FAQ: What is a suitable laboratory floor material?

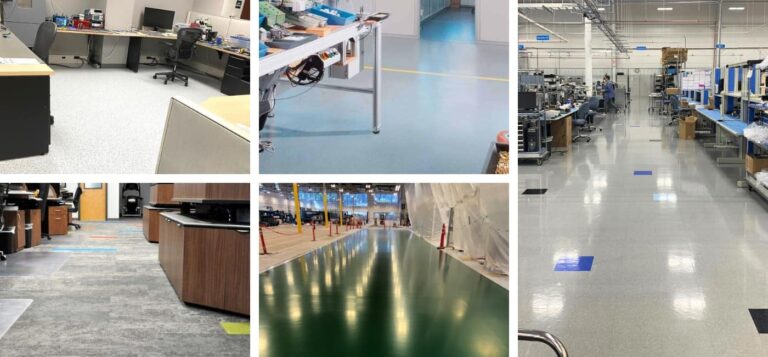

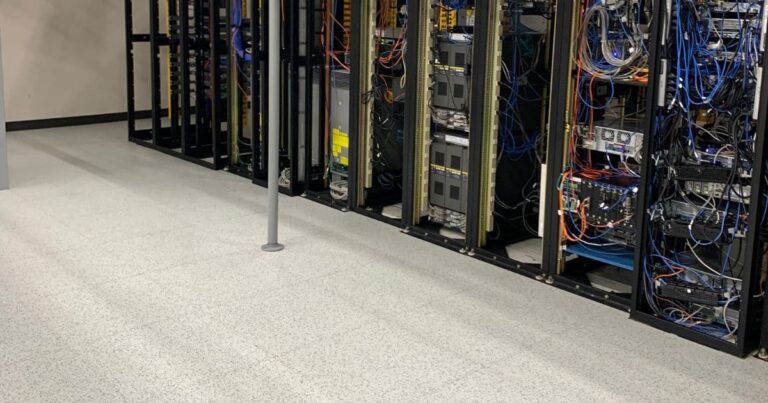

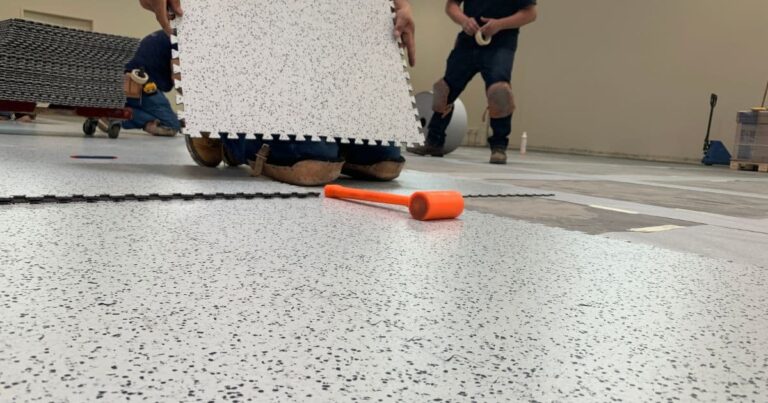

Lab flooring is used for laboratories in healthcare or manufacturing facilities. Laboratory floors are typically covered with vinyl or rubber tile or sheets, sometimes epoxy or urethane, because these materials are hygienic, easy to clean and generate low particulate counts. Labs and cleanrooms usually prefer either coatings or sheet goods to tile because sheets are seamless, minimizing the risk of dirt and particulates accumulating on the floor, contaminating the space. Lab personnel prefer flooring materials like rubber with certain key ergonomic attributes – i.e., that limit foot and back fatigue, and provide sound attenuation and slip resistance.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.