Choosing ESD Flooring for Mission-Critical Spaces

[16 min read]

Post Sections

Mission-critical spaces must operate 24/7. ESD can disrupt data and damage or destroy equipment. Learn how to protect your space against static discharge.

Need additional information about specific ESD products? Visit our product section.

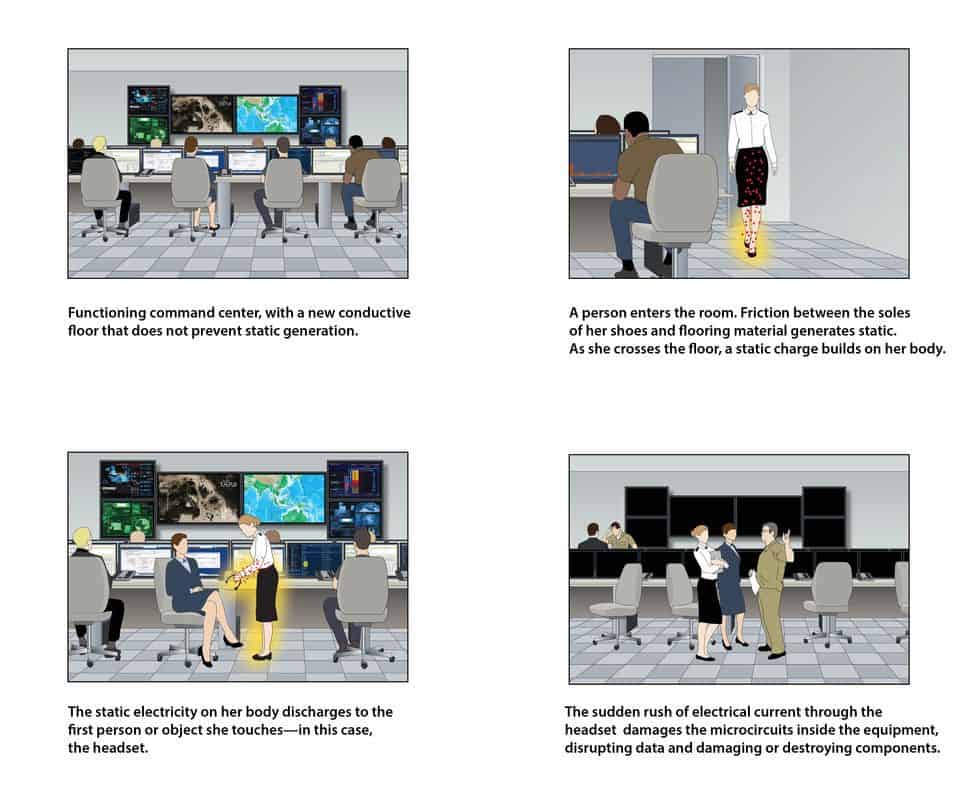

According to the National Emergency Number Association, in the U.S. alone, more than 240 million 9-1-1 calls are placed each year. In a 9-1-1 dispatch center—and other mission-critical spaces, such as FAA flight towers, data centers, server rooms, critical-call centers, and networked government offices, such as Social Security, the IRS or Homeland Security, to name just three—static electricity can wreak havoc. In worst case scenarios, electrostatic discharge (ESD) can result in lost calls or misdirected traffic, putting human safety at risk.

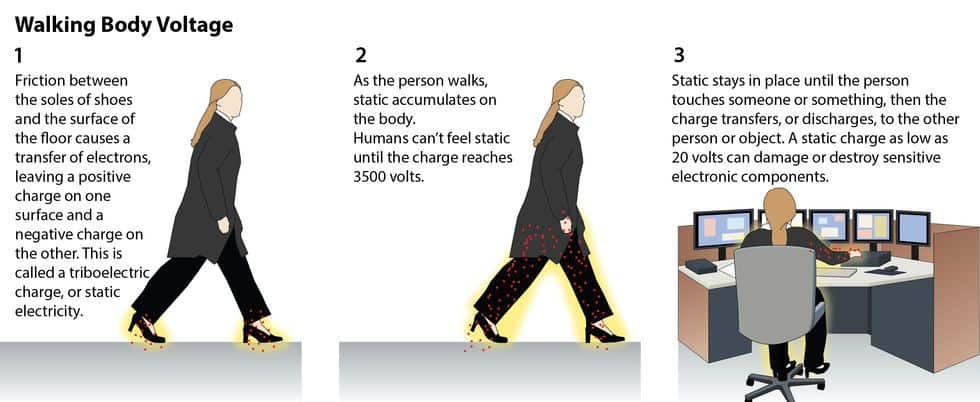

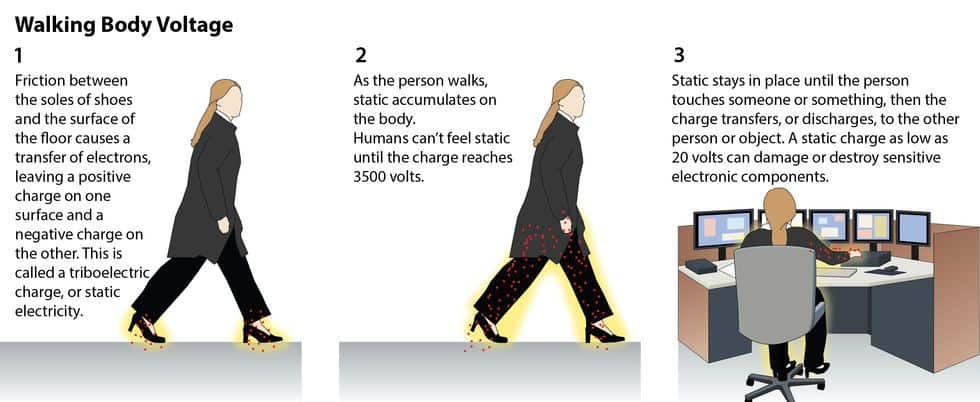

Often called the “invisible threat,” static charges are imperceptible by humans—until they reach 3500 volts. To put that number in perspective, according to Todd Hubing, from the Electromagnetic Compatibility Laboratory at the University of Missouri-Rolla, as you walk across a floor 20,000 – 25,000 volts of static can accumulate on your body. 20 – 25 thousand volts!

Yet a discharge of only 20 volts can destroy the sensitive microcircuits in electronic equipment.

According to the National Emergency Number Association, in the U.S. alone, more than 240 million 9-1-1 calls are placed each year. In a 9-1-1 dispatch center—and other mission-critical spaces, such as FAA flight towers, data centers, server rooms, critical-call centers, and networked government offices, such as Social Security, the IRS or Homeland Security, to name just three—static electricity can wreak havoc. In worst case scenarios, electrostatic discharge (ESD) can result in lost calls or misdirected traffic, putting human safety at risk.

Often called the “invisible threat,” static charges are imperceptible by humans—until they reach 3500 volts. To put that number in perspective, according to Todd Hubing, from the Electromagnetic Compatibility Laboratory at the University of Missouri-Rolla, as you walk across a floor 20,000 – 25,000 volts of static can accumulate on your body. 20 – 25 thousand volts!

Yet a discharge of only 20 volts can destroy the sensitive microcircuits in electronic equipment.

Why Static-Control Flooring?

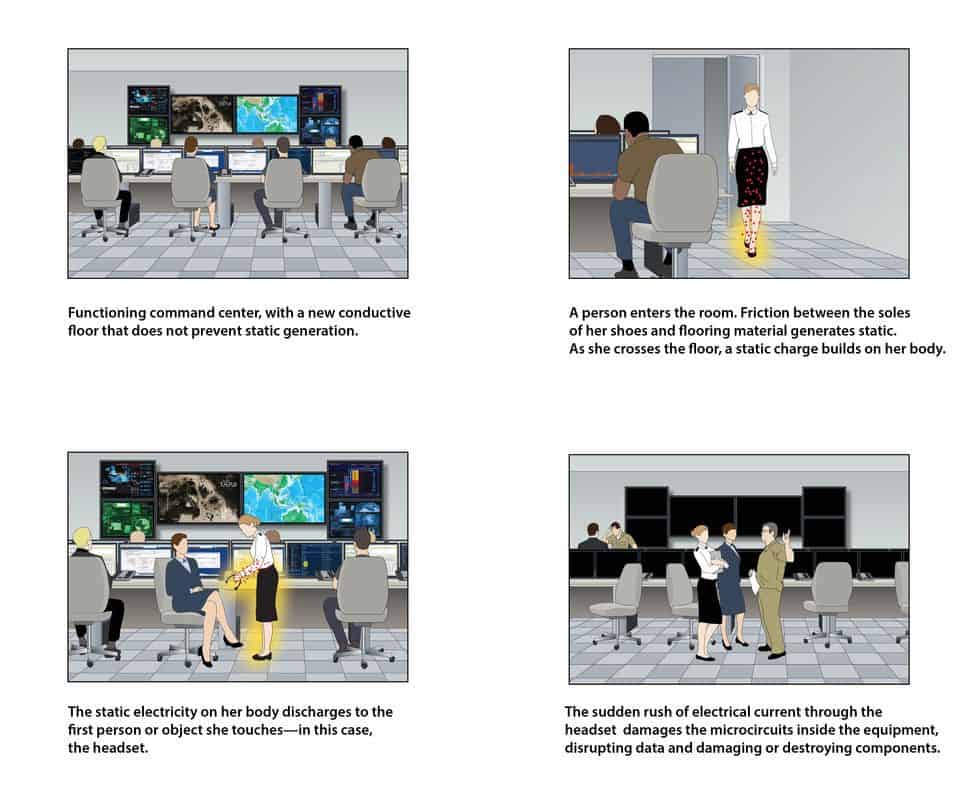

When we walk across a floor, the frictional contact between the soles of our shoes and the surface of the floor generates a static charge, called Walking Body Voltage. As we continue to walk, static accumulates on the surface of our body. The charge stays in place until we touch someone or something, then it jumps—or discharges—to that person or object.

This sudden spike in electrical current can blow headsets, and damage or destroy the microcircuits inside electronic equipment, disrupting data—resulting in dropped calls, lost connections, misdirected traffic—or causing PC lockup or even complete network failure.

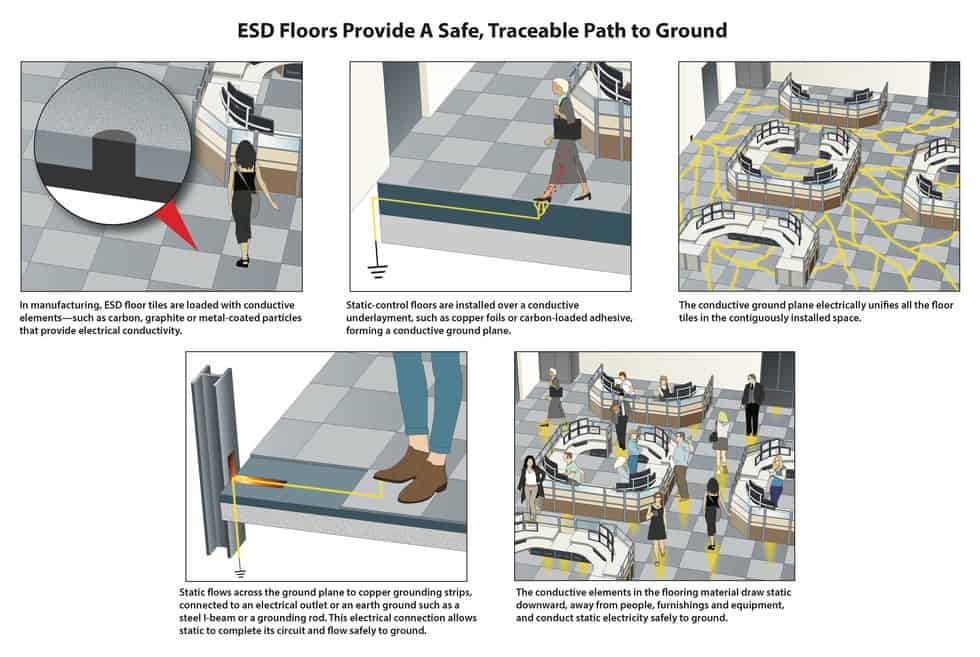

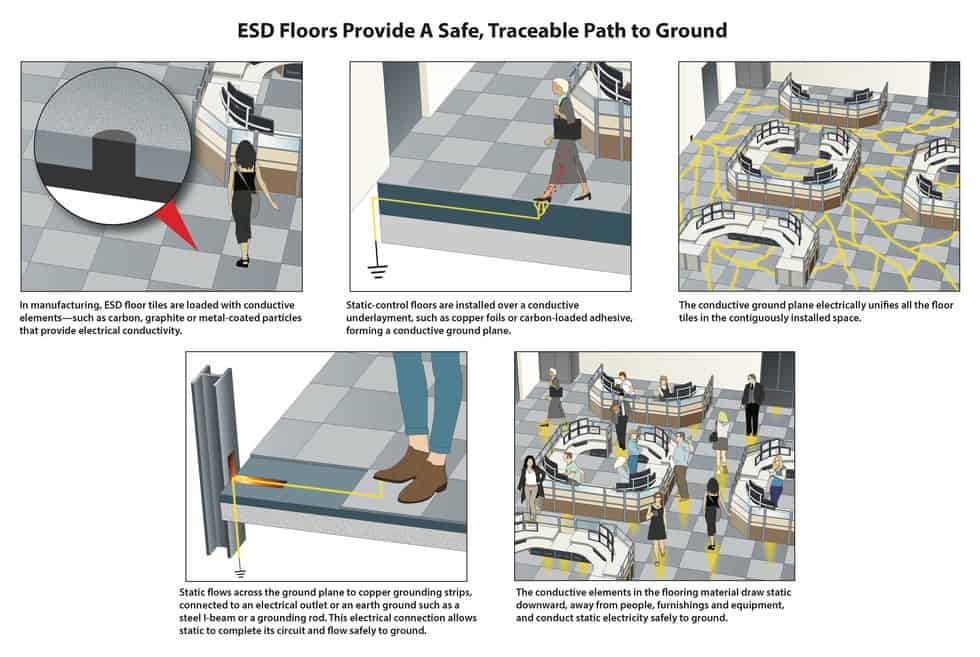

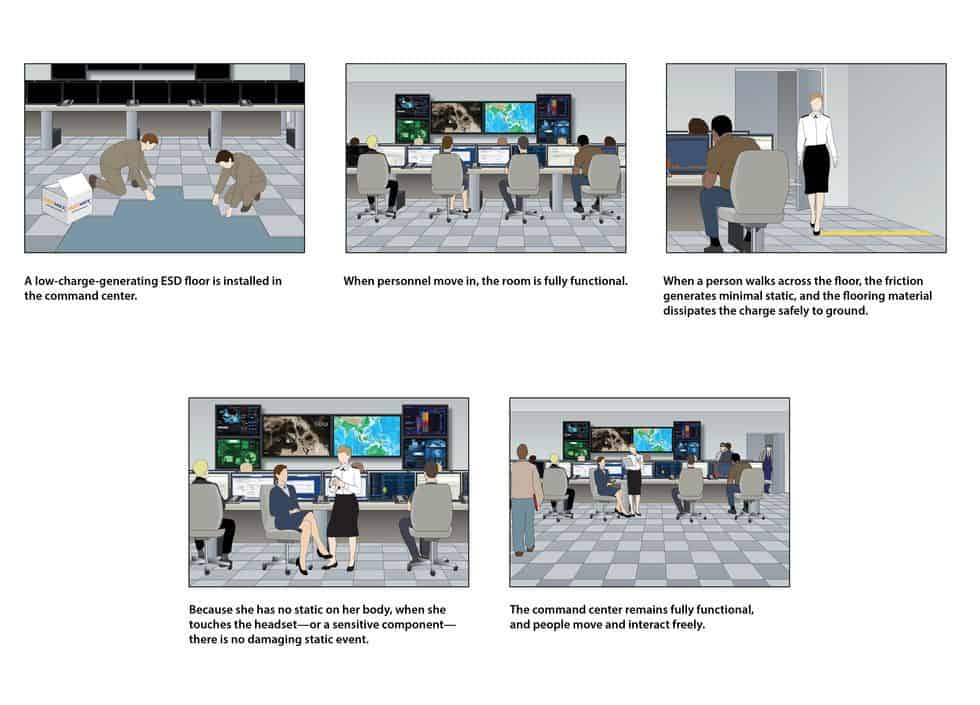

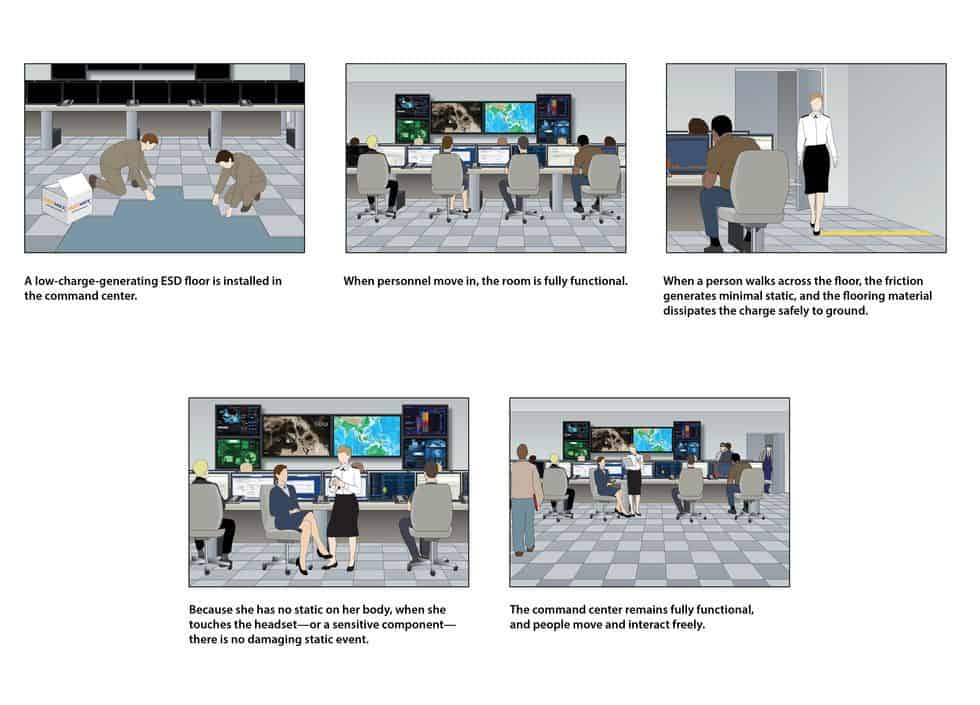

Static-control floors are designed to inhibit static generation. That’s why ESD floors are considered the first line of defense in preventing damage from random static discharge.

To protect mission-critical spaces, with no protocols mandating the use of special static-control footwear, ESD floors must perform two separate, equally important functions:

- Provide a traceable path to ground;

- Prevent static from accumulating as people walk.

Not all static-control floors perform both functions. ESD vinyl, for instance, does an excellent job of grounding people and equipment but does not inhibit static generation—unless every person walking through the space wears special ESD footwear. In electronics manufacturing or handling operations, where footwear is tightly controlled, vinyl is a great option. In a mission-critical space, where people wear street shoes, ESD vinyl would fail.

Important Note: only static-dissipative and conductive floors can be grounded.

Low kV, computer-grade floors are not groundable and do not prevent static generation. Likewise, standard floors installed with conductive adhesive or copper grounding strips do not provide a path to ground and offer no static protection.

Providing a Traceable Path to Ground: How Conductive Does the Floor Need to Be?

Every floor has some degree of electrical resistance. In other words, all floors stop, or resist, a certain amount of electricity from taking its natural path to ground. ESD floors are designed to decrease resistance enough to dissipate static electricity safely to ground.

During the manufacturing process, conductive elements, such as carbon fibers, are added to the flooring material. These conductive additives draw static away from the surface of the floor, through its thickness, across an underlying conductive ground plane, to ground.

We can predict how quickly or slowly a floor will dissipate static by measuring its electrical resistance with an ohm meter. If a floor is too resistive, static will not discharge quickly enough to prevent so-called “static events”—blown headsets, disruption of data, dropped calls, or PC lockup.

The goal is to choose a floor with sufficient conductivity to provide a functional path to ground, and enough resistance to meet the requirements outlined in mission-critical safety standards.

We can predict how quickly or slowly a floor will dissipate static by measuring its electrical resistance with an ohm meter. If a floor is too resistive, static will not discharge quickly enough to prevent so-called “static events”—blown headsets, disruption of data, dropped calls, or PC lockup.

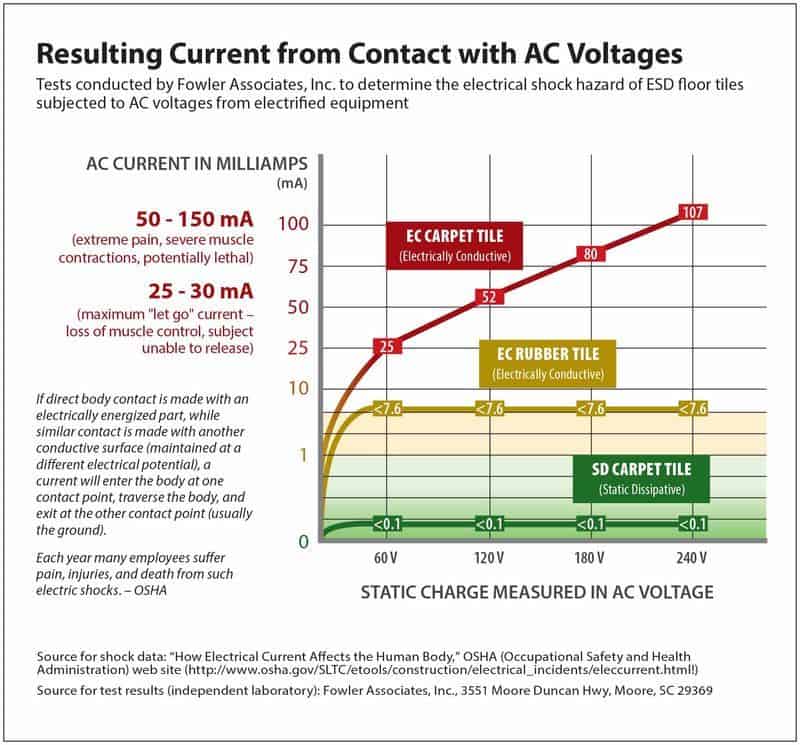

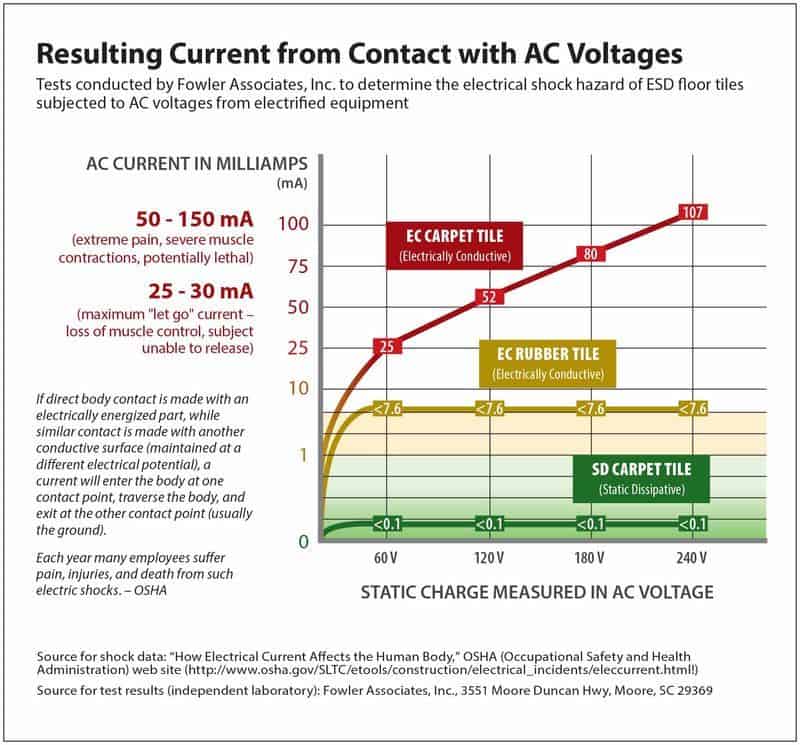

If the floor is too conductive—doesn’t provide enough electrical resistance—current from a short circuit in energized equipment could rush to ground too quickly. In certain circumstances—e.g., if a person fixing or inspecting an electrical appliance or component were exposed to live electricity—an overly conductive floor could make the person become part of a closed electrical circuit, from the source, through the person, to the floor, to ground, posing the risk of a serious electrical shock. That’s why industry standards, such as FAA 019f and Motorola R56, require the use of dissipative flooring for use around energized equipment.

The goal is to choose a floor with sufficient conductivity to provide a functional path to ground, and enough resistance to meet the requirements outlined in mission-critical safety standards.

Measuring Electrical Resistance

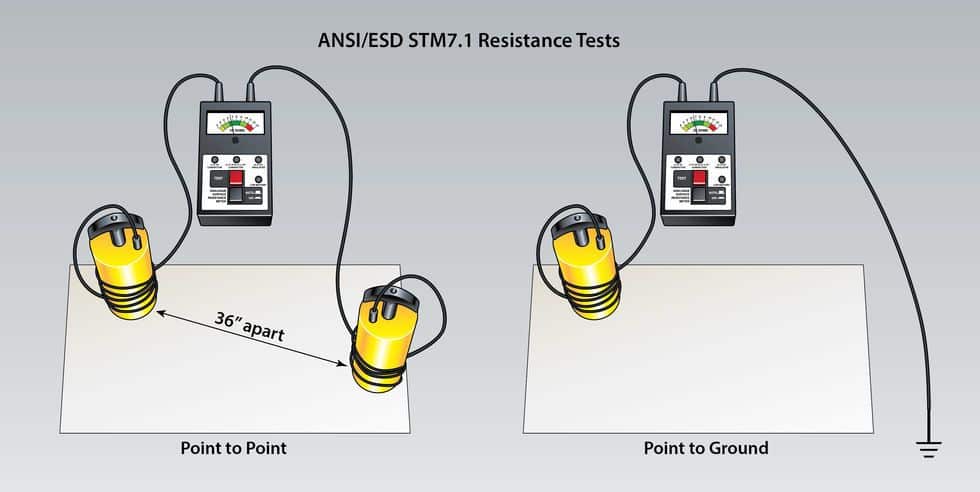

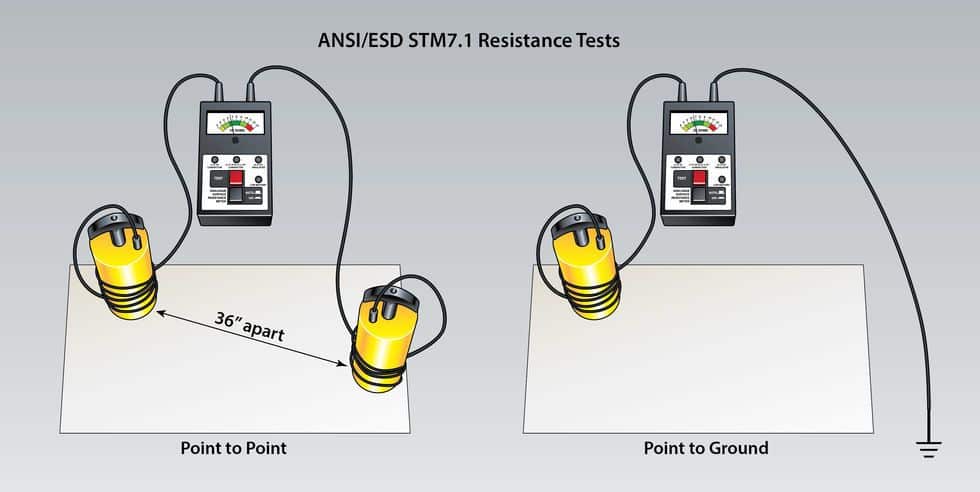

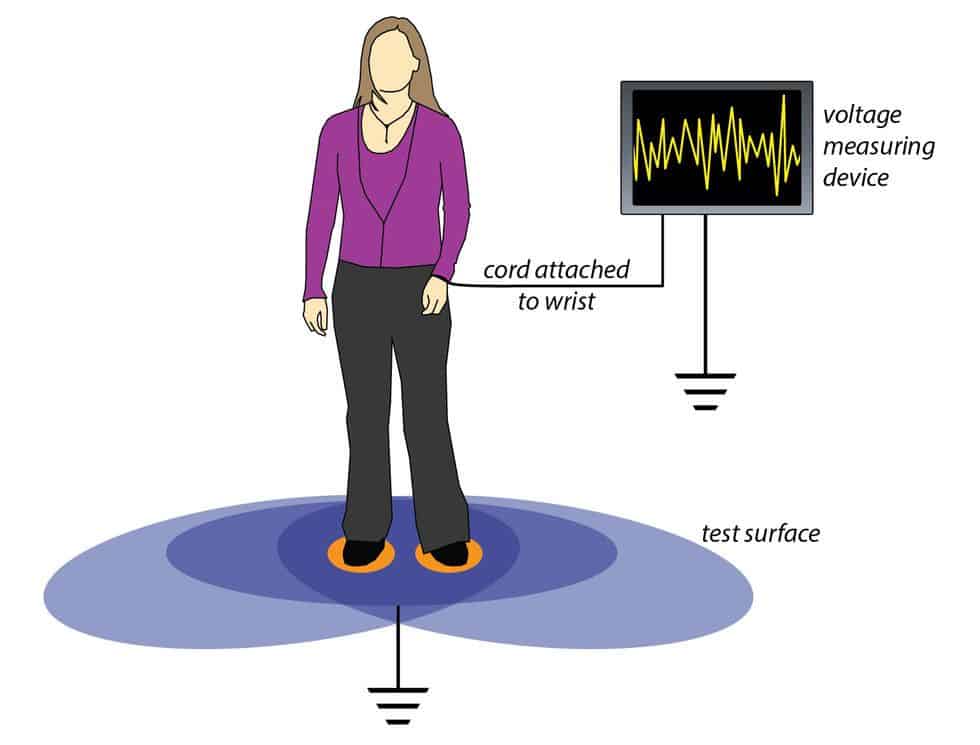

To measure a floor’s electrical resistance, we use test method ANSI/ESD STM7.1-2013.

Most commercial and data center grounding documents recommend that floors for data and call centers measure above 1.0 x 10E6 ohms and below 1.0 x 10E9 ohms.

Samples should be preconditioned at humidity levels below 20%. In temperature-controlled workspaces, heat and air conditioning tend to have a drying effect on the environment. As we know, water conducts electricity. Lowering RH to below 20% removes moisture from the flooring material, eliminating the possibility of moisture as a performance variable.

Before testing, the floor should sit for several days in a humidity chamber set to 12% RH; this same RH level should be maintained throughout the test. Low humidity affects the performance of every ESD floor in some way. At 12% RH, the performance of epoxies, floor waxes, and some hydroscopic materials diminishes, in some cases beyond acceptability.

When testing static-control carpet, the test should be performed on both a mock-up installation, with the carpet affixed to plywood, and uninstalled carpet tiles to determine if the tile surface complies with the electrical parameters cited in grounding documents, such as Motorola R56, FAA 019f, and ATIS-0600321, the new American National Telecommunications Standard: Electrical Protection for Network Operator-Type Equipment Positions.

Preventing Static Accumulation: Not the Same as Conductivity

Some people mistakenly believe if a floor is conductive, it is also antistatic, or low-charge generating.

Not true.

The amount of static generated when people walk has partly to do with the flooring material and partly with the type of shoes people wear when they walk across its surface.

Because of its unique triboelectric characteristics, ESD rubber is naturally low-charge generating and, generally, prevents static accumulation without regard to footwear. ESD carpet is also low charge generating, in this case it’s because the carpet fibers sweep static off the soles of shoes, much like the brushes in a copying machine sweep across the charged paper as it exits the machine.

Other materials—ESD vinyl and epoxy, for instance—can provide excellent conductivity and still generate enough walking body voltage on people wearing ordinary street shoes to negatively impact electronic systems. The only way vinyl or epoxy would be a suitable ESD floor in a mission-critical application would be if every person walking in or through the space wore special static-control footwear.

In most mission-critical spaces, there are no protocols in place to control or police the shoes people wear. For this reason, specifiers are best advised to select a floor that will prevent static regardless of the type of footwear people choose to wear in the environment.

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

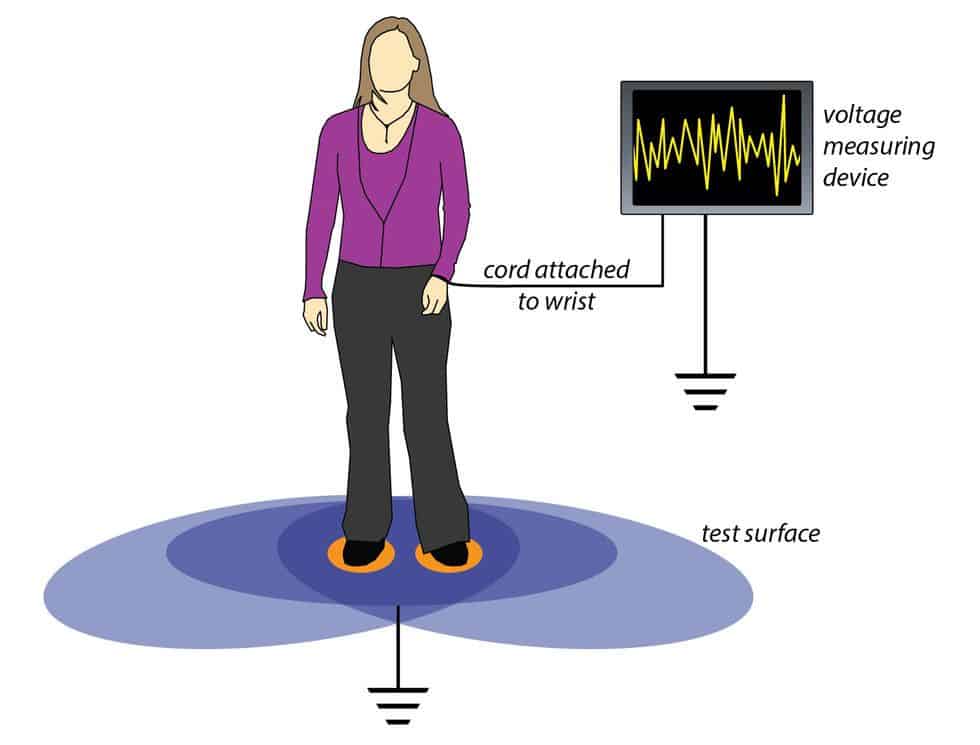

Measuring Walking Body Voltage

We measure charge generation, or Walking Body Voltage, using test method ANSI/ESD S97.2. This test measures, in volts, the static generated when people walk on the floor.

As noted above, static generation depends in part on the flooring material and in part on the type of shoes people wear. For example, hiking shoes, made with electrically insulative polyurethane soles, will generate more static than shoes with leather soles or special static-free footwear. For this reason, tests to predict static generation (walking body voltage) should be conducted with the subject wearing a variety of types of footwear likely to be worn in the space.

The Best and Worst ESD Floors for Mission-Critical Spaces

Ideal, Best Practice Use

Static-dissipative carpet tile: carbon-loaded carpet fibers inhibit static generation regardless of footwear. Easy installation. Sound-deadening ergonomic surface. Can be installed as a floating floor without any adhesive. Material cost is approximately $4.50-$5.50 per square foot.

Disadvantage: Soft surface.

Rubber tile and sheet flooring: Unique triboelectric characteristics inhibit static generation regardless of footwear. Rubber looks great, wears well, is significantly easier to clean than any other option, and total cost of ownership is low. Material cost is approximately $8.00-$10.00 per square foot.

Disadvantage: High initial cost.

Use ONLY if Everyone on the Floor is Required to Wear Antistatic Footwear

(Do NOT use if antistatic footwear will not be worn)

Conductive vinyl: Highly durable, easy rolling of heavy systems. Material cost is approximately $4.00-$5.00 per square foot.

Disadvantage: ESD vinyl is not a low-charge generating material; in spaces where personnel wear ordinary (non-ESD) shoes, conductive vinyl will not prevent static from building on people as they walk (walking body voltage).

Without the controlled use of ESD footwear, such as conductive heels straps, booties or special static-control shoes, an ESD vinyl floor will actually generate static events—thus is not a suitable floor for mission-critical spaces.

Not recommended

Conductive carpet measuring below 1.0 x 10E5 – or 100,000 – ohms.

While infrequent, carpet products that measure below 1.0 x 10E5 could expose workers, working on or near operational equipment, to an unnecessary, low-resistance path to ground. Recent independent testing revealed that a conductive carpet can support dangerous AC electrical currents as great as 50 milliamps. To put this number in perspective, any current over 10 milliamps can produce a painful to severe shock.*

For the reasons outlined above, flooring materials that measure, or could measure, as low as 2.5 x 10E4, are prohibited by FAA, ATIS and other grounding standards.

Do not use, ever

Computer grade floors—e.g., low kV carpet, LVT, SDT and High Pressure Laminates (HPL). These floors do not contain conductive or permanently dissipative fibers or particles. They offer no traceable path to ground when tested with an ohm meter.

The anti-static properties of SDTs and computer-grade floors are typically achieved with topically applied anti-static polishes and treatments that quickly degrade after installation. As documented in numerous studies, all of these materials become ineffective without the regular application of special antistatic waxes, dissipative polishes, and special sprays.

Note: These floors are often described as generating low charges during an AATCC 134 test. The AATCC test examines only two types of shoe sole material: leather and neolite. While the test method is sound, the test does not investigate enough shoe sole materials to provide a proper picture of performance, nor does it predict the long-term effectiveness of a floor that is not stringently cleaned or regularly maintained with new applications of antistatic floor polish.

Checklist: Choosing the Right Static-Control Flooring

- Static-control floors should be tested with an ohm meter to determine their electrical resistance. If the material resistance tests above 1 x 10E9, it cannot be grounded. Only dissipative or conductive floors that measure under 1 x 10E9 can be grounded.

- Standard flooring installed with ground strips or conductive adhesive will not offer any static protection.

- Do not specify any material for a static-control application unless the manufacturer provides electrical resistance test data.

- According to IBM recommendations, flooring used in data centers and server rooms should measure above 150,000 ohms (1.5 x 10E5).

- According to FAA 019f and Motorola R56, floors in flight towers and critical-call centers must measure between 1 x 10E6 and 1 x 10E9.

- The floor must pass the Walking Body Voltage test, conducted with the subject wearing a variety of footwear—showing that the floor will prevent static buildup in real-world conditions without special static-control shoes or shoe straps.

- When in doubt, ask for verification citing independent lab test data. The data should include tests performed on multiple types of footwear.

- Static-control floors should never require any antistatic sprays or waxes to enhance or maintain static-control performance.

- Static-dissipative properties should be achieved by the physical composition of the material—not by a topically applied maintenance additive.

- The floor should reduce static electricity regardless of relative humidity.

- Ask the supplier specifically about performance in very dry conditions.

- Never assume that a shock-free environment means a static-free environment.

- A shock-free environment means only that static charges are below 3500 volts.

- A charge as low as 20 volts, well below the human sensory threshold, can damage or destroy the sensitive microcircuits inside electronic components.

- A shock-free environment means only that static charges are below 3500 volts.

- Require a performance test and written certification for the static-control performance of your finished installation.

- Any mission-critical space is only as secure as its Achilles’ heel.

Do the homework up front. It is much more expensive to remove and replace an ineffective floor than it is to choose and install the right floor the first time. Even if your present electronics are immune to static, if at some point in the future they will be upgraded or replaced with state-of-the-art equipment, then static will be a problem. As with any potential security breach, it is always best to plan ahead.

Further Information

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.