4 Things to Know So You Don't Buy the Wrong ESD Epoxy Floor

Coatings are high on many facility managers’ lists as the most desirable floor for manufacturing spaces. From a maintenance perspective, epoxy is considered a relatively easy flooring surface to maintain. A well-installed coating doesn’t show any seams or surface variation, so epoxy looks nice. Epoxy floors don’t stain and can be cleaned without much effort. It’s also easy to roll heavy equipment over coatings with either fork lifts or flotation equipment such as air skids.

When the coating requires ESD properties, there are additional factors to consider. Overlooking these factors can affect the performance of an ESD epoxy floor, to the point that it may not protect electronics against static discharge.

1. ESD coatings are intended to get rid of static electricity.

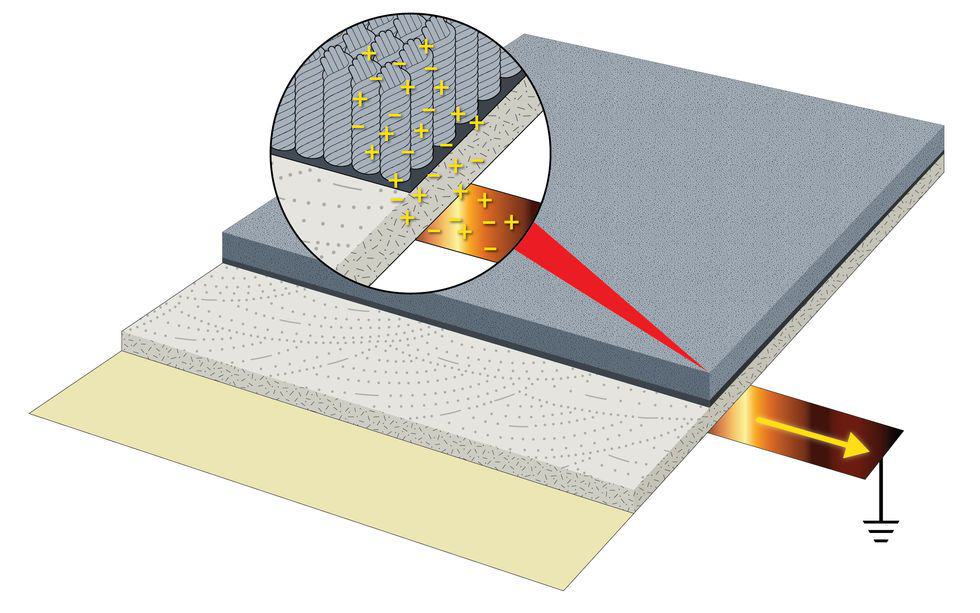

This means they need to perform electrical tasks such as grounding and charge prevention. Grounding is not the same as charge prevention. Grounding involves installing copper strips under the coating and attaching the copper to either the frame of the building or an electrical ground. This allows the floor to dissipate static charges, from the surface to the copper strips to ground.

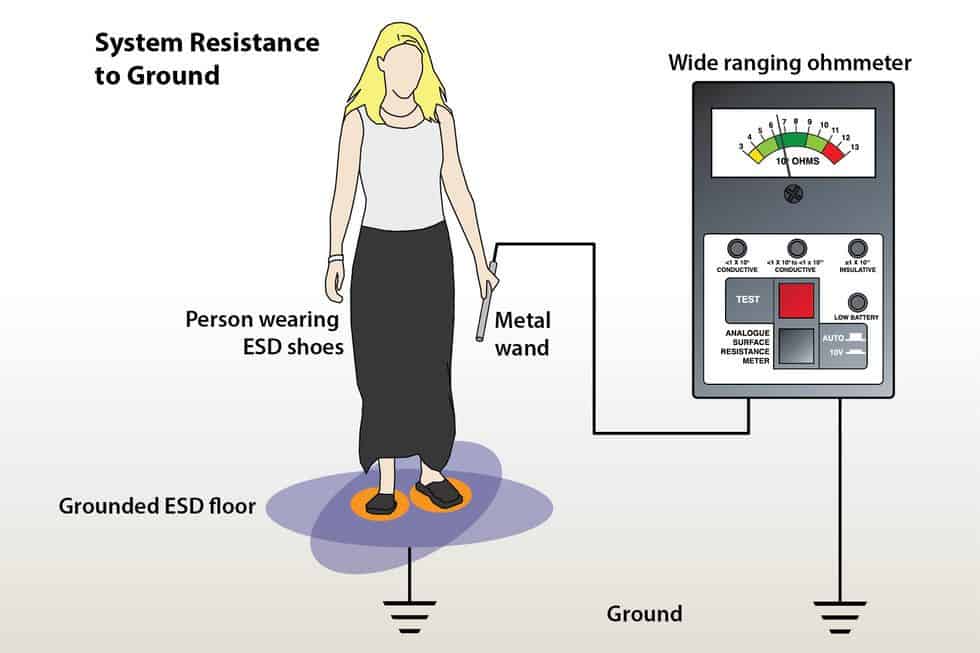

For an ESD floor to be grounded, the floor needs to have a certain amount of conductivity. You evaluate conductivity with a megohm meter. Best practices such as ASTM and ANSI/ESD state that an ESD floor should never have a resistance at or above 1 billion ohms.

Resistance: ANSI/ESD STM7.1

This is what a spec should look like:

ESD S20.20 Specification: < 1.0 x 10E9 ohms

Conductive: < 1.0 x 10E6 ohms

Static Dissipative: ≥ 1.0 x 10E6 ohms

What is System Resistance?

System resistance measures the resistance to ground (ohms) of a person standing on a floor, wearing static control footwear. System resistance measures the person, the footwear they’re wearing, the contact resistance of the floor surface, and the resistance to ground of the floor covering. Multiple tests should be conducted with the test subject wearing every type of footwear that will be allowed in the space. System resistance must measure less than 1.0 x 10E9.Most manufacturers can supply a floor that meets this baseline level of performance, but special considerations do not end with resistance or properly grounding the floor.

Charge prevention means inhibiting static charges from building on people and moving equipment – e.g. mobile carts – in the first place.

2. In addition to dissipating charges to ground, ESD coatings must prevent static charge generation.

Often, specifiers assume that if a grounded floor passes the resistance test – measures under 1 billion ohms – it will prevent charge generation. This is not true. A floor can be conductive and generate significant static charges. Due to their multi-layer design, this is especially true of some ESD coatings.

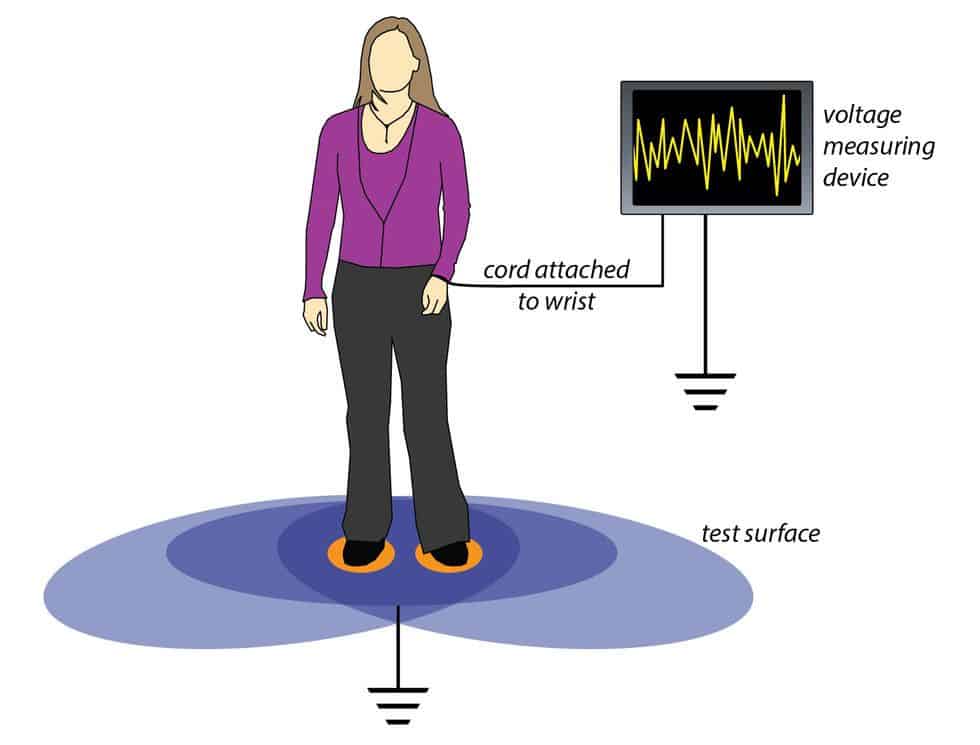

Almost 10 years ago, seeing this misconception as a serious problem, the ESDA began requiring a test method that would help organizations avoid installing grounded conductive floors that do not prevent charges from building on people. This test is called ANSI/ESD STM97.2.

Body Voltage Test: ANSI/ESD STM97.2

Here’s what the spec should look like:

< 100 volts @12% RH with the same footwear to be used in the facility

Body voltage tests are performed using a volt meter and measure the voltage generated by a person walking on the floor wearing the type of footwear that will be used in the space.

STM97.2 measures how much static a person will accumulate when they walk on an ESD floor. Many engineers falsely assume that if the floor is very conductive, this second test is unnecessary. In fact, most multi-layer ESD coatings do not pass static charge generation testing. That’s why this second test is now a hard and fast requirement for ANSI/ESD certification. So why is a short article about ESD coatings beginning to sound like, Don’t buy coatings because they don’t work?

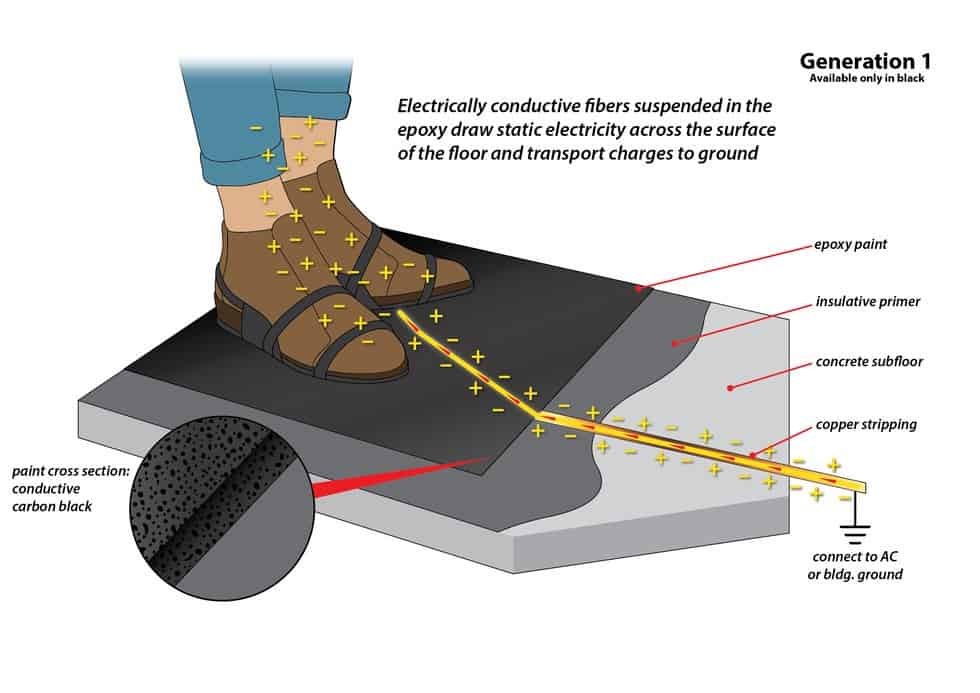

3. There have been three evolutions in the ESD coatings world.

We call these evolutions generation 1, 2 and 3. Generation 1 coatings were created by and for the munitions industry to prevent explosions triggered by static discharge. Gen 1 coatings were comprised of black carbon-loaded epoxy. They worked well, and still work, but their black carbon loaded surfaces don’t meet the aesthetic needs of electronics manufacturing.

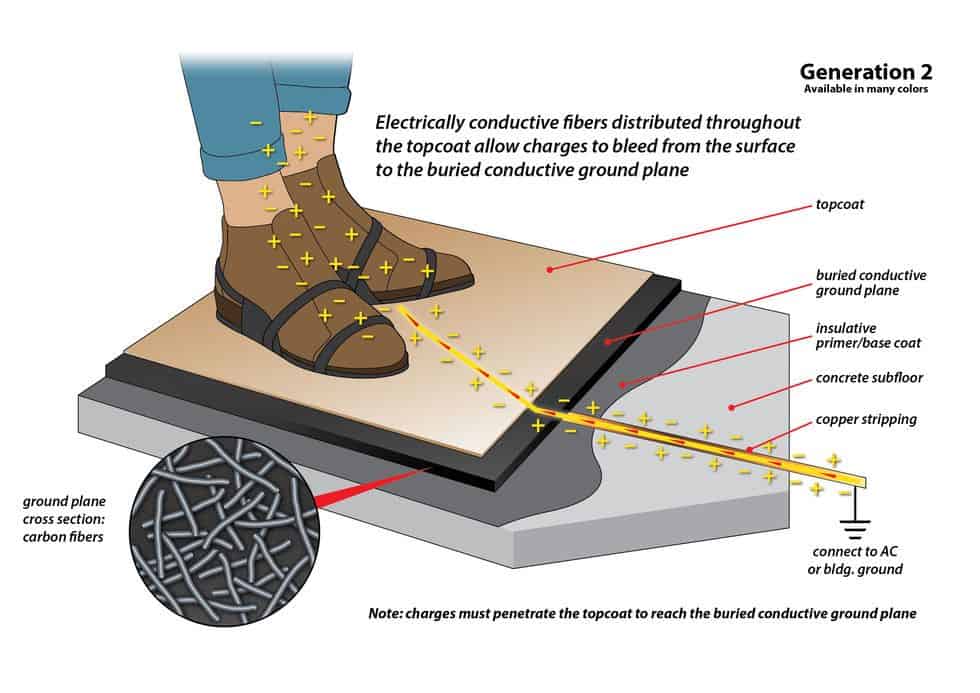

Generation 2 coatings were created by applying a thin, marginally conductive light-colored topcoat directly over a conductive primer aka a generation 1 carbon-loaded coating. Because their surface is only marginally conductive, Gen 2 coatings rely on the conductivity of the Gen 1 conductive primer underneath the surface to create a path to ground. If the floor works properly, charges move from the surface of the thin light-colored topcoat through the black sublayer to ground.

While Gen 2 coatings can measure in the very conductive range with an ohm meter, they don’t prevent static generation and fail ANSI/ESD STM 97.2 testing. If Gen 2 floors are conductive, why don’t they prevent static generation? Simple answer: the surface, which touches your feet, has very little conductivity; it is almost insulative. Because the test probes sit on the surface of the floor, the surface appears conductive. However, the meter is actually finding and measuring the conductive properties of the buried conductive primer.

Skewed test results are the reason the ESDA requires charge generation testing in a lab. You should also require that the charge generation report for a floor you’re considering is done in a lab. The report should also include testing with the footwear you plan to use in your facility.

When you read an ESD test report, always ask what footwear was used when the test was performed. ESD floors perform differently with people wearing different footwear. For example a person wearing heel straps will generate more static than a person wearing full-coverage shoe sole straps. If the test was not done using the footwear you plan to use in your facility, get the test done with your type of footwear.

4. Many Gen 2 epoxy floors appear to pass ESD testing because the tests are done at high humidity or performed on subjects wearing ESD shoes

Most electronics manufacturers use heel straps in their facilities, not ESD shoes. If people in your facility use heel straps, your floor needs to get rid of static on people wearing heel straps. Results obtained with the subject wearing ESD shoes say nothing about how the floor will perform in your facility.

Body Voltage Generated with Different Footwear

| ESD Flooring Material | Regular Footwear | ESD Heel Straps | Conductive Shoes |

|---|---|---|---|

| Conductive Vinyl Interlocking Floor Tile A with PU Surface Coating | > 4,000 volts | 827 volts peak | 62 volts peak |

| Conductive Vinyl Interlocking Floor Tile B with no PU Coating | > 2,500 volts | 33 volts peak | 15 volts peak |

| Static Dissipative Epoxy, Generation 2, Buried Conductive Layer | > 3,000 volts | 350 volts peak | 18 volts peak |

| Static Dissipative Carpet Tile Squares (500 mm x 500 mm) | < 400 volts | < 25 volts | < 25 volts |

| Conductive Rubber Floor Tiles (24″ x 24″, 2 mm thickness) | < 400 volts | < 10 volts | < 10 volts |

| Conductive Vinyl Tile (12″ x 12″, 3 mm thickness) | > 3,500 volts | 10 volts peak | 12 volts peak |

| Conductive Epoxy Coating, Generation 2, Buried Conductive Layer | > 3,500 volts | 329 volts peak | 35 volts peak |

| Conductive Epoxy Coating, Generation 3, No Buried Layer, Surface Fully Conductive | > 3,500 volts | 23 volts peak | no test result |

Important notes

- Flooring should always be evaluated based on charge-generation testing of flooring in combination with footwear.

- Surface conductivity greatly impacts the performance of ESD epoxy coatings.

- A minimum charge of 3,000 volts is necessary for a static shock to be perceptible to most people.

- A maximum charge of 100 volts is specified by ANSI/ESD S20.20.

- All test results provided by Fowler Associates, Inc.

Notice in the chart above: A generation 2 floor will generate 329 volts on a person wearing heel straps while a Gen 3 floor only generates 23 volts. Considering that the maximum allowable is 100 volts, the Gen 2 floor that generates 329 V is not a floor you want to use. If you didn’t understand the relationship between ESD flooring performance and footwear, it would be easy to misread STM97.2 test results. For example, the same Gen 2 floor might test at 35 volts on a person wearing ESD shoes. But if every person in your facility will not be required to wear special ESD shoes, the results of tests using ESD shoes would be irrelevant to your application.

Generation 2 coatings are still available on the market today. They have not become extinct because many buyers are unaware of recent test requirements for ESD floors. They still rely solely on an ohm meter/resistance test to determine if a floor will get rid of static electricity. In many case the installers know nothing about the charge generation test. Bear in mind, installers probably spend 95% of their time installing industrial floors in factories that don’t make or handle electronics. They are not ESD experts.

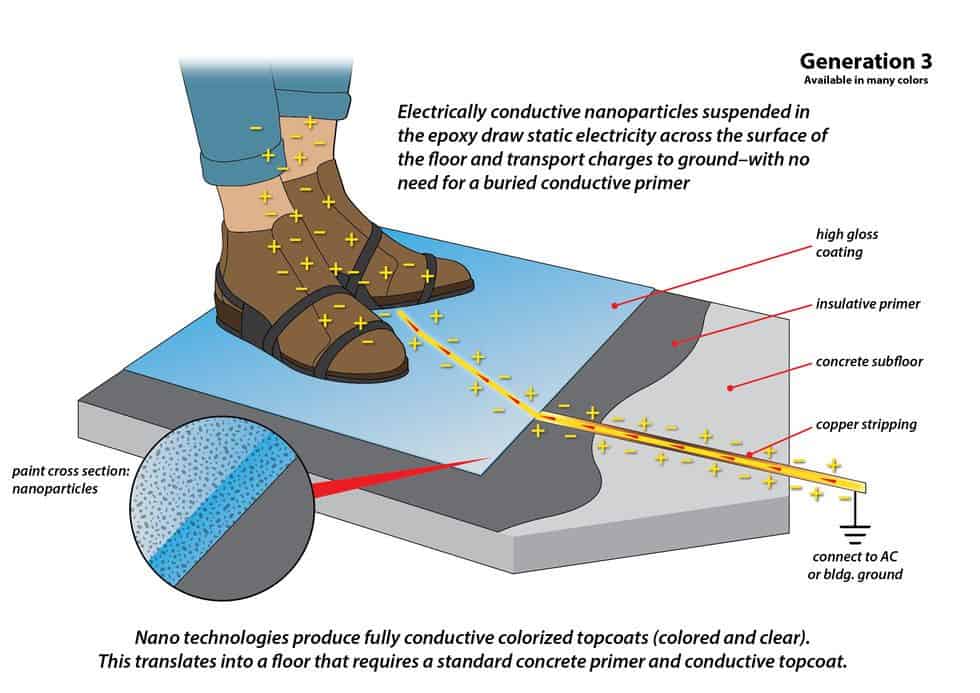

Newer generation 3 coatings are manufactured and installed so that the topcoat acts as both the decorative walking surface and the conductive ground-plane. With Gen 3 coatings, the part of the floor that touches your feet is both conductive and low charge generating. This means a Gen 3 floor will dissipate static and prevent you from generating a static charge. The top surface acts as the conductive ground-plane and decorative surface all-in-one.

ESD epoxy floors offer many advantages, particularly in heavy-duty areas like electronics manufacturing facilities. To ensure that the floor performs and you get the floor you paid for, do your due diligence. Don’t just apply a section of an ESD coating on your loading dock and perform tests at ambient humidity. Be sure the floor is properly tested and meets both resistance and charge generation requirements set out in ANSI S20.20. And be sure charge generation tests are conducted in a lab at low humidity with the footwear you’ll be using in your facility. These few simple precautions will help you avoid purchasing a floor that doesn’t do its intended job.

Learn more about about Generation 1, 2 and 3 Epoxy.

Learn about GroundWorx Basics.

Learn about GroundWorx Ultra.

Further Reading

READ

- Grounding ESD/Coatings

-

Why Some Epoxy Coatings

Fail Body Voltage Tests -

StaticWorx GroundWorx

Ultra Case History

Grounding ESD Coatings [Read/Download]

There are several ways to ground an ESD epoxy floor – including circuit ground, earth ground, and natural earth ground. Learn more.

Why Some Epoxy Coatings Fail Body Voltage Tests [Read]

There are different ways to produce these coatings and technologies have changed over the years. Many of today’s conductive epoxy coatings fail ESD body voltage tests. Gen 3 epoxies use nanotechnology for an attractive floor, in any color, that meets all ESD standards. Learn more.

StaticWorx GroundWorx Ultra Case History [Read/Download]

For an electronic components manufacturer, electricity is at the heart of business. But static electricity? That’s a very different story. That was the conundrum for Extreme Engineering Solutions (X-ES), which manufactures and tests hardware for the embedded computing market at its headquarters just outside Madison, Wisconsin. The choice for X-ES’s production floor was the HB-97.2 epoxy line [GroundWorx Ultra] from StaticWorx, which includes both an epoxy primer and polyurethane topcoat. Learn more.

Why Some Epoxy Coatings Fail Body Voltage Tests [Read]

There are different ways to produce these coatings and technologies have changed over the years. Many of today’s conductive epoxy coatings fail ESD body voltage tests. Gen 3 epoxies use nanotechnology for an attractive floor, in any color, that meets all ESD standards. Learn more.

StaticWorx GroundWorx Ultra Case History [Read/Download]

For an electronic components manufacturer, electricity is at the heart of business. But static electricity? That’s a very different story. That was the conundrum for Extreme Engineering Solutions (X-ES), which manufactures and tests hardware for the embedded computing market at its headquarters just outside Madison, Wisconsin. The choice for X-ES’s production floor was the HB-97.2 epoxy line [GroundWorx Ultra] from StaticWorx, which includes both an epoxy primer and polyurethane topcoat. Learn more.

LISTEN

Epoxy coatings were introduced in the 1950s to meet the needs of the munitions industry.

Gen 1 coatings were essentially black or dark gray paint, with a conductive surface. They were cheap, easy to repair, and ugly.

Gen 2 epoxies were created in the 60s and 70s for electronics manufacturers, who wanted light, shiny surfaces. Gen 2 was more attractive, but subject to damage over time. With three layers – consisting of a primer, conductive ground plane, and top layer – Gen 2 epoxies can be difficult to install correctly and difficult and costly to repair. ESD performance can also be unreliable.

Current Gen 3, all-in-one coatings, consist of a single layer, with decorative and conductive properties in all-in-one. Gen 3 ESD coatings work extremely well. They’re easy to install and repair and offer superior ESD performance.

WATCH

Comparing the scratch resistance of shiny no-wax HB 97.2 (GroundWorx Ultra) with an entry-level Water-Based 2-Part Epoxy-Acrylate Finish.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Unless otherwise stated, standards referenced are the most up-to-date versions.

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Flooring Products

We accept these major credit cards.

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

All rights reserved. © 2008-2024, StaticWorx® GroundSafe™ ESD Flooring. Privacy Policy