FAQ: Can ShadowFX carpet tile be installed one to one over raised flooring panels?

Your website says ShadowFX carpet tile can be installed one to one over raised flooring panels? Is this in new construction situations only? What about renovations where quick release adhesive was previously applied? Would you still recommend a one to one installation?

One-to-one installation of floor finishes over raised access panels offers advantages but also some disadvantages.

Let’s start with the advantages:

Panel removal is easy. One panel and one floor finish – no picking up multiple overlapped tiles to remove just one access panel.

Air diffusers can be relocated with no need for cutting. Just pull the panel and tile and bring it to a new location.

Disadvantages and Precautions:

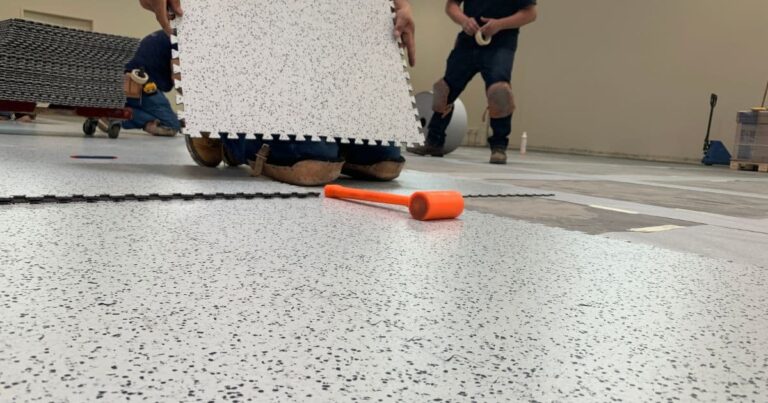

It is very difficult to install tiles one-to-one in the field. One-to-one usually requires removing panels one at a time and using a fixture to align the tiles over the old panels. This process can be obstructive, expensive and time-consuming.

The easiest installation methods for field installs involve buying panel systems that are compatible with tile positioning devices. IFS Global panels require using CarpetLok® positioners and Tate Concore panels require carpet tiles with ultrasonically bonded PosiTile buttons.

If you are changing out floor tiles in the field you will need to determine if the old adhesive needs to be removed. Some adhesives cannot be applied over the old adhesive. Excessive adhesive residue can telegraph through the new tiles.

When carpet tiles are installed one-to-one, the seams can be exposed to gapping if the panels are not perfectly aligned. Gapping can subject carpet tile seams to far more abuse than an overlap installation.

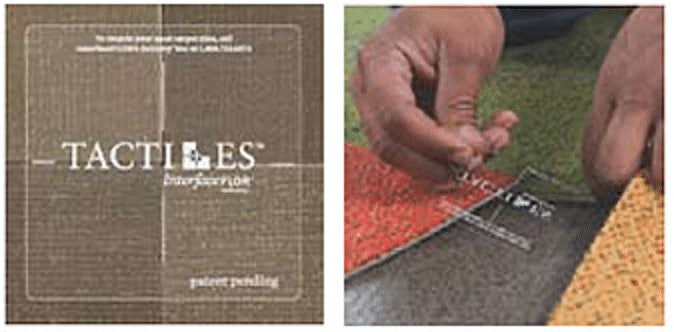

Overlap installations are fastest and least expensive. They can be done without adhesive by using glue free methods like ShadowFX tiles with TacTiles.

More FAQs

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

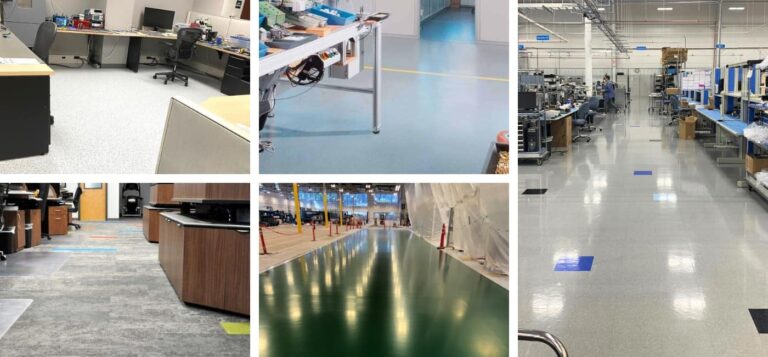

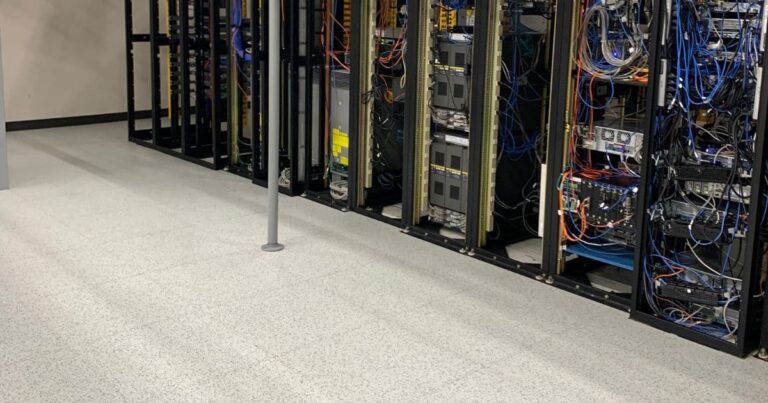

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.