The Invisible Threat To Data Centers:

Finding the Right ESD Floor

Written by David H. Long

Originally published in Data Center Journal, WEDNESDAY, 07 MAY 2007

Updated February 28, 2021

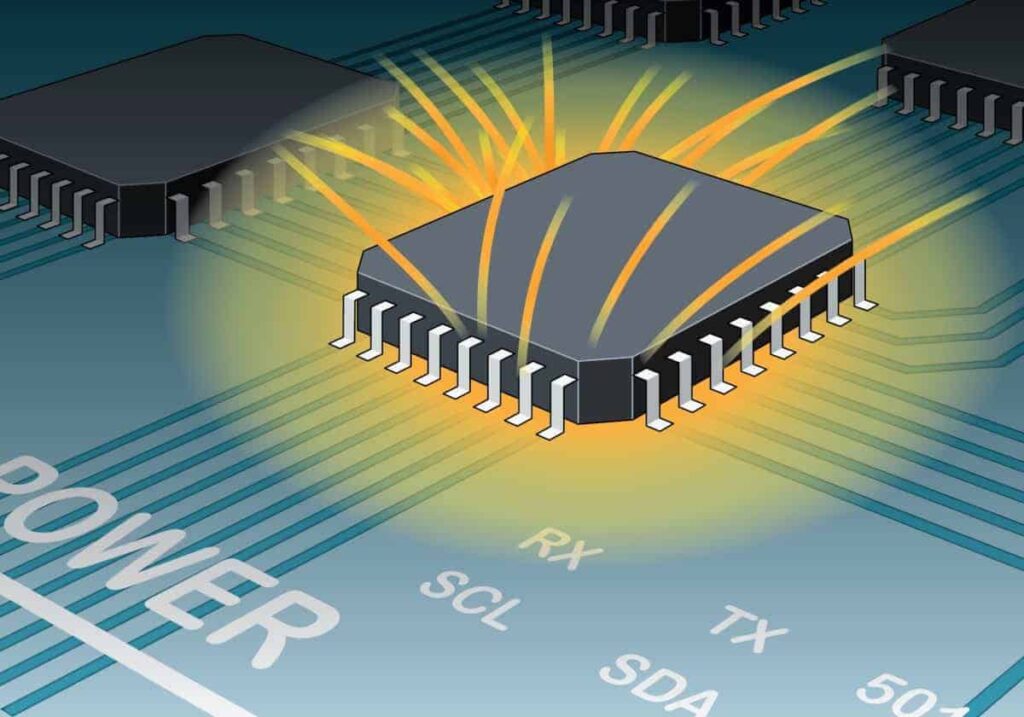

Designers of 24/7/365 mission critical spaces such as data centers, 911 call centers, command centers, server rooms and flight control towers routinely design their spaces to withstand external threats such as weather, power outages, earthquakes and, in some cases, even biological threats. An invisible internal threat that is sometimes overlooked, electrostatic discharge (ESD) can wreak havoc inside any mission-critical space. Dropped calls, blown headsets, PC lockup and lost or corrupted data represent just a few of the problems caused by random static charges.

Why is static a threat?

Microcircuits inside electronic systems perceive a static discharge as an overwhelming burst of energy. Older, more rugged components, though still prone to ESD failure, contained special microcircuit gate protectors, capable of diverting a random ESD strike away from the heart of the device. These interior shields slowed the performance of the devices. Designers of new electronic circuits have done away with these cumbersome internal protection devices in exchange for faster, more capable computers and telephony equipment. Without the internal shields, however, these new devices are far more susceptible to the invisible threat of static electricity discharge events.

Microcircuits inside electronic systems perceive a static discharge as an overwhelming burst of energy. Older, more rugged components, though still prone to ESD failure, contained special microcircuit gate protectors, capable of diverting a random ESD strike away from the heart of the device. These interior shields slowed the performance of the devices. Designers of new electronic circuits have done away with these cumbersome internal protection devices in exchange for faster, more capable computers and telephony equipment. Without the internal shields, however, these new devices are far more susceptible to the invisible threat of static electricity discharge events.

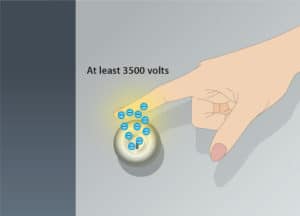

Most people, having experienced the nuisance of static cling or felt the zap of a shock, assume that static is something that can be seen and felt. Yet it takes at least 3500 Volts of static electricity for human beings to perceive the effects of a static discharge. To put that number in perspective, according to a leading edge consulting group, www.dangelmayer.com, sensitive electronic components can be damaged or destroyed by discharges under 25 Volts. Random static discharge and field effects caused by such common events as removing a sweater, rising from a seated position or walking across a floor will generate 1000s of volts of static, causing problems in data centers, server rooms and mission critical call centers.

Why antistatic HPL, SDT vinyl and computer-grade flooring should be avoided.

Almost every conceivable floor covering can be manufactured with some sort of static protective properties. Whether the floor surface is carpet tile, vinyl tile, rubber or epoxy, there is a version that can mitigate ESD problems. The right flooring in combination with ESD compliant chairs prevents static from ever generating in the first place.

To be effective, the ESD floor—also known as an antistatic floor or static-control floor—must meet several key metrics. Often, floors are loosely described with terms like antistatic, computer-grade and low kV. These terms are fine for a floor purchased for the purpose of reducing shocks when people walk across a room. For the mission-critical facility manager, these terms are misleading and inadequate.

The term “antistatic” is too broad to be useful.

By antistatic, people usually mean that the floor will reduce the generation of static between shoe soles and the floor. But which type of shoe soles? What type of floor? How much antistatic mitigation is adequate and how will the antistatic properties be measured for effectiveness? How long will the antistatic properties last?

Since most anti-static ratings are the result of one-time lab tests, most flooring manufacturers do not provide a quantifiable form of static control warranty. For example carpet manufacturers state that their product provides lifetime static-control protection, but when you look at the specification they document charge reduction no lower than 2kV or 3kV.

These are meaningless statements: the test they use is performed with a person walking on the floor wearing neolite and leather shoe covers. Neolite shoe soles no longer exist and leather is now the most uncommon shoe sole material. Some shoe soles produce low levels of static when they rub against certain flooring materials (antistatic) and high levels of static when they interact with others (static-generating). The important distinction is that describing a floor as antistatic is merely providing a snapshot condition that will change when any parameter is altered — from the humidity in the room to surface hardness to footwear composition.

The term “computer-grade flooring” is meaningless for static control.

“Computer-grade flooring” only means that the floor will suppress static charges below a level of about 3.5 kilovolts (3,500 volts)-so you won’t feel a discharge. What good is a computer-grade flooring product that will reduce static charges to under 3.5 kV – or even less than 2 kV – when sensitive electronics and telephony equipment can be destroyed or impacted by a static charge of less than 1/100 of that amount? And how will an antistatic or computer grade floor tested in the summer at 50 percent humidity perform in dry winter conditions when the RH drops to 10 percent?

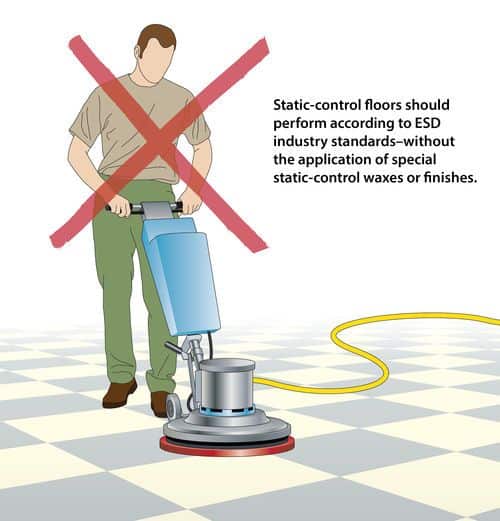

The keys to success are finding a product that provides permanent protection, requires no special sprays or coatings, provides a low static rating at all humidity levels, and provides a verifiable path to ground.

Three objectives when choosing a protective static-control floor in a data center.

To ensure electrical performance, the static control floor must meet three basic objectives:

- The floor must not contribute to static generation.

- It must be groundable after it is installed.

- The static-resistant properties should be permanent regardless of temperature, humidity, maintenance or traffic.

Many static-control floors are capable of meeting one of these objectives, but not all three.

Computer-grade flooring and static dissipative waxes provide a false sense of security.

A computer-grade carpet, for example, might marginally address the first objective, but any test with an ohm meter proves it cannot be grounded and it will lose all anti-static properties after the antistatic additives break down. An ungrounded floor can allow a person to remain charged; as soon as they make contact with equipment or some other item in the room, unwanted rapid static discharge takes place.

A computer-grade carpet, for example, might marginally address the first objective, but any test with an ohm meter proves it cannot be grounded and it will lose all anti-static properties after the antistatic additives break down. An ungrounded floor can allow a person to remain charged; as soon as they make contact with equipment or some other item in the room, unwanted rapid static discharge takes place.

What is to be gained from a floor that prevents shocks if it cannot be grounded, so will not reduce charges below the threshold of damage to the mission critical equipment it was intended to protect?*

- As you ponder this question keep in mind that ASHRAE has set 500 volts as the maximum voltage for static on a person in a data center.

Similarly, certain vinyl composite materials like SDT vinyl are comprised of ordinary static generating materials (standard VCT) in combination with adhesives loaded with a chemical known as an amine to provide conductivity. The amines help make the floor less resistant (more conductive) than ordinary vinyl. When shoe soles contact and separate from the SDT, static charges build.

To prevent static buildup, the manufacturers of these floors require the application of 3 to 5 coats of expensive antistatic floor polish. The most common objections to this technology involve questions like who applies the wax? How long does the wax last? And, how do I know when the wax needs to be reapplied?

Alternatively, some static dissipative vinyl is comprised of regular vinyl and conductive chips. Because the main component is ordinary static-generating PVC, these floors prevent static charges only on a person who is wearing conductive footwear. Without the conductive footwear, these vinyl floors generate as much static as ordinary vinyl composition tile (VCT.) Requiring everyone who walks on the floor to wear special conductive shoes or conductive heel straps would be difficult if not impossible to enforce in a data center or other mission critical space.

HPL – The typical floor in most data centers

For years high pressure laminate (HPL) has been the standard factory-applied surface on raised-access panels in data centers. Let’s examine closely possible reasons why this is the case.

- Static is invisible:

Most HPL surfaces will not generate more than a couple of thousand volts from walking. This means that it’s highly unlikely a person will ever get a shock from walking on an HPL floor.

In an ASHRAE-sponsored ESD study HPL was found to be the highest static-generating floor of any floor type tested. Not generating enough static to cause a 3500 volts shock is not an endorsement when we are looking for a floor to generate less than 500 volts.

- HPL is inexpensive.

It’s a fact that HPL cost less than ½ of real static-control flooring.

- HPL is hard and enables easy rolling of heavy equipment.

This is proably the second most salient property after low purchase cost. However, if the space requires static control it would make sense to specify the conductive version of HPL. Conductive HPL is more expensive and less effective at static mitigation than all other static-control flooring options. Hence by default conductive HPL is rarely specified.

- It has always been done this way.

Make no mistake, the old adage, “because we have always done it that way” shuts down most conversations when the central talking points include a potential increase in price and involve solving invisible problems.

- Floors are rarely tested for static-control properties.

As a result, no one actually knows that an installed floor does not have static-control properties.

The average data center facility manager juggles numerous responsibiites – from reducing downtime to handling safety auditors to controlling energy usage. The last item on their agenda is purchasing an ohm meter or hiring a contractor to periodically measure the resistance of the floor they walk on every day.

With HPL, the bottom line is that it has no antistatic or conductive properties. It will not pass an ohm meter test for resistance to ground, and it will absolutely not discharge a person with static buildup – no matter what type of footwear they are wearing.*

Static control carpet protects data centers from the threat of ESD.

You might think that static-dissipative carpet would be less effective than carbon loaded hard surface floors in preventing static buildup. In fact, the opposite is often true.

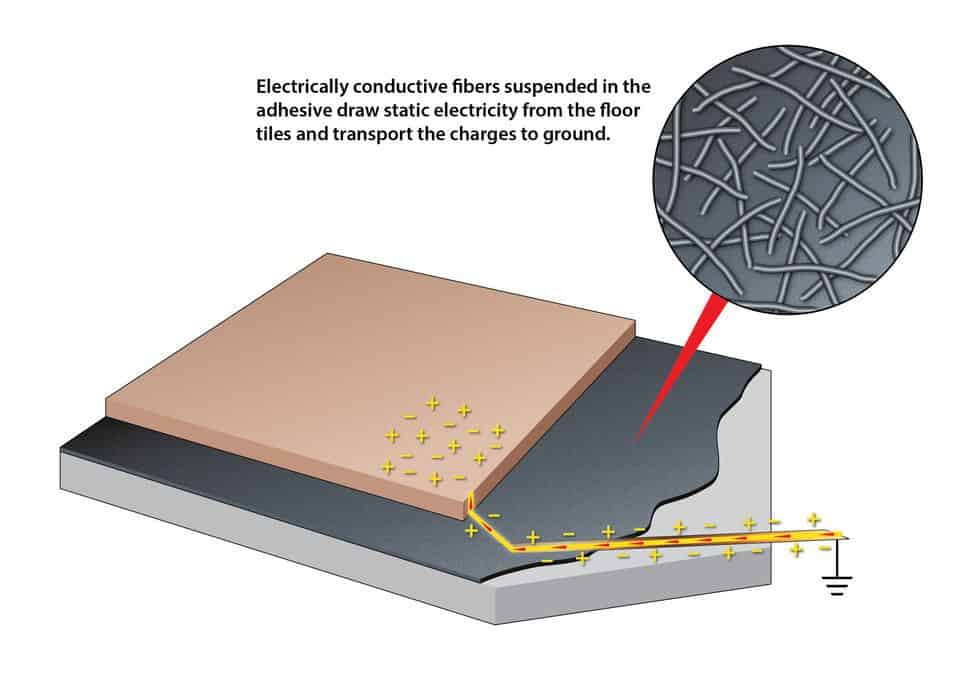

Static-dissipative carpet tiles contain thousands of grounded static-dissipative fibers that sweep static from shoes, safely discharging the static to ground. Static-dissipative carpet resembles standard carpet except for the addition of special carbon fibers woven throughout the surface and backing.

When a person walks on the carpet, the dissipative fibers extract excess static build-up from the shoe sole – before it damages components – and safely discharge the static through the static dissipative backing. The charge is then routed through a conductive releaseable adhesive that secures all of the tiles in place.

The release adhesive contains a conductive additive that creates a low electrical resistance network below all of the tiles. The adhesive’s conductive network is connected to ground along the edges of the room through 24-inch copper strips (one ground strip per one thousand square feet) that bridge the gap between the perimeter floor tiles and electrical conduit.

When properly installed, every single floor tile is at the exact same electrical potential as all of the others. This condition is called electrical continuity. This procedure requires the same skills as a standard carpet tile installation. The key to success is specifying carpet tile products manufactured with static-dissipative fibers in conjunction with conductive adhesive and grounding strips.

Key to Success: Specify carpet products with static-dissipative fibers in conjunction with conductive adhesive and grounding strips.

Other ESD flooring solutions: Eclipse Rubber and Vinyl Flooring

Carpet may be not be the best choice for certain situations, such as entry areas and areas with frequent movement of equipment. Some people see carpet as inferior to vinyl or rubber because of particle entrapment or difficulty rolling heavy equipment over softer surfaces. Some data center managers choose resilient flooring simply because a resilient floor was installed when their facility was built and no other flooring material has ever been tested or used.

EC Rubber is an inherently low static generating material

Indeed, some rubber and vinyl flooring options provide the same optimal static protection as static-dissipative carpet. Eclipse electrically conductive (EC) rubber flooring, in particular, provides static inhibiting properties similar to conductive and static-dissipative carpet tiles, though for very different reasons. Similar materials generate less static when they interact. The base compound used in EC rubber flooring sufficiently resembles most shoe soles to the degree that it inhibits the buildup of static by preventing static generation in the first place.

Unlike SDT vinyl, EC rubber is a permanent static-control material with carbon chips distributed across the surface and throughout the thickness of the tile. Rubber never needs waxing or other types of polishes. The full distribution of static-control properties means that shoe soles will never contact anything on the surface of the floor that can generate static. Like all effective static-control flooring options, rubber meets the second critical criterion: it can be grounded.

Carbon capillaries in conductive vinyl are present through the thickness of the tile.

Conductive vinyl contains thousands of conductive carbon capillaries that extend across and through the entire thickness of the tile. These veins make contact with the bottoms of shoes as people walk across the floor. As static is generated, the carbon capillaries pull the static from the surface of the floor and dissipate it safely to ground.

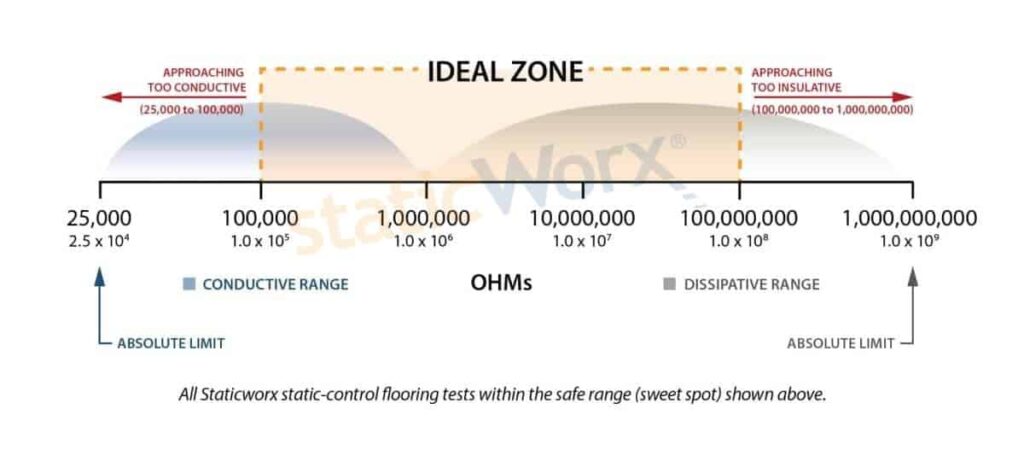

Static-control vinyl must have an electrical resistance below 1.0 X 10E7 to be effective. Research has shown that flooring materials, whether they are rubber or vinyl, do not perform as well if they measure in the upper region of the static-dissipative range.

The chart below, called The Sweet Spot, shows the ideal ohms range for effective static control in a data center. Keep in mind that the floor should not be too conductive. According to IBM, the floor must “provide a resistance of no less than 150 kilohms (1.5 X 10 E5) when measured between any two points on the floor space 1 m (3 ft) apart.”

Summary

To protect their sensitive electronic equipment, data centers and mission-critical command centers need a level of static protection on which they can rely – regardless of humidity and independent of additives. With so many options, choosing the right static-control floor can be a challenge for architects, designers and facilities managers. The most important criteria to remember are these:

- The floor must be compatible with the environment.

- The grounding properties of the floor must be verifiiable

- The floor should not rely on static-control waxes or polishes during routine maintenance.

- The floor should not be too conductive or it will not comply with operational end- user equipment standards.

- The floor must meet the electrostatic requirements of the facility.

By following these few simple guidelines, choosing the right floor can be relatively painless and easy. And static, the invisible threat inside the call center, will no longer compromise job performance or threaten to damage or destroy sensitive electronic or telephony equipment.

Final words

According to the authors of most comprehensive study to date, “there is little merit in using environmental moisture (absolute and relative humidity) to control static electricity without a controlled flooring and footwear system.” If we add ESD controlled seating to the facility we have eliminated the main sources of all static generation.

From IBM website:

“Recently, results of an ASHRAE-funded research program, led by the EMC Laboratory at the Missouri University of Science and Technology6, showed that with appropriate ESD floors and ESD shoes in the data center, there is only minimal impact on IT equipment when extending the recommended relative humidity envelope.”

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.