Installing AmeriWorx vinyl tile using StatBond Pressure-sensitive adhesive.

Conductive Adhesives

Conductive Adhesives: An Integral Part of the ESD Flooring System

Of all ESD flooring products evaluated by architects, engineers and contractors, adhesives receive the least amount of scrutiny. Buyers and specifiers alike agonize over their choice of ESD flooring materials. Yet, despite this lack of attention, adhesives are the critical element in ESD flooring installations, providing structural and electrical integrity – or creating disaster.

Some conductive adhesives require tremendous skill on the part of an installer. Mixing processes along with ensuring that tiles are placed in “wet-set” two-part epoxy adhesives within the proper timeframe require competence and attention to detail. One-part acrylic adhesives must be spread on the floor and subsequently covered with tile with very little margin of error for dry time. After tiles are set, when the floor is rolled, all wet-set adhesives bleed through the seams.

The adhesive and electrical properties of the floor are both integral to making the right ESD flooring choice and should be viewed as a system—not evaluated as singular items.

Many of these factors contribute to heightened labor costs increased to compensate for a slow installation. These and other considerations should be paramount when choosing ESD flooring. But they are not. The fact is, with ESD flooring the adhesive and electrical properties are all integral to making the right ESD flooring choice and should be viewed as a system—not evaluated as singular items.

How Conductive Adhesives Work

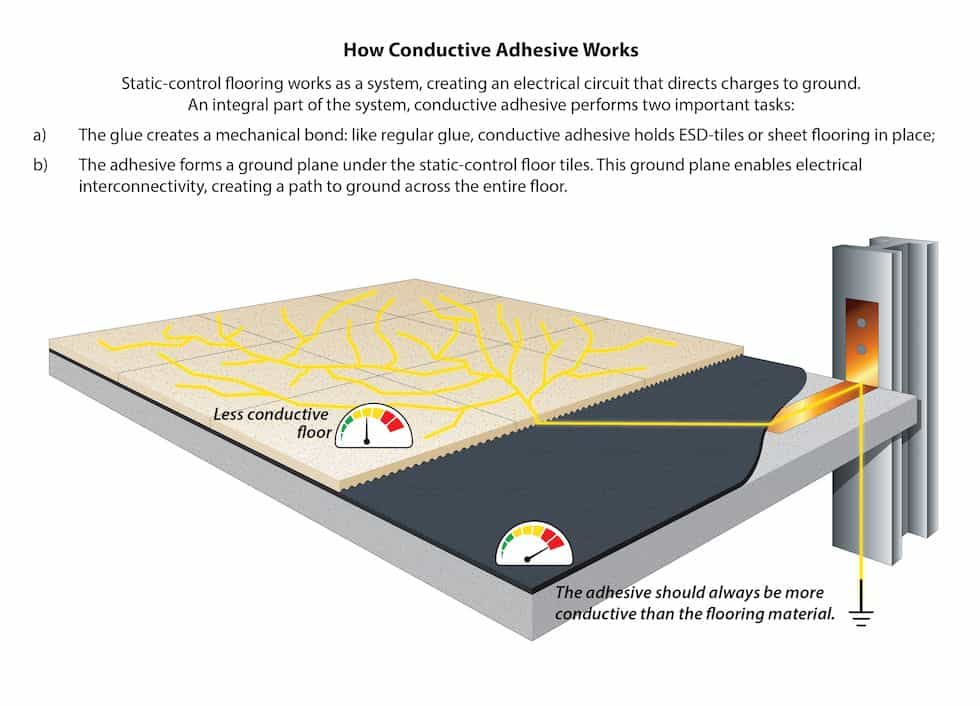

Without a conductive ground plane, ESD tiles would have no place to discharge unwanted static charges. Every tile would be like an isolated island – in other words, electrostatic charges would be stuck on individual tiles with no place to go. That would mean anyone walking on the floor would also remain charged.

StaticWorx conductive adhesives don’t just hold the floor in place. The adhesive acts as a conductive ground plane, providing electrical continuity between every ESD tile in a room.

How?

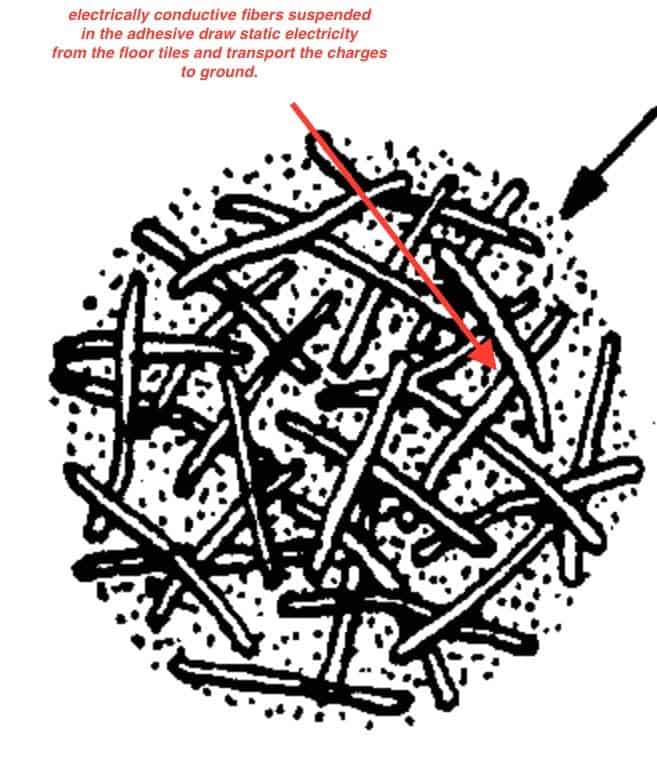

Electricity always flows to the path of least resistance. The electrically conductive fibers suspended in conductive emulsion draw static charges to the adhesive. The adhesive pulls charges downward, away from the surface of the floor, through the thickness of the tiles, to the underlying conductive adhesive/ground plane – the adhesive, in this case, being the fastest path to ground. Charges then move across the adhesive ground plane and transport static safely back to earth, enabling your ESD floor to do its job.

With StaticWorx Adhesives, grounding is straightforward and easy

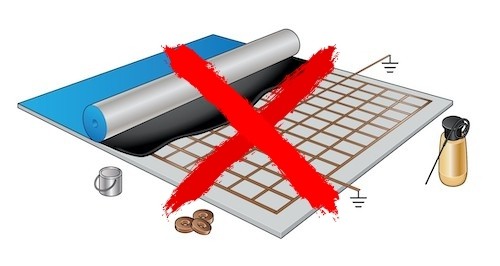

With conductive adhesives, expensive copper equipotential grounding grids are a thing of the past

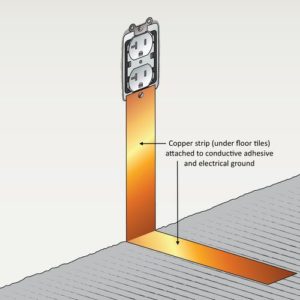

StaticWorx conductive adhesives link to ground with copper connector strips. The strips can be attached to electrical conduit, building steel or a dedicated grounding bar. Copper ground connectors are 24″ long and are supplied with every StaticWorx flooring shipment. Only one ground connection is necessary for every 1000 square feet of contiguous ESD flooring.

With StaticWorx adhesives, grounding your ESD floor is straightforward and easy. Our adhesives eliminate the need for expensive copper equipotential grounding grids of the past.

StaticWorx conductive adhesives link to ground with copper connector strips. The strips can be attached to electrical conduit, building steel or a dedicated grounding bar. Copper ground connectors are 24″ long and are supplied with every StaticWorx flooring shipment. Only one ground connection is necessary for every 1000 square feet of contiguous ESD flooring.

Adhesives and Conductivity

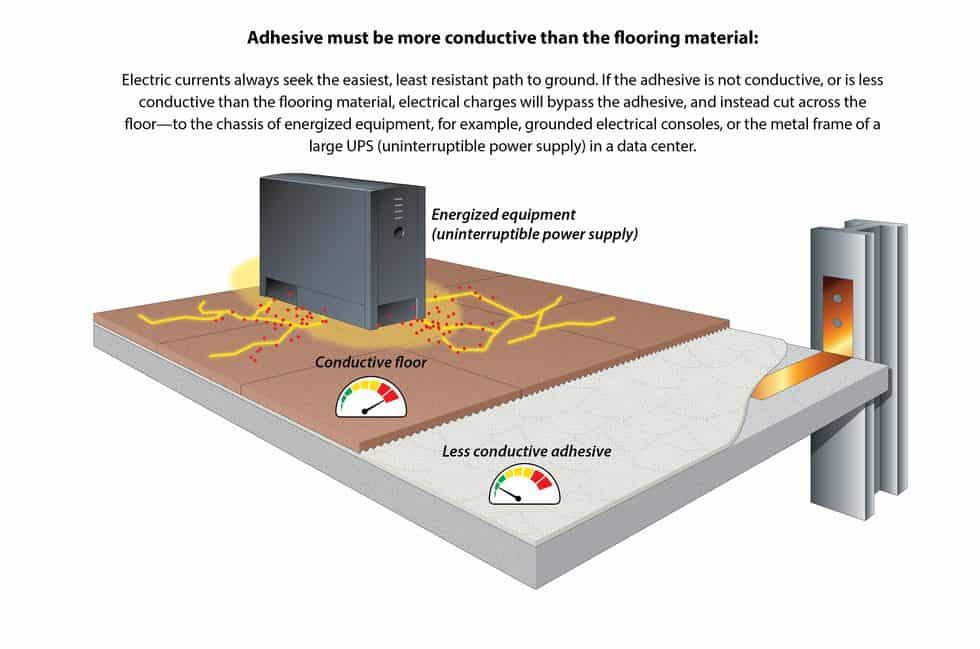

The conductive adhesive must always be more conductive than the surface of the floor.

Why?

Because conductive adhesives form a ground plane under the ESD floor. EC (electrically conductive) adhesives work by drawing charges downward, through the thickness of the tile, across the conductive ground plane, to copper tiles installed at the perimeters of the room, to ground.

The conductive adhesive must always be more conductive than the surface of the floor.

As we know, electricity always seeks its fastest path to ground. If the flooring material is more conductive than the underlying adhesive, electrostatic (ESD) charges will remain on the floor surface, potentially creating a safety hazard for people walking on the floor.

That’s why all StaticWorx adhesives measure in the conductive range – under 1.0 x 10E6 ohms.

StaticWorx Adhesives provide a fail Safe Path to Ground.

- Read more about correct grounding methods for ESD floors and Tile using copper grounding strips.

- View Flooring Attributes Comparison

- View Flooring by Application Type

If you have further questions, click here to contact us or call StaticWorx at 617-923-2000.

Comparison of StaticWorx Conductive Adhesives

| CHARACTERISTIC | GroundTack | StatBond Acrylic | StatBond Pressure-Sensitive | StatBond Two-Part Epoxy | DryFix Dry Adhesive |

| Releasable | Wet Set | Permanent | Wet Set | Tape | |

| Material | |||||

| Wet Set | No | Yes | No | Yes | N/A |

| Color When Dry | Clear | Dark Gray | Clear | Black | No |

| Releasable | Yes | No | No | No | Yes |

| Solvent-Free | Yes | Yes | Yes | Yes | Yes |

| RH Tolerance | 85% | 85% | 85% | 85% | 85% |

| Floor Score Certified | Yes | Yes | Yes | Yes | GreenGuard |

| Installation | |||||

| Can Be Applied to Non-Porous Surfaces | Yes | No | Yes | Yes | Yes |

| Ready to Apply | Yes | Yes | Yes | No, Requires Mixing | Yes |

| Trowel Size | 1/16″ x 1/32″ U-Notch | 1/16″ square notch | 1/16″ square notch | 1/32″ x 1/16″ U-Notch | N/A |

| Spread Rate | 180-225 ft2 per gallon | 110-130 ft2 per gallon | 180-225 ft2 per gallon | 185-245 ft2 per gallon | N/A |

| Open/Work Time | 4 Hours | < 1 Hour | 4 Hours | 30 Minutes | Use Immediately |

| Pressure Sensitive | Yes | No | Yes | No | Yes |

| Full Cure Time | 120 Hours (5 days) | 72 Hours (3 days) | 40 Minutes | 36 Hours | Instant |

| Can Receive Traffic Immediately | Yes | No | Yes | No | Yes |

| Compatible Flooring Materials | |||||

| Carpet Tile | Yes | Yes | Yes | No | No |

| Vinyl | Yes | Yes | Yes | Yes | No |

| Rubber | No | Yes | Yes | Yes | Yes |

GroundTack Clear Releasable Adhesive

GroundTack is a clear, conductive pressure-sensitive adhesive. GroundTack creates an electrical ground plane, providing total continuity across an ESD flooring installation. Far superior to expensive conductive tapes, messy wet-set black adhesives and complex grounding grids, StaticWorx GroundTack is easy to install and can be walked on immediately. When installed under modular carpet, GroundTack provides an excellent bond while providing the flexibility of a release adhesive. With GroundTack, the adhesive stays tacky and never dries completely; static dissipative carpet tiles are easily lifted and removed for repair, replacement or reuse, without ever even having to put down more adhesive.

For use with ShadowFX ESD carpet tile.

Key Benefits

- No special skills required

- Releases for easy removal and replacement of tiles

- Well-suited for use with modular flooring

- Not for use with vinyl and rubber tile

- Excellent conductivity

- Clear adhesive with carbon fiber technology

- Easy cleanup

- Easy to install

- Provides LEED points

- Low VOCs

- No special skills required

- Releases for easy removal and replacement of tiles

- Well-suited for use with modular flooring

- Not for use with vinyl and rubber tile

- Excellent conductivity

- Clear adhesive with carbon fiber technology

- Easy cleanup

- Easy to install

- Provides LEED points

- Low VOCs

StatBond Permanent Pressure-Sensitive (PS) Adhesive

A solvent free, acrylic adhesive designed for use with any conductive or static- dissipative rubber and vinyl floor covering. StatBond adhesive creates a permanent conductive bond between rubber or vinyl flooring and the subfloor. Well-suited for use with vinyl tile, roll goods or in any area where a strong, permanent bond is required. StatBond™ can be used on all grades of concrete – on, above or below grade – in the absence of moisture as well as over old VCT, HPL, metal and approved wood floors (APA.)

For use with rubber and vinyl tile: under rubber and vinyl, StatBond PS provides a permanent conductive bond. StatBond can be spread over a large area and allowed to dry before installing tiles. No oozing of adhesive into the seams when the floor is rolled. No mess and easy clean-up. Enables immediate use of the space.

Key Benefits

- Exceptional side-to-side stability

- No odor, no VOC's

- Permanent bond

- Ideal for rugged applications

- Partially used containers can be resealed

- Meets ANSI/ESD S20.20 in conjunction with StaticWorx Flooring

- Excellent conductivity

- For porous and non-porous surfaces

- Installs over old floors

- Provides LEED points

- No mixing required

- Easy cleanup

StatBond Wet-Set: Conductive One-Part Acrylic Adhesive

StatBond Wet-Set one-part acrylic adhesive is a waterborne, one-part, ready to use, acrylic, conductive flooring adhesive.

A solvent free, acrylic adhesive designed for use with any conductive or static dissipative rubber and vinyl floor covering. StatBond adhesive creates a permanent conductive bond between rubber or vinyl flooring and the subfloor. Well-suited for use with roll goods or in areas where a strong bond is required. StatBond can be used on all grades of concrete on, above or below grade in the absence of moisture as well as suspended approved wood floors (APA.)

Key Benefits

- Excellent conductivity

- For porous and non-porous surfaces

- Provides LEED points

- No mixing required

- Easy cleanup

- Exceptional side-to-side stability

- No odor, no VOC's

- Permanent bond

- Ideal for rugged applications

- Partially used containers can be resealed

- Meets ANSI/ESD S20.20 in conjunction with StaticWorx Flooring

StatBond Epoxy Two-Part Wet-Set Adhesive

For those who traditionally use two-part epoxy adhesives, we offer StatBond Epoxy, a two-part wet-set adhesive offering the firmest bond.

Designed for use with ESD Rubber and Ameriworx vinyl tiles.

DryFix Dry Adhesive Tape

Minimize Risk, Maximize Profitability in Cleanrooms and Labs

DryFix™ conductive dry adhesive is a fuss-free solution for quick, easy ESD flooring installations in 24/7 operational spaces with minimal downtime. Designed for use with EC (electrically conductive) rubber, DryFix can be installed without the use of mixing equipment, trowels or messy wet adhesives.

Ideal for cleanrooms and labs, StaticWorx Eclipse rubber tile/roll goods work as both a floor and integral flash cove. Seams can be welded providing a seamless installation, for a clean, monolithic surface that’s contaminant- and particulate-free throughout the installation.

With DryFix dry conductive adhesive there are no wet or messy adhesives to deal with and the new floor can be used or walked on immediately after installation, minimizing costly production losses.

With DryFix adhesive, ESD floors can be installed 24/7 with minimal downtime.

Key Benefits

- Ideal for labs and cleanrooms

- Seamless installation

- Dirt & particle free

- No messy adhesives

- Rapid 24/7 installation

- Can be installed in occupied spaces

- Minimal downtime

- Can be used immediately

- Eclipse rubber is PVC free

- No outgassing

Understanding Moisture and Adhesives

You need to understand moisture vapor testing before installing any static control flooring adhesives on new or old concrete. Visit our moisture vapor information section. Be sure to test your concrete for moisture. Order a Moisture Test Kit, also known as a Anhydrous Calcium Chloride Moisture Test Kit, from StaticWorx.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.