FAQ: We are comparing ESD carpet to ESD vinyl and would like to know the technical reasons for choosing one over the other.

For example, what are the differences between point-to-point and point-to-ground resistance readings?

To better understand the complexities involved in selecting an antistatic or static-control floor, you need to ask a few questions:

- What types of footwear will be used in the space?

- Will there be times when people wear regular footwear, such as sneakers or boots?

- Are there fault-tolerant flooring options, with good AATCC test reports, that can control static to an acceptable level if people wear the wrong footwear in my lab, server room, control center, cleanroom, etc?

We ask about footwear because there is a hierarchy of effectiveness in situations where the floor may be expected to mitigate static on a population wearing street shoes.* A multi-year study commissioned by ASHRAE** found that, while many ESD floors provided adequate protection against static build-up on people wearing ESD-control footwear, several types of ESD flooring actually generate static on a person wearing ordinary footwear. Ordinary footwear includes sneakers, dress shoes, work boots, and so on.

*ESD carpet and EC/electrically conductive rubber are low charge-generating flooring materials, with and without the use of ESD footwear.

** In 2022, In Compliance magazine published an article we wrote about the ASHRAE study with regards to server rooms and data centers.

Marketing Terms Versus Evidence-based Technical Information

There is a common misconception about static control flooring regarding the relationship between conductivity and the floor’s ability to control static charges. The misconception has, in part, to do with how static control floors are marketed. Terms for static-control flooring include “mission critical flooring, “Level 3 static control,” “super conductivity,” “best in class,” and, our favorite – “proprietary patented formula.” All of these are marketing, not technical, terms.

Fortunately there is a door through the haze of marketing mumbo jumbo. To bypass smoke-and-mirror terms, rely instead on standardized testing to established industry standards. Standardized tests are objective and give you the evidence-based information you need to make a reasoned decision on ESD flooring and to choose the floor that best suits your needs

When evaluating ESD flooring, there are several things you need to know:

- How conductive is the floor?

- What are the risks if the floor is too conductive?

- How much static can be generated on a person walking on the floor wearing static control footwear?

- How much static can be generated on the floor on a person wearing regular footwear?

- If a person is sitting in a regular chair on a grounded floor, will they accumulate static on their body?

All of these questions are addressed by established standardized test methods.

Standard Test Methods

Electrical Resistance Provides Only Part of the Information You Need

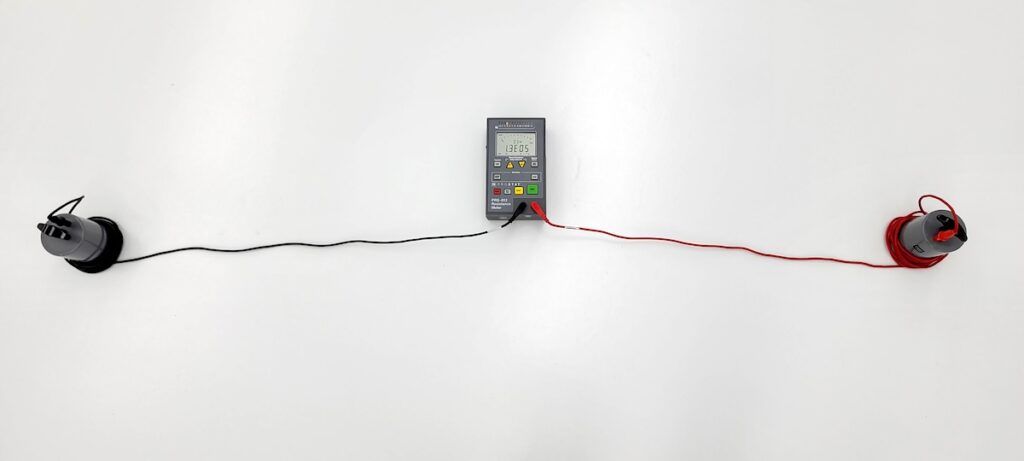

ASTM F150 is the test method for determining the electrical resistance of a floor. This is the test method most government documents reference. The electronics manufacturing industry uses test method ANSI/ESD STM7.1.

Both test methods use the same meter and the same general procedure. STM7.1 simply requires the floor to measure under 1.0 x 10E9 ohms. The advantage of the ASTM method is that F150 states that the floor must have a minimum resistance of 25,000 ohms. There is no advantage in having a grounded floor that is too conductive. There is an advantage to building resistance into the floor that’s sufficient to protect people from possible electrical hazards.

It is not uncommon for ESD specs to cite only conductivity/resistance. But conductivity/resistance is only part of the equation. To solve a static problem, and ensure that the floor is not a static generator, you must know how much static will build on a person when they walk on the floor. Electrical resistance doesn’t tell you that. Even if resistance tests in the ideal range, some floors will still generate static. The only way to be sure that a floor you’re evaluating will not generate static when people walk is to also test for charge generation.

Testing for Charge Generation

Why do you need to test for charge generation? Because electrical resistance/conductivity is not the same as charge generation; resistance and charge generation are separate properties. Some flooring surfaces, such as conductive epoxy and static-dissipative vinyl, have excellent conductivity, can be grounded, and do a good job of controlling charges on people wearing special ESD-control footwear. Because vinyl and epoxy are made with static-generating base materials, such as plasticizers and polymers, they can prevent charge generation only when the conductive elements in ESD footwear make continual contact with the conductive elements in the floor. ESD vinyl and epoxy will not – and cannot – prevent static on people in street shoes.

Think about it this way: your skin/hand is conductive, like an ESD floor. A balloon is not conductive, like the soles on the shoes you are probably wearing. Even though your hand is a conductor, when you rub the balloon it generates enough static to make your hair stand up. The same happens when we walk on a static-dissipative vinyl floor wearing the latest Nike sneakers.

That’s why we must test for charge generation regardless of how good or bad the floor’s electrical resistance.

Test Methods for Charge Generation, also called Body Voltage

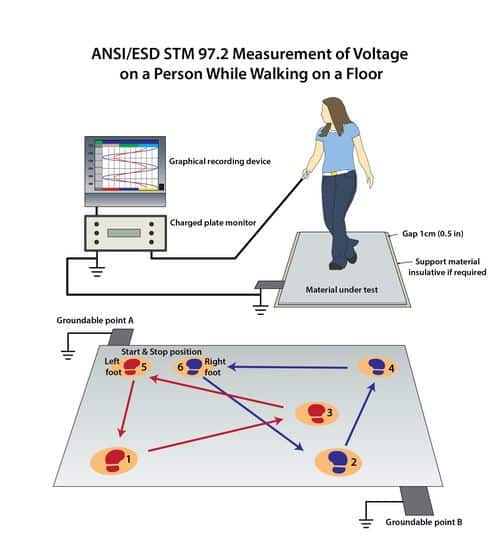

There are two tests for charge generation. The main test is ANSI/ESD STM97.2. Many ESD flooring brochures reference this test. Here’s the problem: the method outlined in STM97.2 measures charges on a person walking on a floor while wearing static-control footwear.

Regardless of how good these test results, measured according to STM97.2, might be, if you anticipate people walking on the floor with regular footwear, you need to test the floor with the test subject wearing regular footwear. AATCC 134 is the test method we use for measuring static charge on a person walking on a floor wearing regular footwear.

Whether or not you’ve been told that static-control footwear will be required in the space, you may want to test under both conditions, with and without ESD footwear, in case personnel don’t comply with the footwear requirement – for example, a lab full of scientists.

Don’t be fooled by manufacturer’s claims, sales pitches, or meaningless marketing terms. By doing your due diligence, testing any floor under consideration to industry standards for both resistance and charge generation, you can be sure you’ll get the floor best for your application.

More FAQs

Learning Center Articles

- ESD Basics

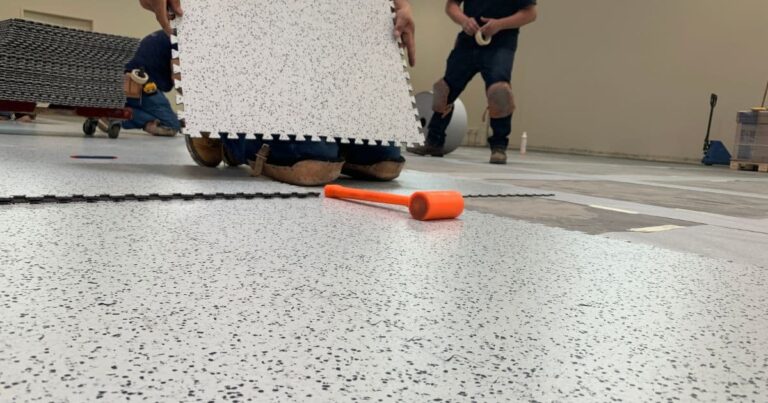

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

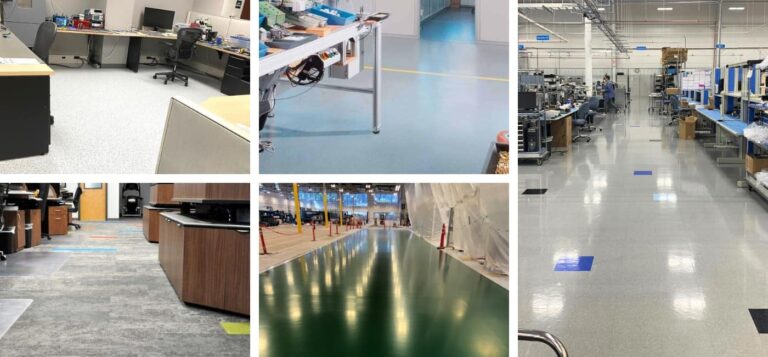

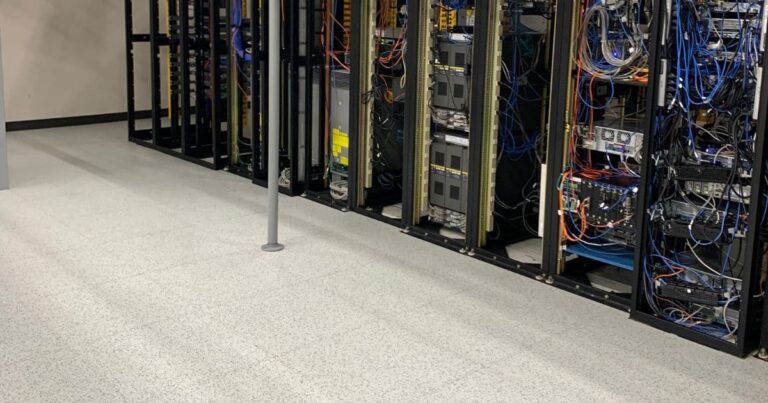

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.