Initial (Post-Installation) Maintenance Guidelines

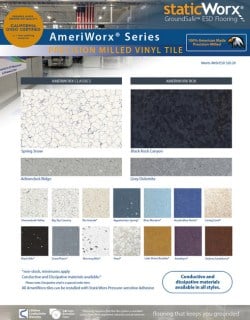

The AmeriWorx Collections

- AmeriWorx ESD Solid Vinyl Tile Product Page

- AmeriWorx ESD Solid Vinyl Tile Classics

- AmeriWorx ESD Solid Vinyl Tile ROX

Information

- 10 Reasons to Install AmeriWorx SVT in Your Facility

- Compare Imperfect OFFSHORE Tile to AmeriWorx ESD Vinyl Tile

- Do You Need a Substitute for Armstrong Vinyl Tile?

- Meet Your Buy American Requirements

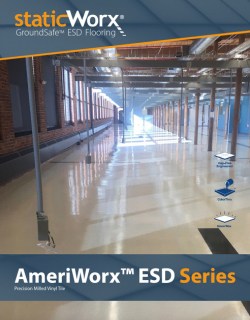

- Precision Milled Conductive Flooring

- StaticWorx vs Armstrong ESD Vinyl Tile

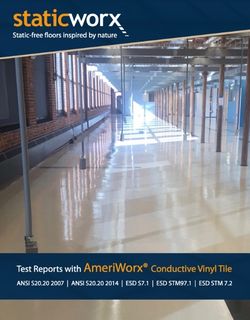

- Test Reports

- VOCs? Heavy metals? What are you breathing from your ESD flooring?

- Why Vinyl?

Cleaning and LEED information

Initial (Post-Installation) Procedures for StaticWorx Solid ESD Vinyl Tile (AmeriWorx)

NECESSARY TOOLS AND MATERIALS

- Single disc low-speed commercial floor buffer –must operate <375 rpm

- Buffing pads: gray (for new/lightly soiled tile), maroon (for existing/heavily soiled tile), and natural (for spray buff application).

- Standard dry mop, dedicated mop (microfiber ideal)

- Single mop bucket with wringer, double-sided mop bucket with wringer

- StaticWorx-approved cleaning and buffing chemicals

Instructions

- Allow the floor a minimum of 72 hours for the adhesive to cure adequately before performing any maintenance procedures.

- Sweep and damp mop the floor to remove all loose dirt/grime (never use an oil treated mop).

- Dilute StaticWorx EcoScrub Floor Degreaser (1 part degreaser : 10 parts water) with cool water and apply to the floor using a dedicated mop (microfiber is ideal). Apply liberally so the floor remains wet, but do not flood the floor. Allow the solution to sit for 4-5 minutes before moving on.

- Scrub the floor at <375 rpm using a rotary swing buffer machine in conjunction with a gray StaticWorx Initial Scrub Pad. Be sure to buff at least 5-6 passes per row of tile at a slow to moderate speed to unify the surface. Additional passes may be necessary, depending on the speed of each pass or on site conditions. To enhance cleaning, place a floater pad (such as a standard red or white pad) underneath the Initial Scrub Pad before beginning the buffing process.

- Remove the degreasing agent from the floor using a wet vacuum, auto scrubber, or a microfiber mop and a bucket. Rinse the floor with clean water and a clean wet mop to remove any remaining degreasing agent. Allow the floor to dry completely before moving on.

- The floor should appear as a uniform matte surface. Areas with excess variation in gloss should be re-addressed with the initial scrubbing procedure before proceeding. Lightly mist StaticWorx Formula 20.20 onto the floor (spray on application) and buff it in at <375 rpm using a Staticworx Natural Hair Pad. Work the solution in evenly with one initial pass of the buffer per row of tile to create a level surface. To avoid spotting, be sure to buff in any stray drips. As in step 4, buff 5-6 passes per row of tile to ensure a proper finish. Buff the solution until the floor is dry to the touch.

- If desired, repeat step 6 once to optimize the finished appearance.

Note: Ongoing maintenance requirements will vary depending on the desired final gloss as well as various environmental conditions.

You can now buy StaticWorx cleaning supplies online.

Videos

More Downloads

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

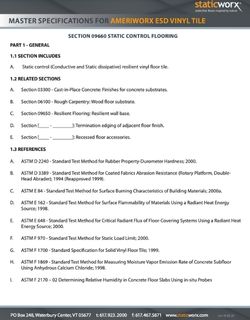

Unless otherwise stated, standards referenced are the most up-to-date versions.

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Flooring Products

We accept these major credit cards.

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

Flooring Products

We accept these major credit cards.

Get in Touch

East Coast: 617-923-2000

Email: [email protected]

“I’m so glad we were able to find an attractive solution that didn’t leave us with some run-of-the-mill ugly disaster.”

Share This

subscribe to newsletter

Sign up for our newsletter and occasional updates.

The FAA has updated its standard for facilities and electronic equipment. StaticWorx meets all requirements for ESD flooring.

Unless otherwise stated, standards referenced are the most up-to-date versions.

All rights reserved. © 2008-2024, StaticWorx® GroundSafe™ ESD Flooring. Privacy Policy