Video: ESD Flooring: Some Carpet Cannot Be Grounded

April 10, 2020

We’re back in the den today for another episode of Static Shorts with Dave Long: Right from my den. Today, Dave’s talking about conductivity and testing the electrical resistance of regular, static-dissipative, and highly conductive carpet.

To find out more about Conductive vs Static-Dissipative flooring, visit our Learning Center.

For help or advice about choosing an ESD floor, call us on 617-923-2000, email [email protected], or visit our Guide to ESD Flooring Selection.

Hi I’m Dave Long, from StaticWorx. Just like the video we made yesterday, I’m at home again. I’m guessing you are too. So what I discussed yesterday was the difference between low kV carpet, and static-dissipative carpet. Today we’re going to continue that discussion, but today, we’re going to talk about conductivity.

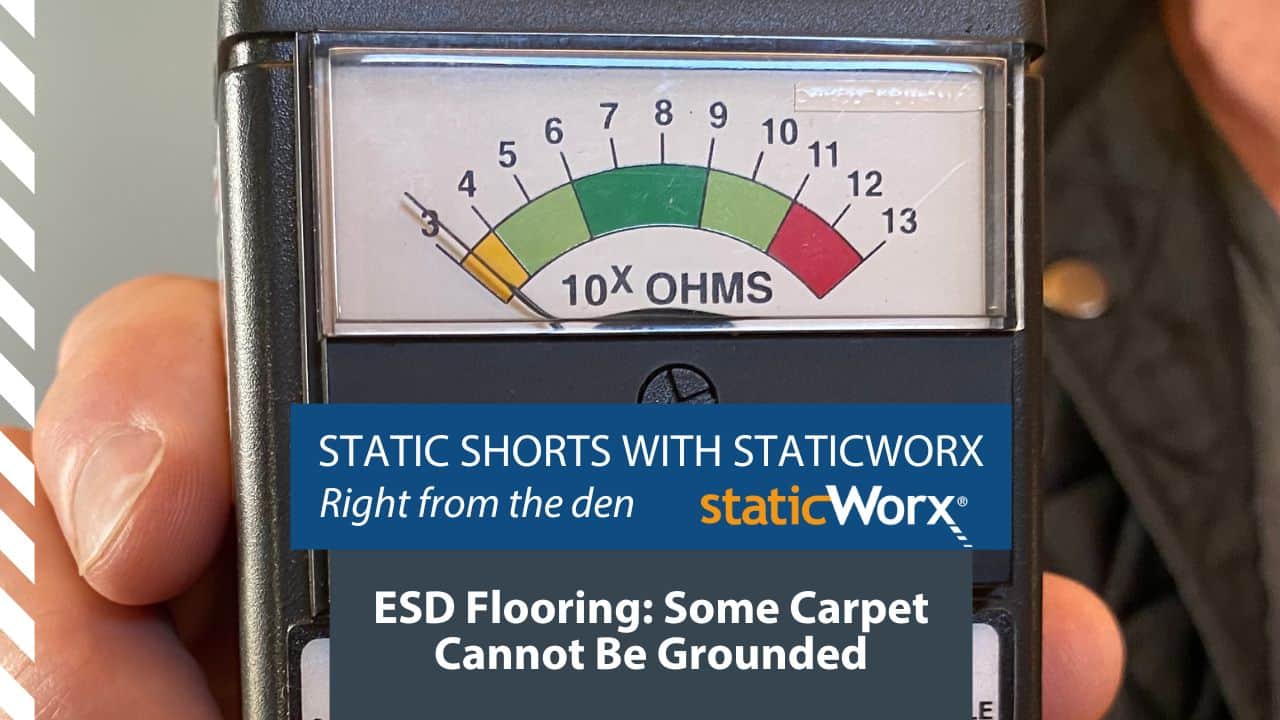

So what I’ve done, is I’ve gathered together a bunch of meters that measure electrical resistance. So this is what’s called a digital ohm meter. I have a handheld meter, with two blades on the bottom, where we measure the resistance between the blades. And I have an analog meter, which represents the electrical resistance by these various numbers that are on here. And for those of you who like math, the numbers are logarithmic. So it goes from 10E3, to 10E4, to 10E5, all the way up to 10E13. And all that means is that at 10E3, we’re talking about something that’s 1000 ohms. At 10E4, we’re talking about 10,000. At 10E5 we’re talking about 100,000. So each number, the actual numerical representation grows by a factor of 10.

So like yesterday, I have low kV carpet. Which if you look closely at the bottom of it, has a light colored material backing. And I have static-dissipative carpet, where the backing is a little bit darker than this material. And, here’s a piece of low kV carpet. You can see the big difference between the two colors. That’s because this has carbon in the bottom of it, which is a conductor, and this doesn’t have any.

So what I’m going to do, is I’m going to turn on this meter. And I’m going to measure the electrical resistance, just simply between two points on the carpet tile. So when I press the button, as you can see, I’m measuring between 10 and 11. That means 10E10, to 10E11. So to give you some perspective, 10E9 is one billion. So 10E10 is 10 billion. So this has an electrical resistance of over 10 billion ohms. In order for us to call a product static safe, and for that product to be used in applications where we need to reduce static electricity, it has to measure under nine. Which is 10E9, which I just told you is a billion. So with this meter, I’m measuring something that’s clearly not acceptable.

Now I’m going to take the two probes. Put them on the static-dissipative carpet. Make the same measurement. And I’m measuring less than 10E8. So by definition, any material that measures between six and nine, is called a static-dissipative material. If it measures less than six, it’s called a conductive material. And for those of you who are writing specifications for applications like call centers, or FAA flight towers, or server rooms, you don’t want the flooring material to measure less than 10E6.

I’ll give you an example of that. Here’s a material. It’s got a black back on it. When I put the two probes on it, it measures less than 10E5. That’s a piece of conductive carpet. That would not be acceptable if the requirement for the application called for static dissipative. So what we’ve got is regular carpet, highly conductive carpet, and static-dissipative carpet. Let’s pull out the probes, let’s plug them into a different meter. The reason the meter says good, it doesn’t mean there’s anything special going on, the battery’s good. And hit test. And, the conductive carpet is measuring six times 10E4. If the application calls for a material that measures greater than 10E6, this is two orders of magnitude too conductive. Let’s put the probes on the static-dissipative carpet. Let’s hit test again. 5.7, 5.8, 5.9, six. Six times 10E7. Pretty close to the same reading we got with the analog meter. This falls right in the middle of static dissipative. If the application were to call for a static-dissipative carpet, you’ve got your winner.

Now let’s take it, and put it on the regular carpet. And by the way, when I say regular carpet, this is commercial grade carpet. It’s actually the same carpet style as the one I just tested. But it doesn’t have static-dissipative properties. When I test it, it measures over 10E10. I already told you, anything above 1.0 x 10E9 is unacceptable. So low kV carpet, which is what this is, doesn’t have any conductivity. What that means, is you can’t ground it. If you can’t ground a floor, you don’t have a solution to a static problem.

So yesterday I showed you how I could charge up this metal plate, and discharge it to these materials. Today, I showed you why that metal plate would not discharge to this, and why it would discharge to this. The next time we talk, I’ll show you other materials, hard surface materials, rubber, vinyl, epoxy. But for today, what we’ve done is we’ve shown you why it’s important, when you write a specification, that you actually require the supplier to test the floor after the floor is installed, and in writing, tell you what they got for measurements. You saw how easy the measurements were. It’s not that difficult. Thank you for listening.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.