AmeriWorx: Precision Milled Conductive FloorinG

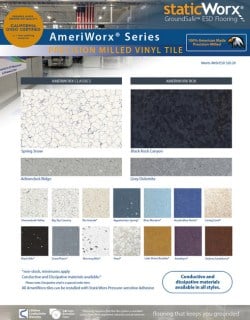

The AmeriWorx Collections

- AmeriWorx ESD Solid Vinyl Tile Product Page

- AmeriWorx ESD Solid Vinyl Tile Classics

- AmeriWorx ESD Solid Vinyl Tile ROX

Information

- 10 Reasons to Install AmeriWorx SVT in Your Facility

- Compare Imperfect OFFSHORE Tile to AmeriWorx ESD Vinyl Tile

- Do You Need a Substitute for Armstrong Vinyl Tile?

- Meet Your Buy American Requirements

- StaticWorx vs Armstrong ESD Vinyl Tile

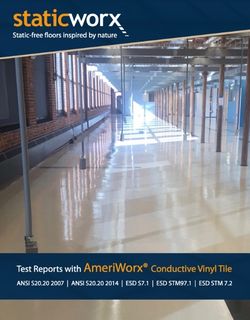

- Test Reports

- VOCs? Heavy metals? What are you breathing from your ESD flooring?

- Why Vinyl?

Cleaning and LEED information

Precision milling ensures a tight, gap-free installation

We’re often asked if precision milling really is necessary. If aesthetics are important, if your project requires a clean, tight, gap-free installation—then the answer is yes.

die cut tiles are irregularly shaped and prone to shrinkage

During installation, minute irregularities cause unsightly gaps between adjoining tiles. Gaps collect water and debris and make shiny white installations look like a soiled checkerboard. To minimize fractures, some manufacturers cut the tile on a slight angle, or bevel. Bevels between adjacent tiles create voids, or air pockets, weakening seams. If heavy loads happen to rest on seams, seam deflection can occur—crushing or popping tiles.

Die-cut tiles are never perfectly square and tiles vary in size. Die-cutting itself produces tile with shattered, irregular edges. Like all polymers, Solid Vinyl Tile (SVT) is prone to shrinkage, as well as dimensional changes during shipping and storage. Affected by tile composition, temperature and pressure, these changes are inconsistent and unpredictable.

During installation, minute irregularities cause unsightly gaps between adjoining tiles. Gaps collect water and debris and make shiny white installations look like a soiled checkerboard. To minimize fractures, some manufacturers cut the tile on a slight angle, or bevel. Bevels between adjacent tiles create voids, or air pockets, weakening seams. If heavy loads happen to rest on seams, seam deflection can occur—crushing or popping tiles.

Die-cut tile has irregular edges, resulting in uneven seams.

Die-cutting is an imperfect procedure. By nature, it creates slight irregularities in the edges of the tiles. A die slams down on a 1/8″ piece of solid plastic. As the die cuts the tile, it also fractures the edges. The fractured edges may be only a couple of degrees off from a perfect right angle. On one tile, such variation is insignificant, often invisible to the naked eye. During installation, even infinitesimal variations can create unsightly gaps between tiles, compromising appearance and increasing installation time and cost.

Beveling weakens tile seams, creating high susceptibility to seam deflection.

Point loads can crush any floor at its weakest point. Adhesive is far softer than solid vinyl. When heavy loads rest on seams that are filled in with adhesive, seam deflection can occur, crushing tiles or popping the seams. The only way to avoid this potential problem is by creating a perfect 90-degree angle on all four tile edges, through the entire thickness of the tile. Perfectly milled tile rests snugly against adjacent tile, eliminating any possibility of unsightly gaps, while providing extreme resistance against heavy loads.

Regular SVT is prone to dimensional instability and shrinkage.

Lack of squareness creates uneven joints between tiles. Over a 50 foot span, these small variations grow cumulatively to as much as ½”.

Solid vinyl tile is pressed, cut, processed and polished at high temperatures. As hot tiles move through the automated system, they begin to cool. Next, tiles are chilled by a series of water baths (filtered, recycled and reused water), in a process called annealing, used to inhibit dimensional changes. After this step, the tile is die-cut and prepared for shipment.

As with all polymers, the dimensions of SVT change slightly after manufacturing. This dimensional instability, caused by post-production temperature trauma and curling, can last for up to 72 hours. Because these changes are never perfectly proportionate, the size of die-cut tile varies. During shipment and storage, pressure and temperature changes can cause further dimensional instability, changing the size of a tile by as much as 1/16 of an inch, depending on tile composition, temperature, pressure and shipping distance.

Imperfect tile costs you time and money and creates ugly installations.

All StaticWorx AmeriWorx ESD vinyl tile meets ESD Association (ESDA) standards.

During a recent survey of large flooring contractors we asked them to list the biggest complaints they have with the recent influx of offshore conductive and static dissipative vinyl flooring. Every response included major concerns about:

- Squareness, and shrinkage which create seam gaps – and call backs

- Economic liability for the contractor, the janitorial service and ultimately the owner, because of shrinkage and lack of squareness

Less than perfect vinyl tile costs time and money for the installer

The installer has to sort tiles and cut them in order to make them fit properly; they also need to buy extra tile to compensate for the tiles they can’t use. After installation, the owner is harnessed with permanent maintenance problems, including gaps in seams and ongoing shrinkage. Gaps collect dirt and compromise the visual appeal of a floor that was supposed to look like an operating room in a hospital.

Die-cutting is an imperfect procedure. By nature, it creates slight irregularities in the edges of the tiles. A die slams down on a 1/8″ piece of solid plastic. As the die cuts the tile, it also fractures the edges. The fractured edges may be only a couple of degrees off from a perfect right angle. On one tile, such variation is insignificant, often invisible to the naked eye. During installation, even infinitesimal variations can create unsightly gaps between tiles, compromising appearance and increasing installation time and cost.

Beveling weakens tile seams, creating high susceptibility to seam deflection.

Point loads can crush any floor at its weakest point. Adhesive is far softer than solid vinyl. When heavy loads rest on seams that are filled in with adhesive, seam deflection can occur, crushing tiles or popping the seams. The only way to avoid this potential problem is by creating a perfect 90-degree angle on all four tile edges, through the entire thickness of the tile. Perfectly milled tile rests snugly against adjacent tile, eliminating any possibility of unsightly gaps, while providing extreme resistance against heavy loads.

Regular SVT is prone to dimensional instability and shrinkage.

Lack of squareness creates uneven joints between tiles. Over a 50 foot span, these small variations grow cumulatively to as much as ½”.

Solid vinyl tile is pressed, cut, processed and polished at high temperatures. As hot tiles move through the automated system, they begin to cool. Next, tiles are chilled by a series of water baths (filtered, recycled and reused water), in a process called annealing, used to inhibit dimensional changes. After this step, the tile is die-cut and prepared for shipment.

As with all polymers, the dimensions of SVT change slightly after manufacturing. This dimensional instability, caused by post-production temperature trauma and curling, can last for up to 72 hours. Because these changes are never perfectly proportionate, the size of die-cut tile varies. During shipment and storage, pressure and temperature changes can cause further dimensional instability, changing the size of a tile by as much as 1/16 of an inch, depending on tile composition, temperature, pressure and shipping distance.

Imperfect tile costs you time and money and creates ugly installations.

All StaticWorx AmeriWorx ESD vinyl tile meets ESD Association (ESDA) standards.

During a recent survey of large flooring contractors we asked them to list the biggest complaints they have with the recent influx of offshore conductive and static dissipative vinyl flooring. Every response included major concerns about:

- Squareness, and shrinkage which create seam gaps – and call backs

- Economic liability for the contractor, the janitorial service and ultimately the owner, because of shrinkage and lack of squareness

Less than perfect vinyl tile costs time and money for the installer

The installer has to sort tiles and cut them in order to make them fit properly; they also need to buy extra tile to compensate for the tiles they can’t use. After installation, the owner is harnessed with permanent maintenance problems, including gaps in seams and ongoing shrinkage. Gaps collect dirt and compromise the visual appeal of a floor that was supposed to look like an operating room in a hospital.

Precision milled for tight, gap-free installations. When quality matters.

The only way to prevent gaps is by producing tile with 90-degree angles on all four edges—through the entire thickness of the tile. That is what precision milling does. If you ran your hand down a stack of precision-milled tile, the surface would feel as smooth and glassy as a granite counter. AmeriWorx tiles rest snugly against adjacent tiles, eliminating unsightly gaps, while providing extreme resistance against heavy weight loads. Our precision-milled tile is rated at over 2500 PSI—everywhere on the tile, not just the center.

All StaticWorx AmeriWorx ESD vinyl tile meets ESD Association (ESDA) standards.

AmeriWorx Tile is Conditioned Before Precision Milling.

No Shrinkage—Ever

Foreign producers die-cut their tile, then immediately box, label and ship it for export. Sure, it’s expensive to delay production processes or store tile in the factory after a run. Following the pack would be cheaper. But we refuse to skip steps simply to reduce costs.

Knowing SVT shrinks, we cut our AmeriWorx vinyl sheet flooring into oversized tiles. For best results, precision milling should occur several days after the rough tile is produced. Conditioning gives the tile time to cure, the dimensions to stabilize before final milling. Conditioning also prevents dimensional changes that can occur later, during shipping and storage. After we cut our vinyl, we store the tiles in an environmentally-controlled space for 72 hours. This costly but important step guarantees that every single tile is perfect.

Perfect tile increases installation productivity

In our final milling process, a computer numerical controlled (CNC) machine mills our AmeriWorx vinyl tile to precisely 12″ x 12″ or 24″ x 24″, guaranteeing that every tile is perfectly square and exactly the right size. In this environmentally-friendly process, tile shavings are captured and reused in future production—so there is never any waste. Because our tile is conditioned for 72 hours then precision-milled, you can be assured that AmeriWorx vinyl tile will never shrink—even when it’s installed using releasable or pressure-sensitive adhesives like GroundTack and StatBond Pressure-Sensitive ESD adhesives.

No Shrinkage—Ever

Foreign producers die-cut their tile, then immediately box, label and ship it for export. Sure, it’s expensive to delay production processes or store tile in the factory after a run. Following the pack would be cheaper. But we refuse to skip steps simply to reduce costs.

Knowing SVT shrinks, we cut our AmeriWorx vinyl sheet flooring into oversized tiles. For best results, precision milling should occur several days after the rough tile is produced. Conditioning gives the tile time to cure, the dimensions to stabilize before final milling. Conditioning also prevents dimensional changes that can occur later, during shipping and storage. After we cut our vinyl, we store the tiles in an environmentally-controlled space for 72 hours. This costly but important step guarantees that every single tile is perfect.

Perfect tile increases installation productivity

In our final milling process, a computer numerical controlled (CNC) machine mills our AmeriWorx vinyl tile to precisely 12″ x 12″ or 24″ x 24″, guaranteeing that every tile is perfectly square and exactly the right size. In this environmentally-friendly process, tile shavings are captured and reused in future production—so there is never any waste. Because our tile is conditioned for 72 hours then precision-milled, you can be assured that AmeriWorx vinyl tile will never shrink—even when it’s installed using releasable or pressure-sensitive adhesives like GroundTack and StatBond Pressure-Sensitive ESD adhesives.

Downloads

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Unless otherwise stated, standards referenced are the most up-to-date versions.

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Flooring Products

We accept these major credit cards.

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

All rights reserved. © 2008-2024, StaticWorx® GroundSafe™ ESD Flooring. Privacy Policy