Conductive and antistatic are terms to describe an ESD floor. These properties work together to prevent & dissipate harmful static charges.

5 Ways ESD Flooring Differs from Standard Flooring

9 min read

When people walk or when robots or mobile transport carts move electronic parts and assemblies across a floor, the friction between the floor and shoe soles or casters generates static electricity. Static charges stay in place until the charged person or transport device touches another person or object. If the object happens to be an electronic component, the sudden pulse of electricity can damage or destroy its complex internal circuitry.

This transfer of electricity is called an electrostatic discharge or ESD.

A well-documented problem in electronics manufacturing, ESD also affects electronics in call centers, server rooms, flight towers, financial institutions and other mission-critical operations. ESD events can run the gamut from interference to lost connections or dropped calls to equipment failure in the plant or in the field to, in worst case scenarios, operational shutdown.

Applications include but are not limited to: electronics manufacturing and handling, SMT (surface mount technology) facilities, TRACON, electronics labs and cleanrooms, networked government offices (such as Homeland Security), military, DOD, explosives plants, 9-1-1 dispatch, flight control towers, critical call centers, banks and other financial institutions, television studios and many others.

While standard, non-ESD, floors typically don’t generate enough static electricity to cause pesky static shocks, they cannot protect electronics from damage caused by electrostatic discharge.

ESD floors protect electronic equipment by performing two equally important functions:

- The floor draws static charges away from people and moving objects and transports charges to ground;

- The floor inhibits static generation, preventing static from building in the first place.

Here are 5 major differences between standard and ESD floors- plus the reasons why standard floors should never be used in facilities that manufacture, handle or use complex electronics.

Standard, Non-ESD Floors Cannot Protect

Electronics Against Random Static Discharge

Standard, Non-ESD Floors Cannot Protect Electronics Against Random Static Discharge

Standard, non-ESD, floors – sometimes called low kV or computer-grade floors – prevent static charges from exceeding 3.0 kV, the threshold for human perception. When you walk across a low kV or computer-grade floor, the antistatic component, whether an additive or topical spray, inhibits static enough so that you don’t feel static charges building on your body.

A 3000 or 3500 volt charge may be too small for humans to feel, but a 3500-volt static discharge is 5 – 10 times greater than the threshold for damaging electronic equipment. The most sensitive electronics, called Class-0, can be damaged by a charge as tiny as only 10 volts.

10 volts. Think about that for a minute. 10 volts.

Like the difference between a bubbler and a volcano.

That’s why we call electrostatic discharge – or ESD – an invisible threat. You don’t see, hear, or perceive static until your equipment malfunctions, a GPS signal transmits incorrectly, you lose or drop calls, your products are rejected in the factory or fail in the field, or you experience one of the other myriad problems that can be caused by a random electrostatic discharge event.

Standard, non-ESD, floors are not designed to – and cannot – prevent static at the incredibly low threholds that harm electronic components. With zero conductivity, standard floors cannot ground static charges on people or moving objects.

ESD floors, on the other hand, are designed to inhibit static generation, preventing static from building on people, mobile carts and robotics as they move about the facility. The conductive elements in ESD floors draw static charges away from shoe soles and wheels and transport charges to ground. This combination of low charge generation and static dissipation to ground prevents ESD from harming valuable electronics.

Non-ESD Floors Cannot Be Grounded

The reason some standard floors may reduce static but cannot protect electronic equipment is that standard, non-ESD, floors cannot be grounded. While some standard floors may contain antistatic solutions or be sprayed with topical anti-stats* that reduce static to some degree, standard floors have no conductive elements – e.g. conductive veins, chips or fibers. With no conductive elements in the material, there can be no path to ground – i.e., no conductivity. In fact, when tested with a resistance meter, standard floors show no conductivity at all.

- Over time, antistatic solutions rise to the surface of the flooring material and evaporate and topical anti-stats wear off, eliminating any anti-static properties.

Electrical resistance measurements above 1 billion ohms ( 1 x 10E9) are considered to be in the insulative range. Insulative materials cannot carry/transport/conduct electrical charges.

Standard floors may inhibit static charges to the threshold of human perception but that’s it. Because they are not grounded or even groundable, they do not drain charges from shoe soles and they cannot transport static charges to ground.

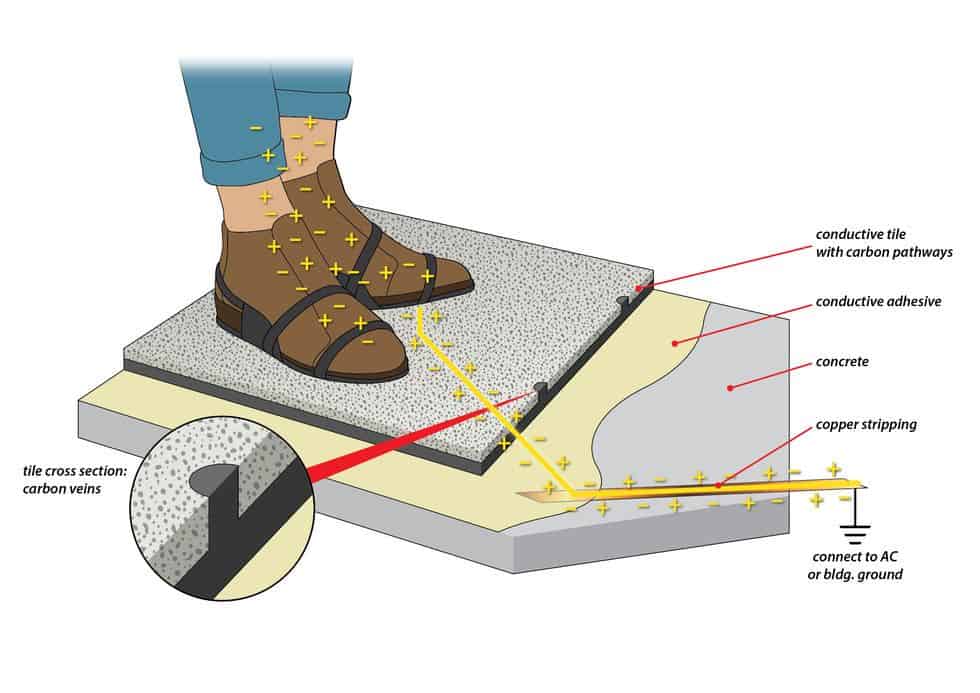

ESD floors are part of a grounded flooring system. A grounded flooring system consists of:

- whatever footwear people wear when they walk in the space;

- an ESD flooring material with measurable conductivity,

- A resistance reading below 1 billion ohms (1 x 10E9), tested with an ohm meter;

- An underlying conductive groundplane – e.g., conductive adhesive, metal access floor panels or GroundBridgeTM conductive underlayment – and copper strips;

- A connection to an earth ground, such as a grounded electrical outlet.

ESD Floors Contain Electrically Conductive Elements

Standard, non-ESD, floors may contain temporary antistats – for example, to prevent nuisance static shocks, standard carpet is sometimes sprayed with a topical antistatic solution – but they do not contain conductive elements. As standard floors are not conductive, they cannot ground static charges.

With ESD floors, conductive elements are added to the flooring material during the manufacturing process. These conductive elements may be carbon particles, carbon filament (in carpet), carbon veins, metals, or conductive nano-particles. A permanent part of the floor, these conductive elements form an electrical connection with an underlying conductive groundplane – e.g., conductive adhesive or GroundBridgeTM conductive underlayment.

The inherent conductive elements in ESD flooring draw static away from people or objects (such as wheels on robotics or moving carts). Static charges move from the surface of the floor through the thickness of the flooring material to the conductive underlayment. Charges are transported across the underlayment to copper strips, located at the perimeter of the room, and from the copper strips to an earth ground, where static electricity is discharged to ground.

The Electrical Resistance of ESD Floors Can Be Verified By Measuring With an Ohm Meter

An ohm meter measures the electrical resistance of a flooring material. The opposite of conductivity, electrical resistance is a measurement of a floor’s ability to slow or stop the flow of electricity. We measure resistance following Standard Test Method (STM) 7.1: place two five-pound probes on the surface of the floor and run 10 volts of electricity through the probes. With an ohm meter, measure how quickly or slowly current moves across the flooring material.

ANSI/ESD S20.20, the standard used by electronics manufacturing and handling facilities, requires the electrical resistance of ESD flooring materials to measure below 1 x 10E9 ohms.*

9-1-1 dispatch, critical call centers, telecommunications, FAA facilities, financial institutions, and other end-user applications use the same test method. Because people in these spaces typically work near electrified equipment, standards are tighter, generally requiring floors to measure between 1 x 10e6 and 1 x 10e9 ohms.

With no measurable conductivity, standard, non-ESD, floors will fail electrical resistance tests.

Unlike Standard Flooring, ESD Floors Do Not Generate Static

Standard flooring is insulative. Because insulative floors prevent the flow of electricity and store static charges, they generate static, whether or not you can feel it. Remember, it takes only a miniscule static charge to damage or destroy electronic equipment – only 500 volts for most commercial electronics and as low as 10 volts for ultra-sensitive high-speed components.

Standard floors treated with temporary anti-stats – e.g., antistatic solutions, ESD Wax or topical anti-static spray – reduce charges temporarily. Because temporary treatments wear off over a short period of time span, electrical resistance should be monitored and treatments reapplied on a regular basis. Floors treated with temporary antistats must also be tested regularly with a volt meter to determine how much static is generated when people walk on the floor. If these protocols are not followed, the floor will generate static when people walk or objects move on the floor, putting electronic equipment at risk.

A Properly Executed ESD Flooring/Footwear System Will Not Generate Static Charges

Properly executed means selecting the right material for the application, being aware of, and if necessary mandating, ESD footwear, ensuring that the underlying groundplane is more conductive than the floor, and placing ground strips at the perimeter of the room.

ESD carpet and rubber are inherently low-static-generating. Like the tiny brush on a printer, the conductive fibers in ESD carpet sweep static from shoe soles and transport charges to ground. Due to its triboelectric propensities, ESD rubber is an inherently low-static-generating flooring material. That is, the electrical potential of a rubber floor is sufficiently similar to shoe soles so that when shoes contact and separate from a rubber floor there is minimal electron transfer.

Certain other ESD flooring materials, such as conductive epoxy and conductive vinyl, do not prevent charge generation on their own. ESD vinyl and epoxy are manufactured from a base of insulative polymers or resins, which generate static. It’s imperative for anyone walking on these floors to wear some type of static-protective footwear – ESD heel straps, toe or sole straps, or conductive shoes. When the conductive ribbon or sole on ESD footwear makes contact with the conductive elements in the ESD vinyl floor, the conductors in the footwear and floor form an electrical bond, drawing static from people as they walk and transporting charges to ground.

About StaticWorx, Inc

All StaticWorx posts are written by our technical team and based on industry standards and specifications, test data, independent lab reports and other verifiable data. We provide ESD training and offer CEU credits to architects.

If you’re interested in an ESD training session or architects’ ESD workshop, give us a call: 617-923-2000.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

More Blog Posts

Learn the differences between ESD solid vinyl tile and interlocking ESD tile. The post compares specs, installation, maintenance and intangibles.

To maintain performance, ESD floors require specially formulated products. We offer tips on what to consider when choosing cleaning supplies.

Static-dissipative floors transport harmful static charges to ground. Dissipative is also a term for flooring with a specific, measurable electrical resistance.

StaticWorx recognized as one of the fastest growing private companies in the U.S. 2023 marks StaticWorx fourth appearance on Inc. 5000 list.

Conductive and dissipative flooring protect electronics by transporting charges to ground, conductive at a quicker rate, dissipative slower & more controlled.

We explain the 3 main ways to test an ESD floor: Electrical resistance; body voltage & ESD audits, with advantages and reasons for each.

Three critical factors—application, industry standards & footwear—help you choose the best ESD floor, while ensuring the safety & efficiency of your operations.

StaticWorx Founder and President Dave Long shares three of his recommended reads: Quit, How to Change, and The Goal.

There are leadership qualities StaticWorx strives to embody every day, with every product, throughout each project.

No matter how you slice and dice a project, an ESD floor is a major investment. This blog post examines five ways to keep undue costs down.

What’s the difference between static control and static resistant? Or anti-static flooring? Find out more in our blog post.

A major part of any ESD control program is getting proper flooring in place. How can one replace a floor without generating any debris? Learn more.

A well-designed, comprehensive, fully realized program is a must for manufacturers serious about ESD control. Learn why ESD programs fail.

ESD Floors should never be specified based on the descriptive terms conductive or static dissipative. Always base ESD specs on verifiable metrics. Find out why.

To comply with relevant ESD standards, test electrical properties using methods outlined in ESD S20.20. For best results require testing by an independent lab.

If the vapor barrier fails to adhere to the subfloor, tiles will lift. Bond test and manufacturer oversight are crucial to ESD floor installation success.

Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer

What’s the difference between conductive and static-dissipative flooring? Facts, analogies and images illustrate the difference in easily understood terms.

Qualifying an ESD floor helps ensure you get the floor you paid for. Find out why you should always qualify according to ESD S20.20

Qualification is the first step in selecting an ESD floor. Learn how to perform resistance tests to be sure the floor meets electrical & safety standards.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

- The Case Against Overly Conductive Flooring

- Conductive vs Dissipative

- Electrical Resistance

- Electrical Resistance in Mission-Critical Spaces

- Ensuring Accuracy: Why It’s Critical to Clean Floors and Probes Before ESD Testing

- ESD Standards and Test Methods

- Resistance, Resistivity, and Real World Application

- Walking Body Voltage

Why It’s Critical to Clean Floors and Probes Before ESD Testing

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.