts. Epoxy is also cleaned with simple machine-scrubbing and does not require ESD floor finishes or waxes to maintain its performance.

In terms of the need for a low-charging material, however, epoxy is usually a poor choice.

With street shoes, ESD epoxy becomes a significant static charge generator and will actually generate more static than conventional flooring.

ESD epoxy should never be used without special footwear. Prior to installation, ESD epoxy should be carefully tested and qualified—in conjunction with whatever footwear will be worn by people walking through the space—for compliance with ANSI/ESD S20.20 charge generation requirements.

| Category | ESD Carpet Tile | ESD Solid Vinyl Tile (conductive) | ESD Multi-layer Poured Epoxy | Interlocking Plastic Flooring | ESD Rubber |

|---|---|---|---|---|---|

| Inhibits static with ordinary footwear; per ASHRAE, the upper limit for the environment is 500 V maximum | Yes: < 400 V maximum | No: > 3500 V | No: > 3500 V | No: > 3500 V | Yes: < 400 V maximum |

| Meets standard ANSI/ESD S20.20 for electrical resistance | Yes, when using any ESD footwear | Yes, when using any ESD footwear | Yes, depending on type of ESD footwear | Yes, depending on type of ESD footwear | Yes, when using any ESD footwear |

| Class-0 qualified | Yes, depending on type of ESD footwear | Yes, depending on type of ESD footwear | No | No | Yes, when using any ESD footwear |

Permanent Static Protection

When evaluating any ESD floor, buyers should determine whether or not the floor will provide permanent static protection. The static-control properties of some floors wear off, requiring periodic buffing or waxing to maintain performance.

As noted above, some SDT vinyl tiles have a negligible effect on static without the frequent application of special antistatic floor finishes. Any interlocking or vinyl flooring with manufacturer’s specifications claiming it has been treated with a special low-maintenance coating should be carefully evaluated for walking body voltage; and the test should be performed with different types of footwear. Because they are not low-charging materials, factory-applied coatings rarely meet walking body voltage standards.

In mission-critical areas like flight-control towers and power plants that must be fully functional 24/7, buyers should consider whether it’s prudent to install a floor that requires periodic rejuvenation. Remember: static is invisible. If a floor requires waxes or sprays to maintain its electrical properties, it will be impossible to know precisely when the floor has stopped performing.

Buyers must also decide whether or not they’re prepared to pay the additional cost—which over time can be substantial—of maintaining the conductivity/static-preventive properties of their floor.

Which Static-Control Floor Do You Recommend?

The definition of the ideal static-control floor varies, depending upon the application, the environment, and the budget. While the initial cost of some flooring materials is low, frequent or difficult maintenance procedures or costly repairs, requiring work areas to be shut down for several days or a week, can add up.

When evaluating costs, it’s smart to factor not only the initial material costs but the total cost of ownership into the budget.

| Category | ESD Carpet Tile | ESD Solid Vinyl Tile (Conductive) | ESD Multi-layer Poured Epoxy | Interlocking Plastic Flooring | ESD Rubber |

|---|---|---|---|---|---|

| Total cost of ownership (includes material, installation, and ongoing maintenance) | Low | Moderate | Low to moderate | Highest | Lowest |

| Cost of material | Low to moderate | Lowest | Low | Highest | Moderate to high |

| Installation | Easiest and fastest | Easy and fast | Difficult | Time consuming | Moderate and fast |

| Cost of maintenance | Low to moderate | Moderate | Low Note: shine cannot be restored once surface is scratched | Moderate | Lowest |

Today, there are static-control floors in attractive styles and designs to meet every flooring requirement and every budget. As with any specialty product, it’s easy to be confused by technical jargon, marketing lingo, and complicated industry standards and test methods.

Before making any decisions, it’s wise to identify reputable suppliers who:

- offer more than one form of ESD flooring;

- reference appropriate industry standards;

- provide objective third-party evidence of performance—such as lab reports and other data specific to your application;

- offer post-installation testing and written certification, after installation, that the floor meets the specific standards of the application.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Useful Content

Article: Conductive Adhesive for ESD Flooring

Conductive adhesive forms a ground plane unifying ESD tiles. Learn how it works and why the adhesive must be more conductive than the floor.

Read MoreESD Database

This resource includes information about and links to ESD standards, associations, training, consultants, and education.

Read MoreArticle: Avoid Costly Failures: What to Know When Specifying ESD Flooring

Avoid Costly Failures: What to Know When Specifying ESD Flooring [12 min read] The most attractive ESD floor will fail if it’s specified for an incompatible space or does not...

Read MoreESD Flooring Video Library

Dynamic, short-form videos provide detailed technical information on ESD flooring. Explanations supported by easily understood graphics.

Read MoreLearning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.