Avoid Costly Failures: What to Know When Specifying ESD Flooring

[12 min read]

The most attractive ESD floor will fail if it’s specified for an incompatible space or does not meet the proper industry-specific ESD standards. A flooring failure can force a facility to shut down production and result in liabilities no architect wants to—or should have to—deal with. With due diligence, by adhering to industry-specific protocols, you can avoid the costly mistakes that get specifiers in trouble.

THE GIST: Avoid Costly Failures:

What to Know When Specifying ESD Flooring

Standards vary by industry. Standards for electronics manufacturing and handling differ from those governing telecom, PSAPs, FAA flight towers, and other end-user spaces. To avoid costly mistakes, do due diligence and follow industry protocols.

Before specifying a floor:

- Familiarize yourself with the basics of ESD flooring;

- Know ESD terminology;

- Be sure flooring materials are appropriate for the application (note: some static-control floors perform only in conjunction with ESD footwear)

- make an ESD flooring checklist:

- the environment

- conductivity (find the “sweet spot”)

- upper limits for charge generation (application specific)

- standards and test methods (industry specific)

- Be sure the floor provides permanent static protection;

- Do not rely on manufacturer’s specifications: require independent test reports.

After the floor has been installed, require a post-installation audit.

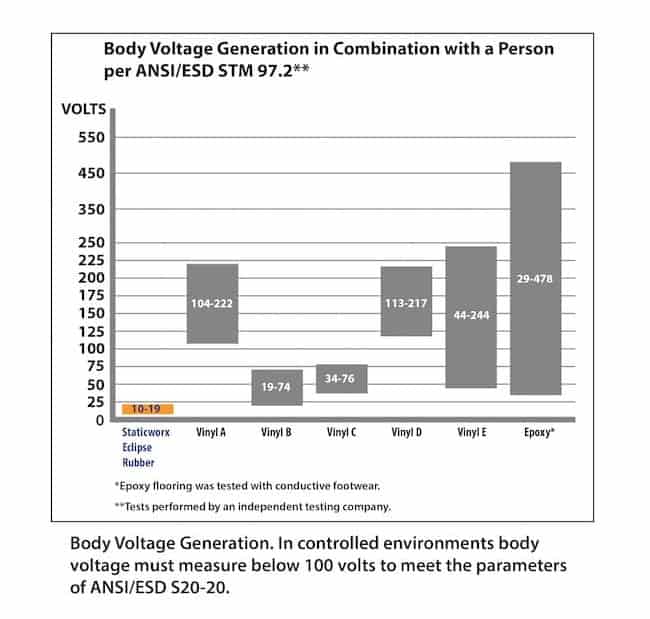

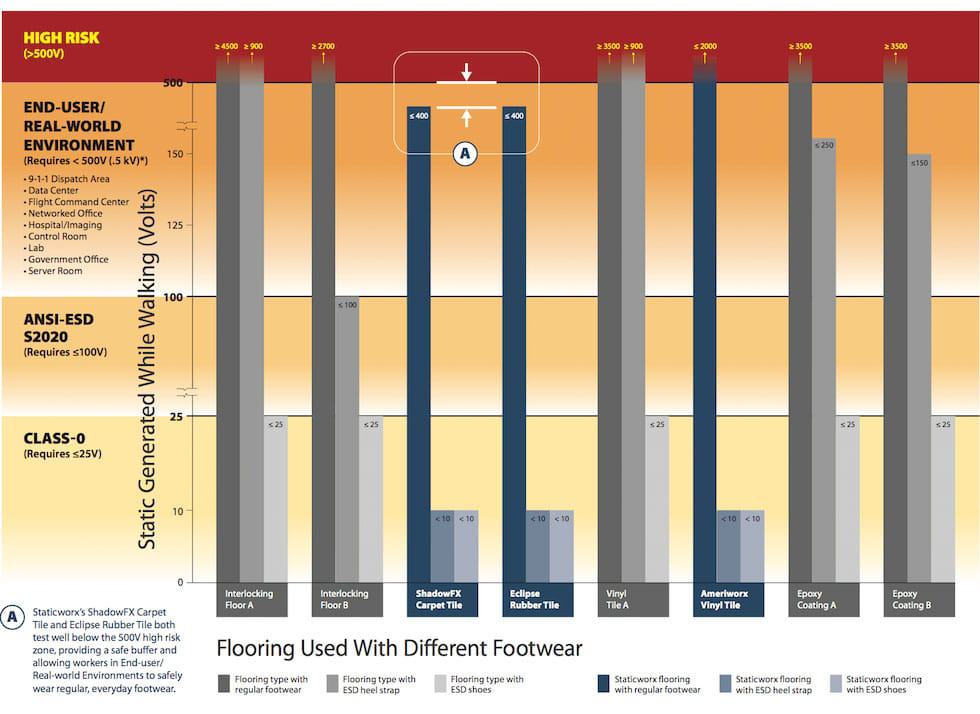

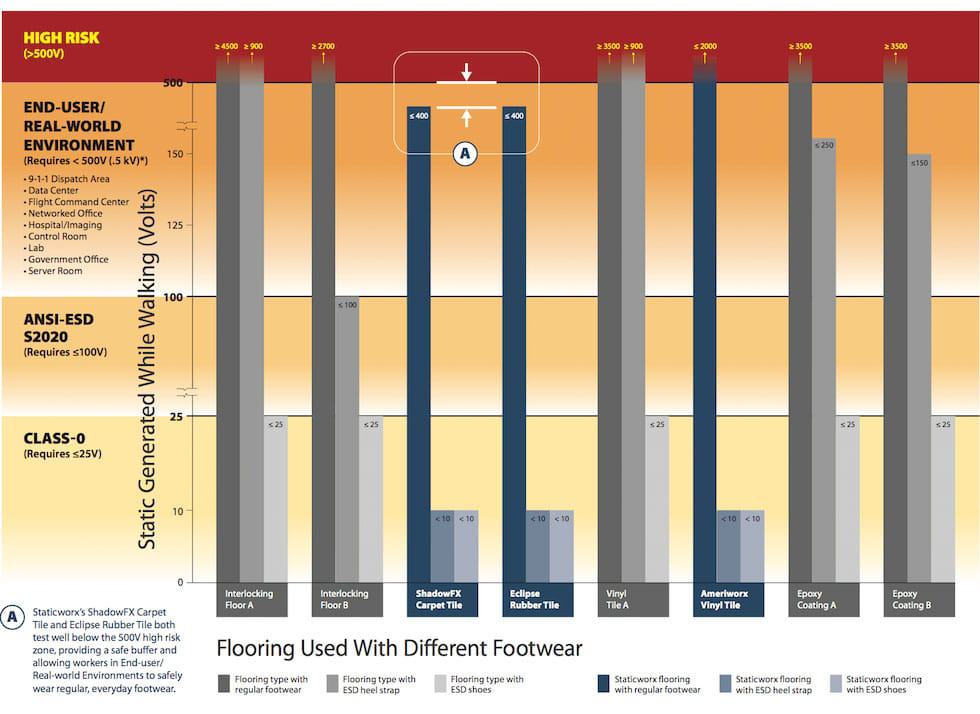

All ESD flooring options should be tested and evaluated based on the type of footwear that will be used in the space. Epoxy coatings and ESD vinyl offer no static protection without the (enforced) use of special static-control footwear.

To be sure the floor meets industry-specific standards and specifications, always request independent lab test reports.

ESD Flooring Is Easy To Install

Hire Locally or Consider Using Your In-House Facilities Team

Before specifying any floor—or thinking about design, color, ergonomics, or even budget—it’s crucial that you understand the basics about static electricity and electrostatic discharge (ESD) and that you’re familiar with common ESD terms. If this is your first exposure to ESD flooring, taking a few minutes to read an article or two now will save you time, energy, and headache down the line. To learn the basics of ESD and ESD flooring, click here.

Here are spaces where ESD flooring is required and used:

If you’re an architect or designer charged with specifying or selecting a static-control floor, you know that aesthetics is only part of the picture. The most attractive ESD floor will fail if it’s specified for an incompatible space or fails to meet the proper industry standards. And product failure can result in liabilities that no architect wants to—or should have to—deal with. By following industry protocols, you can avoid the mistakes that sometimes get specifiers in trouble.

In addition to color and design, your objectives for any floor you specify probably include items such as budget, durability, ergonomics, and sustainability. These are important considerations. There’s no reason why you shouldn’t be able to find an ESD floor with excellent static-protective properties that also meets these secondary objectives.

Before specifying any floor—or thinking about design, color, ergonomics, or even budget—it’s crucial that you understand the basics about static electricity and electrostatic discharge (ESD) and that you’re familiar with common ESD terms. If this is your first exposure to ESD flooring, taking a few minutes to read an article or two now will save you time, energy, and headache down the line. To learn the basics of ESD and ESD flooring, click here.

Here are spaces where ESD flooring is required and used:

Spaces Requiring ESD Flooring

Controlled Environments/Manufacturing

- Examples: ESD-protected areas (EPA), including microelectronics fabrication; circuit board assembly; manufacturing test and repair of electronics; cleanrooms

Complies with ANSI/ESD S20.20: 100 volt static-charge maximum

- Handles open electronic parts

- Floor in combination with special static-control footwear provides ground connection

- Foot grounders or ESD shoes mandated and enforced

- Wrist straps required

- Examples: ESD-protected areas (EPA), including microelectronics fabrication; circuit board assembly; manufacturing test and repair of electronics; cleanrooms

Complies with ANSI/ESD S20.20: 100 volt static-charge maximum

- Handles open electronic parts

- Floor in combination with special static-control footwear provides ground connection

- Foot grounders or ESD shoes mandated and enforced

- Wrist straps required

Mission-Critical Spaces

Examples: mission-critical areas such as server rooms; 9-1-1 dispatch areas; development labs; university labs; data centers; certain cleanrooms; flight command centers; hospitals; government offices

- Requires uninterrupted operation of electronic systems

- No wrist straps or special footwear

- Floor must prevent charges on people wearing all types of footwear

Examples: mission-critical areas such as server rooms; 9-1-1 dispatch areas; development labs; university labs; data centers; certain cleanrooms; flight command centers; hospitals; government offices

- Requires uninterrupted operation of electronic systems

- No wrist straps or special footwear

- Floor must prevent charges on people wearing all types of footwear

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Before Specifying Any Floor, Make an ESD Checklist

- First and foremost, check the environment. Are you specifying a floor for an ESD-protected area (EPA)—where the use of special footwear and wrist straps is mandatory? Are mandates enforced? Or will the floor be used in an end-user equipment environment—where there are no static-control protocols?

To be sure electronics are protected, whether or not people follow footwear rules to a T, strive for fault-tolerant, ESD protection that provides low-static-generation performance with or without special footwear. Check the footwear requirements. When evaluating the static-generating properties of a floor, account for all types of footwear—including special static-control footwear as well as regular street shoes.

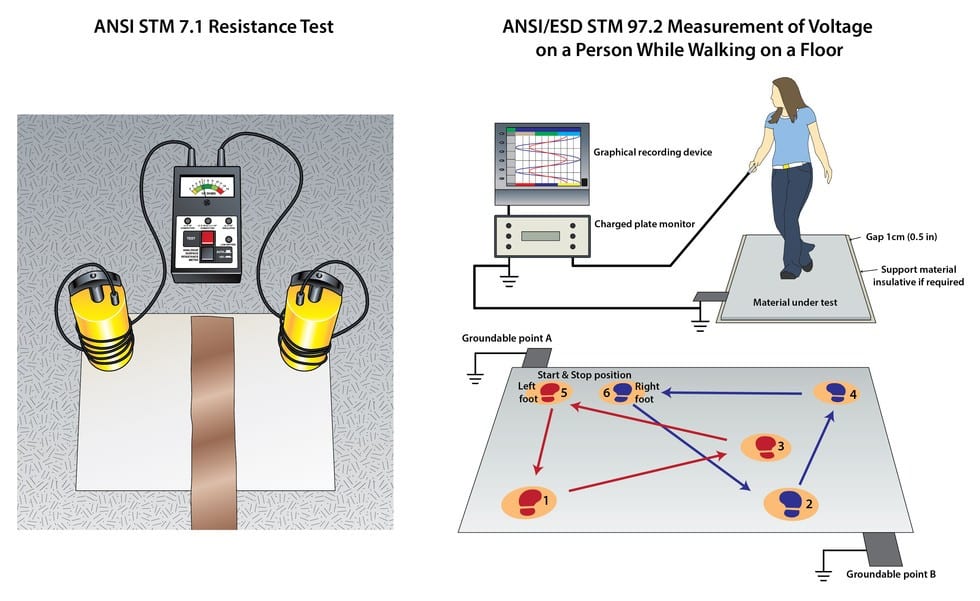

Ensuring compliance is easy: simply require that the floor under consideration has been tested and meets ESD-industry standards. Test method ANSI/ESD STM97.1 evaluates the electrical resistance of a floor with the test subject wearing ESD footwear. ANSI/ESD STM97.2 measures the amount of static—or voltage—generated when the test subject walks on the floor wearing various types of footwear.

- Check to be sure flooring materials are appropriate for the application. ESD rubber, vinyl, carpet, and epoxy are all appropriate for different environments.

Rubber

ESD rubber, a naturally low-static-generating material, works well in spaces where people typically wear regular street shoes. Because it’s a softer material, rubber is also great for labs and other spaces where people are on their feet for long periods of time.

Vinyl

ESD vinyl, with its low cost and clean, hospital-like appearance, can give electronics manufacturing or handling facilities—where personnel are required to wear ESD-protective shoes—a striking appearance without breaking the budget.

In a 24/7 mission-critical space, where people wear street shoes, an ESD vinyl floor will generate enough static to blow headsets, disrupt data, and destroy the microcircuits inside sensitive electronic components.

Carpet

Like rubber, ESD carpet is a soft, low-static-generating material; because carpet reduces noise when people walk, it’s great for spaces, such as flight towers or mission-critical call and 9-1-1 dispatch centers, where noise levels need to be kept to a minimum.

Epoxy

The least expensive material, ESD epoxy has some downsides, such as a long drying time and difficulty of repairs, that prevent its being an optimal choice for many applications. In environments where forklifts are used or people push heavy carts, a hard, durable surface makes ESD epoxy an excellent choice.

Multiple Flooring Materials

Consider using a combination of flooring, as needed. ESD flooring materials can be mixed and matched, with ESD vinyl or rubber, for example, placed in heavy traffic areas and carpet in quiet adjacent spaces.

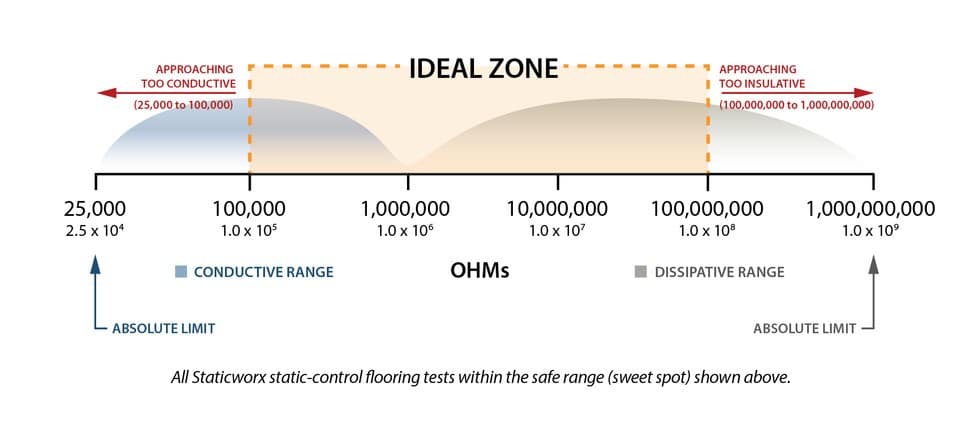

- Check conductivity levels. Conductivity—the opposite of electrical resistance—determines how quickly, or slowly, a material will transport electrical charges, such as static electricity, to ground.

- Find the “sweet spot” for conductivity.

- Industry standard ANSI/ESD S20.20 requires the electrical resistance of ESD floors to measure under 1 x 10E9 ohms. Materials that measure at or close to 10E9 may not bleed static to ground quickly enough to prevent damage to sensitive components.

- Materials that measure under 1 x 10E5 may be too conductive and compromise the safety of people working on or near energized equipment. That’s why standards such as Motorola R56 (used by the telecommunications industry) and FAA 019f (regulating flight towers) forbid the use of materials that measure under 1 x 10E5.

The Sweet Spot for Conductivity

- Find the “sweet spot” for conductivity.

- Electrical resistance should be verified with an Ohm meter. If the material does not pass the Ohm meter test—measures above 1 x 10E9 ohms—it cannot be grounded.

- If a material can’t be grounded, it doesn’t work—and it won’t protect electronic equipment from damage caused by random static discharge.

- Avoid materials measuring less than 1.0 x 10E5 Ohms for mission-critical operations.

- As noted above, these materials are too conductive to be used safely around energized equipment, and forbidden by the telecommunications industry and FAA.

Check terminology. Pay special attention to terms like conductive, static dissipative, Ohms, volts, resistive properties, ground, Resistance to Groundable Point (RTG), Resistance–Point to Point (RTT), and static generation.

- Check specifications to determine the upper limits for body voltage generation.

- ANSI/ESD S97.2: the ideal upper limit for charge generation:

- Mission-Critical: should not exceed 500 volts (.5 kV)

- EPA: cannot exceed 100 volts (.1kV)

- Class 0 ESD: should not exceed 25 volts

- ANSI/ESD S97.2: the ideal upper limit for charge generation:

- Check grounding standards and test methods.

- Write your specification based on performance parameters.

- Reference ANSI/ESD S20.20 for electronics manufacturing.

- Reference FAA 019f for flight control towers.

- Reference Motorola R56 and ATIS-0600321 for mission-critical environments, such as 9-1-1 dispatch areas, control rooms, and data centers.

- Write your specification based on performance parameters.

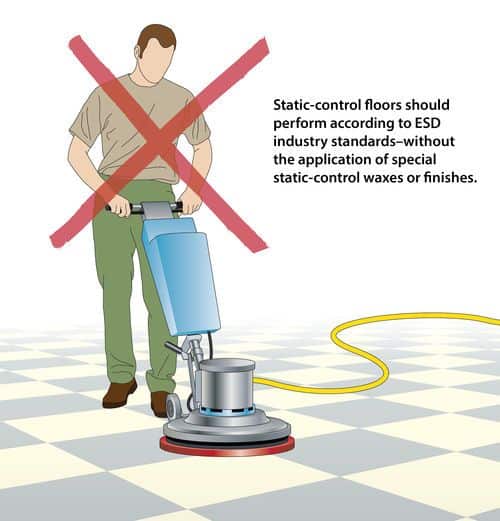

Check to be sure the floor provides permanent static protection. Static-control floors should never require anti-static sprays or waxes to enhance their static-control performance properties.

- Check the floor after it is installed. Request a free flooring audit.

- Environmental conditions often change post-installation. Air conditioning, for instance—which is rarely in use during installation—will lower relative humidity. Testing the floor post installation will determine whether or not it has retained its electrical properties.

Static-control Flooring Options

| Static-Control Flooring Options | Environment Complies with ANSI/ESD S20.20 using ESD Footwear 100 volt maximum | Environment Mission-Critical No ESD Footwear 500 volt maximum |

|---|---|---|

| Eclipse EC and GF Rubber | Yes | Yes |

| Conductive Vinyl Tile | Yes | No |

| Static-Dissipative Vinyl Tile | Yes | No |

| Plastic Interlock Conductive Flooring | Yes1 | No |

| Plastic Interlocking Dissipative Flooring | Yes1 | No |

| Conductive Epoxy Coatings | Yes1 | No |

| Static-Dissipative Epoxy Coatings | Yes1 | No |

| Shadow FX Static-Dissipative Carpet Tile | Yes | Yes |

| Antistatic High-Pressure Laminate (HPL) | No | No |

| Conductive High-Pressure Laminate (HPL) | Yes | No |

Note1: Always request independent lab test reports. Some epoxy coatings and Interlocking ESD vinyl floors do not meet the maximum 100 volt charge generation requirements of ANSI/ESD S20.20 when tested with ESD footwear.

All static-control flooring options should be tested and evaluated based on the type of footwear that will be used in the specific space. Epoxy and vinyl offer no static protection without the use of static control footwear.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.

Check the footwear requirements. When evaluating the static-generating properties of a floor, account for all types of footwear—including special static-control footwear as well as regular street shoes.

Check the footwear requirements. When evaluating the static-generating properties of a floor, account for all types of footwear—including special static-control footwear as well as regular street shoes.

Check terminology. Pay special attention to terms like conductive, static dissipative, Ohms, volts, resistive properties, ground, Resistance to Groundable Point (RTG), Resistance–Point to Point (RTT), and static generation.

Check terminology. Pay special attention to terms like conductive, static dissipative, Ohms, volts, resistive properties, ground, Resistance to Groundable Point (RTG), Resistance–Point to Point (RTT), and static generation. Check to be sure the floor provides permanent static protection. Static-control floors should never require anti-static sprays or waxes to enhance their static-control performance properties.

Check to be sure the floor provides permanent static protection. Static-control floors should never require anti-static sprays or waxes to enhance their static-control performance properties.