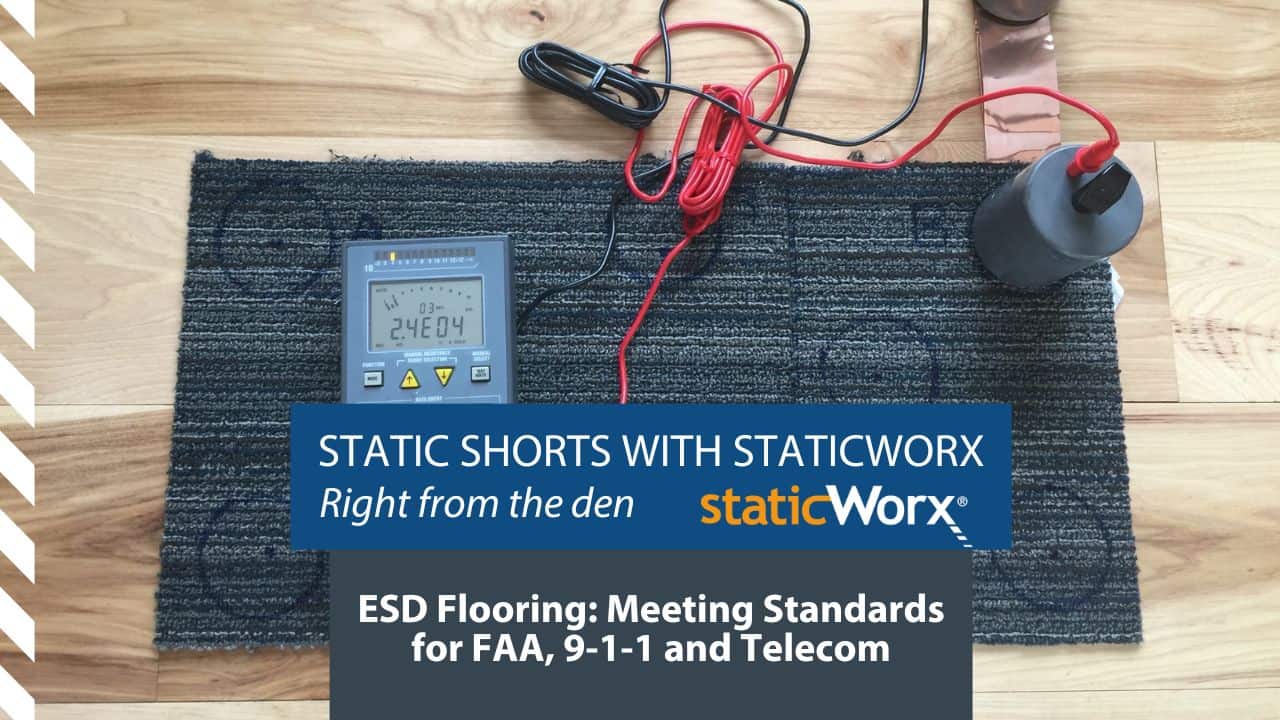

Video: In 24/7 Environments Use Dissipative Not Conductive Flooring

July 2, 2011

Close to 80% of static control floors are incorrectly specified. There are several reasons this occurs. For example, many specifiers don’t realize that most static control flooring materials can not eliminate static unless the person walking on the floor is wearing static control footwear. In other words, many of these floors – ESD vinyl tile in particular – will not prevent static on a person wearing ordinary footwear. With regular footwear ESD vinyl is actually a static generator. Research has shown that the only ESD floors that will inhibit static on all footwear are either static dissipative (SD) carpet or ESD rubber. A second specification problem involves the choice of the correct ohms resistance range for critical environment applications. The correct ohms range for floors installed in critical environments like computer rooms, 911 call centers, FAA flight towers spans from 1 million ohms to 1 billion ohms. One of the reasons for this recommended range is to protect people from exposure to excessive electrical current in the unlikely event of a stray voltage short circuit from energized equipment. This is a significant concern because electrical engineering studies have documented that materials like conductive carpet (as opposed to SD) are capable of passing electrical currents amounting to four times the OSHA limit that could electrocute a human being. One study measured 50 milliamps of current passing through a conductive carpet tile. the same study measured only .1 milliamps of current passing through an SD carpet tile. Most important takeaway: If you need to prevent static problems with flooring in a critical environment use SD not conductive flooring.

For help or advice about choosing an ESD floor, call us on 617-923-2000, email [email protected], or visit our Guide to ESD Flooring Selection.

When you’re looking at static-control flooring, make sure that you view an end-user environment completely different than you look at a manufacturing production environment. These are very different spaces. If you’re looking at the use of static-control flooring in an end-user environment–maybe it’s a 9-1-1 call center, maybe it’s a server room, a computer room, a data center, or war room–then you should be looking at flooring from the perspective of will it prevent static on people wearing regular shoes.

If it’s an ESD-protected environment where components are handled, you’re going to be looking at it as a grounding mechanism using static-control shoes. Second distinction in an end-user environment: you need to worry about safety. The reason you need to worry about safety is there are no monitors used to determine whether people’s shoes are too conductive.

There are actually grounding standards that we can utilize and that we can require in some cases our contractors, our general contractors and our installers to follow. So the three main standards: one is put up by a group called ATIS which is the Association of Telecommunications People, so it’s going to be people like Lucent, Alcatel, Cisco–anyone building product that is used in the communications world.

The second group is Motorola themselves, the people who make the wireless communication devices, and then the last standard that we refer to is put out by the FAA, and what’s interesting, these three standards are all basically unrelated and yet when it comes to flooring they all agree on what type of electrical properties the flooring should have. So we’ve got three documents out. We have FAA019e. We have Motorola r56. We have ATIS 0600321. All these documents are all available on [staticworx.com].

Now let’s get into safety a little bit, just so everybody understands why we should even be thinking about it.

In electricity there’s a number of laws, just like Newton’s Law and whatever other law you want to refer to. In electricity we have one called Ohm’s Law and Ohm’s Law is basically an equation that uses three variables: voltage, current and resistance.

When we talk about protecting ourselves from short circuits of electricity–in other words from being part of a circuit that’s very dangerous–one of the things that can protect us is resistance. Maybe a good analogy for you to think about is if we were going to be pulling the charge away very rapidly that would be the equivalent of standing in a couple of inches of water as you walk up to the circuit breaker in your house. Obviously everyone knows you don’t do that. With the other end, we don’t want the floor to drain static electricity so slowly that it behaves like the carpet in your living room because obviously we all know the carpet in our living rooms charges us up.

So when we look at floors what we’re actually trying to do is find a floor that somewhere is in between two inches of water and the carpet and your living room. Something in the middle there–in our industry, we call that the sweet spot–and fortunately, we have these documents–the ATIS document, the Motorola document, the FAA document–to guide us and if you look at all these documents they tell you specifically what that ohms rating is supposed to be and what it’s not supposed to be.

So we have three options right now in the world of carpet. We have what’s called computer grade carpet, we have what’s called ESD grade carpet tile, and then we have what’s called operational equipment grade.

ESD grade carpet tile has been in use for probably 20 years and these three standards that I mentioned before–ATIS, Motorola and FAA– have recently revised their electrical specifications and they no longer approve ESD grade carpet tile because it’s too conductive and by too conductive I mean that the ohms rating of the ESD grade carpet tile starts out too low. It starts out of 25,000 ohms and goes up to a million ohms.

What we’re looking for is something that starts out at a million ohms and goes up to about a hundred million ohms.We don’t like computer grade carpet tile for these spaces because we’ve discovered it only prevents people from getting static shocks. It does not prevent circuit boards inside of servers from being disrupted by static charges and that’s because when you eliminate a shock hazard using the floor, all you’re doing is preventing the floor from generating charges over 3,500 volts. Computer equipment is sensitive to 20, 40, 50, very low numbers of volts.

That brings us to the third type of carpet, what we’re calling operational equipment grade carpet, and what this carpet is made to do is to drain static electricity but to do it at a controlled rate and to do it with an ohms rating that allows you the possibility of touching voltage and the floor not being so conductive that it’s going to become a harmful path to ground.

So you’ll read some of these documents that I mentioned and they’ll say “safe for use around energized equipment.” All they mean when they say energized equipment is something that’s plugged into the wall. Could be a printer, could be your computer, could be a console in a call center. Anything that’s plugged into the wall, if it’s operating it’s energized. What we’re trying to do is find flooring that eliminates static electricity but can be used around energized equipment.

So criteria for end-user: we want a static dissipative floor, we want the floor to prevent static electricity, regardless of footwear.

In an electronics handling environment, we want a conductive floor, we want that floor to work in conjunction with some kind of conductive or static dissipative footwear.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.